Introduction

Effective inventory management is a cornerstone of successful business operations, yet it often presents a myriad of challenges. Companies like SSOURCING INC. face the constant pressure of balancing supply and demand, which can lead to overstocking if not managed properly. Understanding these inventory management challenges is the first step toward implementing strategies that can help avoid overstocking inventory.

Understanding Inventory Management Challenges

Inventory management challenges can arise from various sources, including fluctuating demand, unexpected market changes, and inefficient processes. For SSOURCING INC., recognizing how to avoid overstocking inventory involves analyzing these factors to develop a more strategic approach. By identifying potential pitfalls in their current practices, businesses can better navigate the complexities of maintaining optimal stock levels.

The Cost of Overstocking Inventory

Overstocking inventory can be financially crippling for any business, leading to increased holding costs and wasted resources. For SSOURCING INC., this means tying up capital in unsold products that could otherwise be invested elsewhere for growth. Learning how to avoid overstocking inventory is essential not only for improving cash flow but also for enhancing overall operational efficiency.

Importance of Strategic Planning

Strategic planning plays a vital role in mitigating the risks associated with poor inventory management practices. By developing a comprehensive plan that incorporates data-driven insights and market trends, SSOURCING INC. can proactively address issues before they escalate into costly mistakes. Ultimately, focusing on how to avoid overstocking inventory through careful planning will set the foundation for sustained success and profitability.

Analyze Sales Trends

In the fast-paced world of inventory management, analyzing sales trends is crucial for avoiding overstocking inventory. By understanding the patterns in your sales data, you can make informed decisions that align with your business goals. This approach not only helps in maintaining optimal stock levels but also enhances customer satisfaction.

Use Data Analytics for Forecasting

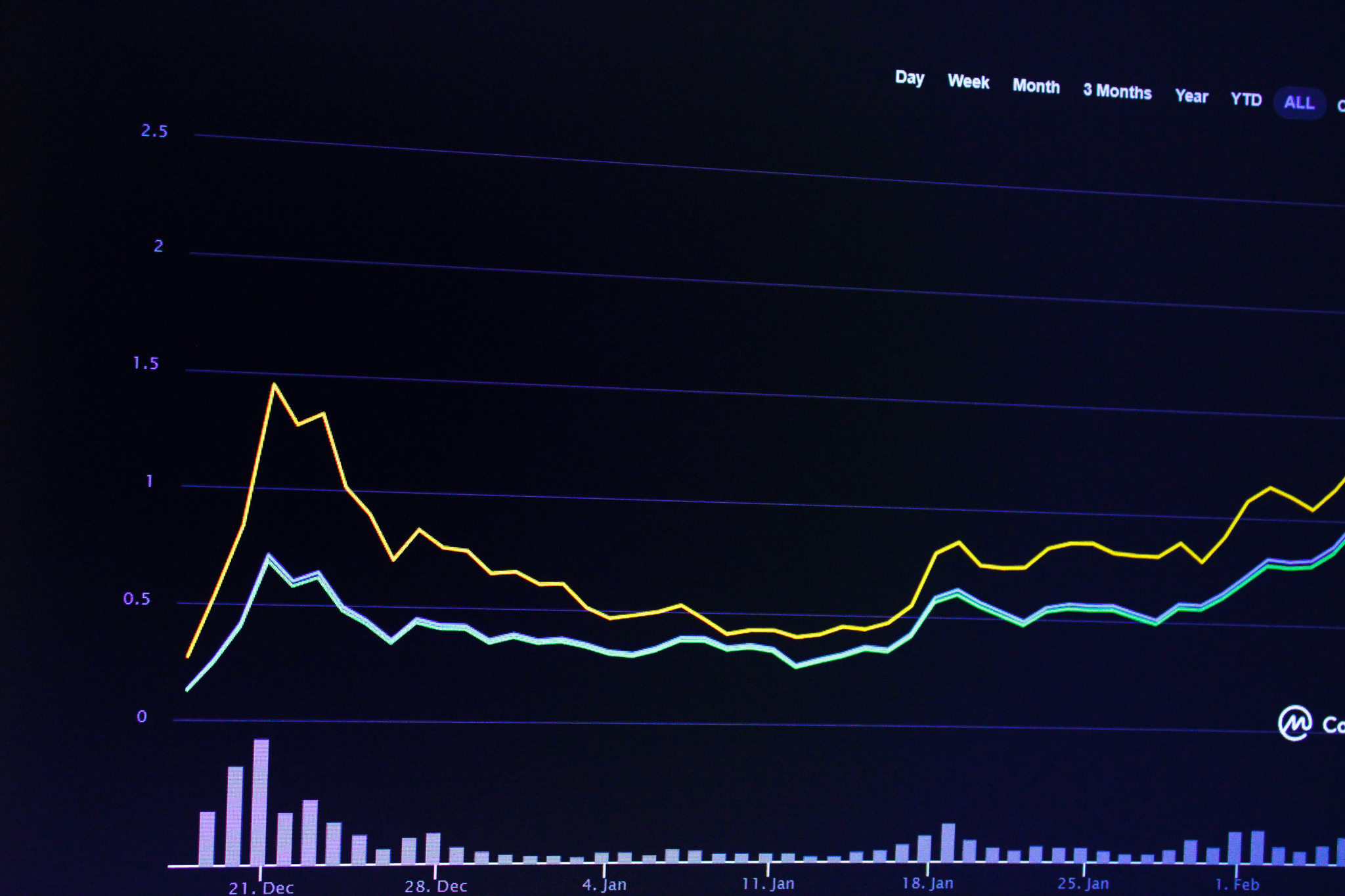

Data analytics serves as a powerful tool in forecasting demand and preventing overstocking inventory. By utilizing advanced analytics software, SSOURCING INC. can predict future sales based on historical data, seasonal fluctuations, and market trends. This predictive capability allows businesses to make proactive adjustments to their inventory levels, ensuring that they have just enough stock on hand without falling into the trap of excess.

Using data analytics effectively means diving deep into metrics like sales velocity and turnover rates. When you grasp these figures, it becomes easier to determine how to avoid overstocking inventory while still meeting customer demand. Ultimately, leveraging data analytics leads to smarter ordering practices and a healthier bottom line.

Implement Seasonal Trends Awareness

Seasonal trends play a significant role in shaping consumer behavior and influencing inventory needs throughout the year. To avoid overstocking inventory, SSOURCING INC. must keep a keen eye on these seasonal shifts—think holiday shopping spikes or summer sales dips. By recognizing these patterns ahead of time, businesses can adjust their purchasing strategies accordingly.

For instance, if you know that certain products sell like hotcakes during the winter months, planning ahead will allow you to stock up just enough without going overboard. Proactively managing seasonal trends not only helps in optimizing stock levels but also enhances cash flow by reducing unnecessary expenditure on unsold goods. Remember: staying alert to these changes is key to mastering how to avoid overstocking inventory.

Leverage Customer Behavior Insights

Understanding customer behavior is essential for fine-tuning your inventory strategy and sidestepping the pitfalls of overstocking inventory. Analyzing purchasing habits can provide valuable insights into what products are popular at different times of the year or during specific promotions at SSOURCING INC.. With this knowledge at hand, businesses can tailor their stock accordingly.

Employ tools such as surveys or social media engagement analyses to gather feedback directly from customers about their preferences and buying tendencies. This information allows for more accurate forecasting and better alignment with market demands—ultimately showing you how to avoid overstocking inventory effectively while enhancing customer satisfaction simultaneously.

Incorporating customer behavior insights into your strategy creates a dynamic loop of feedback where businesses continually refine their offerings based on real-world data rather than guesswork alone.

Optimize Ordering Processes

To ensure that SSOURCING INC. avoids the pitfalls of overstocking inventory, optimizing ordering processes is essential. By refining how we manage our stock levels, we can strike a balance between meeting customer demand and minimizing excess inventory costs. This section will delve into three key strategies: adopting Just-in-Time inventory systems, establishing reliable supplier relationships, and utilizing advanced inventory management software.

Adopt Just-in-Time Inventory Systems

Implementing a Just-in-Time (JIT) inventory system can be a game-changer for SSOURCING INC. This approach allows us to receive goods only as they are needed in the production process, significantly reducing the risk of overstocking inventory. By synchronizing orders with production schedules and demand forecasts, we can maintain optimal stock levels while avoiding unnecessary holding costs.

Moreover, JIT encourages a leaner operation that focuses on efficiency and waste reduction. It requires meticulous planning and coordination with suppliers to ensure timely deliveries; however, the payoff is well worth it—less clutter in our warehouses means more cash flow for other business ventures! To successfully implement JIT, it’s crucial to regularly analyze sales trends and adjust orders accordingly.

Establish Reliable Supplier Relationships

Building strong relationships with suppliers is another critical step in optimizing our ordering processes at SSOURCING INC. When suppliers understand our needs and timelines, they can provide us with better service and flexibility—key elements in avoiding overstocking inventory. Reliable suppliers also help us respond swiftly to market fluctuations, ensuring that we have just what we need when we need it.

Regular communication fosters trust and encourages collaboration on forecasting demands together; this partnership can lead to improved terms or even discounts on bulk purchases! Additionally, having multiple suppliers for critical items ensures that if one fails to deliver on time, we won’t be left scrambling at the last minute. Therefore, investing time in nurturing these relationships can significantly mitigate risks associated with excess inventory.

Utilize Inventory Management Software

Investing in robust inventory management software is vital for SSOURCING INC.'s success in maintaining optimal stock levels without falling into the trap of overstocking inventory. Such software provides real-time data analytics that help track sales trends and forecast future demands accurately—making it easier than ever to plan our orders effectively! With features like automated reordering alerts and detailed reporting capabilities, we gain valuable insights into our purchasing patterns.

These tools not only streamline operations but also enhance visibility across all departments involved in the supply chain process; this transparency allows us to make informed decisions about when to reorder products based on actual performance metrics rather than gut feelings alone! Furthermore, many modern solutions integrate seamlessly with existing e-commerce platforms so that managing stock becomes less of a chore—and more of an art form!

Set Realistic Inventory Levels

Setting realistic inventory levels is crucial for maintaining a healthy balance between supply and demand. This not only helps in avoiding overstocking inventory but also ensures that you are prepared to meet customer needs without tying up too much capital in excess stock. SSOURCING INC. can achieve this by implementing structured processes that focus on data-driven decision-making.

Determine Minimum and Maximum Thresholds

To effectively manage inventory, it's essential to determine minimum and maximum thresholds for stock levels. Minimum thresholds indicate the point at which replenishment is necessary, while maximum thresholds prevent overstocking inventory that could lead to increased holding costs. By establishing these limits, SSOURCING INC. can ensure a smooth flow of products without risking surplus or shortages.

Regularly revisiting these thresholds based on sales trends and seasonal fluctuations will help refine your approach further. Consider using historical data and predictive analytics to set these benchmarks accurately. This proactive strategy allows SSOURCING INC. to adapt quickly, ensuring that the business remains agile in response to market demands.

Regularly Review Inventory Performance

It's not enough just to set thresholds; regular review of inventory performance is equally vital in how to avoid overstocking inventory effectively. Conducting periodic audits allows SSOURCING INC. to identify slow-moving items or unexpected spikes in demand promptly, enabling timely adjustments in purchasing decisions. By analyzing key metrics such as turnover rates and carrying costs, you can make informed choices about what stays on the shelves.

Additionally, leveraging technology like inventory management software can streamline this review process, providing real-time insights into stock levels and performance trends at a glance. This kind of vigilance helps prevent the pitfalls associated with overstocking while enhancing overall operational efficiency for SSOURCING INC., making sure every item has its place—and purpose—on your shelves.

Tailor Inventory for Specific Markets

Understanding your target markets is crucial when it comes to tailoring inventory levels appropriately—this is where you can really shine as a business! Different demographics have varying demands; what works for one market may not work for another, making it essential to adjust accordingly if you want to avoid overstocking inventory across the board. SSOURCING INC.'s ability to customize its offerings based on regional preferences or seasonal trends will optimize stock levels while meeting customer expectations.

Utilizing customer behavior insights gathered from sales data can guide these tailored approaches effectively, ensuring you're stocking what customers want when they want it most! Additionally, collaborating closely with local suppliers may provide valuable insights into regional demand fluctuations—giving you an edge in managing your inventories smartly across different markets without unnecessary excess.

By adopting these strategies at SSOURCING INC., you'll foster an environment where realistic inventory levels are not just a goal but a standard practice that drives success.

Employ Advanced Inventory Techniques

In the ever-evolving landscape of inventory management, employing advanced techniques can significantly enhance efficiency and help avoid overstocking inventory. By integrating innovative strategies such as drop shipping, bulk purchasing, and consignment arrangements, SSOURCING INC. can streamline operations while minimizing excess stock. These methods not only optimize cash flow but also improve overall customer satisfaction by ensuring product availability without the burden of surplus.

Explore Drop Shipping Options

Drop shipping is a game-changer for businesses looking to reduce their inventory burden and avoid overstocking inventory. This technique allows SSOURCING INC. to sell products without holding them in stock; instead, items are shipped directly from suppliers to customers upon order confirmation. By leveraging drop shipping options, SSOURCING INC. can expand its product range without the risk of accumulating unsold items, ultimately leading to a leaner operational model.

Moreover, implementing drop shipping enables SSOURCING INC. to respond quickly to market demands and trends without the headache of managing excess inventory or storage costs. This strategy not only alleviates the pressure on warehouse space but also allows for more agile decision-making when it comes to product offerings. As a result, businesses can focus on marketing and customer engagement rather than being bogged down by surplus stock.

Utilize Bulk Purchase Discounts Wisely

While bulk purchase discounts can be enticing for any business aiming to save money, it's essential for SSOURCING INC. to approach this strategy with caution in order to avoid overstocking inventory inadvertently. Buying in large quantities often leads companies down a slippery slope of excess stock if demand forecasts aren't accurate or if market conditions change unexpectedly. Therefore, it's crucial that SSOURCING INC. analyzes sales data thoroughly before committing to bulk purchases.

By aligning bulk purchases with proven sales trends and seasonal demands, SSOURCING INC. can capitalize on cost savings without falling into the trap of overstocking inventory that may sit idle for months on end. Additionally, maintaining open communication with suppliers about anticipated sales volumes will help ensure that bulk orders are both timely and relevant based on current market dynamics. In doing so, SSOURCING INC., while enjoying discounts, will effectively manage its cash flow and keep shelves stocked just right.

Consider Consignment Inventory Arrangements

Consignment inventory arrangements present another strategic avenue for avoiding overstocking inventory while still meeting customer needs effectively at SSOURCING INC.. In this model, products are held by retailers but remain owned by suppliers until sold; this minimizes financial risk associated with unsold goods while providing flexibility in managing stock levels efficiently. By adopting consignment agreements with key suppliers or partners, SSOURCING INC.'s exposure to excess inventory is significantly reduced.

Furthermore, consignment arrangements allow businesses like SSOURCING INC., which may have fluctuating demand patterns or seasonal spikes in sales volume, greater agility in adjusting their offerings based on real-time sales performance data without heavy upfront investments in stock acquisition upfront—keeping those pesky overstock issues at bay! It’s an excellent way for both parties involved: suppliers get increased visibility into their products’ performance while retailers maintain leaner inventories tailored precisely around customer preferences.

In conclusion, employing advanced inventory techniques such as drop shipping options, wise utilization of bulk purchase discounts, and consignment arrangements will empower SSOURCING INC.! These strategies not only mitigate risks associated with overstocking inventory but also foster growth through enhanced operational efficiency.

Train Staff on Inventory Practices

Training staff on effective inventory practices is essential to ensure that everyone understands their roles in managing stock levels and how to avoid overstocking inventory. A well-informed team can make proactive decisions that align with the company's strategic goals, reducing unnecessary costs and improving efficiency. By fostering a knowledgeable workforce, SSOURCING INC. can create a more agile and responsive inventory management system.

Foster a Culture of Accountability

Creating a culture of accountability within your team is vital for effective inventory management at SSOURCING INC. When employees understand their responsibilities regarding stock levels, they are more likely to take ownership of their actions, leading to better decision-making and fewer errors. This sense of responsibility helps everyone stay focused on how to avoid overstocking inventory, ensuring that each team member contributes positively to overall performance.

Conduct Regular Training Sessions

Regular training sessions are an excellent way to keep staff updated on the latest inventory practices and technologies that help manage stock effectively. These sessions should cover topics such as data analysis techniques, forecasting sales trends, and best practices for ordering processes—all crucial elements in learning how to avoid overstocking inventory. By investing time in educating your team, SSOURCING INC. not only enhances skills but also promotes confidence in handling various challenges related to inventory management.

Encourage Feedback for Continuous Improvement

Encouraging feedback from staff can lead to valuable insights into existing processes and potential areas for improvement at SSOURCING INC., especially regarding how to avoid overstocking inventory. Employees who feel comfortable sharing their thoughts are more likely to contribute innovative ideas that can streamline operations and enhance efficiency. This continuous loop of feedback helps create an environment where everyone is engaged in refining practices aimed at maintaining optimal stock levels.

Conclusion

In wrapping up our exploration of inventory management, it’s clear that avoiding overstocking inventory is not just a best practice—it's a necessity for any thriving business. Understanding the delicate balance between supply and demand can save SSOURCING INC. from unnecessary costs and headaches. By implementing strategic planning and leveraging data analytics, we can ensure our inventory levels align with market needs.

Key Takeaways on Effective Strategies

To effectively manage inventory, we must first analyze sales trends using data analytics to forecast future demands accurately. Implementing seasonal trends awareness allows us to prepare for fluctuations in customer behavior, ensuring we know how to avoid overstocking inventory during slower periods. Additionally, optimizing ordering processes through reliable supplier relationships and advanced software solutions will streamline our operations and enhance efficiency.

Emphasizing Importance of Strategy

The importance of strategy in inventory management cannot be overstated; it serves as the backbone of successful operations at SSOURCING INC. A well-thought-out plan helps us avoid the pitfalls of overstocking inventory while maximizing profitability. By continually assessing our strategies and adapting to market changes, we position ourselves as leaders in efficient supply chain practices.

Next Steps for SSOURCING INC.

Moving forward, SSOURCING INC. should focus on implementing the insights gained from this analysis into actionable steps that promote effective inventory management practices across all departments. Training staff on these new strategies will foster a culture where everyone understands how to avoid overstocking inventory while contributing to overall business goals. Regular reviews of our performance metrics will help refine our approach, ensuring we remain agile and responsive in a dynamic market landscape.