Introduction

In the fast-paced world of manufacturing, understanding the significance of China injection molds is crucial for businesses looking to maintain a competitive edge. These molds are not just tools; they are the backbone of efficient production processes that can make or break product quality and market viability. As global demand continues to rise, investing in high-quality China injection molds becomes an essential strategy for companies aiming to optimize their manufacturing capabilities.

Why China Injection Molds Matter

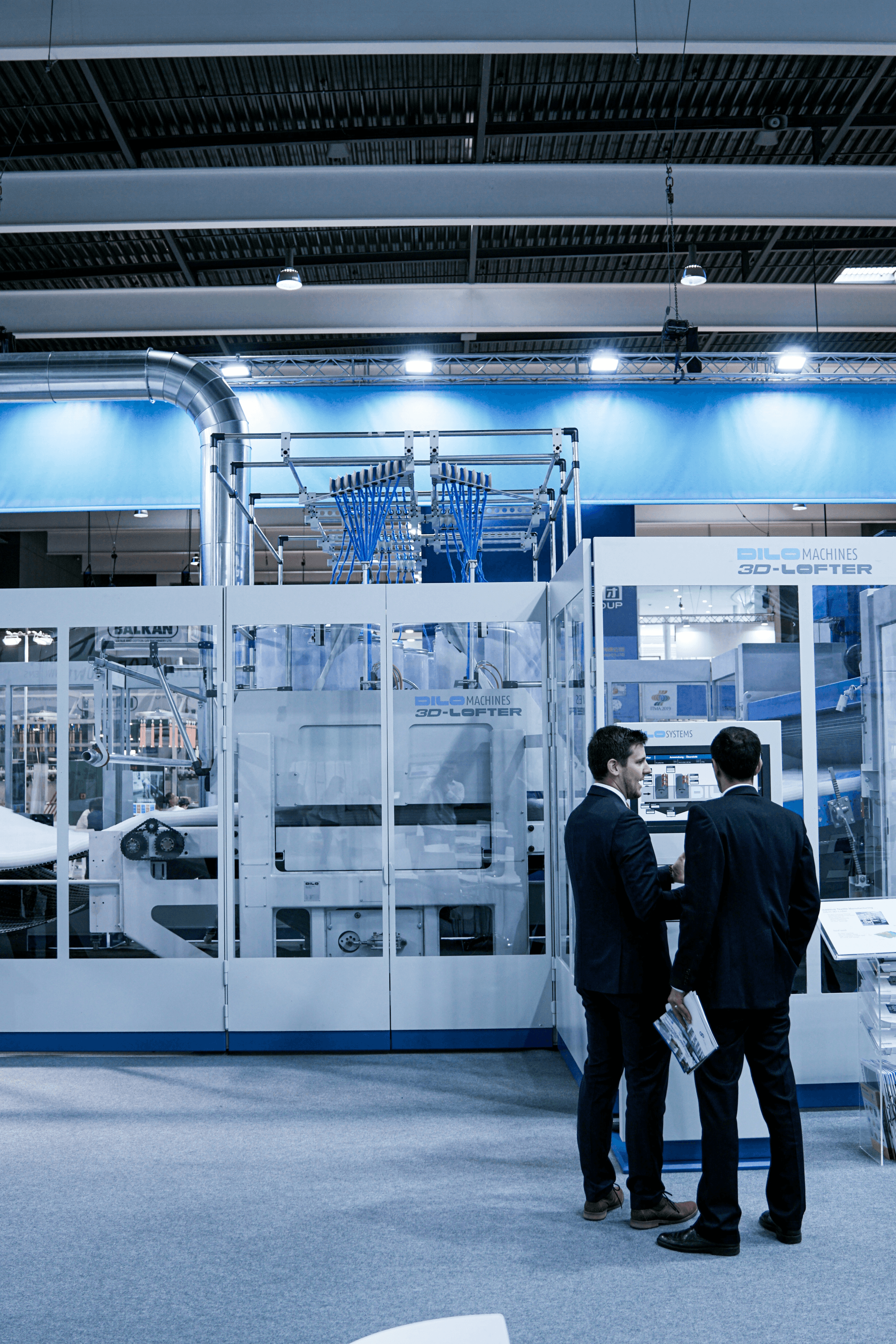

China injection molds have gained immense popularity due to their ability to produce complex shapes with precision and speed. The country's robust manufacturing infrastructure allows for rapid prototyping and scalability, making it a go-to destination for businesses across various industries. Moreover, these molds contribute significantly to cost savings without compromising on quality, which is why savvy manufacturers prioritize sourcing from China.

The Competitive Edge of China Injection Molds

The competitive edge provided by China injection molds lies in their combination of affordability, quality craftsmanship, and advanced technology. Manufacturers can leverage this advantage to streamline production processes while ensuring that their products meet stringent industry standards. With SSOURCING INC., you can tap into a network of reputable suppliers who specialize in delivering top-notch china injection molds tailored to your specific needs.

Key Factors in Choosing China Injection Molds

Selecting the right china injection molds involves careful consideration of several key factors such as material compatibility, mold design complexity, and manufacturer reputation. Businesses must evaluate potential suppliers based on their experience, customer feedback, and adherence to international quality standards. By partnering with SSOURCING INC., companies can navigate these complexities with confidence and ensure they make informed decisions that align with their production goals.

Understanding Injection Molding

Injection molding is a fascinating process that has transformed the manufacturing landscape, especially when it comes to producing high-quality parts efficiently. Essentially, it involves injecting molten material into a mold to create various shapes and components. This method is particularly popular for creating plastic products, which is where China injection molds come into play, offering both quality and cost-effectiveness.

The Basics of Injection Molding

At its core, injection molding starts with heating plastic pellets until they melt into a viscous state. The molten material is then injected under pressure into a pre-designed mold cavity, where it cools and solidifies to form the final product. Understanding this fundamental process is crucial for anyone considering using China injection molds since the efficiency and precision of the operation can significantly impact production timelines and costs.

The beauty of injection molding lies in its ability to produce complex shapes with high repeatability. This means businesses can rely on consistent quality across large production runs—a vital factor for maintaining brand integrity. As you explore options for China injection molds, keep in mind that mastering these basics will help you make informed decisions about your manufacturing needs.

Types of Injection Molds

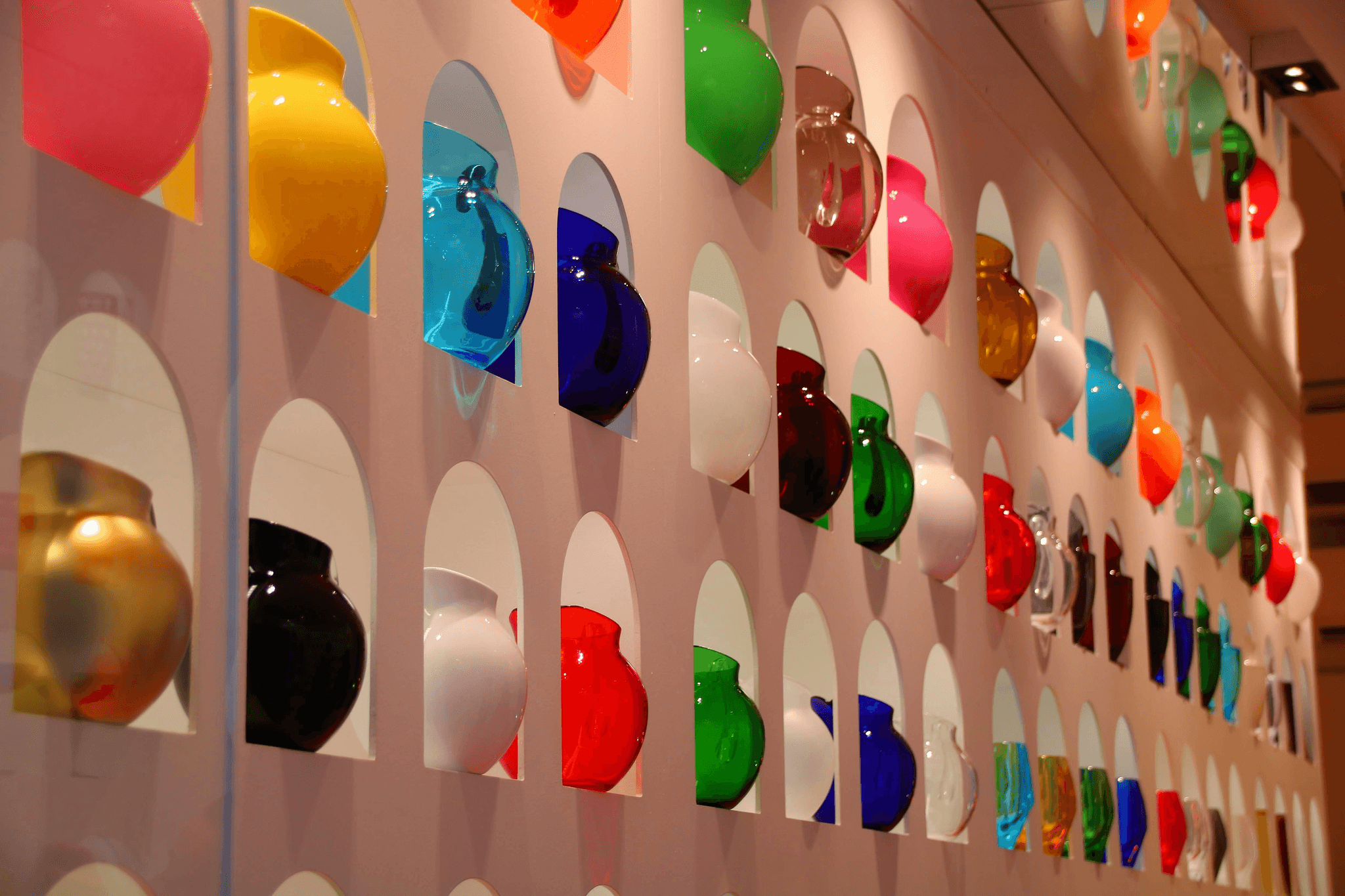

When discussing China injection molds, it's essential to recognize that not all molds are created equal; they come in several varieties tailored to different applications. Common types include single-cavity molds, multi-cavity molds, family molds, and hot runner systems—each serving unique purposes depending on your production goals. For instance, single-cavity molds are ideal for low-volume runs while multi-cavity designs increase output without sacrificing quality.

Moreover, family molds allow manufacturers to produce multiple parts simultaneously within one mold—perfect for companies looking to streamline processes or reduce costs associated with tooling changes. Hot runner systems enhance efficiency by keeping the material heated within the mold channels during production cycles, minimizing waste and improving cycle times significantly. By understanding these types of China injection molds available through SSOURCING INC., you can better align your choices with your specific manufacturing requirements.

Importance of Material Selection

Choosing the right materials for your project is just as critical as selecting the appropriate type of mold when working with China injection molds. The material affects not only the final product's strength and durability but also how well it performs during the molding process itself. Common materials include thermoplastics like ABS or polycarbonate; each has unique properties that may suit different applications.

It's also worth noting that some materials require specialized processing techniques or equipment—something SSOURCING INC. can help navigate smoothly given their extensive experience in this field. Ultimately, making informed decisions about material selection ensures that you achieve optimal results while maximizing cost-effectiveness throughout production cycles using China injection molds.

Evaluating Manufacturer Reputation

When diving into the world of China injection molds, evaluating the reputation of potential manufacturers is crucial. A solid reputation can be your best ally in ensuring that you receive high-quality products and reliable service. With so many options available, understanding how to assess a manufacturer's credentials and track record will save you time, money, and headaches down the line.

Researching Manufacturer Credentials

The first step in evaluating a manufacturer’s reputation is to research their credentials thoroughly. Check for industry certifications that validate their expertise in producing china injection molds. Look for memberships in professional organizations or accolades that showcase their commitment to quality and innovation—these are good indicators that you're dealing with a reputable company like SSOURCING INC.

Additionally, it’s wise to explore how long the manufacturer has been in business. Longevity often reflects stability and experience; companies that have weathered market changes are typically more reliable when it comes to delivering consistent quality in china injection molds. Don’t hesitate to ask potential partners about their manufacturing processes, technology used, and workforce qualifications as well.

Customer Reviews and Case Studies

Customer reviews can provide invaluable insights into a manufacturer's reliability and product quality. Look for testimonials from previous clients who have worked with china injection molds; they often reveal important information about the manufacturing process, delivery times, and customer service experiences. Websites like Trustpilot or industry-specific forums can be gold mines for real-world feedback on manufacturers.

Case studies showcasing successful projects can also help gauge a manufacturer’s capabilities. If they’ve worked with reputable brands or handled complex projects successfully, it’s likely they’ll meet your standards as well—especially if SSOURCING INC.'s name comes up positively! Just remember to consider both positive reviews and constructive criticism; they both offer valuable lessons about what you might expect.

Red Flags to Watch Out For

While researching manufacturers for china injection molds, be vigilant for red flags that could indicate trouble ahead. A lack of transparency regarding pricing or unwillingness to provide detailed information about their processes is often a warning sign of potential issues down the line. If you encounter numerous negative reviews or complaints about poor communication or product quality, it's best to steer clear.

Another red flag is an overly aggressive sales approach without sufficient technical support or guidance offered during your initial inquiries—this could suggest they prioritize sales over customer satisfaction. Additionally, if a manufacturer does not hold any relevant certifications or fails to comply with industry standards, it's wise to reconsider partnering with them altogether.

In summary, taking the time to evaluate manufacturer reputations ensures that your investment in china injection molds pays off in terms of quality and reliability down the road.

Analyzing Cost vs. Quality

When it comes to sourcing china injection molds, the balance between cost and quality can feel like walking a tightrope. On one hand, everyone loves a good bargain; on the other, compromising quality for a lower price can lead to disastrous consequences down the line. Understanding how to navigate this delicate balance is crucial for manufacturers who want their products to shine in today's competitive market.

Balancing Budget and Quality

Finding that sweet spot between budget constraints and high-quality china injection molds is no small feat. It's tempting to chase after the lowest price, but remember: you often get what you pay for. Investing in quality molds from reputable manufacturers like SSOURCING INC. may seem pricier upfront, but it pays off with improved production efficiency and fewer defects in the long run.

Moreover, consider your project's specific needs when evaluating costs; sometimes spending a little more on tailored solutions can save you money by reducing waste or downtime later on. It’s also wise to factor in potential savings over time—higher-quality molds typically last longer and require less maintenance than their cheaper counterparts. In short, balancing budget with quality isn’t just smart; it’s essential.

Hidden Costs in China Injection Molds

Ah, hidden costs—the sneaky little gremlins that can turn your budget into Swiss cheese! When it comes to china injection molds, these costs can manifest in various ways: unexpected shipping fees, customs duties, or even additional charges for revisions might be lurking around every corner. This is why thorough research and clear communication with suppliers like SSOURCING INC. are vital before signing any contracts.

Additionally, don't overlook the importance of post-production expenses such as maintenance or repairs that could arise from using lower-quality molds. Sometimes what looks like a great deal initially can end up costing you far more than anticipated due to these hidden pitfalls—so keep your eyes peeled! By being aware of potential hidden costs upfront, you’ll make more informed decisions that align with both your budget and quality expectations.

Long-Term Value of High-Quality Molds

Investing in high-quality china injection molds is akin to planting seeds for future growth; while they may require more resources now, they yield significant returns down the road. Quality molds not only produce better parts but also offer reliability that reduces downtime—a critical factor for any manufacturer looking to stay competitive in today’s fast-paced environment. Companies like SSOURCING INC., which prioritize durability and precision in their mold designs, ensure you're not just buying a product but investing in peace of mind.

Furthermore, consider how high-quality molds enhance your brand's reputation over time; consistently producing superior products helps build trust among consumers and fosters loyalty—key ingredients for long-term success! So while the initial investment may seem daunting at first glance, think of it as an investment into your company's future rather than just another expense on the ledger sheet.

In conclusion, navigating the cost versus quality landscape when choosing china injection molds requires careful consideration and strategic planning—but fear not! With diligence and guidance from reputable partners like SSOURCING INC., you'll find yourself equipped with all necessary tools for making informed decisions that will ultimately lead you toward success.

Communication and Support

When it comes to sourcing china injection molds, effective communication is the backbone of a successful partnership. Clear communication not only ensures that your specific requirements are understood but also helps in avoiding costly misunderstandings down the line. In a global market where time zones and languages can create barriers, establishing a solid communication framework is essential.

Importance of Clear Communication

Clear communication sets the stage for successful collaboration in any project involving china injection molds. It allows both parties to align their expectations, timelines, and deliverables from the outset. Moreover, a transparent dialogue can help mitigate risks associated with production delays or design modifications, ultimately saving you both time and money.

Evaluating Customer Service

When selecting a manufacturer for your china injection molds, customer service should be at the forefront of your evaluation criteria. A responsive and knowledgeable customer service team can make all the difference when navigating challenges or queries during the manufacturing process. Look for manufacturers who prioritize customer support as much as they do quality production; this will ensure smoother operations and peace of mind throughout your project.

Role of SSOURCING INC. in Bridging Gaps

SSOURCING INC. excels in bridging gaps between clients and manufacturers of china injection molds by facilitating clear communication channels and offering robust support services. We understand that sourcing from overseas can be daunting; hence we strive to simplify complexities through dedicated assistance at every step of the journey. With our expertise, you can navigate potential pitfalls confidently while focusing on what really matters—your product's success.

Compliance and Quality Assurance

When it comes to sourcing china injection molds, compliance and quality assurance are non-negotiable aspects that can make or break your manufacturing process. Understanding industry standards is crucial for ensuring that the molds you select meet both safety and performance benchmarks. With the right knowledge, you can navigate through the complexities of regulations and certifications that govern the injection molding industry.

Understanding Industry Standards

Industry standards for china injection molds are designed to ensure product safety, reliability, and performance. Familiarizing yourself with these standards will help you assess whether a manufacturer adheres to best practices in mold design and production. Organizations such as ISO (International Organization for Standardization) set forth guidelines that can provide a solid foundation for evaluating potential suppliers.

Checking Certifications and Compliance

Before finalizing any deal, it's essential to check the certifications of your chosen manufacturer of china injection molds. Look for relevant certifications like ISO 9001 or other industry-specific credentials that demonstrate a commitment to quality management systems. SSOURCING INC. emphasizes this step because verified compliance not only minimizes risks but also enhances your confidence in the supplier's capabilities.

Ensuring Quality Assurance Processes

Quality assurance processes are vital when dealing with china injection molds, as they ensure consistency throughout production runs. A robust QA process includes regular inspections, testing protocols, and feedback loops to catch any issues early on before they escalate into costly problems. By partnering with manufacturers who prioritize these processes, like those vetted by SSOURCING INC., you can secure high-quality molds that meet your specifications reliably.

Conclusion

Wrapping up our discussion on China injection molds, it's clear that making the right selection can significantly impact your manufacturing success. The nuances of choosing the right mold are many, but with careful consideration and informed decision-making, you can set your project up for triumph. Remember, investing in quality now can save you headaches later on.

Final Thoughts on Injection Mold Selection

When it comes to selecting china injection molds, understanding your specific needs is paramount. Each project is unique, and so are the molds that will best serve them; this requires a tailored approach rather than a one-size-fits-all mentality. Take the time to evaluate all aspects—costs, materials, and manufacturer reputation—because these factors will ultimately dictate the quality of your end product.

The Importance of Strategic Partnerships

Forging strategic partnerships with reliable manufacturers is not just beneficial; it's essential in navigating the complexities of sourcing china injection molds. Companies like SSOURCING INC. excel at building these connections, ensuring that you have access to top-tier resources and expertise throughout your project lifecycle. Strong partnerships foster trust and open lines of communication which are crucial for overcoming challenges that may arise during production.

Moving Forward with Confidence in China Injection Molds

As you embark on your journey towards utilizing china injection molds, remember that confidence comes from preparation and knowledge. Equip yourself with insights gleaned from thorough research and expert guidance from companies like SSOURCING INC., which specialize in facilitating smooth transactions between manufacturers and clients. With the right tools at your disposal, you’ll be well-positioned to make informed decisions that propel your business forward.