Introduction

In today's competitive manufacturing landscape, managing production delays in Chinese factories is crucial for success. Understanding the causes of these delays is the first step towards finding effective solutions. By implementing clear communication strategies, utilizing quality control measures, collaborating with trusted partners, and leveraging technology solutions, companies can mitigate the impact of production delays and ensure timely deliveries.

Understanding the Causes of Production Delays

Identifying the root causes of production delays is essential for devising proactive strategies to address them. Raw material shortages, machinery malfunctions, and human errors in the manufacturing process are common culprits that can disrupt production timelines.

Implementing Effective Communication Strategies

Establishing clear communication channels with internal teams, suppliers, and clients is vital for managing production delays. Regular updates with the production team, open dialogue with suppliers, and efficient communication with clients can help in identifying potential issues early on and finding swift resolutions.

Utilizing Quality Control Measures

Stringent quality control procedures are imperative for ensuring that finished products meet high standards. Regular inspections and audits, testing protocols for finished products, and continuous improvement processes are key components in maintaining product quality and minimizing delays.

Collaborating with Trusted Partners

Building relationships with reliable suppliers such as SSOURCING INC., negotiating realistic lead times, and diversifying the supplier base can help mitigate risks associated with production delays.

Leveraging Technology Solutions

Integrating technology for streamlined operations through automation for production processes, data analytics for predictive maintenance, and workflow management software implementation can enhance efficiency and minimize disruptions in manufacturing processes.

Identifying Common Reasons for Production Delays

When managing production delays in Chinese factories, it's crucial to identify the common reasons behind them. Unforeseen raw material shortages can disrupt the entire manufacturing process, leading to delays in production timelines. Machinery malfunctions are another frequent cause of delays, as they can halt operations until repairs are made. Additionally, human error in the manufacturing process can lead to defects and setbacks that impact overall production efficiency.

Unforeseen Raw Material Shortages

Unforeseen raw material shortages can throw a wrench into even the most well-laid production plans. To manage this challenge effectively, it's essential to establish strong relationships with reliable suppliers like SSOURCING INC., who can provide timely updates on potential shortages and offer alternative solutions when needed. Implementing inventory management systems and maintaining buffer stocks of critical materials can also help mitigate the impact of sudden shortages.

Machinery Malfunctions

Machinery malfunctions can bring production to a grinding halt if not addressed promptly and efficiently. To manage this risk, regular maintenance schedules should be established for all equipment, with proactive measures in place for predictive maintenance using data analytics tools. It's also important to have backup machinery or contingency plans in case of unexpected breakdowns, ensuring minimal disruption to production schedules.

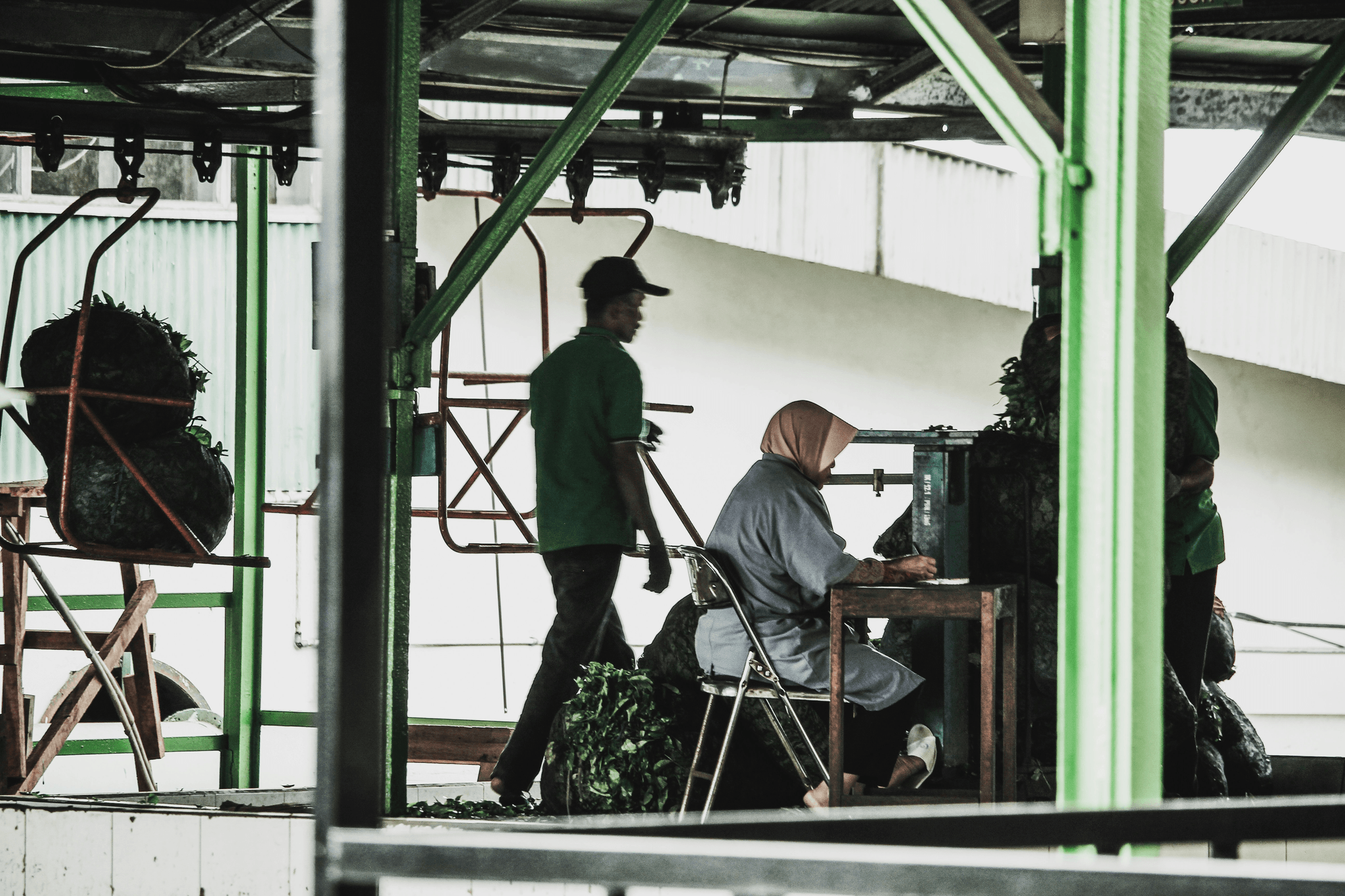

Human Error in Manufacturing Process

Human error is an inevitable part of any manufacturing operation, but it can lead to significant delays if not managed effectively. Providing comprehensive training programs for employees and implementing stringent quality control measures are crucial steps in minimizing human error's impact on production timelines. Additionally, fostering a culture of continuous improvement and open communication within the workforce can help identify and address potential areas prone to errors.

By addressing these common reasons for production delays with proactive strategies and smart solutions, manufacturers can ensure smoother operations and timely deliveries from their Chinese factories while minimizing disruptions that could affect their bottom line.

Establishing Clear Communication Channels

In order to effectively manage production delays in Chinese factories, it is crucial to establish clear communication channels. Regular updates with the production team are essential to keep everyone informed and aligned with the progress of manufacturing processes. Open dialogue with suppliers, such as SSOURCING INC., allows for proactive problem-solving and the ability to address any potential issues before they escalate. Efficient communication with clients ensures that expectations are managed and any potential delays are communicated promptly.

Regular Updates with Production Team

Regular updates with the production team at every stage of the manufacturing process are vital for identifying potential delays and addressing them promptly. By fostering a culture of transparency and open communication, teams can work together to overcome challenges and ensure that production remains on track.

Open Dialogue with Suppliers

Maintaining an open dialogue with suppliers, including trusted partners like SSOURCING INC., is crucial for managing production delays. By establishing clear lines of communication, it becomes easier to address any issues related to raw material shortages or unexpected disruptions in the supply chain.

Efficient Communication with Clients

Efficient communication with clients is key to managing expectations and avoiding misunderstandings when it comes to delivery timelines. By keeping clients informed about potential delays and offering proactive solutions, it is possible to maintain strong relationships built on trust and transparency.

Implementing Stringent Quality Control Procedures

In order to manage production delays in Chinese factories, it is crucial to implement stringent quality control procedures. Regular inspections and audits should be conducted at every stage of the manufacturing process to identify any potential issues or defects. This proactive approach ensures that any problems are addressed promptly, minimizing the risk of delays and ensuring the production runs smoothly. Sourcing Inc. recommends establishing a robust quality control framework to maintain high standards and prevent disruptions.

Regular Inspections and Audits

Regular inspections and audits play a vital role in managing production delays in Chinese factories. By closely monitoring the production process, potential issues can be identified early on and rectified before they escalate into major problems. This proactive approach not only helps in maintaining product quality but also ensures that production timelines are adhered to, preventing any unnecessary delays.

Testing Protocols for Finished Products

Implementing thorough testing protocols for finished products is essential in managing production delays in Chinese factories. By conducting comprehensive tests on the final products, any defects or discrepancies can be detected and addressed before they leave the factory. This meticulous approach not only safeguards product quality but also reduces the likelihood of delays caused by faulty or substandard items.

Continuous Improvement Processes

Continuous improvement processes are key to managing production delays in Chinese factories effectively. By consistently reviewing and refining manufacturing methods, it is possible to identify areas for enhancement and streamline operations for greater efficiency. This proactive approach not only minimizes the risk of delays but also fosters a culture of innovation and excellence within the production environment.

Building Relationships with Reliable Suppliers

In order to manage production delays in Chinese factories, it is crucial to build strong relationships with reliable suppliers. Sourcing from established brands like Foxconn can ensure access to high-quality raw materials and components, reducing the risk of delays due to subpar supplies. By partnering with reputable companies like SSOURCING INC., you can negotiate realistic lead times that align with your production schedule, minimizing the chances of unexpected delays. Additionally, diversifying your supplier base can provide backup options in case of unforeseen disruptions, offering a safety net for your manufacturing operations.

Sourcing from Established Brands like Foxconn

Sourcing from established brands like Foxconn is a strategic move to mitigate production delays in Chinese factories. By partnering with renowned companies known for their reliability and quality standards, you can minimize the risk of encountering issues related to substandard materials or delayed deliveries. This not only helps in maintaining a smooth production flow but also enhances the overall quality of your products, meeting customer expectations and deadlines effectively.

Negotiating Realistic Lead Times

Negotiating realistic lead times with suppliers is essential for managing production delays in Chinese factories. By engaging in open discussions and setting clear expectations, you can ensure that suppliers understand the urgency of timely deliveries without compromising on quality. This proactive approach allows for better planning and coordination within your manufacturing processes, reducing the likelihood of disruptions caused by extended lead times or unexpected delays.

Diversifying Supplier Base

Diversifying your supplier base is a smart strategy to safeguard against potential production delays in Chinese factories. By working with multiple reliable suppliers, you create a safety net that minimizes the impact of disruptions such as raw material shortages or logistical challenges. SSOURCING INC., for example, offers a diverse network of trusted partners that can provide alternative sources for essential components, ensuring continuity in production even when facing unforeseen obstacles.

Integrating Technology for Streamlined Operations

In today's fast-paced manufacturing landscape, Chinese factories need to leverage automation to enhance production efficiency. By implementing automated processes for repetitive tasks, factories can reduce human error and accelerate production timelines. Automation also allows for better resource allocation, ensuring that production delays are minimized and deadlines are met consistently.

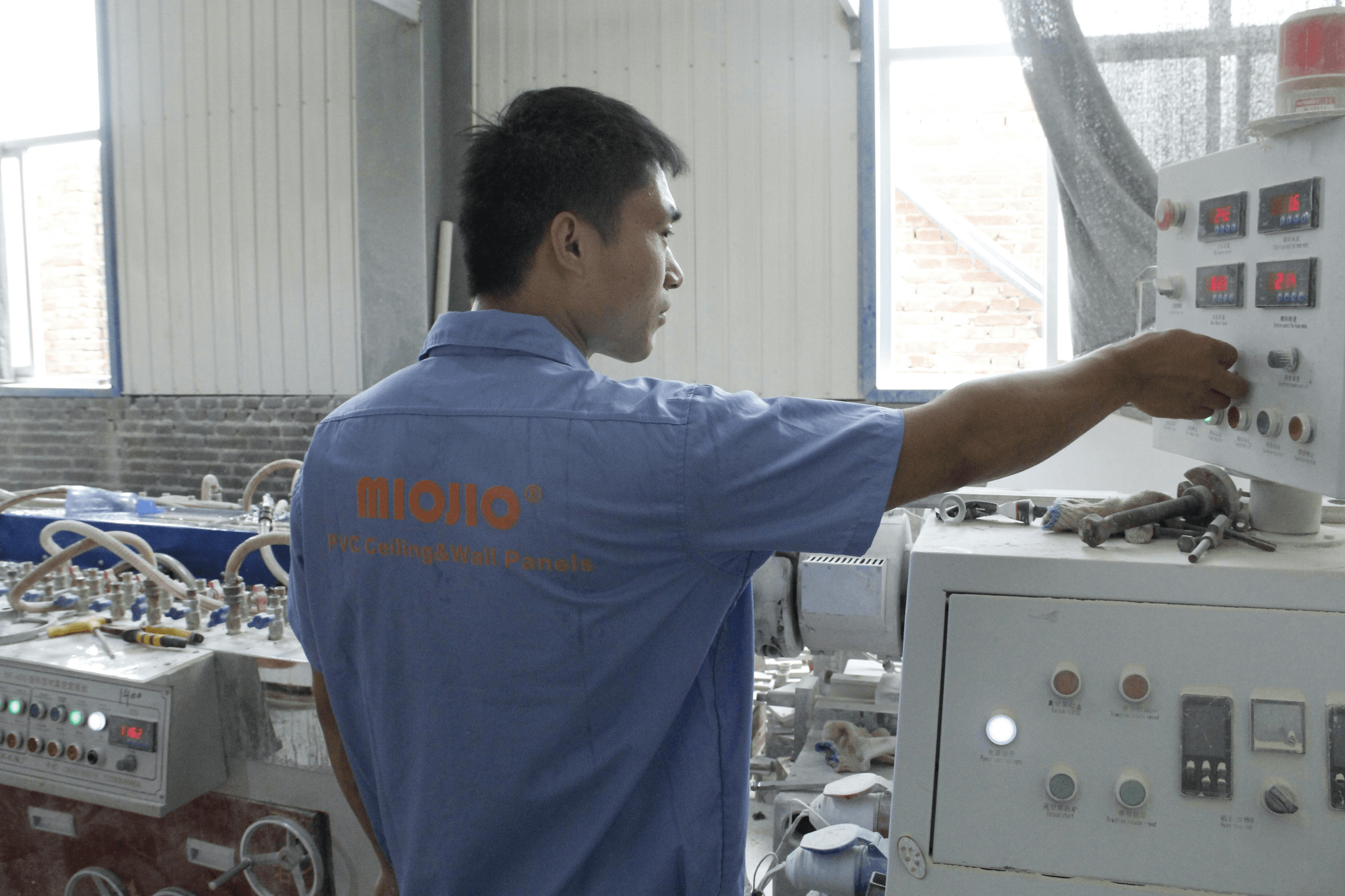

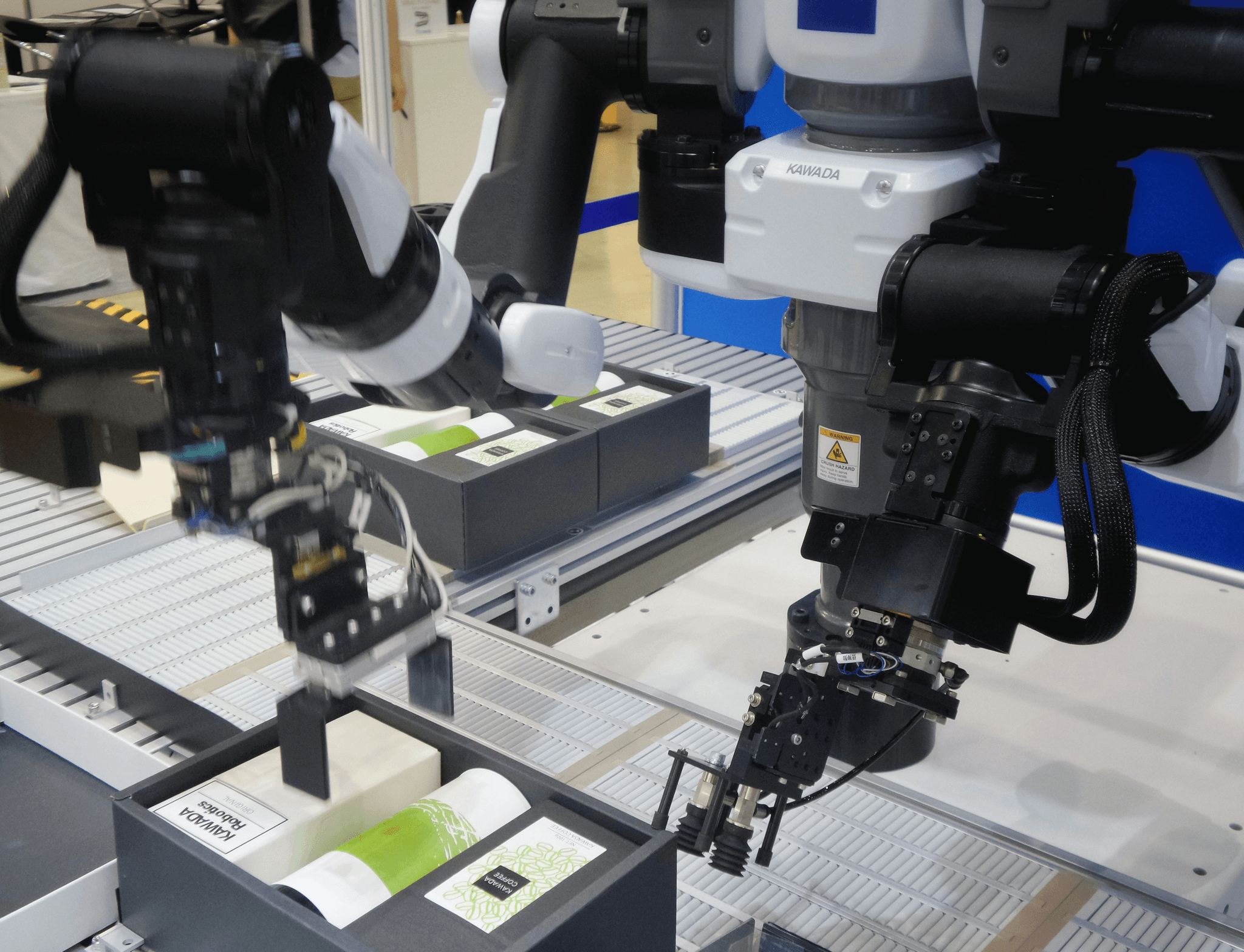

Automation for Production Processes

Automation technology, such as robotic arms and conveyor belts, can significantly improve the speed and accuracy of manufacturing processes in Chinese factories. By automating repetitive tasks like assembly or packaging, factories can reduce the risk of delays caused by human error or fatigue. Sourcing Inc. recommends investing in state-of-the-art automation solutions to streamline operations and maintain a competitive edge in the market.

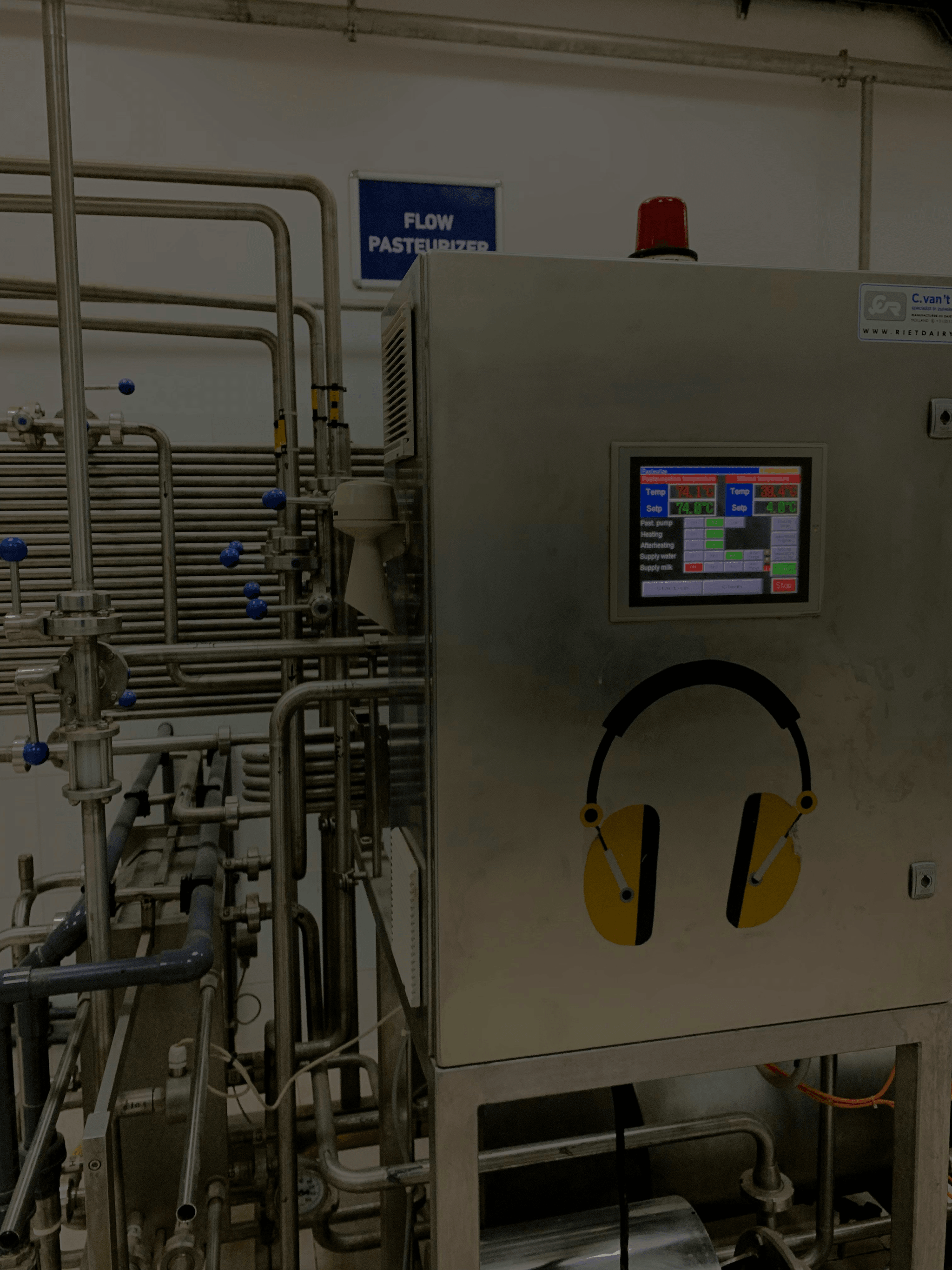

Data Analytics for Predictive Maintenance

Implementing data analytics tools enables Chinese factories to predict and prevent machinery malfunctions before they cause production delays. By analyzing equipment performance data in real-time, manufacturers can schedule maintenance proactively, minimizing downtime and optimizing production schedules. Leveraging data analytics is crucial in managing production delays effectively while maintaining high-quality standards.

Workflow Management Software Implementation

Integrating workflow management software allows Chinese factories to optimize their production processes by streamlining communication and task management. With a centralized platform for tracking orders, inventory levels, and production schedules, manufacturers can identify potential bottlenecks early on and take corrective actions swiftly. Sourcing Inc. emphasizes the importance of implementing workflow management software to enhance operational efficiency and mitigate production delays effectively.

By embracing advanced technologies like automation, data analytics, and workflow management software, Chinese factories can revolutionize their operations and overcome common challenges that lead to production delays.

Conclusion

In conclusion, managing production delays in Chinese factories requires a multi-faceted approach. By implementing proactive strategies, such as effective communication, stringent quality control, and leveraging technology solutions, companies can ensure timely deliveries. Sustainable solutions like building relationships with reliable suppliers and diversifying the supplier base are essential for overcoming production hurdles. Smart approaches to overcoming challenges in manufacturing involve integrating technology for streamlined operations and continuous improvement processes.

Proactive Strategies for Timely Deliveries

To manage production delays in Chinese factories, it is crucial to proactively plan and communicate with all stakeholders involved in the manufacturing process. Regular updates with the production team, open dialogue with suppliers, and efficient communication with clients are essential for identifying potential issues and addressing them promptly. By collaborating with trusted partners like SSOURCING INC., companies can navigate through unforeseen challenges more effectively.

Sustainable Solutions for Production Hurdles

Sustainable solutions for managing production delays in Chinese factories involve building strong relationships with reliable suppliers such as Foxconn, negotiating realistic lead times, and diversifying the supplier base to mitigate risks associated with unforeseen shortages or malfunctions. This approach not only ensures a steady flow of raw materials but also provides backup options in case of disruptions.

Smart Approaches to Overcome Challenges in Manufacturing

Smart approaches to managing production delays in Chinese factories include integrating technology for streamlined operations through automation, data analytics for predictive maintenance, and workflow management software implementation. These smart solutions enable companies to identify potential bottlenecks early on and take proactive measures to prevent or minimize their impact on production schedules.