Introduction

When it comes to finding a manufacturer to make your product, there are several common mistakes that can be easily avoided with the right approach. At SSOURCING INC., we understand the importance of thorough research and quality control in manufacturing. Effective communication and negotiation with manufacturers are also key factors in ensuring a successful partnership. In this guide, we will explore these crucial aspects of finding the right manufacturer for your product.

Common Mistakes When Finding a Manufacturer

One of the most common mistakes when finding a manufacturer is rushing into a partnership without proper research. At SSOURCING INC., we advise against overlooking important details such as reputation, production costs, and lead times. By carefully planning your approach and avoiding these pitfalls, you can set yourself up for success in manufacturing your product.

Researching Potential Manufacturers

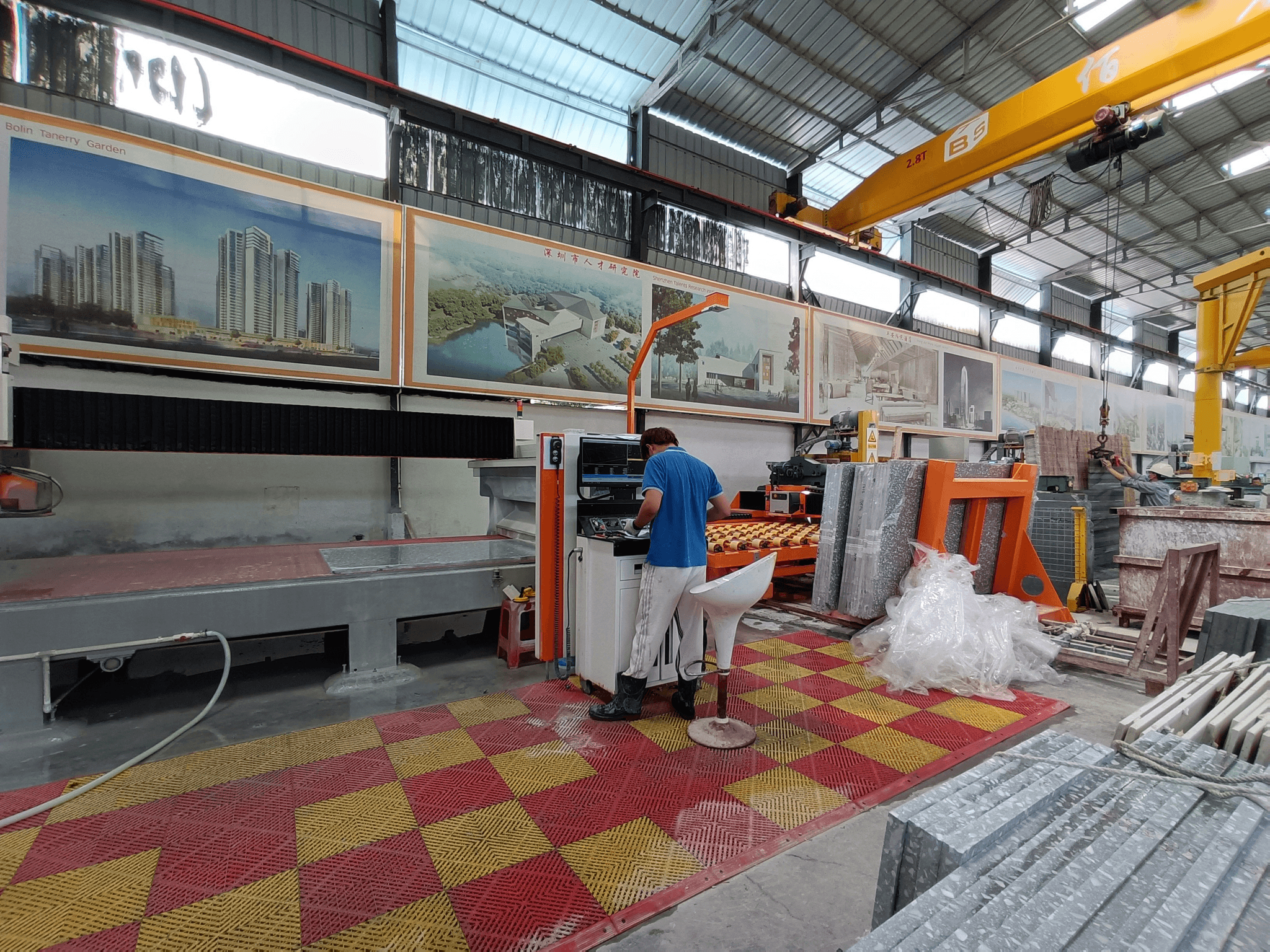

Researching potential manufacturers is a crucial step in the process of finding the right partner for your product. It's important to thoroughly vet each manufacturer to ensure they have the capabilities and experience to meet your needs. At SSOURCING INC., we emphasize the importance of checking references, reviewing past work, and visiting facilities if possible to make an informed decision.

Quality Control in Manufacturing

Quality control is non-negotiable when it comes to manufacturing your product. Ensuring that your manufacturer has robust quality control processes in place is essential for maintaining product consistency and meeting customer expectations. At SSOURCING INC., we prioritize quality control as a fundamental aspect of any manufacturing partnership.

Communication and Transparency with Manufacturers

Effective communication and transparency with manufacturers are vital for a successful partnership. Clearly outlining expectations, specifications, and timelines from the outset can help avoid misunderstandings down the line. At SSOURCING INC., we believe that open communication fosters trust and collaboration between our clients and their manufacturing partners.

Negotiating with Manufacturers

Negotiating terms and agreements with manufacturers requires careful consideration of pricing, contracts, and protecting your interests in the agreement. At SSOURCING INC., we understand the art of negotiation and can assist our clients in securing favorable terms while maintaining a mutually beneficial relationship with their manufacturing partners.

Overlooking Manufacturer's Reputation

When finding a manufacturer to make your product, it's crucial to research their reputation thoroughly. Look for online reviews and testimonials from other businesses that have worked with them. Check for any red flags or warning signs that could indicate a problematic manufacturer. Ignoring a manufacturer's reputation could lead to issues with quality, communication, and delivery, ultimately affecting your business's success.

Researching Manufacturer's Reputation

Before partnering with a manufacturer, take the time to research their reputation in the industry. Look for any awards or certifications they may have received, as well as any negative feedback or complaints from previous clients. By understanding their reputation, you can make an informed decision about whether they are the right fit for your product manufacturing needs.

Checking Reviews and References

One way to gauge a manufacturer's reputation is by checking reviews and references from other businesses. Look for detailed feedback on their performance, communication, and overall satisfaction with the manufacturing process. Positive reviews and strong references can give you confidence in the manufacturer's ability to meet your expectations.

Avoiding Scams and Fraudulent Manufacturers

In the world of manufacturing, there are unfortunately scams and fraudulent practices that can put your business at risk. By overlooking a manufacturer's reputation, you may fall victim to these unscrupulous entities. Avoiding scams and fraudulent manufacturers is essential for protecting your investment and ensuring the success of your product launch with SSOURCING INC.

Not Considering Quality Control

When finding a manufacturer to make your product, overlooking the importance of quality control can lead to disastrous results. At SSOURCING INC., we understand that ensuring product quality and consistency is crucial for the success of your business. By prioritizing quality control, you can avoid costly recalls and reputation damage due to subpar products.

Importance of Quality Control in Manufacturing

Quality control is essential in manufacturing as it ensures that your products meet the required standards and specifications. At SSOURCING INC., we emphasize the significance of implementing robust quality control measures to guarantee that every item produced meets your expectations and satisfies customer needs. By prioritizing quality, you can build trust with your customers and establish a strong brand reputation.

Ensuring Product Quality and Consistency

When working with manufacturers, it's vital to communicate your quality expectations clearly and ensure that they have processes in place to maintain consistency. SSOURCING INC. assists clients in articulating their quality requirements and works closely with manufacturers to enforce strict adherence to these standards throughout the production process. This commitment helps maintain uniformity across all batches of products.

Quality Control Processes and Standards

At SSOURCING INC., we advocate for thorough inspections, testing, and adherence to industry-specific standards as part of our quality control processes. We guide our clients on setting clear quality benchmarks for their products and help them select manufacturers who are dedicated to upholding these standards. Through stringent quality control measures, you can safeguard your brand's integrity and deliver exceptional products consistently.

With SSOURCING INC.'s expertise in manufacturing partnerships, we prioritize the importance of implementing effective quality control measures throughout the production process to ensure that every product meets your high standards when finding a manufacturer for your product.

Poor Communication and Transparency

Effective Communication with Manufacturers

Effective communication with manufacturers is crucial when finding a manufacturer to make your product. At SSOURCING INC., we understand the importance of clear and open lines of communication to ensure that your vision is accurately conveyed to the manufacturer. This involves regular updates, prompt responses, and a willingness to address any concerns or issues that may arise during the manufacturing process.

When working with manufacturers, effective communication involves being clear about your expectations while also being open to feedback and suggestions from the other party. This collaborative approach can lead to better outcomes for both parties involved.

Clear Expectations and Specifications

Clear expectations and specifications are essential in avoiding misunderstandings and costly mistakes. When working with manufacturers, it's vital to provide detailed instructions, technical specifications, and quality standards for your product. At SSOURCING INC., we help our clients articulate their requirements clearly so that there is no room for error or misinterpretation.

Clearly outlining your expectations and specifications ensures that everyone is on the same page regarding what needs to be produced. This helps avoid misunderstandings or discrepancies in the final product.

Transparency in Pricing and Production Process

Transparency in pricing and the production process is non-negotiable when finding a manufacturer to make your product. It's essential to have a thorough understanding of all costs involved, including production, shipping, and any additional fees. Our team at SSOURCING INC. ensures that our clients have full visibility into the entire manufacturing process, from start to finish.

Transparency in pricing means being upfront about all costs involved in manufacturing your product. This includes production costs, shipping fees, as well as any potential additional expenses that may arise during the manufacturing process.

Failing to Negotiate Terms and Agreements

When it comes to finding a manufacturer to make your product, negotiating pricing and terms is crucial. SSOURCING INC. recommends that you carefully discuss the cost of production, minimum order quantities, and payment terms with potential manufacturers. By doing so, you can ensure that both parties are on the same page and avoid any misunderstandings down the line.

Negotiating Pricing and Terms

Negotiating pricing and terms with manufacturers is a delicate dance that requires finesse and knowledge of the industry. It's important to strike a balance between getting a fair price for your product while also ensuring that the manufacturer's costs are covered. SSOURCING INC. advises entrepreneurs to be prepared to walk away from deals that don't align with their budget or production needs.

Establishing Clear Contracts

Once you've agreed on pricing and terms, it's essential to establish clear contracts with your chosen manufacturer. These contracts should outline all aspects of the production process, including timelines, quality standards, payment schedules, and intellectual property rights. SSOURCING INC. stresses the importance of having legal counsel review these contracts to protect your interests.

Protecting Your Interests in the Agreement

Protecting your interests in the agreement means safeguarding your company's assets and ensuring that the manufacturer upholds their end of the deal. This includes setting clear expectations for product quality, delivery schedules, and any potential penalties for non-compliance. SSOURCING INC. advises entrepreneurs to include clauses in their contracts that address issues such as defective products or late deliveries.

With these tips in mind, entrepreneurs can navigate negotiations with manufacturers more effectively while protecting their business interests.

Ignoring Production Costs and Lead Times

When finding a manufacturer to make your product, it's crucial to understand the production costs involved. This includes not just the cost of materials and labor, but also overhead expenses and any additional fees that may arise. Ignoring these costs can lead to unexpected financial burdens for your company, so it's important to thoroughly analyze and budget for all potential expenses.

Understanding Production Costs

Understanding production costs involves breaking down all the elements that contribute to the manufacturing process. This includes raw materials, machinery, labor, packaging, shipping, and any other related expenses. By having a clear understanding of these costs, SSOURCING INC. can make informed decisions about pricing strategies and profit margins.

Managing Lead Times and Production Schedules

Lead times and production schedules are critical factors in ensuring timely delivery of your products to market. Failing to manage lead times effectively can result in delays that impact customer satisfaction and revenue generation. SSOURCING INC. must work closely with manufacturers to establish realistic production schedules that align with market demand and business goals.

Balancing Cost and Quality

Finding a manufacturer to make your product involves striking a balance between cost and quality. While it's important to keep production costs in check, cutting corners on quality can have detrimental effects on your brand reputation and customer loyalty. SSOURCING INC. should prioritize working with manufacturers who offer competitive pricing without compromising on product quality.

Conclusion

Finding a reliable manufacturer for your product is crucial to the success of your business. It's important to thoroughly research potential partners and consider factors such as reputation, quality control, communication, and negotiation. SSOURCING INC. can help you navigate these challenges and find the right manufacturing partner for your needs.

Finding a Reliable Manufacturer for Your Product

When finding a manufacturer to make your product, it's essential to look for one with a proven track record of delivering high-quality products on time. SSOURCING INC. can assist you in identifying reputable manufacturers who align with your business goals and values.

Key Factors to Consider in Manufacturing Partners

Key factors to consider in manufacturing partners include their reputation, quality control processes, communication transparency, and negotiation terms. SSOURCING INC. has the expertise to guide you through this process and ensure that you find a manufacturing partner that meets all of your requirements.

Ensuring Success in Manufacturing Your Product

Ensuring success in manufacturing your product involves careful planning, effective communication, and thorough research into potential manufacturers. With SSOURCING INC.'s assistance, you can navigate the complexities of manufacturing and set yourself up for success in bringing your product to market.