Introduction

In the ever-evolving landscape of commerce, mastering manufacturer sourcing is crucial for businesses aiming to thrive. The dynamics of this process involve not only finding the right products but also establishing fruitful relationships with suppliers who can deliver quality and reliability. For small businesses, navigating these waters can often feel like a daunting task filled with obstacles.

Understanding Manufacturer Sourcing Dynamics

Manufacturer sourcing involves a multifaceted approach that requires an understanding of market demands, production capabilities, and supplier reliability. It's about more than just identifying manufacturers; it's about aligning your business goals with their offerings to create a seamless supply chain. As you delve into the intricacies of manufacturer sourcing, you'll discover that knowledge is your greatest ally in ensuring sustainable growth.

Importance of Partnering with Reliable Suppliers

Partnering with reliable suppliers is not merely a choice; it’s an essential strategy for long-term success in manufacturer sourcing. When you collaborate with trustworthy manufacturers, you gain access to high-quality materials and consistent delivery schedules that can significantly impact your bottom line. SSOURCING INC. emphasizes that these partnerships are built on transparency and communication, which ultimately foster mutual growth.

Challenges Small Businesses Face in Sourcing

Small businesses often encounter unique challenges in the realm of manufacturer sourcing, from limited resources to fierce competition from larger corporations. These hurdles can make it difficult to secure favorable terms and maintain quality standards without straining budgets or timelines. However, by understanding these challenges and leveraging tools at their disposal, small businesses can effectively navigate the complexities of sourcing while carving out their niche in the market.

The Fundamentals of Manufacturer Sourcing

When diving into the world of manufacturer sourcing, the first step is to lay a solid foundation. Understanding your product needs is crucial for a successful sourcing journey, as it sets the stage for everything that follows. With a clear vision in mind, you'll be better equipped to identify potential manufacturers and ensure they align with your goals.

Defining Your Product Needs

Defining your product needs is like drawing up a blueprint before constructing a house; without it, chaos reigns! Start by detailing every aspect of your product—its materials, dimensions, functionality, and even aesthetic qualities. By being specific about what you want from manufacturer sourcing, you can avoid miscommunication down the line and ensure that suppliers understand exactly what you're looking for.

Moreover, consider how your product fits into the market landscape. Are there specific features that set it apart from competitors? Understanding these nuances will not only help in finding the right manufacturer but also in crafting compelling marketing narratives later on.

Researching Industry Standards

Once you've defined your product needs, it's time to turn to industry standards—think of this as learning the rules of the game before you play! Familiarizing yourself with regulations and quality benchmarks relevant to your industry will arm you with essential knowledge during manufacturer sourcing discussions. This research helps ensure that any potential manufacturers you engage with can meet or exceed these standards.

Additionally, staying informed about compliance requirements can prevent costly setbacks later on. Whether it's safety certifications or environmental regulations, knowing what's required allows SSOURCING INC. to approach manufacturers confidently and responsibly. After all, compliance isn't just a box to check; it's integral to building trust with consumers.

Identifying Potential Manufacturers

Now comes the fun part: identifying potential manufacturers! This step requires a mix of creativity and diligence—think outside the box while also doing thorough research. Utilize online platforms like Alibaba or ThomasNet where countless manufacturers are waiting for businesses like yours to connect.

Networking at trade shows can also unveil hidden gems in manufacturer sourcing that aren't easily found online. Engaging directly with representatives gives you insight into their capabilities while allowing them to see how passionate you are about your products—a win-win situation! With SSOURCING INC.'s commitment to building strong partnerships, you'll find that establishing connections early on pays off immensely in terms of reliability and quality.

Building Relationships with Manufacturers

Building solid relationships with manufacturers is crucial for successful manufacturer sourcing. A strong partnership can lead to better pricing, improved quality, and more reliable delivery timelines. With the right approach, small businesses can navigate the complexities of sourcing and create lasting alliances that drive growth.

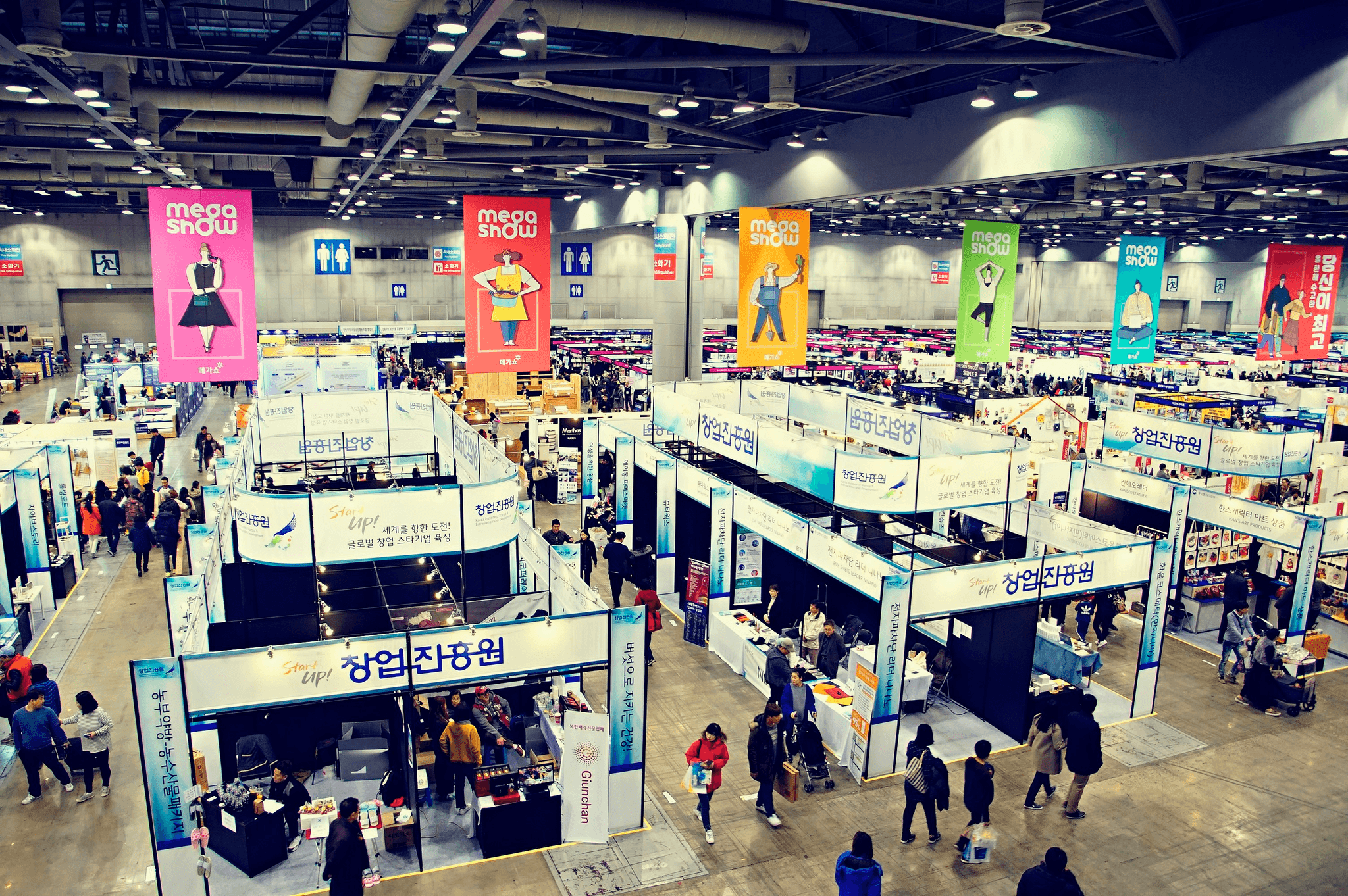

Networking in Trade Shows

Trade shows are a goldmine for small businesses looking to enhance their manufacturer sourcing strategies. These events provide opportunities to meet potential suppliers face-to-face, allowing you to gauge their capabilities and build rapport. When you attend trade shows, come prepared with questions about production processes, timelines, and how they align with your brand values—this will set the stage for a fruitful relationship.

Moreover, trade shows often host seminars and workshops that can offer insights into industry trends and best practices in manufacturer sourcing. Engaging with fellow attendees can also lead to valuable referrals or partnerships that could strengthen your supply chain. Remember, networking isn’t just about exchanging business cards; it’s about fostering connections that can benefit your business in the long run.

Utilizing Platforms like Alibaba and ThomasNet

In today's digital age, platforms like Alibaba and ThomasNet have revolutionized manufacturer sourcing by connecting buyers with suppliers worldwide at the click of a button. These platforms allow you to filter manufacturers based on specific criteria such as location, production capacity, and product offerings—making it easier than ever to find the right fit for your needs. When using these sites, be sure to thoroughly vet potential partners by checking reviews and requesting samples before committing.

Additionally, utilizing these platforms enables you to compare multiple manufacturers side-by-side quickly—a significant advantage when you're trying to find the best balance between cost and quality. Don’t forget that communication is key; reaching out directly through these platforms allows you to assess responsiveness and professionalism before entering any agreements. Ultimately, leveraging technology through these platforms can streamline your manufacturer sourcing process significantly.

Communicating Your Brand Values

Effective communication of your brand values is essential when establishing relationships with manufacturers during the sourcing process. By clearly articulating what your brand stands for—be it sustainability, innovation, or quality—you invite manufacturers who align with those principles into your network. This alignment not only fosters trust but also encourages collaboration on product development that resonates with consumers.

When discussing your brand values with potential suppliers at trade shows or online platforms like Alibaba or ThomasNet, be specific about what matters most to you—whether it's ethical labor practices or eco-friendly materials used in production processes during manufacturer sourcing efforts at SSOURCING INC.. This clarity helps ensure both parties are on the same page from day one.

Moreover, don’t underestimate the power of storytelling; sharing anecdotes about how your brand was founded or its mission can resonate deeply with manufacturers who share similar values. Building this emotional connection strengthens relationships over time while enhancing mutual understanding throughout the manufacturing journey.

Evaluating Manufacturer Capabilities

When diving into the world of manufacturer sourcing, it’s essential to evaluate the capabilities of potential suppliers. This step is crucial for ensuring that the manufacturers can meet your production needs while maintaining quality standards. A thorough assessment will help you build a strong foundation for a successful partnership, which is vital for small businesses navigating this complex landscape.

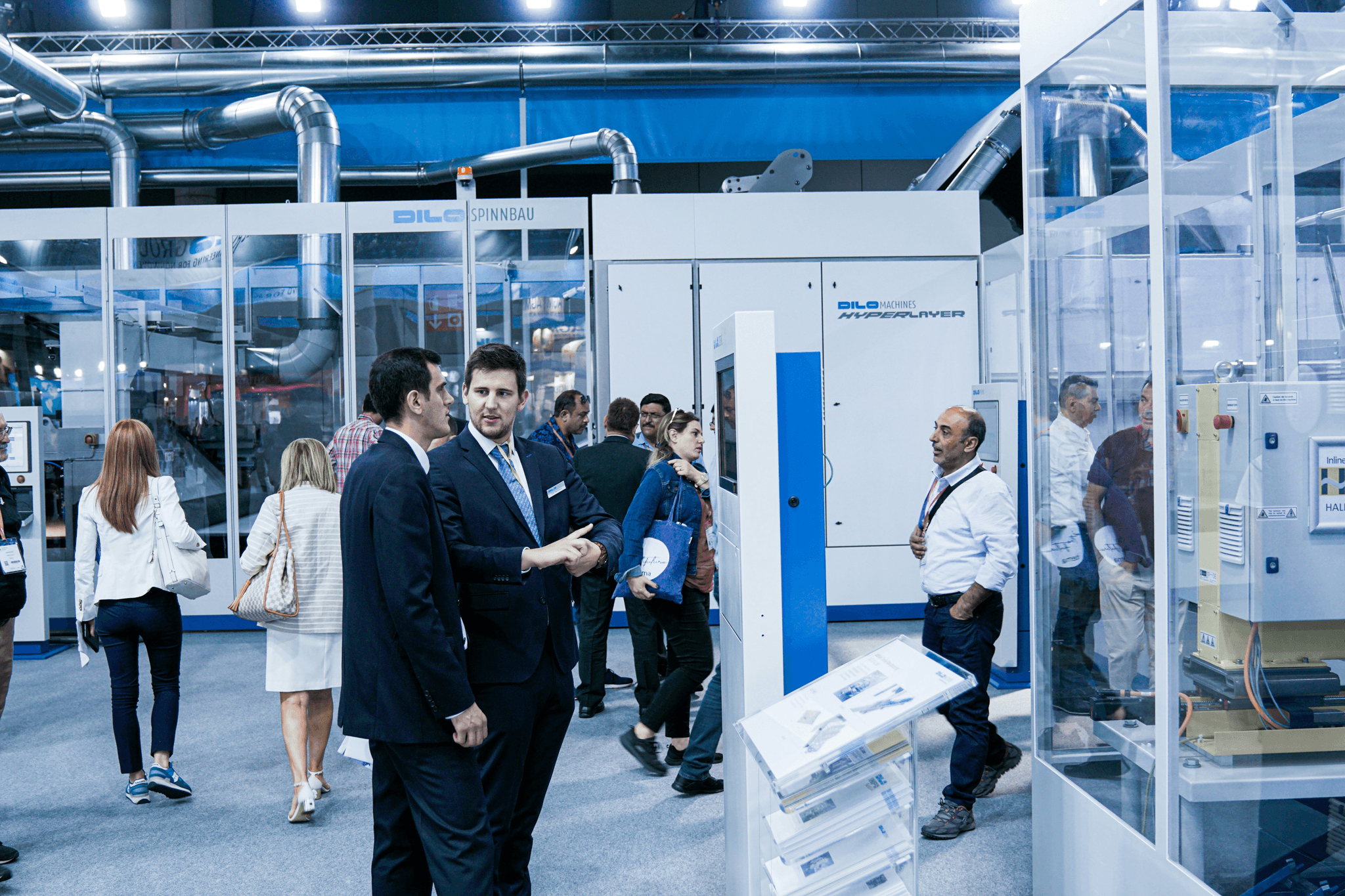

Assessing Production Capacity

Understanding a manufacturer’s production capacity is like checking the horsepower of a car before buying it; you want to know if it can handle your demands. In manufacturer sourcing, this means evaluating how much product they can produce within your required timelines without sacrificing quality. Be sure to ask about their current workload and any scalability options they might offer, as these factors will directly impact your ability to fulfill customer orders efficiently.

Moreover, consider whether they have experience with similar products or industries; this can provide insight into their capability to deliver what you need. SSOURCING INC. recommends visiting the manufacturing facility if possible or requesting detailed reports on their production processes and timelines. After all, knowing that your supplier has the capacity to grow alongside your business can be a game-changer in today’s competitive market.

Quality Control Measures

Quality control measures are non-negotiable when it comes to manufacturer sourcing; after all, nobody wants to deal with defective products flooding their inventory! Investigate what systems and processes manufacturers have in place to ensure consistent quality throughout production runs. Look for certifications such as ISO 9001 or industry-specific standards that demonstrate their commitment to maintaining high-quality outputs.

Additionally, ask about their inspection protocols—do they conduct regular audits? Are there checks at various stages of production? SSOURCING INC. emphasizes that understanding these measures not only protects your brand reputation but also fosters trust between you and your manufacturer partner.

Checking References and Reviews

Just like you'd read reviews before booking a vacation or purchasing a new gadget, checking references and reviews is vital in the realm of manufacturer sourcing too! Reach out to other businesses that have worked with the manufacturers you're considering; firsthand experiences can reveal valuable insights about reliability and performance over time. Don’t shy away from asking tough questions about delivery times, communication style, and product quality.

Online platforms such as Alibaba often feature reviews from previous clients which can also serve as an initial gauge of reliability—just remember that not every review may tell the full story! SSOURCING INC. suggests compiling feedback from multiple sources so you get a well-rounded view before making any commitments; after all, due diligence now could save you headaches later on!

Negotiating Terms and Pricing

Negotiating terms and pricing is a crucial step in the manufacturer sourcing process that can significantly impact your business's bottom line. Understanding the intricacies of cost structures, employing effective negotiation strategies, and fostering win-win agreements are essential for small businesses looking to thrive in today's competitive market. At SSOURCING INC., we believe that mastering these elements not only secures better deals but also strengthens relationships with your suppliers.

Understanding Cost Structures

To navigate the world of manufacturer sourcing effectively, it's vital to grasp how cost structures work. Costs can vary widely based on materials, labor, overhead, and even shipping fees; understanding these components will empower you during negotiations. By dissecting these costs, you can identify areas where savings might be realized or where investment may yield higher quality products.

Moreover, knowing the typical pricing benchmarks in your industry helps you avoid overpaying for goods or services. This insight allows you to approach negotiations with confidence and clarity about what constitutes a fair price for both parties involved. Ultimately, a solid grasp of cost structures positions you as an informed buyer who values quality without compromising on price.

Strategies for Effective Negotiation

When it comes to negotiating with manufacturers, preparation is key—especially in the realm of manufacturer sourcing. Start by setting clear objectives regarding price points and terms; this will give you a roadmap as discussions unfold. Additionally, consider employing tactics such as anchoring (starting negotiations with an initial offer) to establish a favorable reference point.

Another effective strategy involves building rapport with your potential suppliers; people tend to negotiate better when they feel respected and valued. Listen actively to their needs while articulating yours clearly—this two-way communication fosters trust and opens doors for collaborative solutions that benefit both parties. Remember that patience is essential; sometimes taking a step back can lead to breakthroughs in negotiations.

Creating Win-Win Agreements

The ultimate goal in any negotiation should be crafting win-win agreements that leave both parties satisfied—a principle at the heart of successful manufacturer sourcing strategies at SSOURCING INC. When both sides feel they’ve gained something valuable from the deal, it lays the groundwork for long-term partnerships built on mutual respect and understanding.

To achieve this balance, explore creative solutions beyond just price adjustments—think about flexible payment terms or bulk order discounts that could entice manufacturers while still meeting your budgetary constraints. Documenting clear terms regarding delivery schedules and quality expectations also ensures accountability down the line; this clarity minimizes disputes and enhances collaboration moving forward.

In conclusion, mastering negotiation skills is paramount when engaging with manufacturers during sourcing processes. By understanding cost structures thoroughly, employing strategic negotiation techniques effectively, and focusing on creating win-win scenarios, small businesses can secure favorable deals while nurturing lasting relationships within their supply chains.

Leveraging Technology for Efficient Sourcing

In the fast-paced world of manufacturer sourcing, technology plays a pivotal role in streamlining processes and enhancing efficiency. By leveraging the right tools, small businesses can navigate the complexities of sourcing with greater ease and precision. SSOURCING INC. recognizes that integrating technology into your sourcing strategy not only saves time but also fosters better relationships with suppliers.

Using Sourcing Software and Tools

Sourcing software is akin to having a personal assistant who never sleeps—always ready to help you find the best manufacturers for your needs. These tools can simplify everything from identifying potential suppliers to managing communications, making them invaluable in the realm of manufacturer sourcing. With platforms designed specifically for sourcing, you can easily compare options, check certifications, and even analyze pricing models—all at your fingertips.

Moreover, utilizing advanced software allows businesses to keep their supplier database organized and up-to-date. This means no more digging through piles of emails or spreadsheets; instead, you’ll have instant access to vital information about each manufacturer’s capabilities and track record. For companies like SSOURCING INC., adopting these technologies helps ensure that every decision made during the sourcing process is informed and strategic.

Automating Supplier Management

Automation is revolutionizing supplier management by eliminating manual tasks that can bog down operations during manufacturer sourcing. By automating routine processes such as order tracking or invoice approvals, businesses can focus on building stronger relationships with their suppliers rather than getting lost in paperwork. This shift not only saves time but also minimizes errors associated with manual data entry—an absolute win-win!

Furthermore, automated systems allow for real-time updates on orders and inventory levels, providing transparency that strengthens trust between you and your manufacturers. With tools that send alerts when stock levels are low or when production timelines shift, you’ll always stay one step ahead in managing your supply chain effectively. At SSOURCING INC., we believe that embracing automation paves the way for proactive decision-making in every aspect of manufacturer sourcing.

Tracking Trends with Data Analytics

Data analytics might sound like a buzzword thrown around at tech conferences, but it’s a game-changer for those involved in manufacturer sourcing! By analyzing market trends and consumer behavior data, businesses can make informed decisions about which suppliers to partner with based on current demands and future projections. This insight helps ensure that you're not just reacting to changes but anticipating them—keeping your business agile.

Additionally, tracking trends allows companies like SSOURCING INC. to identify emerging opportunities within various industries quickly. For example, if data indicates a rising demand for sustainable products, you can pivot your sourcing strategy accordingly by seeking out manufacturers aligned with eco-friendly practices. Ultimately, leveraging data analytics means you're not just surviving in today's market; you're thriving by staying ahead of the curve!

Conclusion

In the ever-evolving landscape of business, mastering the art of manufacturer sourcing is not just a necessity; it's an opportunity for growth and innovation. By implementing effective strategies, small businesses can navigate the complexities of sourcing with confidence and agility. SSOURCING INC. is here to guide you through these essential tactics to ensure your success in building a sustainable sourcing model.

Strategies for Sustainable Manufacturer Sourcing

To achieve sustainable manufacturer sourcing, it’s crucial to prioritize transparency and ethical practices within your supply chain. This means selecting manufacturers who share your values regarding environmental responsibility and fair labor practices, which not only enhances your brand image but also fosters trust with consumers. Additionally, implementing long-term contracts with reliable suppliers can stabilize costs and secure consistent quality, making it easier for businesses to plan ahead without the anxiety of sudden price hikes or supply disruptions.

Maintaining Long-Term Supplier Relationships

Building strong relationships with manufacturers is akin to cultivating a fine wine; it requires patience, understanding, and consistent effort over time. Regular communication is key—keeping lines open ensures that both parties are aligned on expectations and any potential challenges can be addressed swiftly before they escalate into larger issues. Moreover, showing appreciation for your partners’ efforts through feedback or incentives can solidify these relationships further, ensuring that you have dependable allies in your manufacturer sourcing journey.

Adapting to Market Changes with SSOURCING INC.

In today’s fast-paced market environment, adaptability is paramount for successful manufacturer sourcing strategies. SSOURCING INC. equips businesses with the tools needed to pivot quickly in response to shifting consumer demands or economic fluctuations by leveraging data analytics and real-time market insights. Embracing technology not only streamlines operations but also allows companies to stay ahead of trends—ensuring that their product offerings remain relevant while maintaining strong connections with their suppliers.