Introduction

In the ever-evolving landscape of production management, inspections play a pivotal role in ensuring quality and efficiency. The types of inspection in production management serve as essential checkpoints that help businesses like SSOURCING INC. maintain high standards while minimizing risks. Understanding the importance of these inspections is crucial for any organization aiming to thrive in a competitive market.

Understanding the Importance of Inspection

Inspection is more than just a routine task; it’s a vital process that safeguards product quality and operational integrity. By implementing various types of inspection in production management, companies can identify defects early, saving time and costs associated with rework or recalls. For SSOURCING INC., effective inspections are synonymous with customer satisfaction and brand reputation.

Why Production Management Needs Inspections

Production management without inspections is like sailing without a compass—risky and uncertain! Inspections provide valuable insights into every stage of the production process, ensuring that products meet specified standards before they reach customers. For SSOURCING INC., embracing different types of inspection in production management not only enhances product quality but also fosters trust among stakeholders.

An Overview of Key Inspection Types

There are several key types of inspection in production management, each designed to address specific needs within the manufacturing process. From quality control inspections to compliance checks, understanding these categories can significantly impact overall productivity and success rates. As we delve deeper into this topic, SSOURCING INC. will highlight effective practices that exemplify how these various types contribute to operational excellence.

Quality Control Inspections

Quality control inspections are a critical component of production management, ensuring that products meet specific standards before they reach consumers. These inspections help identify defects, maintain consistency, and enhance customer satisfaction. In the realm of types of inspection in production management, quality control stands as a cornerstone for operational excellence.

What is Quality Control?

Quality control (QC) refers to the systematic processes employed to ensure that products or services adhere to defined quality standards. It involves various activities aimed at detecting defects and ensuring that the outputs meet the required specifications. By implementing effective QC measures, companies like SSOURCING INC. can minimize waste and maximize efficiency in their production processes.

Techniques for Effective Quality Control

To achieve effective quality control, several techniques can be employed, including statistical process control (SPC), Six Sigma methodologies, and total quality management (TQM). SPC uses statistical methods to monitor and control production processes, while Six Sigma focuses on reducing defects by improving process capabilities. TQM emphasizes continuous improvement across all levels of an organization; all these techniques contribute significantly to enhancing the types of inspection in production management.

Moreover, regular training for staff involved in QC can lead to better adherence to protocols and improved identification of potential issues early in the production cycle. The integration of automated inspection tools also plays a vital role by providing real-time data analysis and feedback loops that help streamline processes further. With these strategies in place, SSOURCING INC. ensures high-quality outputs while fostering a culture of excellence.

Famous Cases of Quality Control Success

One notable case highlighting successful quality control is Toyota's implementation of its renowned Toyota Production System. This approach emphasizes continuous improvement and respect for people while systematically reducing waste through rigorous quality checks at every stage of production. As a result, Toyota has become synonymous with reliability and efficiency—an exemplar among various types of inspection in production management.

Another inspiring example comes from Motorola's adoption of Six Sigma practices during the 1980s, which led them to dramatically reduce defects across their product lines while increasing customer satisfaction rates significantly. This success story showcases how prioritizing quality control not only enhances product integrity but also drives brand loyalty among consumers—something every company should aspire to emulate.

In conclusion, effective quality control inspections are indispensable for any organization aiming for success in today's competitive marketplace; they ensure that products not only meet but exceed customer expectations while minimizing costs associated with rework or recalls.

Incoming Material Inspections

Incoming material inspections are a critical component in ensuring the quality and reliability of products in production management. They serve as the first line of defense against defects that can arise from subpar materials, which could lead to costly rework or even product recalls. By implementing robust incoming material checks, companies like SSOURCING INC. can maintain high standards and safeguard their production processes.

The Role of Incoming Material Checks

The role of incoming material checks cannot be overstated when discussing types of inspection in production management. These inspections verify that materials meet specified standards before they enter the production line, preventing potential issues down the road. By catching problems early, businesses not only save time and money but also enhance their overall product quality.

Best Practices for Material Inspections

To maximize the effectiveness of incoming material inspections, several best practices should be adopted. First, establishing clear criteria for acceptance ensures consistency across all inspections—this is where SSOURCING INC.'s expertise shines through! Second, utilizing technology such as automated inspection systems can streamline the process while reducing human error; it’s all about efficiency in today’s fast-paced market. Lastly, maintaining open communication with suppliers fosters a collaborative environment where quality expectations are clearly understood.

Real-World Examples of Material Inspection Issues

Real-world examples illustrate just how crucial these types of inspection in production management can be when it comes to avoiding disasters. Take, for instance, a well-known automotive manufacturer that faced severe backlash after using faulty components due to inadequate incoming material checks; this resulted in massive recalls and loss of consumer trust. Conversely, another company implemented rigorous inspections and successfully identified substandard materials before they could disrupt production—demonstrating how effective incoming checks can lead to success rather than failure.

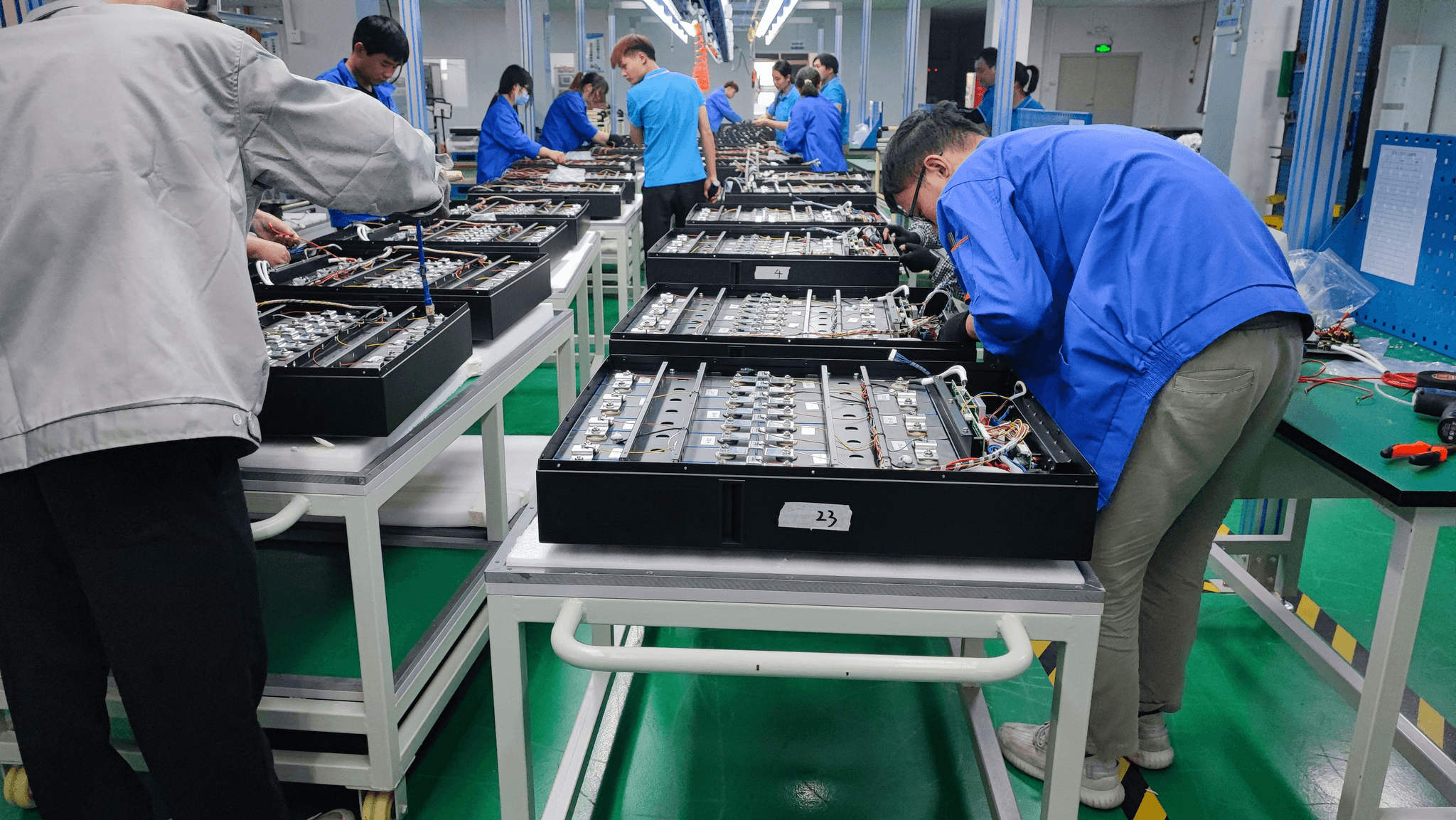

In-Process Inspections

In-process inspections are critical checkpoints in the production management landscape, ensuring that products meet quality standards throughout the manufacturing process. These inspections help identify defects early, minimizing rework and waste while enhancing overall efficiency. By integrating various types of inspection in production management, companies can maintain high standards and customer satisfaction.

Why In-Process Inspections Matter

In-process inspections matter because they act as a safety net, catching potential issues before they escalate into larger problems. This proactive approach not only saves time and money but also fosters a culture of quality within the organization. When employees understand the importance of these inspections, it leads to better adherence to protocols and an overall commitment to excellence.

Moreover, in-process inspections can significantly reduce the risk of non-compliance with industry regulations. By regularly checking products during different stages of production, companies like SSOURCING INC. can ensure that they meet both internal standards and external regulatory requirements. This vigilance is vital for maintaining a competitive edge in today's fast-paced market.

Tools Used for In-Process Inspections

A variety of tools are employed during in-process inspections to enhance accuracy and efficiency. These range from simple checklists to sophisticated technology such as automated inspection systems and real-time monitoring software. Utilizing these tools helps streamline the inspection process while ensuring that all aspects of production are scrutinized thoroughly.

For instance, vision systems equipped with cameras can detect defects on assembly lines faster than any human eye could manage alone. Additionally, data analytics software allows for tracking trends over time, helping organizations identify recurring issues related to specific types of inspection in production management processes. With these tools at their disposal, companies like SSOURCING INC. can elevate their quality assurance game significantly.

Success Stories from In-Process Inspections

There are numerous success stories highlighting the benefits of effective in-process inspections across different industries. For example, a leading automotive manufacturer implemented rigorous in-process checks that led to a 30% reduction in defect rates over just one year! This not only improved product quality but also enhanced their reputation among consumers.

Another inspiring case involves a food processing company that adopted real-time monitoring systems during its production phases; this resulted in faster identification and resolution of contamination risks—ultimately safeguarding consumer health and boosting sales figures dramatically! Such examples underscore how investing time and resources into various types of inspection in production management pays off handsomely.

As we look ahead, it's clear that embracing robust in-process inspection practices will be crucial for maintaining competitiveness while ensuring product excellence across industries.

Final Product Inspections

Final product inspections are the last line of defense in ensuring that products meet quality standards before reaching the consumer. This stage is critical because it directly impacts customer satisfaction and brand reputation. By implementing effective final product checks, businesses can mitigate risks associated with defects and recalls, making it a vital aspect of production management.

The Significance of Final Product Checks

Final product checks serve as an assurance that what leaves the production floor aligns with both regulatory requirements and customer expectations. They are essential for identifying any discrepancies that may have slipped through earlier inspection stages, ultimately safeguarding consumers from faulty products. With various types of inspection in production management, these checks play a crucial role in maintaining a company's credibility and trustworthiness.

Common Techniques in Product Inspections

Several techniques are employed during final product inspections to ensure quality control, including visual inspections, functional testing, and measurement assessments. Visual inspections help identify cosmetic defects while functional testing ensures that the product operates as intended under real-world conditions. Measurement assessments provide quantitative data to verify that products meet specified dimensions or tolerances—an essential part of the types of inspection in production management.

How SSOURCING INC. Ensures Quality

At SSOURCING INC., we prioritize rigorous final product inspections to uphold our commitment to quality assurance. Our team employs a combination of advanced techniques tailored to each type of product we handle, ensuring comprehensive evaluations before shipment. By integrating innovative technology and skilled personnel into our inspection processes, we exemplify best practices within the types of inspection in production management.

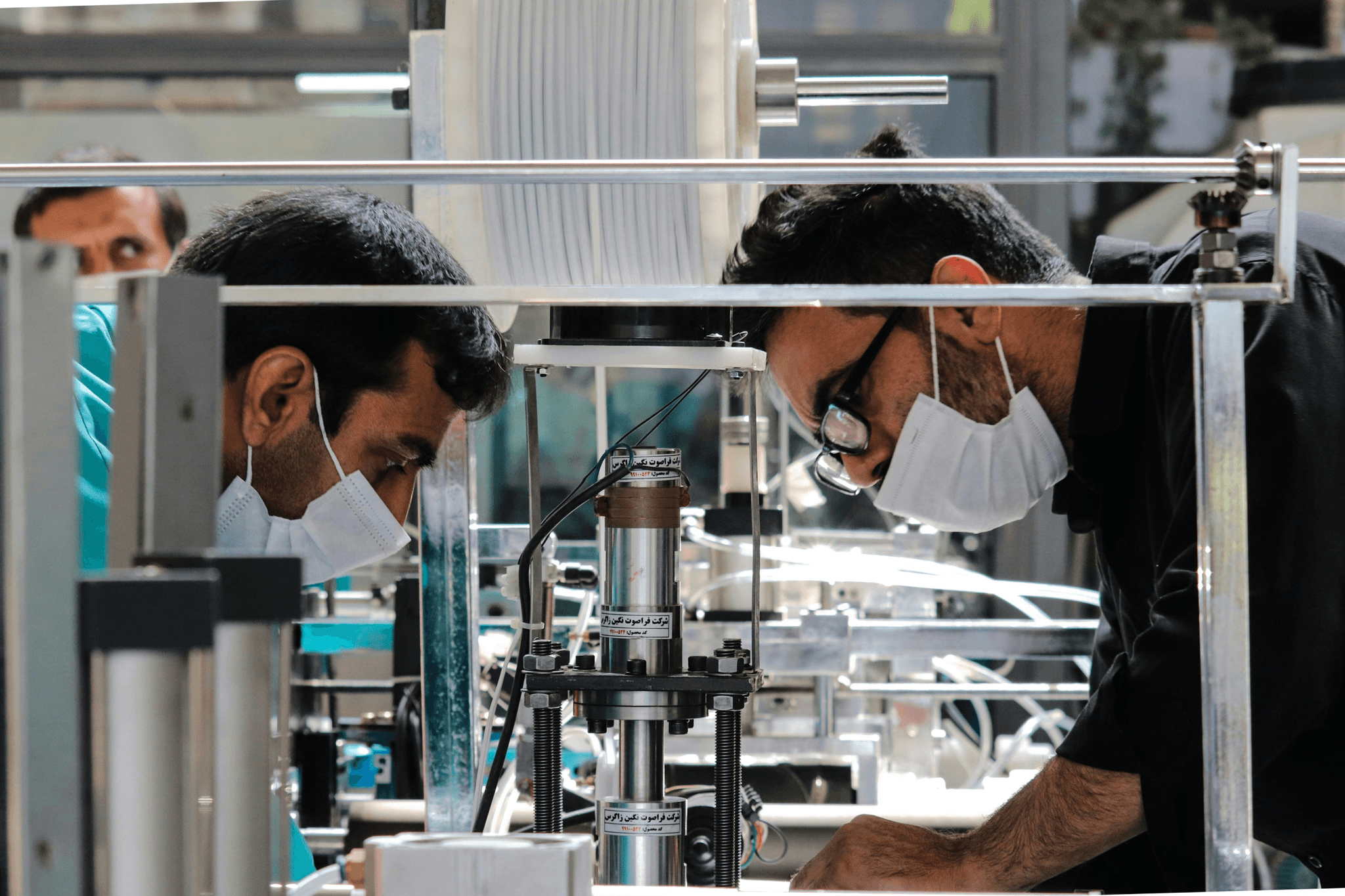

Compliance Inspections

In the realm of production management, compliance inspections play a pivotal role in ensuring that operations meet industry standards and regulations. These inspections are essential not only for maintaining product quality but also for safeguarding a company's reputation and legal standing. SSOURCING INC. emphasizes that understanding the landscape of compliance is crucial for any organization looking to thrive in competitive markets.

Understanding Compliance in Production

Compliance in production refers to adhering to established laws, regulations, and standards relevant to manufacturing processes and products. This includes everything from safety protocols to environmental regulations, ensuring that companies like SSOURCING INC. operate within legal frameworks while delivering high-quality products. Failure to comply can lead to severe consequences, including fines, recalls, or even shutdowns—making it imperative for organizations to stay informed about the various types of inspection in production management.

Compliance inspections serve as a safeguard against these risks by systematically checking processes and products against regulatory requirements. They help identify potential non-conformities early on, allowing companies to rectify issues before they escalate into larger problems. In essence, these inspections are not just about ticking boxes; they’re about fostering a culture of accountability and excellence within production environments.

Procedures for Compliance Inspections

The procedures for conducting compliance inspections typically involve several key steps designed to ensure thoroughness and accuracy. First, organizations must establish clear criteria based on relevant regulations and industry standards that will serve as benchmarks during inspections. SSOURCING INC., for example, develops detailed checklists tailored to specific types of inspection in production management that align with both internal policies and external regulatory requirements.

Next comes the actual inspection process itself—this can include document reviews, on-site evaluations, employee interviews, and equipment assessments. Inspectors must be trained professionals who understand both the technical aspects of the operations being inspected and the nuances of compliance requirements; this combination ensures that no stone is left unturned during evaluations. Finally, after completing an inspection, organizations should document findings comprehensively while outlining corrective actions needed where discrepancies arise.

Noteworthy Compliance Case Studies

Several notable case studies illustrate the importance of effective compliance inspections in production management across various industries. One such example involves a major automotive manufacturer that faced significant penalties due to non-compliance with safety standards; their failure highlighted gaps in their inspection protocols which subsequently led them to overhaul their compliance procedures entirely—resulting in improved safety outcomes over time.

Another case study worth mentioning is from the food industry where rigorous compliance inspections helped uncover serious contamination issues before products reached consumers’ hands; this proactive approach not only saved lives but also protected the brand’s reputation immensely—a win-win scenario! Companies like SSOURCING INC., with robust systems for conducting different types of inspection in production management consistently demonstrate how adherence leads directly towards operational excellence.

In conclusion, compliance inspections are indispensable tools within the framework of production management; they ensure adherence while promoting quality assurance at every stage—from raw materials through final product delivery.

Conclusion

In wrapping up our exploration of the various types of inspection in production management, it’s clear that inspections play a pivotal role in maintaining quality and efficiency. From incoming material checks to final product evaluations, each type serves a specific purpose that contributes to the overall success of production processes. Understanding these different types helps organizations like SSOURCING INC. implement effective strategies for quality assurance.

Key Takeaways on Inspection Types

When considering the types of inspection in production management, it’s essential to recognize their distinct functions and benefits. Quality control inspections ensure products meet predefined standards, while incoming material inspections safeguard against defects before they enter the production line. In-process inspections monitor ongoing operations, and final product checks confirm that finished goods align with customer expectations—each type is integral to a comprehensive quality management system.

The Impact of Effective Inspections

Effective inspections can dramatically influence an organization's bottom line by reducing waste and minimizing costly errors. When SSOURCING INC. implements rigorous inspection procedures across all stages of production, it not only enhances product quality but also boosts customer satisfaction and loyalty. Ultimately, investing time and resources into these types of inspection in production management leads to improved operational efficiency and a stronger market presence.

Future Trends in Production Management Inspections

Looking ahead, we can expect advancements in technology to reshape how we conduct various types of inspection in production management. Automation, AI-driven analytics, and real-time monitoring systems are set to revolutionize traditional practices by enhancing accuracy and speed during inspections. Companies like SSOURCING INC., which embrace these innovations early on, will likely stay ahead of the competition while ensuring top-notch quality.