Introduction

In today's fast-paced business environment, the ability to harness supplier analytics is more critical than ever. As companies strive for efficiency and competitive advantage, understanding the nuances of their supplier relationships can lead to significant growth opportunities. This blog will explore the transformative power of supplier analytics and how it can revolutionize your approach to supply chain management.

The Importance of Supplier Analytics

Supplier analytics is not just a buzzword; it's a vital tool that enables businesses to make informed decisions based on data-driven insights. By analyzing key metrics related to supplier performance, organizations can identify strengths and weaknesses within their supply chains. This level of insight fosters better decision-making, ultimately leading to improved operational efficiency and cost savings.

How Supplier Analytics Drives Growth

When leveraged effectively, supplier analytics can be a game-changer for businesses looking to scale operations and enhance profitability. By utilizing data from various sources, companies can optimize their supplier selection processes, negotiate better terms, and reduce risks associated with supply disruptions. The result? A robust supply chain that not only supports current business needs but also positions you for future growth.

What You Will Learn in This Blog

Throughout this blog, we will delve into the essential elements of supplier analytics—from key metrics that matter to tools that facilitate effective analysis. We'll share real-world applications showcasing how industry leaders like Walmart and Procter & Gamble have successfully utilized supplier analytics for strategic decision-making and risk management. Finally, we'll discuss how SSOURCING INC. can help you harness these insights for continuous improvement in your own organization.

Understanding Supplier Analytics

Supplier analytics is the backbone of modern supply chain management, transforming raw data into actionable insights. By delving into the metrics and tools that matter, businesses can harness the power of supplier analytics to enhance performance, mitigate risks, and foster stronger relationships with their suppliers. Let’s explore what makes supplier analytics a game-changer in today’s competitive landscape.

Key Metrics that Matter

When it comes to supplier analytics, not all metrics are created equal. Key performance indicators (KPIs) such as on-time delivery rates, defect rates, and cost savings are critical for assessing supplier performance. Additionally, metrics like order accuracy and lead time provide insight into operational efficiency and help identify areas for improvement—ensuring your supply chain runs like a well-oiled machine.

Understanding these key metrics allows businesses to make informed decisions based on solid data rather than gut feelings. For instance, if a supplier consistently falls short on delivery times, it may be time to reevaluate that partnership or implement corrective measures. This level of scrutiny through supplier analytics can ultimately lead to better quality products and services for your customers.

Tools for Effective Supplier Analytics

To effectively leverage supplier analytics, companies need robust tools designed specifically for this purpose. Software solutions like SAP Ariba or Oracle Procurement Cloud offer comprehensive platforms that integrate various data sources to provide real-time insights into supplier performance. These tools not only streamline data collection but also enable predictive analysis—allowing businesses to anticipate potential disruptions before they occur.

In addition to traditional software solutions, advanced technologies such as artificial intelligence (AI) and machine learning are increasingly being employed in the realm of supplier analytics. These technologies can analyze vast amounts of data at lightning speed and uncover patterns that human analysts might miss. By investing in these innovative tools through SSOURCING INC., companies can gain a significant edge over their competitors by making smarter decisions faster.

Real-World Applications in Business

The application of supplier analytics goes beyond theoretical concepts; many industry leaders have successfully integrated these practices into their operations with impressive results. For example, companies like Apple utilize sophisticated supplier analytics to monitor their supply chain closely—from sourcing materials to shipping products globally—ensuring they maintain high standards while minimizing costs.

Another great example is Coca-Cola's use of supplier analytics for demand forecasting and inventory management across its extensive network of suppliers worldwide. By accurately predicting customer demand using historical sales data coupled with market trends analyzed through their robust systems, Coca-Cola optimizes its inventory levels while reducing waste—a win-win scenario!

In conclusion, understanding the key metrics and leveraging effective tools in the world of supplier analytics can significantly boost your business's operational efficiency and profitability while enhancing relationships with suppliers—an essential component for sustained growth in today’s fast-paced market.

Leveraging Data for Strategic Decisions

In today’s fast-paced business environment, leveraging data for strategic decisions is not just a luxury; it’s a necessity. Supplier analytics plays a critical role in transforming raw data into actionable insights that guide supply chain strategies. By utilizing these insights, companies can optimize operations, reduce costs, and enhance overall efficiency.

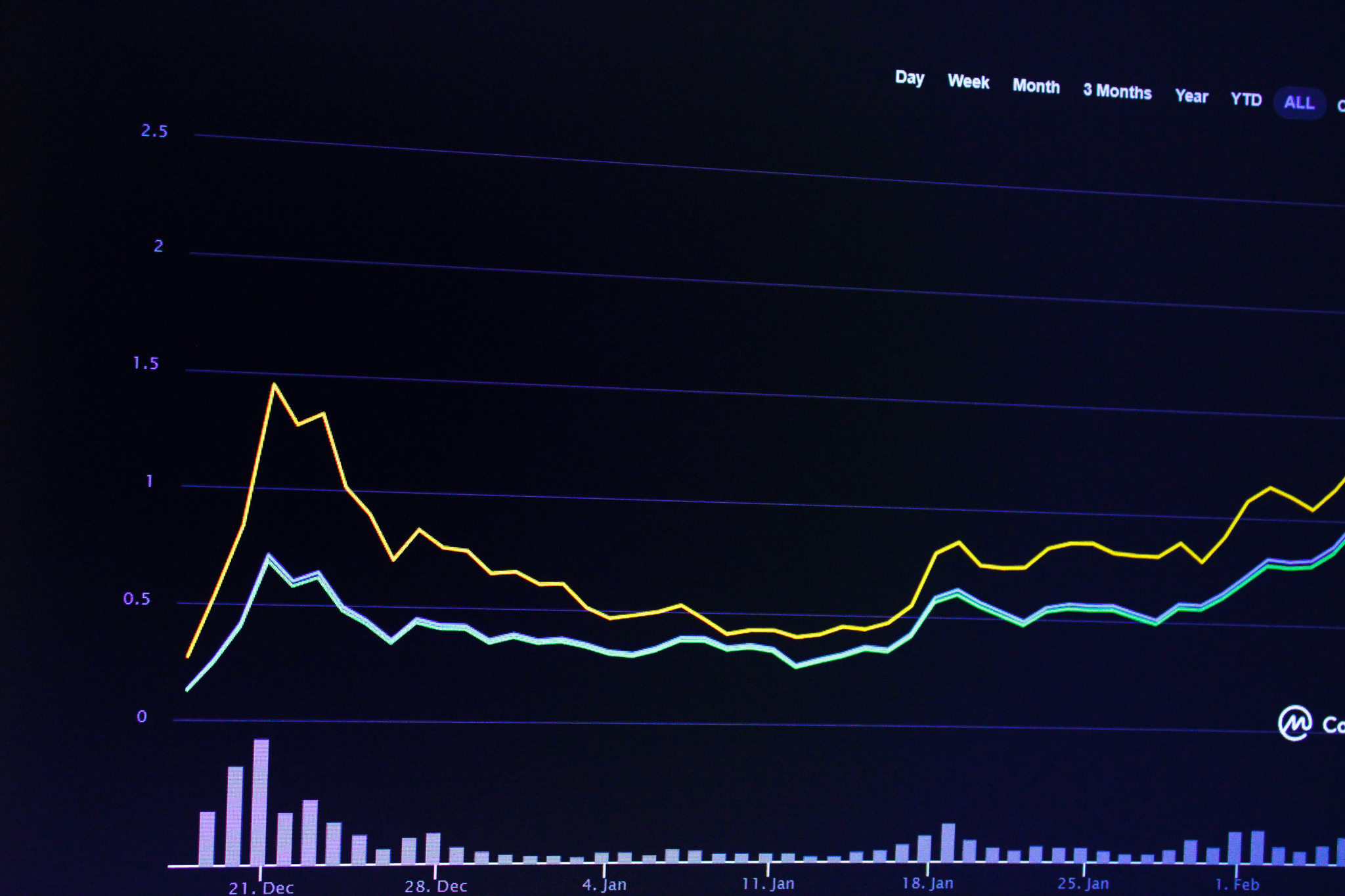

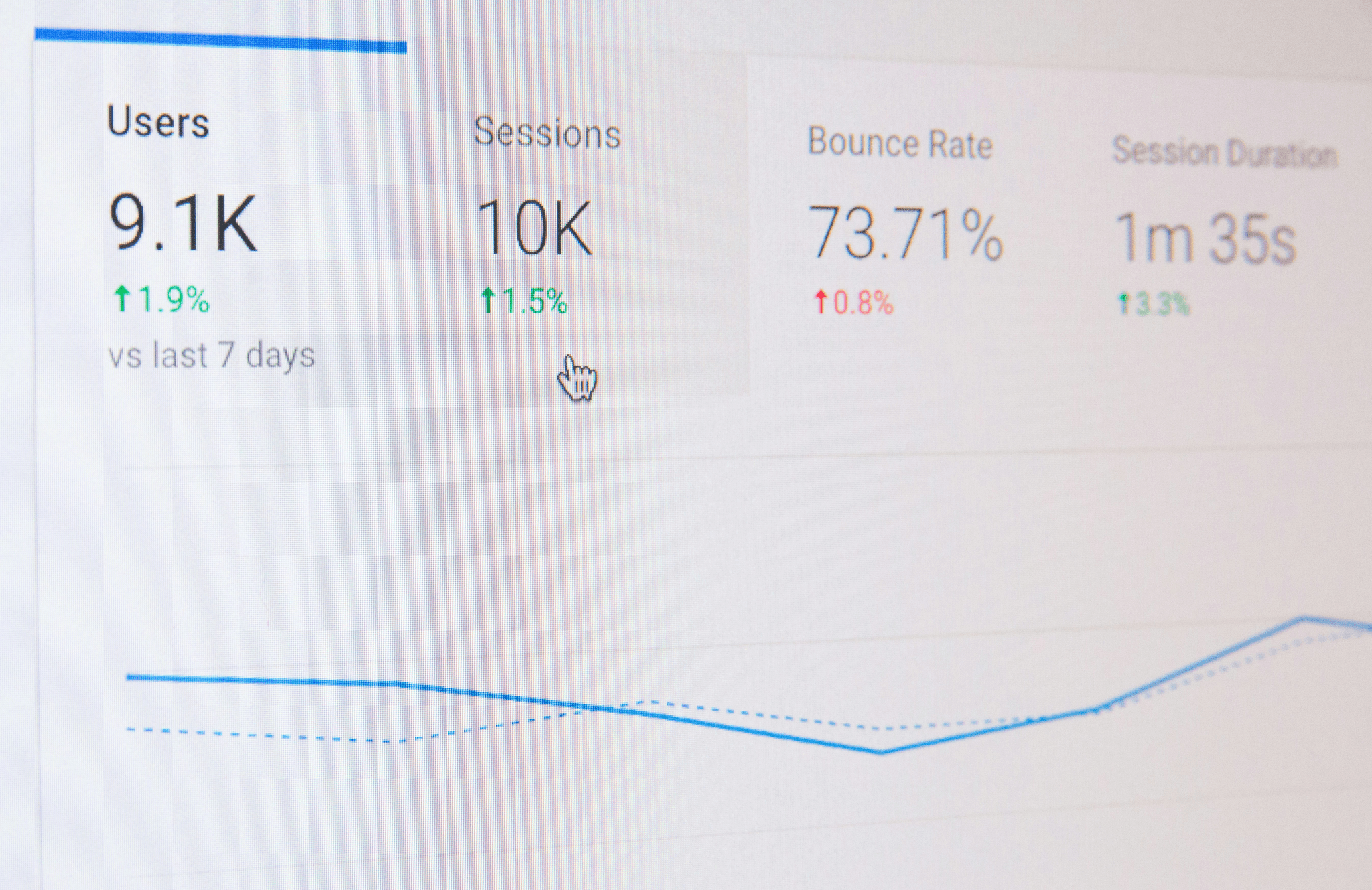

Data-Driven Supply Chain Management

Data-driven supply chain management hinges on the ability to analyze and interpret supplier analytics effectively. This approach allows businesses to make informed decisions based on real-time data rather than gut feelings or outdated information. By integrating supplier analytics into their decision-making processes, companies can streamline operations and respond quickly to market changes.

Moreover, effective data-driven strategies can lead to improved inventory management and reduced lead times. Companies that harness the power of supplier analytics are better equipped to forecast demand accurately and align their procurement strategies accordingly. Ultimately, this leads to enhanced customer satisfaction as businesses can meet demands without overstocking or stockouts.

Case Study: Walmart’s Supplier Analytics Success

Walmart is a shining example of how effective supplier analytics can transform supply chain dynamics. The retail giant employs sophisticated analytics tools that enable them to monitor supplier performance in real-time. This proactive approach allows Walmart not only to maintain low prices but also to ensure product availability across its vast network of stores.

By analyzing purchasing patterns and inventory levels, Walmart can negotiate better terms with suppliers while minimizing waste through efficient stock management practices. Their commitment to leveraging supplier analytics has resulted in significant cost savings and improved operational efficiency—benefits that ultimately flow down to consumers as lower prices and better product availability.

The success of Walmart demonstrates how other companies can embrace similar strategies using SSOURCING INC.'s expertise in supplier analytics solutions tailored for diverse business needs.

The Role of Predictive Analytics in Supply Chains

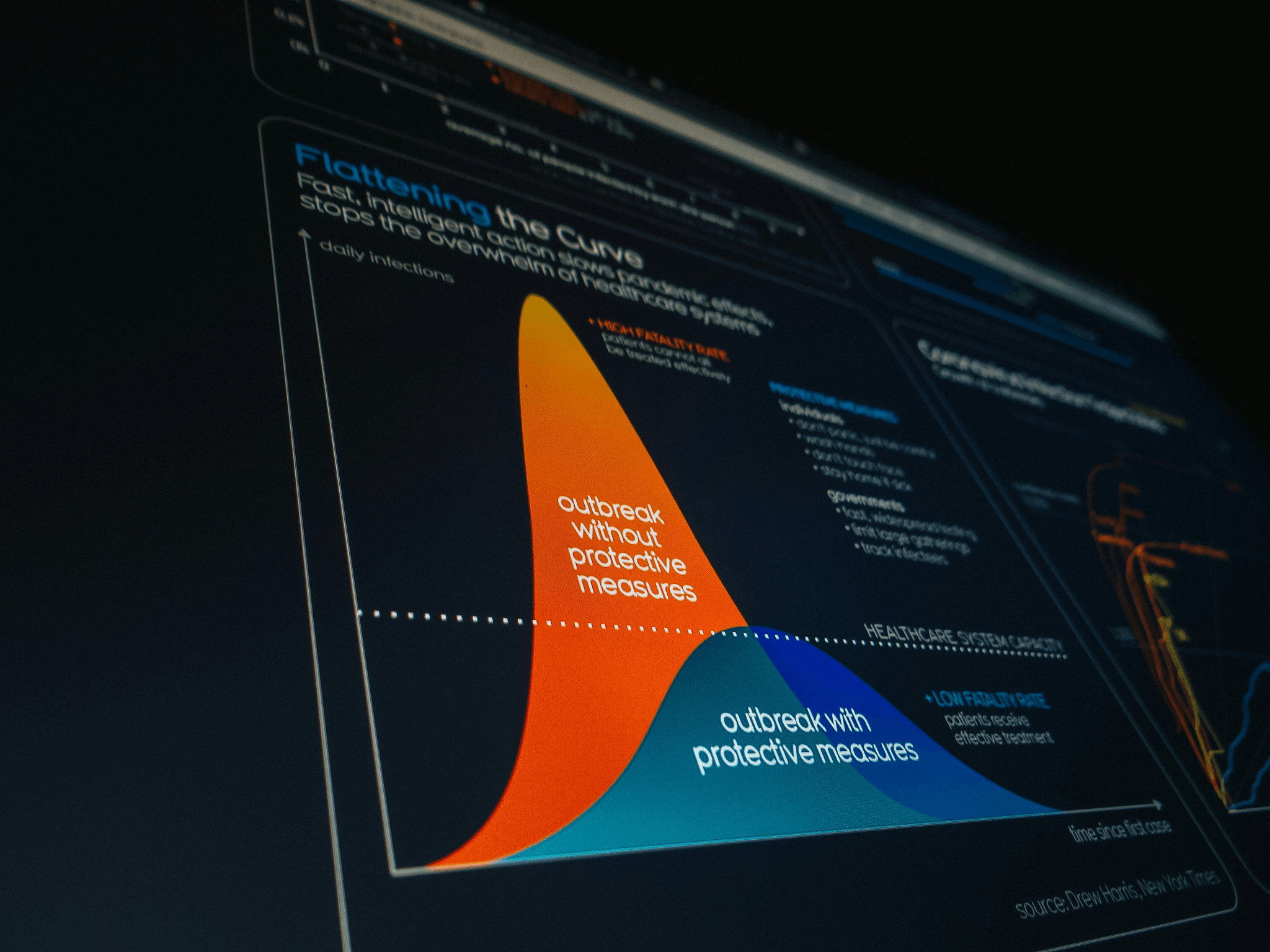

Predictive analytics is revolutionizing how businesses approach supply chains by enabling them to anticipate future trends based on historical data patterns found within their supplier analytics frameworks. With predictive models, organizations can forecast demand fluctuations, identify potential disruptions before they occur, and make more strategic sourcing decisions accordingly.

For instance, by analyzing past sales data alongside external factors such as seasonal trends or economic indicators, companies can optimize their inventory levels ahead of time—minimizing the risk of excess stock or shortages during peak periods. This foresight allows businesses not only to save costs but also enhances their reputation as reliable suppliers who consistently meet customer needs.

In an era where agility is key, harnessing predictive analytics within the realm of supplier management ensures that organizations remain competitive while maximizing profitability through informed decision-making supported by robust supplier analytics frameworks.

Enhancing Supplier Relationships

In the ever-evolving world of supply chain management, enhancing supplier relationships is not just a strategy; it's a necessity. Strong relationships can lead to smoother operations, reduced costs, and improved service levels. By leveraging supplier analytics, businesses can cultivate these vital connections and foster an environment of collaboration and trust.

Building Trust with Transparent Data

Transparency is the cornerstone of trust in any relationship, including those with suppliers. When businesses utilize supplier analytics to share data openly, they create a foundation for mutual understanding and accountability. This transparency allows both parties to align their goals and expectations, ultimately leading to better performance and fewer misunderstandings.

Moreover, sharing insights gained from supplier analytics can empower suppliers to optimize their processes as well. When suppliers see how their performance impacts the overall supply chain metrics, they are more likely to invest in improvements that benefit everyone involved. SSOURCING INC. champions this approach by helping companies implement effective systems that prioritize open communication through data-sharing.

Collaborative Planning and Forecasting

Collaborative planning is where the magic happens in supplier relationships; it’s about working together towards shared goals rather than operating in silos. Utilizing supplier analytics enables organizations to forecast demand accurately while considering input from suppliers on production capabilities and lead times. This synergy not only leads to more accurate forecasts but also reduces excess inventory costs.

By involving suppliers in the planning process through data-driven insights, businesses can ensure that everyone is on the same page regarding expectations and timelines. This collaboration fosters a sense of partnership rather than mere transactional interactions—essentially transforming suppliers into allies in achieving business objectives. At SSOURCING INC., we believe that leveraging collaborative planning tools enhances strategic alignment across all levels of your supply chain.

Case Study: Procter & Gamble’s Supplier Engagement

Procter & Gamble (P&G) serves as an exemplary model when it comes to enhancing supplier relationships through effective engagement strategies backed by robust supplier analytics. P&G employs sophisticated analytical tools that allow them not only to evaluate supplier performance but also actively involve them in product development processes based on consumer insights derived from data analysis.

The results have been impressive: P&G has seen increased innovation rates while simultaneously reducing time-to-market for new products thanks to close collaboration with its suppliers informed by actionable data insights. By prioritizing strong partnerships supported by transparent communication channels and collaborative forecasting methods, P&G demonstrates how effective use of supplier analytics can transform traditional vendor-supplier dynamics into thriving partnerships that drive growth for all involved parties.

Risk Management Through Analytics

In today's fast-paced business environment, managing supplier risks is more critical than ever. Supplier analytics serves as a powerful tool to identify potential risks before they escalate into significant issues. By leveraging data-driven insights, companies can proactively address vulnerabilities in their supply chains and ensure smoother operations.

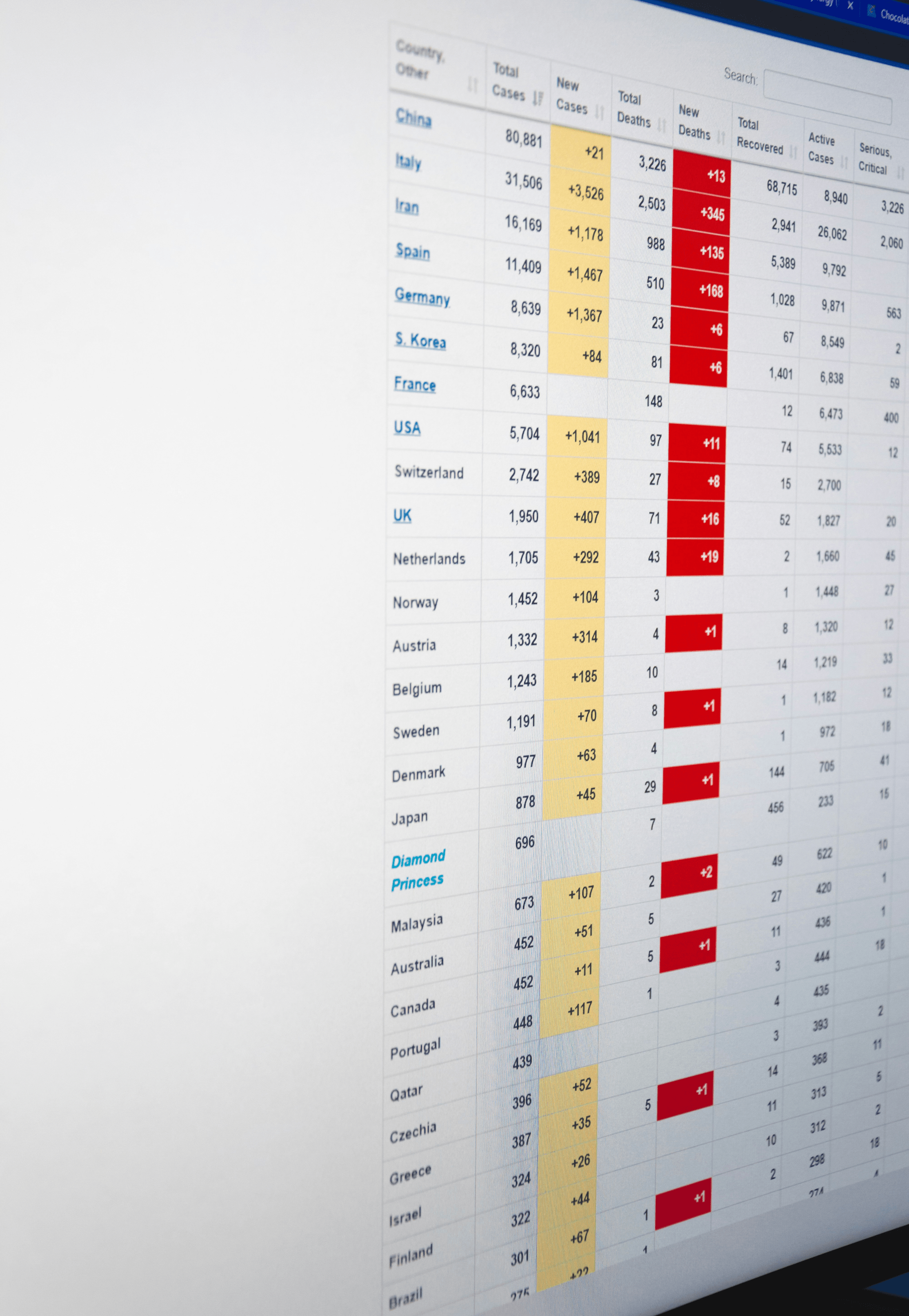

Identifying Supplier Risks Early

Supplier analytics enables organizations to spot potential risks early in the supply chain process. This proactive approach allows businesses to assess various factors such as financial stability, compliance issues, and delivery performance of their suppliers. By continuously monitoring these metrics, companies can mitigate risks before they impact production or customer satisfaction.

Effective risk identification often involves analyzing historical data and trends associated with supplier performance. For example, if a supplier has a history of late deliveries or quality issues, this information can be flagged for further scrutiny. With SSOURCING INC.'s advanced supplier analytics solutions, businesses can enhance their ability to recognize these red flags and take timely action.

Tools for Risk Assessment

To effectively manage supplier risk, organizations must utilize robust tools designed for thorough risk assessment. These tools typically include dashboards that visualize key performance indicators (KPIs) related to suppliers' financial health, operational capabilities, and compliance status. Supplier analytics software can also integrate with existing systems to provide a comprehensive view of the entire supply chain.

Some popular tools for risk assessment include predictive analytics platforms that forecast potential disruptions based on historical data patterns. Additionally, scenario analysis tools allow businesses to simulate different situations and gauge how specific risks might impact overall operations. With SSOURCING INC.'s innovative offerings in supplier analytics technology, companies can make informed decisions that bolster their resilience against unforeseen challenges.

Case Study: Toyota's Response to Supply Chain Disruptions

Toyota’s approach to managing supply chain disruptions offers valuable insights into effective risk management through supplier analytics. Following the 2011 earthquake in Japan, the automaker faced significant challenges due to its reliance on certain suppliers located in affected areas. To address this vulnerability, Toyota implemented advanced supplier analytics techniques that enabled them to identify at-risk suppliers quickly.

By utilizing real-time data monitoring and predictive modeling tools within their supply chain framework, Toyota was able to develop contingency plans swiftly and minimize production downtime during crises. This strategy not only helped them recover from immediate disruptions but also strengthened their overall supply chain resilience for future challenges. SSOURCING INC.'s commitment to providing top-notch analytical solutions ensures that your business can adopt similar strategies for robust risk management.

Continuous Improvement and Supplier Performance

In the realm of supplier analytics, continuous improvement is crucial for sustaining competitive advantage. By consistently evaluating supplier performance, businesses can identify areas for enhancement and establish a culture of accountability. This not only fosters better relationships with suppliers but also drives overall supply chain efficiency.

Setting Benchmarks for Supplier Evaluation

Establishing clear benchmarks is essential in supplier analytics as it provides a framework for evaluating performance objectively. These benchmarks can include metrics such as on-time delivery rates, quality scores, and cost efficiency. By regularly measuring suppliers against these standards, companies can identify top performers and those who may need additional support or intervention.

To effectively set these benchmarks, it’s vital to consider industry standards and historical data specific to your supply chain context. SSOURCING INC. emphasizes the importance of aligning these evaluations with your strategic goals to ensure that you’re not just measuring what’s easy but what truly matters for growth. Ultimately, having well-defined benchmarks allows organizations to make informed decisions about supplier selection and retention.

The Importance of Feedback Loops

Feedback loops play a pivotal role in the continuous improvement process within supplier analytics frameworks. They facilitate communication between businesses and their suppliers, ensuring that both parties are aligned on expectations and performance outcomes. Regular feedback helps identify challenges early on and allows for timely adjustments before minor issues escalate into significant problems.

Moreover, fostering an environment where feedback is welcomed encourages transparency and collaboration among stakeholders. When suppliers feel valued through constructive feedback mechanisms implemented by companies like SSOURCING INC., they are more likely to engage proactively in improving their services or products. This symbiotic relationship ultimately leads to enhanced supply chain resilience and effectiveness.

Case Study: Amazon’s Supplier Performance Metrics

Amazon serves as a prime example of leveraging supplier analytics for continuous improvement through robust performance metrics. The retail giant employs sophisticated algorithms to assess its suppliers based on various criteria such as delivery speed, product quality, and customer satisfaction ratings. By utilizing this data-driven approach, Amazon can swiftly identify underperforming suppliers while rewarding those who consistently exceed expectations.

Furthermore, Amazon's commitment to transparency in sharing performance data with its suppliers has fostered stronger partnerships built on trust and mutual growth objectives. This collaborative approach not only enhances operational efficiency but also drives innovation across the supply chain ecosystem—showcasing how effective supplier analytics can lead to significant competitive advantages in today's market landscape.

Conclusion

As we wrap up our exploration of supplier analytics, it's clear that the future is bright for businesses willing to embrace data-driven strategies. The evolution of supplier analytics is set to redefine how companies manage their supply chains, fostering increased efficiency and collaboration. With emerging technologies like AI and machine learning, the potential for deeper insights and proactive decision-making is virtually limitless.

The Future of Supplier Analytics

Looking ahead, supplier analytics will become increasingly integral to business operations across industries. Companies that harness advanced analytics tools will not only optimize their supply chains but also gain a competitive edge in the marketplace. As real-time data becomes more accessible, organizations can expect more agile responses to market changes and customer demands, making supplier analytics a cornerstone of strategic planning.

Key Takeaways for Your Business

To thrive in today's fast-paced environment, businesses must prioritize supplier analytics as a key component of their operational strategy. Understanding critical metrics and leveraging the right tools can lead to significant improvements in efficiency, risk management, and supplier relationships. Remember, investing in robust supplier analytics isn't just about keeping up with trends—it's about driving sustainable growth and ensuring long-term success.

How SSOURCING INC. Can Help You Grow

At SSOURCING INC., we specialize in providing tailored solutions that enhance your supplier analytics capabilities. Our team is dedicated to helping you uncover actionable insights from your data while building strong partnerships with your suppliers. With our expertise by your side, you’ll be well-equipped to navigate challenges and seize new opportunities for growth.