Introduction

In the world of manufacturing, OEM stands for Original Equipment Manufacturer. This term refers to a company that produces components or products that are purchased by another company and retailed under that purchasing company's brand name. The importance of OEM in manufacturing cannot be understated, as it allows companies to focus on their core competencies while outsourcing the production of specific components or products to specialized manufacturers. Exploring the role of OEM in product development reveals how it enables companies to bring innovative and high-quality products to market without having to invest heavily in manufacturing capabilities.

Understanding the Meaning of OEM

OEM, or Original Equipment Manufacturer, is a crucial concept in the manufacturing industry. It involves a company producing components or products that are then used by another company under its own brand name. At SSOURCING INC., we understand the significance of OEM and its impact on our clients' businesses, which is why we strive to provide top-notch OEM services for various industries.

Importance of OEM in Manufacturing

The importance of OEM in manufacturing cannot be overstated, as it allows companies to streamline their operations and focus on their core competencies. By outsourcing the production of specific components or products to specialized manufacturers, companies can achieve cost savings, improved quality, and increased efficiency. At SSOURCING INC., we recognize the value of OEM partnerships and work tirelessly to ensure our clients reap these benefits.

Exploring the Role of OEM in Product Development

When exploring the role of OEM in product development, it becomes evident that it enables companies to bring innovative and high-quality products to market without having to invest heavily in manufacturing capabilities. This strategic approach empowers businesses to leverage external expertise and resources while maintaining control over product design and branding. SSOURCING INC.'s commitment to facilitating seamless product development through strategic OEM partnerships underscores our dedication to delivering exceptional results for our clients.

Defining OEM in Manufacturing

When it comes to understanding what does OEM stand for in manufacturing, it refers to Original Equipment Manufacturer. This means a company that produces parts and equipment that may be marketed by another manufacturer. SSOURCING INC. understands the importance of OEM partnerships in delivering high-quality products to our clients.

What Does OEM Stand for in Manufacturing?

OEM stands for Original Equipment Manufacturer in the manufacturing industry. This term refers to a company that produces components or products that are purchased by another company and retailed under that purchasing company's brand name. At SSOURCING INC., we work with reputable OEM partners to ensure top-notch quality and reliability in our manufacturing processes.

OEM vs. ODM: Key Differences

While OEM focuses on the production of parts and equipment for use in another company's end product, ODM (Original Design Manufacturer) involves the design and manufacturing of a product as specified and eventually branded by another firm. It's crucial for companies like SSOURCING INC. to understand these differences when forming strategic partnerships with manufacturers.

Examples of OEM in the Manufacturing Industry

Examples of OEM arrangements can be seen across various industries, such as automotive, electronics, and consumer goods. For instance, a car manufacturer may source components like engines or tires from different OEM suppliers to assemble their vehicles. At SSOURCING INC., we carefully select our OEM partners based on their expertise, quality standards, and ability to meet our clients' needs.

Benefits of OEM in Manufacturing

OEM, or Original Equipment Manufacturer, is a strategic approach that offers numerous benefits to manufacturers. SSOURCING INC. recognizes the significance of OEM partnerships in achieving cost efficiency, customization opportunities, and quality control expertise.

Cost Efficiency with OEM

By collaborating with OEM partners, manufacturers like SSOURCING INC. can enjoy cost savings through economies of scale and streamlined production processes. This allows for competitive pricing in the market, ultimately benefiting both the manufacturer and the end consumer.

Customization and Branding Opportunities

OEM partnerships provide manufacturers with the flexibility to customize products according to their specific requirements while also incorporating their own branding elements. This level of customization allows companies like SSOURCING INC. to differentiate their offerings in a crowded marketplace.

Quality Control and Expertise with OEM Partnerships

Working closely with reputable OEM partners ensures that manufacturers can tap into their expertise and stringent quality control measures. This collaboration enables companies like SSOURCING INC. to maintain high product standards and deliver superior quality to customers.

In conclusion, leveraging OEM partnerships is essential for manufacturing success as it provides cost-efficiency, customization opportunities, and access to quality control expertise. SSOURCING INC.'s approach to OEM relationships exemplifies the value of these benefits in driving business growth and customer satisfaction.

The Process of OEM in Manufacturing

When it comes to OEM manufacturing, there are several key steps involved in the process. From initial product design and development to final production and delivery, each stage requires careful coordination and collaboration between the brand and the OEM partner. This ensures that the end product meets the desired specifications and quality standards set by both parties, ultimately leading to a successful partnership.

Steps Involved in OEM Manufacturing

The first step in OEM manufacturing is product design, where the brand outlines its specific requirements and expectations for the final product. This is followed by prototype development and testing to ensure that the product meets all necessary criteria. Once approved, production begins, with regular quality checks and inspections to maintain consistency throughout the manufacturing process. Finally, packaging and logistics are coordinated to deliver the finished products to their intended market.

Finding the Right OEM Partner

Finding the right OEM partner is crucial for a successful manufacturing process. It involves thorough research and due diligence to identify potential partners with a track record of delivering high-quality products within agreed timelines. SSOURCING INC., for example, carefully evaluates potential OEM partners based on their capabilities, expertise, and commitment to quality before entering into any partnerships.

Negotiating Terms and Contracts with OEMs

Negotiating terms and contracts with OEMs is a critical aspect of establishing a successful partnership. This involves discussing pricing, production timelines, quality control measures, as well as intellectual property rights protection. SSOURCING INC.'s approach prioritizes clear communication and transparency throughout these negotiations to ensure that both parties are aligned on all aspects of the partnership.

By following these steps in the process of OEM manufacturing - from finding the right partner to negotiating terms - companies like SSOURCING INC. can effectively leverage OEM partnerships for successful manufacturing outcomes while minimizing risks associated with outsourcing production.

Risks and Challenges of OEM in Manufacturing

Potential Quality Control Issues

When working with OEM partners, there is always the risk of quality control issues arising, leading to defective products and dissatisfied customers. SSOURCING INC. emphasizes the importance of thorough vetting and ongoing monitoring of OEM partners to ensure that quality standards are consistently met throughout the manufacturing process.

Protecting Intellectual Property Rights

One of the major challenges in OEM manufacturing is the protection of intellectual property rights. It's crucial for companies like SSOURCING INC. to establish clear legal agreements with OEM partners to safeguard proprietary designs, technologies, and processes from unauthorized use or replication.

Managing Communication and Logistics with OEM Partners

Effective communication and efficient logistics management are essential for successful OEM partnerships. SSOURCING INC. recognizes the importance of establishing clear lines of communication and implementing robust supply chain management systems to ensure smooth collaboration with OEM partners.

Future Trends in OEM Manufacturing

With the rapid advancement of technology, the impact on OEM practices is undeniable. Automation and data analytics are revolutionizing the manufacturing industry, leading to increased efficiency and productivity in OEM partnerships. As a result, SSOURCING INC. is embracing these technological advancements to streamline processes and deliver innovative solutions to our clients.

Technology's Impact on OEM Practices

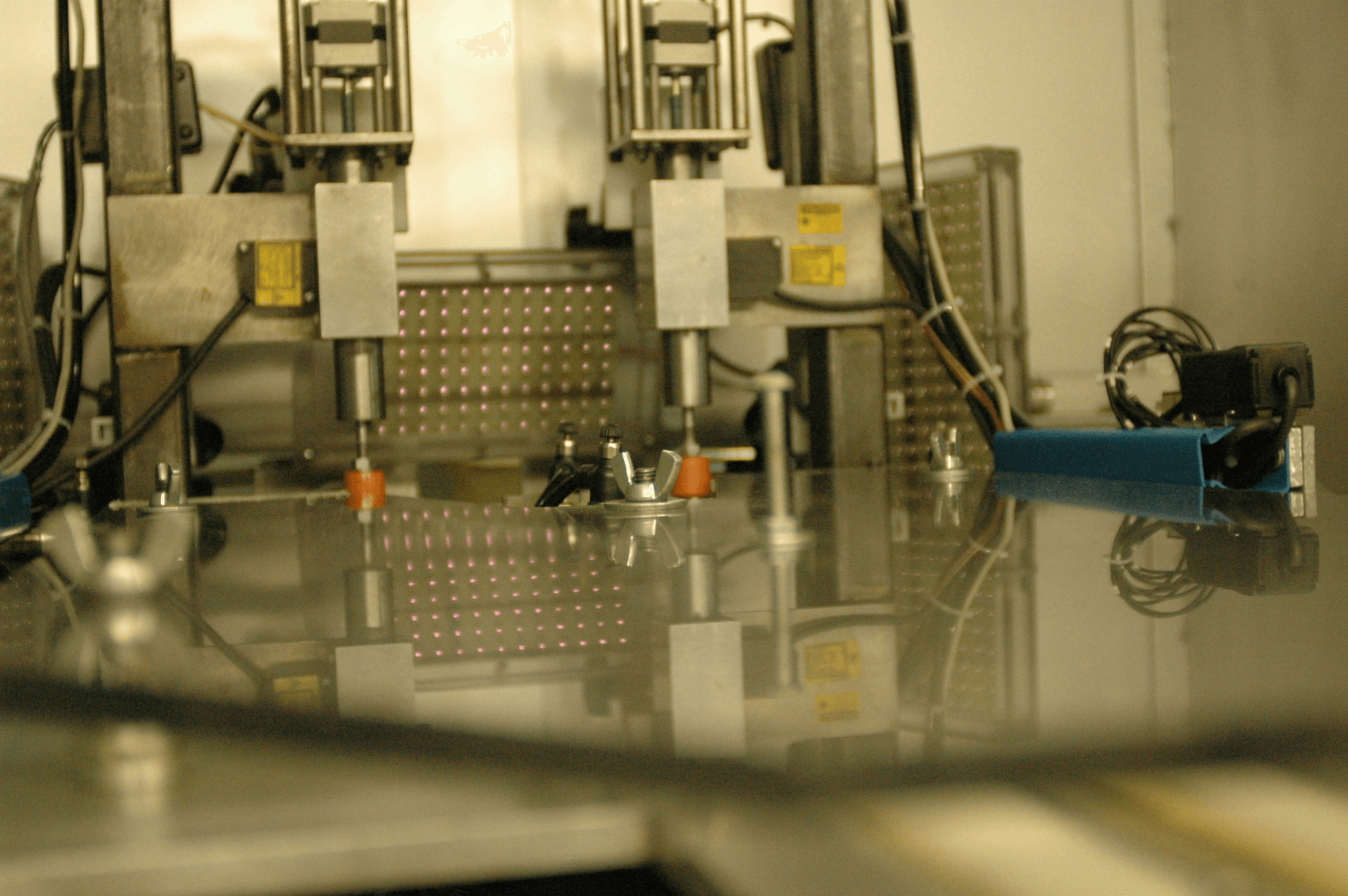

The integration of smart manufacturing technologies, such as IoT devices and robotics, is reshaping the way OEMs operate. These technologies enable real-time monitoring of production processes, predictive maintenance, and improved quality control, ultimately enhancing the overall efficiency of OEM manufacturing. At SSOURCING INC., we leverage these advancements to optimize our OEM partnerships and deliver high-quality products to our customers.

Sustainability and Ethical Considerations in OEM

As sustainability becomes a growing concern in manufacturing, ethical considerations are playing a significant role in OEM practices. With a focus on reducing environmental impact and promoting fair labor practices, SSOURCING INC. is committed to partnering with OEMs that align with our values of sustainability and ethical business conduct.

SSOURCING INC.'s Approach to OEM Partnerships

At SSOURCING INC., we prioritize building long-term relationships with our OEM partners based on trust, transparency, and mutual benefit. Our approach involves thorough vetting of potential partners to ensure alignment with our quality standards and business ethics. We believe that fostering strong partnerships with reputable OEMs is essential for delivering exceptional products to our clients.

Conclusion

Leveraging OEM for Manufacturing Success

In today's competitive manufacturing landscape, understanding what does OEM stand for in manufacturing and leveraging it effectively can be a game-changer for companies like SSOURCING INC. By partnering with reliable OEMs, businesses can tap into cost-effective production, expertise, and quality control to drive success.

Key Considerations for OEM Relationships

When considering OEM partnerships, it's crucial to vet potential partners thoroughly. SSOURCING INC. emphasizes the importance of finding a partner that aligns with your brand's values and quality standards. Clear communication, mutual trust, and a shared vision are key factors in establishing successful long-term relationships.

Maximizing Potential with OEM in Manufacturing

To maximize the potential of OEM relationships, companies must prioritize transparency and collaboration. SSOURCING INC. encourages open dialogue with OEM partners to ensure seamless integration of processes and alignment on goals. By fostering strong relationships, businesses can unlock innovation and efficiency in their manufacturing endeavors.

Remember that while there are risks and challenges associated with OEM partnerships, the benefits far outweigh them when approached strategically. With careful planning and the right partners, companies like SSOURCING INC. can harness the power of OEM to drive manufacturing success while staying ahead of industry trends.