Introduction

In the world of commerce and logistics, understanding weight measurement is more than just a numbers game; it’s a fundamental aspect that can make or break a deal. Whether you're shipping goods across the globe or stocking shelves in a retail store, grasping the nuances of gross weight vs net weight is essential for operational efficiency. This knowledge not only influences pricing strategies but also compliance with industry regulations, making it crucial for businesses to get it right.

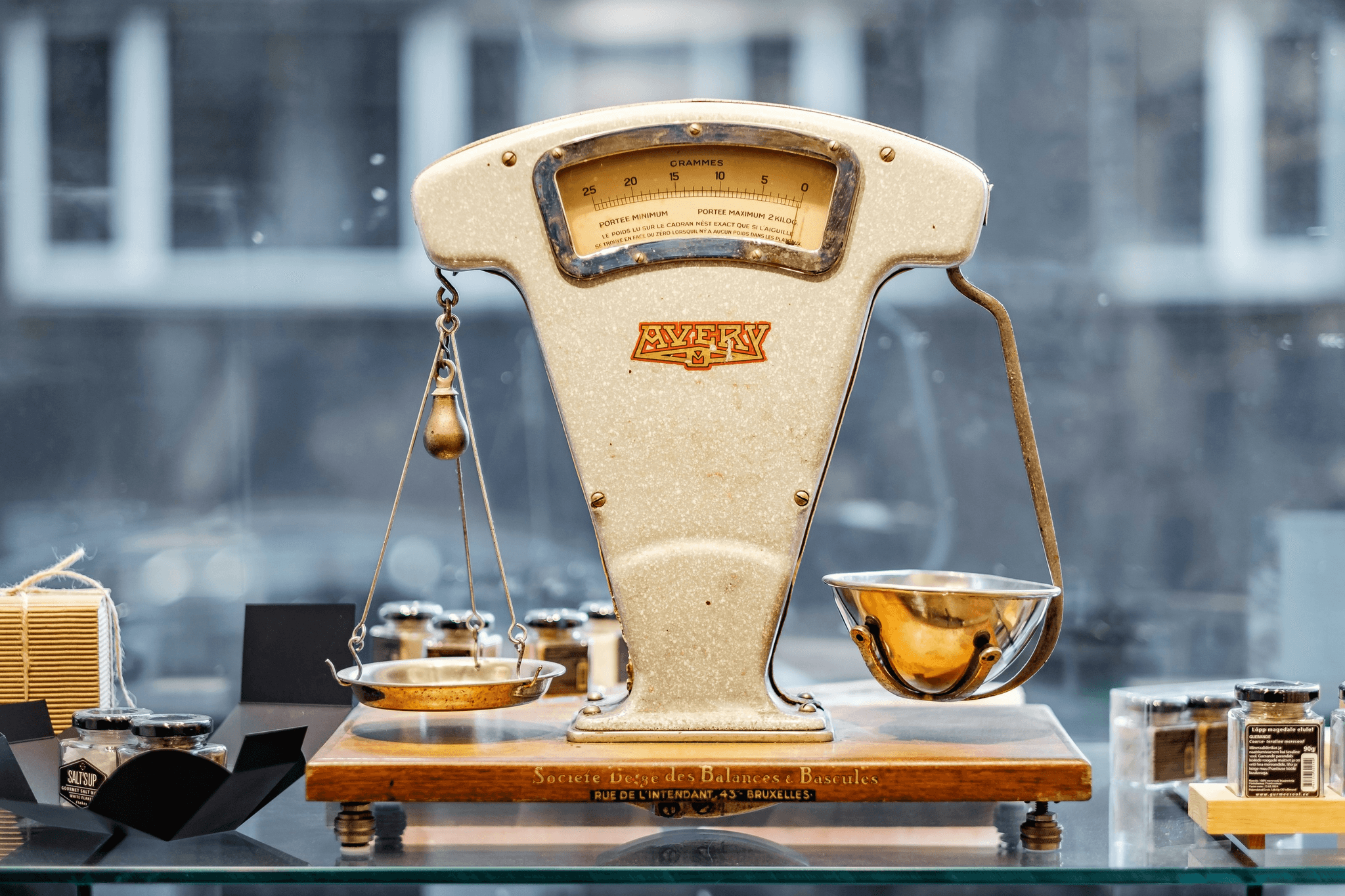

The Basics of Weight Measurement

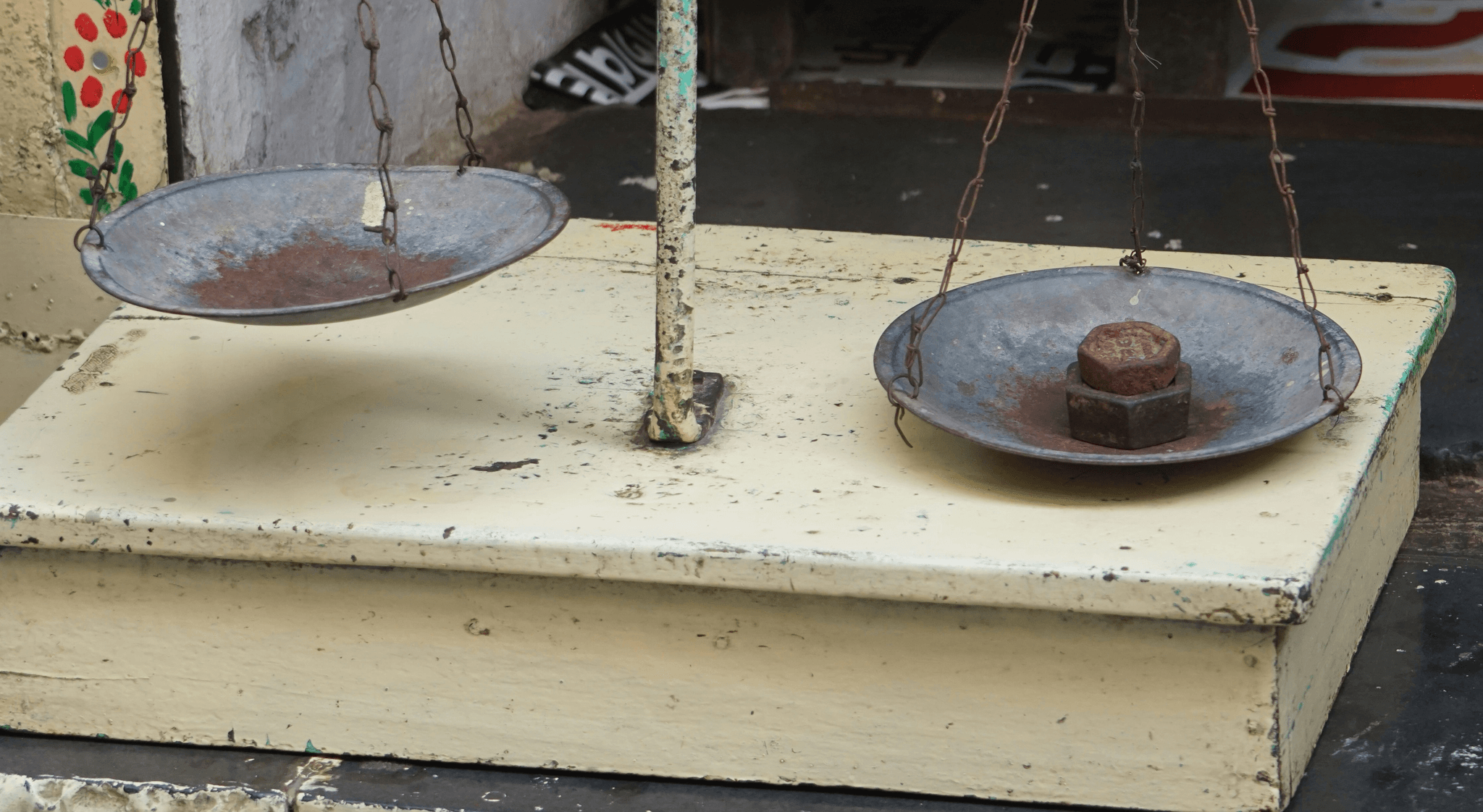

At its core, weight measurement involves determining how heavy an object is, but there’s more to it than meets the eye. Gross weight refers to the total weight of an item, including its packaging, while net weight zeroes in on just the product itself—packaging be gone! Understanding these definitions sets the stage for better decision-making in various sectors, from manufacturing to distribution.

Importance of Understanding Weight Types

Why should anyone care about gross weight vs net weight? Well, knowing these distinctions can lead to significant cost savings and efficiency improvements in supply chains. When businesses like SSOURCING INC. accurately measure and report these weights, they not only adhere to regulations but also enhance customer satisfaction by providing transparent information.

How This Affects Various Industries

The implications of gross weight vs net weight ripple through numerous industries—from food production, where accurate labeling is paramount, to shipping, where costs are calculated based on total weights. Inaccuracies can lead to overcharges or regulatory fines that affect profitability and reputation alike. Therefore, understanding these measurements isn’t just beneficial; it's imperative for any business looking to thrive in today’s competitive landscape.

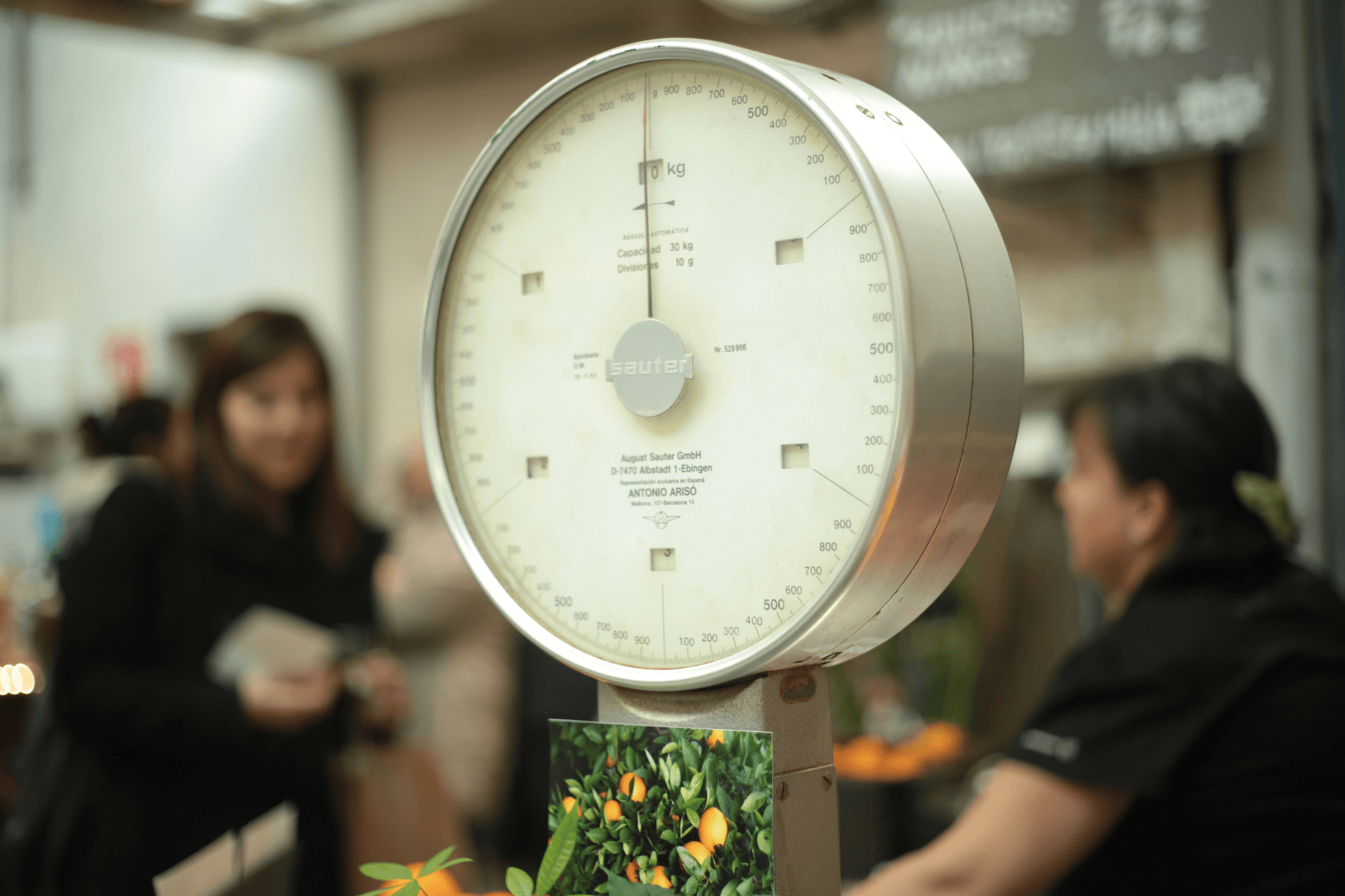

Defining Gross Weight

Understanding gross weight is essential in various industries, particularly in shipping, logistics, and manufacturing. It encompasses not just the weight of the item itself but also includes all packaging and any additional materials that come with it. This comprehensive approach ensures that businesses can accurately assess shipping costs and comply with regulations.

What It Is and What It Includes

Gross weight refers to the total weight of a product along with its packaging. This means that when you’re weighing an item for shipment or sale, you must consider everything from boxes to pallets that it may be placed on. In contrast to net weight—which only measures the product itself—gross weight gives a fuller picture of what’s being transported or sold.

Examples from Shipping and Logistics

In shipping and logistics, gross weight plays a pivotal role in determining freight charges. For instance, if a company ships 100 boxes of widgets, the gross weight will include each box's individual weight plus any additional packing materials used for protection during transit. Understanding gross weight vs net weight is crucial here; shippers often charge based on whichever is greater—gross or dimensional weight—to maximize efficiency.

Real-World Applications in Manufacturing

In manufacturing, knowing the gross weight can help streamline production processes and inventory management. For example, when raw materials are received at a factory, their gross weights are measured to ensure accuracy in inventory records and compliance with safety regulations during handling and storage. Moreover, understanding the difference between gross weight vs net weight can aid manufacturers in optimizing their supply chain operations by providing better insights into material costs and logistics planning.

Understanding Net Weight

When discussing weight measurement, net weight plays a crucial role in various industries by providing a clear picture of the actual product without any packaging or additional materials. It’s essential to differentiate between gross weight vs net weight, as this distinction affects pricing, shipping costs, and consumer understanding. By grasping what net weight entails, businesses can ensure accurate labeling and compliance with industry standards.

Breaking Down the Components

Net weight refers specifically to the weight of the product itself, excluding any containers, packaging materials, or other extraneous items that might be included in a shipment. This means that when you purchase a bag of flour, for instance, the net weight is strictly that of the flour alone—no bags or boxes factored in. Understanding these components is vital for both sellers and buyers to avoid confusion and ensure transparency in transactions.

How Net Weight Is Calculated

Calculating net weight is relatively straightforward: simply subtract the tare (weight of packaging) from the gross weight (total combined weight). For example, if a package weighs 10 pounds, including its box, but the box itself weighs 2 pounds, then the net weight of the product is 8 pounds. This calculation not only helps in determining accurate pricing based on product content but also aids compliance with regulations governing food labeling and shipping practices.

Case Studies in Retail and the Food Industry

In retail settings like grocery stores, understanding gross weight vs net weight can significantly impact customer satisfaction and trust. For instance, if consumers find discrepancies between advertised weights and actual products upon purchase—such as an underfilled jar of peanut butter—they may feel misled or cheated. A case study involving SSOURCING INC.'s partnership with a food manufacturer demonstrated how proper labeling practices improved sales by ensuring customers received exactly what they paid for—reinforcing trust through transparency.

The Significance of Gross Weight vs Net Weight

Understanding the distinction between gross weight and net weight is crucial for various sectors, from shipping to retail. Gross weight includes everything—packaging, pallets, and the product itself—while net weight focuses solely on the product. This differentiation not only impacts logistics but also influences pricing strategies across industries.

Why Both Metrics Matter

The interplay between gross weight vs net weight can significantly affect inventory management and shipping costs. For instance, knowing the gross weight helps in determining transportation fees, while net weight is essential for accurate product labeling and consumer transparency. Companies like SSOURCING INC. utilize both metrics to optimize their supply chain processes and ensure compliance with industry regulations.

In retail, understanding these weights can also influence customer perceptions of value. When consumers see a product's net weight prominently displayed on packaging, it helps them make informed purchasing decisions. Therefore, both metrics are not just numbers; they carry substantial implications for brand trust and customer satisfaction.

Implications for Pricing and Regulations

The difference between gross weight vs net weight can have far-reaching implications for pricing strategies in various industries. For example, shipping companies often charge based on gross weight; hence, if a business miscalculates this figure, it could lead to unexpected costs that eat into profit margins. On the other hand, accurate net weights ensure that consumers pay only for what they actually receive.

Regulatory bodies also emphasize these measurements as part of compliance standards to protect consumers from misleading practices. Companies must remain vigilant about accurately reporting both weights to avoid legal repercussions or fines associated with misrepresentation. SSOURCING INC.'s commitment to transparent practices ensures that clients navigate these complex regulations smoothly.

Furthermore, businesses must adapt their pricing models based on these metrics to remain competitive in a fast-evolving market landscape. As companies increasingly rely on data analytics tools for decision-making, understanding how gross versus net weights impact overall costs becomes more critical than ever.

Insights from Industry Experts

Industry experts emphasize that comprehending the nuances of gross weight vs net weight is essential for operational efficiency and cost management in today's market environment. They argue that businesses should invest in training their staff about these distinctions to minimize errors during measurement processes. With insights from professionals at SSOURCING INC., it's clear that organizations willing to embrace this knowledge gain a competitive edge.

Moreover, experts suggest leveraging technology such as automated weighing systems, which can help eliminate human error when calculating either metric—ensuring accuracy every time! This technological integration not only streamlines operations but also enhances reliability in reporting both weights accurately to stakeholders.

Finally, many industry leaders advocate regular audits of weighing processes as part of best practices within organizations striving for excellence in logistics and inventory management systems related to gross versus net weights. By doing so, businesses can uphold high standards while fostering trust among consumers who expect transparency regarding what they’re purchasing.

Challenges in Measuring Weight Accurately

Measuring weight accurately is not as straightforward as it may seem. Many industries grapple with challenges that can lead to discrepancies between gross weight vs net weight, impacting everything from shipping costs to regulatory compliance. Understanding these challenges is crucial for businesses striving for precision in their operations.

Common Mistakes in Measurement

One of the most prevalent mistakes in weight measurement involves misunderstanding the difference between gross weight vs net weight. Companies often overlook tare weight—the weight of the container or packaging—resulting in inflated figures that misrepresent actual product quantities. Additionally, human error during manual measurements can introduce significant inaccuracies, leading to costly repercussions down the line.

Another common pitfall occurs when businesses fail to calibrate their weighing equipment regularly. Without proper calibration, scales can drift over time, yielding inaccurate readings that affect both gross and net weights. This oversight can have cascading effects on inventory management and financial reporting.

Technology’s Role in Accurate Assessments

Fortunately, advancements in technology are paving the way for more accurate weight assessments across various industries. Automated systems equipped with high-precision scales can significantly reduce human error and ensure consistent measurements of gross weight vs net weight. These systems often integrate with inventory management software, providing real-time data that enhances operational efficiency.

Moreover, innovations like IoT-enabled scales allow businesses to monitor weights remotely and receive alerts if discrepancies arise. This level of oversight helps organizations maintain compliance with industry regulations while ensuring they accurately capture both gross and net weights during transactions. The integration of technology not only streamlines processes but also fosters a culture of accountability within organizations.

Perspectives from SSOURCING INC.

At SSOURCING INC., we recognize that understanding the intricacies of gross weight vs net weight is vital for our clients' success. We emphasize training our partners on best practices for accurate measurements while providing state-of-the-art equipment designed to minimize errors and maximize efficiency. Our team believes that staying ahead of technological trends will empower businesses to adapt swiftly to evolving market demands while maintaining precise control over their operations.

In conclusion, addressing common measurement mistakes and leveraging technology are essential steps toward achieving accuracy in weighing products and shipments. By focusing on these areas, companies can better navigate the complexities associated with gross weight vs net weight, ultimately leading to improved profitability and compliance in an increasingly competitive landscape.

The Future of Weight Measurement

As industries evolve, so too does the need for precision in weight measurement. The ongoing debate of gross weight vs net weight continues to play a significant role in how businesses operate and maintain compliance with regulations. Innovations are on the horizon that promise to revolutionize our understanding and application of these critical metrics.

Innovations to Watch

One exciting area of innovation is the development of smart scales equipped with advanced sensors and AI technology. These devices can provide real-time data on gross weight vs net weight, making it easier for businesses to manage inventory and shipping logistics efficiently. Additionally, automated systems for weighing products at various stages of production are becoming more common, reducing human error and ensuring accuracy in measurements.

Another noteworthy innovation is the integration of blockchain technology into supply chain management, which can enhance transparency regarding gross weight vs net weight throughout the entire process. This means that every stakeholder can access accurate weight data from production to delivery, fostering trust among suppliers, manufacturers, and consumers alike. Companies like SSOURCING INC. are at the forefront of adopting these technologies to streamline operations.

Lastly, advancements in mobile applications that enable quick calculations and comparisons between gross weight vs net weight are gaining traction among small business owners who may not have access to sophisticated equipment. These apps can simplify decision-making processes related to pricing strategies and inventory management while keeping users informed about industry standards.

Trends Influencing Weight Standards

Sustainability is one major trend influencing how we measure weights across industries today; consumers demand eco-friendly practices that often hinge on accurate product weights for packaging purposes. As companies strive to reduce waste by optimizing their packaging based on gross weight vs net weight metrics, they also enhance their brand image as environmentally responsible entities. This shift not only benefits the planet but also aligns with consumer preferences—making it a win-win situation.

Regulatory changes are another factor reshaping how businesses approach measurement standards; governments worldwide are tightening regulations around labeling requirements that necessitate precise declarations of both gross weight and net weight on products sold in stores or online platforms. Companies must stay informed about these evolving regulations or risk penalties—something SSOURCING INC. actively monitors for its clients' benefit.

Furthermore, globalization continues to influence standards as companies engage with international markets where different countries may have varying definitions or requirements concerning gross versus net weights. Understanding these differences is crucial for businesses looking to expand their reach while maintaining compliance with local laws regarding product labeling.

How Businesses Can Adapt

To thrive amidst these changes in the landscape of measurement standards, businesses must embrace a proactive approach toward education and training regarding gross weight vs net weight metrics among their staff members—especially those involved in logistics or inventory management roles! Investing time in workshops or certifications helps ensure everyone understands why accuracy matters when it comes to pricing strategies or regulatory compliance.

Utilizing technology effectively will also be key; implementing smart weighing devices alongside software solutions designed specifically for tracking weights can streamline processes significantly while minimizing errors associated with manual calculations over time! SSOURCING INC.'s expertise lies precisely here—we help organizations navigate this technological transition smoothly so they can focus on what truly matters: growth!

Finally, fostering partnerships within supply chains allows companies greater insight into best practices related directly back towards accurate measurements—collaborating with suppliers who prioritize transparency around their own processes ensures everyone remains aligned when discussing issues like gross versus net weights down the line!

Conclusion

In the world of weight measurement, understanding the nuances between gross weight vs net weight is crucial for businesses across various industries. These metrics not only affect pricing and logistics but also play a significant role in regulatory compliance and consumer transparency. As we’ve explored, grasping these concepts can lead to better decision-making and enhanced operational efficiency.

Key Takeaways on Weight Measurement

First and foremost, gross weight vs net weight are not interchangeable terms; each serves a distinct purpose in measuring products. Gross weight includes everything—packaging, containers, and the product itself—while net weight focuses solely on the product's mass. Recognizing this difference is essential for accurate assessments that influence cost calculations, shipping fees, and inventory management.

Practical Tips for Accurate Weight Assessment

To ensure accuracy in your measurements, always calibrate your scales before use to avoid discrepancies between gross weight vs net weight readings. Additionally, familiarize yourself with the specific requirements of your industry regarding these measurements; regulations may vary widely from one sector to another. Finally, consider investing in technology that streamlines the weighing process—automated systems can help reduce human error and improve efficiency.

How SSOURCING INC. Can Help Your Business

At SSOURCING INC., we understand that navigating the complexities of gross weight vs net weight can be daunting for many businesses. Our team offers tailored solutions designed to enhance your measurement processes while ensuring compliance with industry standards. Let us help you optimize your operations so you can focus on what truly matters: growing your business.