Introduction

In the world of manufacturing, die casting stands out as a pivotal process that combines precision with efficiency. This technique not only enhances product quality but also significantly reduces production costs, making it essential for various industries, from automotive to electronics. Understanding why die casting matters is crucial for businesses looking to partner with a top die casting company to meet their manufacturing needs.

Why Die Casting Matters

Die casting is more than just a method; it's a transformative approach that allows for the creation of complex shapes and intricate designs with remarkable accuracy. The ability to produce durable and lightweight components quickly makes it a favorite among manufacturers aiming for high performance and low waste. For businesses seeking to stay competitive, aligning with a top die casting company can lead to innovative solutions and enhanced product capabilities.

Overview of the Best Companies

When considering die casting, it's essential to recognize the leaders in this field who set the standards for quality and innovation. Companies like Alcoa Corporation, Bühler Group, and Dynacast have made significant contributions through advanced technologies and exceptional service offerings. These top die casting companies not only provide superior products but also foster long-term partnerships that drive success in various sectors.

What to Expect from Top Companies

Partnering with a top die casting company means gaining access to state-of-the-art technology, rigorous quality control measures, and unparalleled customer support. Clients can expect tailored solutions that cater specifically to their unique requirements while benefiting from expert guidance throughout the production process. Ultimately, choosing such companies ensures reliability in delivery times and consistency in product quality—key factors that can make or break any manufacturing project.

What is Die Casting?

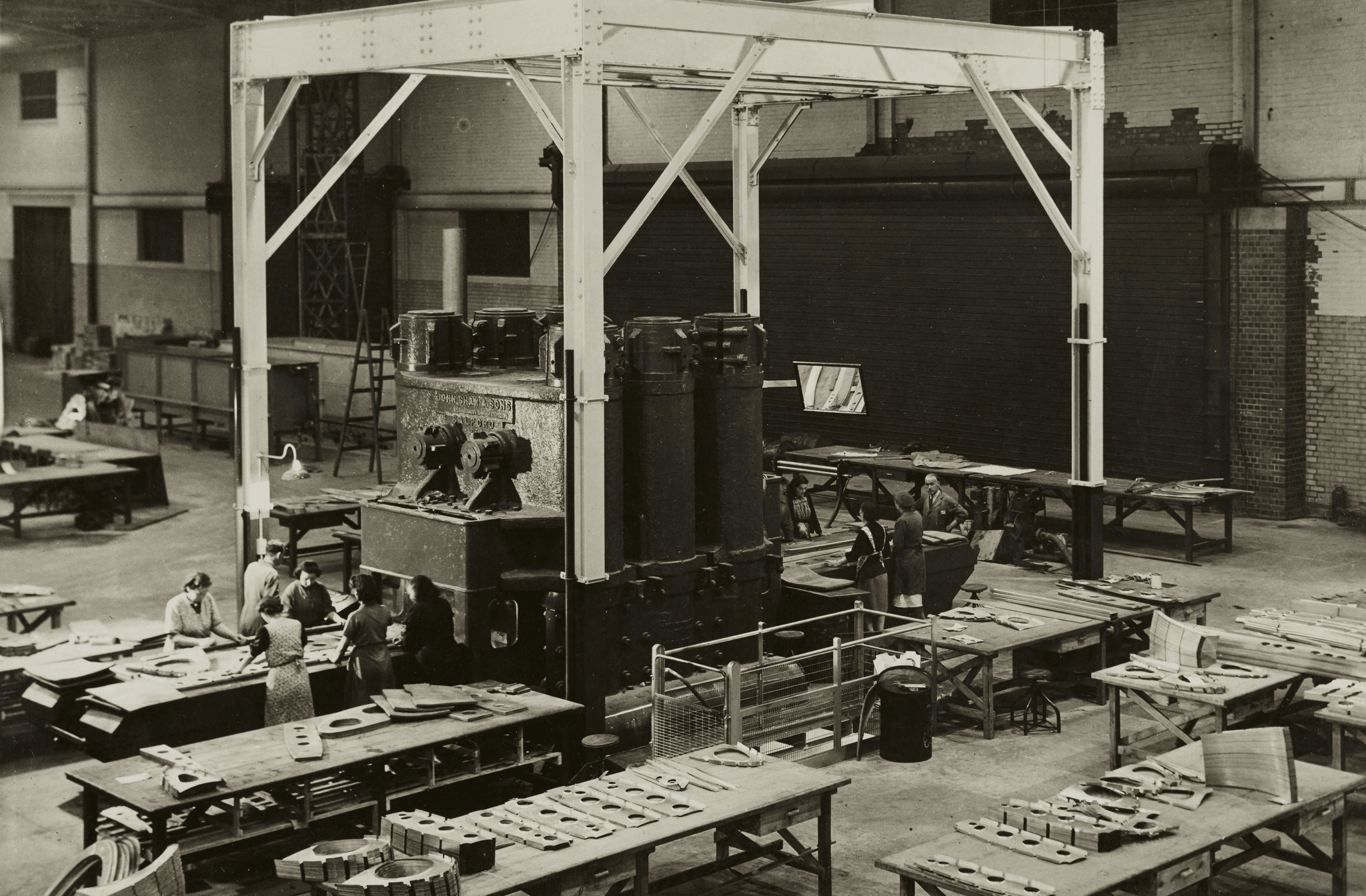

Die casting is a manufacturing process that involves forcing molten metal into a mold cavity under high pressure. This technique is renowned for producing complex shapes with excellent surface finish and dimensional accuracy, making it a favorite among manufacturers worldwide. Understanding die casting is essential for recognizing the capabilities of a top die casting company.

Understanding the Basics

At its core, die casting combines heat and pressure to create metal parts that are both durable and precise. The process typically uses non-ferrous metals like aluminum, zinc, or magnesium due to their favorable properties, such as lightweight and corrosion resistance. By grasping these foundational elements, you can appreciate why industries rely on top die casting companies for their precision-engineered components.

Die casting can be broken down into two primary methods: hot chamber and cold chamber processes. Hot chamber die casting is ideal for metals with low melting points, while cold chamber is suited for higher melting point materials. Knowing these distinctions helps businesses select the right partner—like SSOURCING INC.—that aligns with their specific requirements.

Key Processes in Die Casting

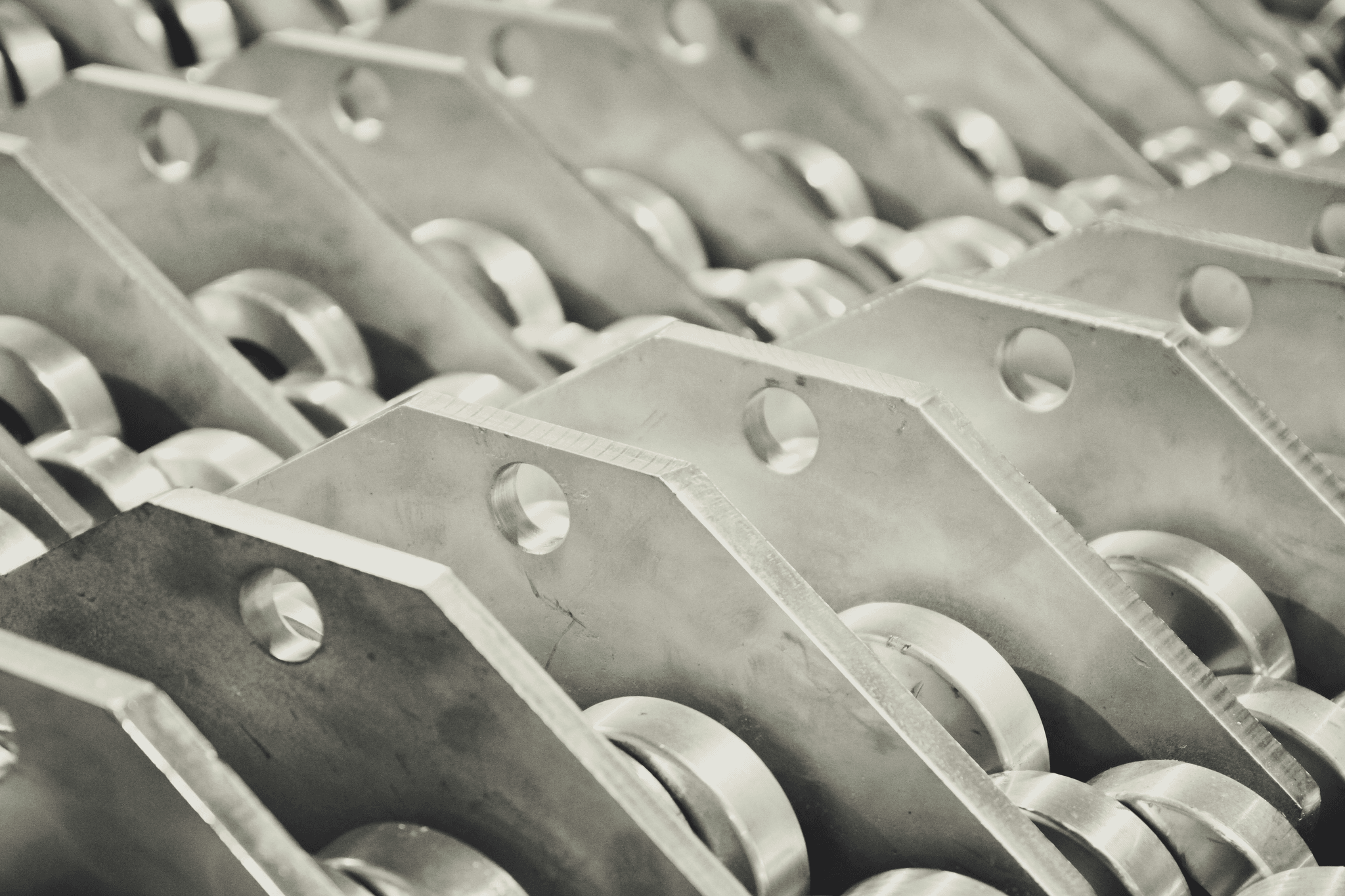

The die casting process begins with preparing the mold, which must be meticulously crafted to ensure accurate reproduction of the desired part's features. Once the mold is ready, molten metal is injected at high speed into the cavity under significant pressure, filling every nook and cranny of the design. This rapid injection not only enhances detail but also minimizes defects—an essential aspect that top die casting companies pride themselves on.

After cooling and solidification occurs within the mold, it’s time for ejection; this step requires precision to avoid damaging either the part or the mold itself. Once ejected, parts undergo secondary processes like trimming or machining if necessary to meet exact specifications. Companies like SSOURCING INC., known for their advanced technology in this field, ensure that every step adheres to rigorous quality standards.

Applications of Die Casting

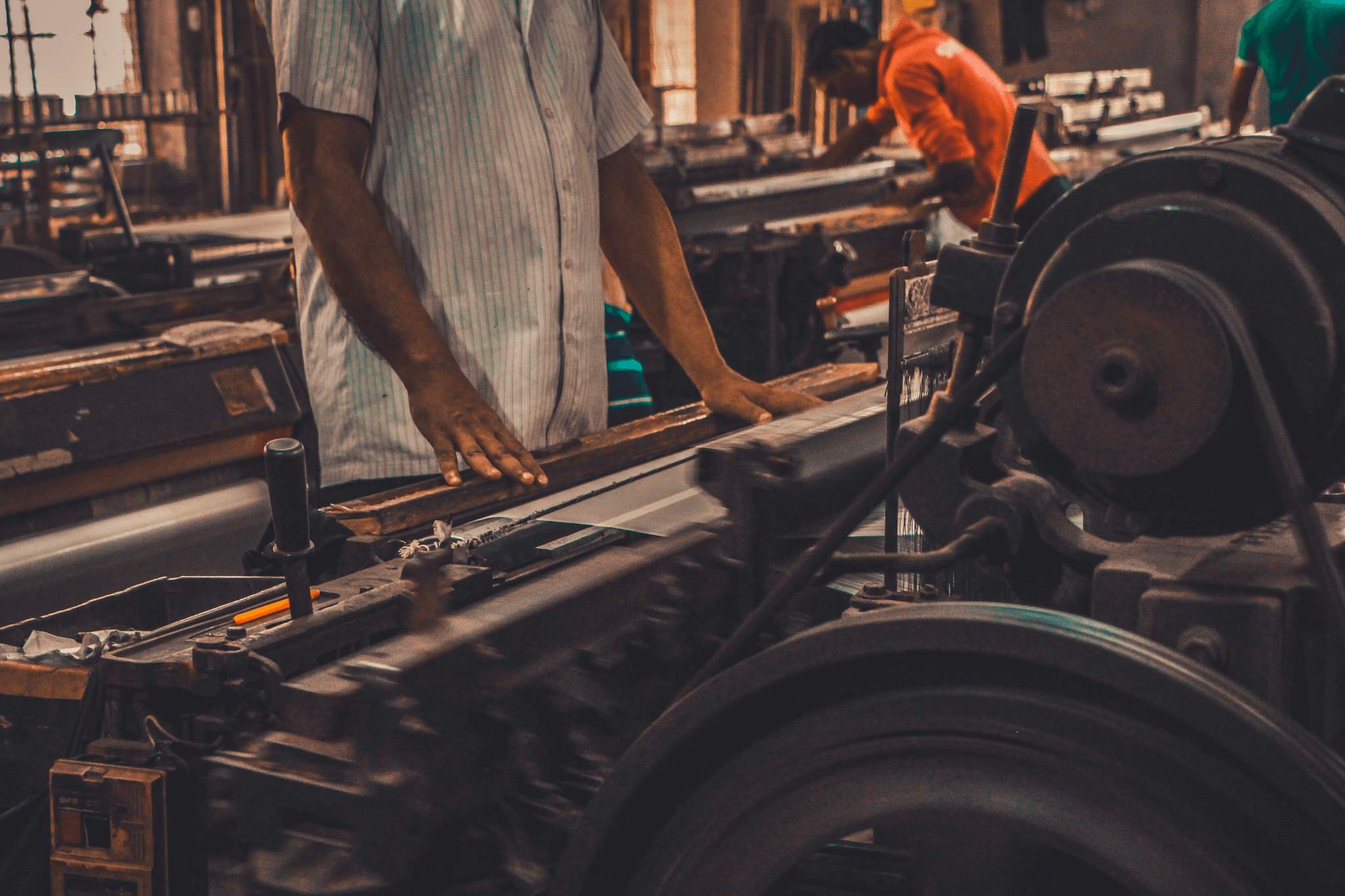

Die casting finds applications across various industries due to its versatility and efficiency in producing intricate components quickly and cost-effectively. Automotive parts are among the most common applications; engine blocks or transmission cases often rely on this method for optimal performance and weight reduction. Additionally, electronics housing components benefit from die casting’s ability to create lightweight yet robust designs.

Beyond automotive and electronics sectors, consumer goods manufacturers also leverage die-cast products for everything from appliances to toys—demonstrating how widespread this technique truly is! The medical industry increasingly adopts die-cast components as well due to their reliability in critical applications where precision matters most. With such diverse applications available through a top die casting company like SSOURCING INC., businesses can confidently find tailored solutions for their needs.

Key Features of a Top Die Casting Company

When it comes to die casting, not all companies are created equal. The top die casting company will stand out due to specific features that elevate their services above the competition. Understanding these key attributes can help businesses make informed decisions when seeking a reliable die casting partner.

Advanced Technology and Equipment

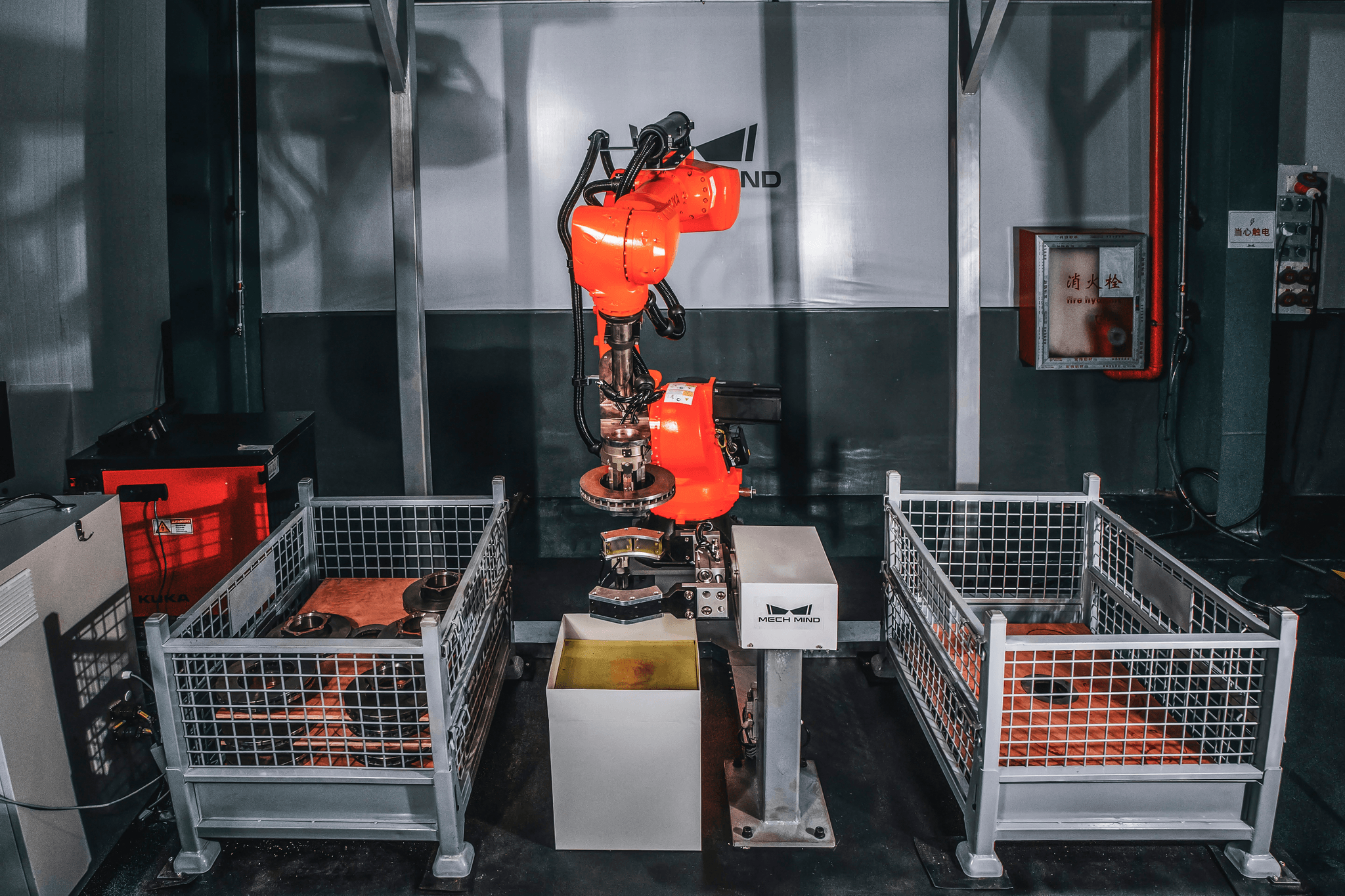

A top die casting company invests heavily in cutting-edge technology and state-of-the-art equipment to ensure precision and efficiency in their processes. This includes advanced machinery capable of producing intricate designs with minimal waste, which is crucial for maintaining cost-effectiveness in production. Companies like SSOURCING INC. leverage such technology to enhance their capabilities, ensuring they meet client demands while delivering high-quality products.

Moreover, automation plays a pivotal role in modern die casting operations, allowing for increased production speeds and reduced human error. With the integration of robotics and smart systems, top die casting companies can optimize every step of the manufacturing process—from mold design to finishing touches—ensuring consistency and reliability in output. This technological edge not only boosts productivity but also positions companies at the forefront of industry innovations.

Quality Control and Assurance

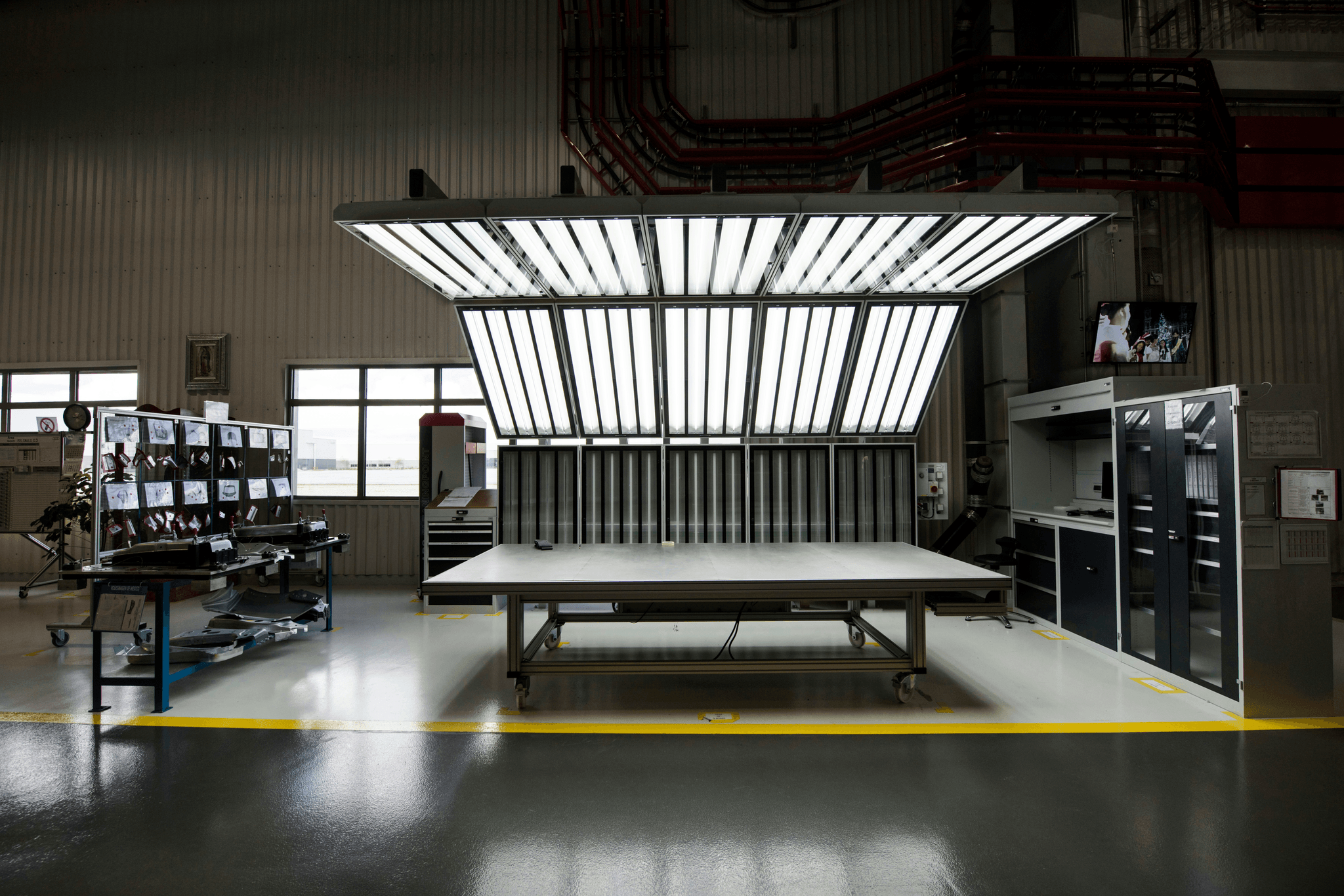

Quality control is non-negotiable for any top die casting company; it's what separates the best from the rest. Implementing rigorous quality assurance protocols ensures that every product meets stringent industry standards before reaching clients' hands. SSOURCING INC., for instance, employs comprehensive testing methods throughout the manufacturing process to identify any potential flaws early on.

Additionally, certifications such as ISO 9001 demonstrate a company's commitment to maintaining high-quality standards consistently over time. This dedication not only fosters trust with clients but also enhances brand reputation within the industry—an essential factor when selecting a die casting partner. Ultimately, effective quality control translates into fewer defects and higher customer satisfaction rates.

Customer Service and Support

Exceptional customer service is often overlooked but is a hallmark of any top die casting company worth its salt. A responsive support team that communicates effectively can make all the difference during complex projects or tight deadlines, ensuring clients feel valued throughout their partnership journey. At SSOURCING INC., client relationships are prioritized through personalized service tailored to specific needs.

Moreover, providing ongoing support after project completion helps build long-term partnerships based on trust and reliability—key elements in today’s competitive market landscape. Top-tier companies often have dedicated teams ready to assist with everything from technical inquiries to logistical challenges post-delivery, reinforcing their commitment to client success beyond mere transactions. In an industry where collaboration is vital, outstanding customer service sets leading firms apart from their competitors.

Leading Companies in Die Casting

When it comes to die casting, a few companies consistently rise to the top, showcasing innovation, expertise, and global reach. These leaders not only set standards but also push the boundaries of what’s possible in the industry. Let’s take a closer look at three of these top die casting companies: Alcoa Corporation, Bühler Group, and Dynacast.

Alcoa Corporation's Innovations

Alcoa Corporation has long been recognized as a top die casting company due to its relentless pursuit of innovation. The company specializes in lightweight metals and is renowned for its advanced manufacturing techniques that enhance efficiency and reduce waste. With a focus on sustainability, Alcoa integrates eco-friendly practices into its production processes, making it a model for other manufacturers.

Moreover, Alcoa's commitment to research and development has led to breakthroughs in high-performance alloys used in various applications. Their innovations have not only improved product durability but also opened new markets for die cast components in sectors like aerospace and automotive. By continuously evolving their technology, Alcoa remains a formidable player among the top die casting companies.

Bühler Group's Global Influence

Bühler Group is another titan in the world of die casting that exemplifies global influence and technological prowess. As a top die casting company with facilities around the globe, Bühler emphasizes precision engineering combined with cutting-edge automation technologies. This approach ensures that their products meet stringent quality standards while also optimizing production efficiency.

Their extensive portfolio includes solutions for various industries such as food processing and automotive manufacturing, showcasing their versatility as a manufacturer. Bühler’s innovative machinery not only enhances productivity but also supports sustainable practices by minimizing energy consumption during operations. This blend of quality and sustainability solidifies Bühler's position as one of the leading companies in die casting.

Dynacast's Industry Expertise

Dynacast stands out with its specialized expertise in precision die casting across multiple sectors including automotive, electronics, and consumer goods. As one of the premier top die casting companies globally, Dynacast prides itself on delivering high-quality components with exceptional accuracy and consistency. Their advanced techniques allow them to produce intricate designs that many competitors find challenging.

What sets Dynacast apart is their deep understanding of customer needs paired with an agile manufacturing process that adapts quickly to market demands. They leverage state-of-the-art technology alongside skilled craftsmanship to ensure each product meets rigorous performance criteria while remaining cost-effective. For businesses seeking reliable partners in precision manufacturing, Dynacast exemplifies what it means to be a leader among top die casting companies.

How SSOURCING INC. Stands Out

In the competitive landscape of die casting, SSOURCING INC. has carved out a unique niche that sets it apart from other top die casting companies. With a combination of innovative offerings, a strong commitment to sustainability, and competitive pricing strategies, SSOURCING INC. is not just another name in the industry; it's a leader paving the way for future advancements in die casting.

Unique Offerings and Services

What makes SSOURCING INC. stand out among the top die casting companies is its diverse range of services tailored to meet varied client needs. From custom designs to rapid prototyping, their offerings are as unique as they are effective. This flexibility allows clients to collaborate closely with experts who understand their specific requirements and can deliver high-quality results.

Additionally, SSOURCING INC.'s advanced technology ensures that they remain at the forefront of innovation in die casting processes. By integrating state-of-the-art machinery with skilled craftsmanship, they produce components that not only meet but exceed industry standards. This commitment to excellence reinforces their reputation as one of the top die casting companies in the market today.

Commitment to Sustainability

In an era where environmental responsibility is more crucial than ever, SSOURCING INC.'s commitment to sustainability sets it apart from many competitors among top die casting companies. They prioritize eco-friendly practices throughout their manufacturing processes, utilizing recycled materials and energy-efficient technologies wherever possible. This approach not only minimizes waste but also positions them as a forward-thinking leader in sustainable manufacturing.

Moreover, SSOURCING INC.'s focus on reducing its carbon footprint resonates well with environmentally-conscious clients looking for partners who share their values. By adopting sustainable practices without compromising quality or efficiency, they demonstrate that being green can go hand-in-hand with being competitive in pricing and service delivery—an attractive proposition for any business looking for a top die casting company.

Competitive Pricing Strategies

When it comes to pricing strategies, SSOURCING INC. knows how to strike the perfect balance between cost-effectiveness and high-quality output—traits essential for any top die casting company aiming for success in today's market landscape. Their transparent pricing model ensures clients understand exactly what they're paying for while benefiting from exceptional value for money.

Additionally, by leveraging efficient production methods and economies of scale, SSOURCING INC. can offer competitive rates without sacrificing quality or service levels—an appealing factor for businesses striving to optimize budgets while still receiving superior products and support from their chosen partners in die casting.

In conclusion, whether you're seeking unique services tailored specifically for your needs or looking for a partner committed to sustainable practices at competitive prices, SSOURCING INC., one of the leading names among top die casting companies today stands ready to exceed your expectations.

Choosing the Right Die Casting Partner

Selecting the right die casting partner can be a pivotal decision for any business looking to innovate and produce high-quality products. With numerous options available, it’s essential to identify a top die casting company that aligns with your specific needs and objectives. This section will guide you through evaluating capabilities, understanding the value of client testimonials, and considering pricing factors.

Evaluating Capabilities and Expertise

When searching for a top die casting company, assessing their capabilities and expertise is crucial. Look for companies that showcase advanced technology and specialized equipment, as these are indicators of their proficiency in the die casting process. Additionally, consider their experience in various industries; a company like SSOURCING INC., known for its versatility in applications, can provide insights into how they handle different project demands.

A thorough evaluation should also include an examination of their production capacity and turnaround times. A reliable partner should demonstrate efficiency without compromising quality, ensuring that your timelines are met consistently. Don't hesitate to ask potential partners about their past projects; this will give you a clearer picture of what they can offer.

Importance of Client Testimonials

Client testimonials serve as valuable windows into the reliability and performance of a top die casting company. Positive feedback from previous customers can help you gauge not only the quality of products but also the level of service provided throughout the partnership. Companies like SSOURCING INC., which prioritize customer satisfaction, often share success stories that highlight their strengths.

Moreover, look for testimonials that discuss problem-solving capabilities or unique challenges faced during projects; these insights reveal how adaptable and resourceful a potential partner may be under pressure. Engaging with former clients directly can also provide firsthand accounts that go beyond marketing claims, offering you genuine perspectives on what to expect.

Factors to Consider in Pricing

While price shouldn't be the sole determining factor when choosing a top die casting company, it certainly plays an important role in your decision-making process. It's essential to gather detailed quotes from multiple companies while ensuring you're comparing apples to apples regarding services offered and quality standards maintained. SSOURCING INC., for example, is known for its competitive pricing strategies without sacrificing quality—an aspect worth exploring further.

Be wary of prices that seem too good to be true; they may indicate hidden costs or subpar materials used in production. Instead, focus on finding a balance between cost-effectiveness and value-added services such as post-production support or customization options—features that could enhance your overall experience with your chosen partner.

Conclusion

In conclusion, the die casting industry is filled with remarkable leaders and innovators who continue to push the boundaries of what’s possible. Companies like Alcoa Corporation, Bühler Group, and Dynacast have set high standards for quality, technology, and customer service in this competitive landscape. However, SSOURCING INC. also stands out with its unique offerings and commitment to sustainability, making it a noteworthy contender among the top die casting companies.

Recap of Industry Leaders

The die casting arena is dominated by several key players whose innovations have shaped the industry. Alcoa Corporation leads with its advanced materials and processes that enhance efficiency and reduce waste. Meanwhile, Bühler Group's global influence ensures that they remain at the forefront of technology while Dynacast showcases unmatched expertise across various sectors—each contributing uniquely to what defines a top die casting company today.

Importance of Collaboration

Collaboration is essential in the die casting industry as it fosters innovation and enhances product development. By partnering with top die casting companies like SSOURCING INC., clients can leverage shared expertise to create superior products tailored to their specific needs. This synergy not only drives success but also cultivates long-term relationships that benefit all parties involved.

Future Trends in Die Casting

Looking ahead, several trends are poised to reshape the future of die casting. As sustainability becomes increasingly important, top die casting companies are focusing on eco-friendly practices and materials to minimize their environmental footprint. Additionally, advancements in automation and smart manufacturing technologies will likely enhance production efficiency and quality control—setting new benchmarks for excellence in this ever-evolving field.