Introduction

In today's fast-paced global economy, understanding supply chain quality is more crucial than ever. It encompasses everything from the raw materials sourced to the final product delivered to consumers, ensuring that every link in the chain meets rigorous standards. As businesses strive for efficiency and excellence, they must navigate a complex landscape where supply chain quality can make or break their reputation.

Understanding Supply Chain Quality Today

Supply chain quality today is not just about meeting specifications; it's about creating value at every step of the process. Companies like SSOURCING INC. recognize that maintaining high standards requires a holistic approach that integrates various functions and stakeholders. This means embracing transparency, accountability, and continuous improvement to ensure that supply chain quality aligns with customer expectations and industry benchmarks.

The Importance of Supply Chain Quality

The importance of supply chain quality cannot be overstated; it directly impacts customer satisfaction, brand loyalty, and ultimately, profitability. Poor supply chain quality can lead to delays, increased costs, and reputational damage—issues no company wants to face in a competitive market. For SSOURCING INC., prioritizing supply chain quality means not only safeguarding their operations but also enhancing their overall business resilience.

Key Trends Affecting Supply Chains

Several key trends are shaping the future of supply chains and influencing how companies approach quality management. From globalization that complicates logistics to technological advancements enabling real-time monitoring, these trends present both challenges and opportunities for enhancing supply chain quality. Staying ahead of these trends is essential for organizations like SSOURCING INC., which aim to lead rather than follow in an ever-evolving marketplace.

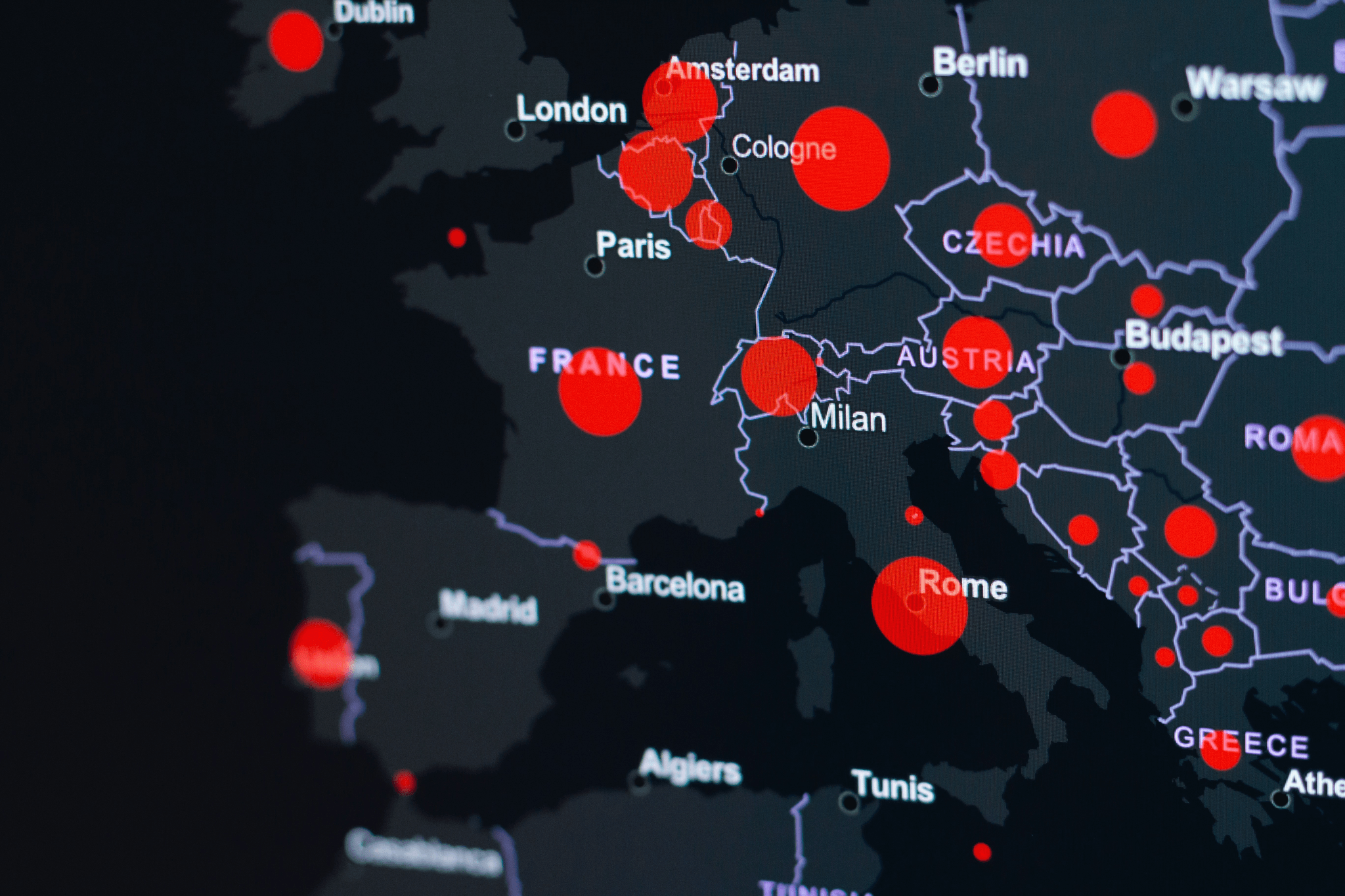

Globalization and Supply Chain Complexity

In today's interconnected world, the complexity of supply chains has reached unprecedented levels. Globalization has opened doors to new markets and opportunities, but it also presents unique challenges that can impact supply chain quality. As businesses expand their reach, they must navigate a labyrinth of international regulations, diverse supplier networks, and potential political risks.

Navigating International Regulations

Understanding international regulations is crucial for maintaining high supply chain quality in a global marketplace. Each country has its own set of rules governing trade, tariffs, and compliance standards that businesses must adhere to. SSOURCING INC. emphasizes the importance of staying informed about these regulations to avoid costly delays and ensure smooth operations across borders.

Moreover, companies must not only comply with local laws but also consider international agreements such as trade treaties and environmental policies. This can be daunting for organizations that rely on multiple suppliers from different regions. By investing in compliance training and leveraging technology to monitor regulatory changes, businesses can enhance their supply chain quality while minimizing risks associated with non-compliance.

Diverse Supplier Networks

The diversity of supplier networks is both a strength and a challenge for maintaining supply chain quality. On one hand, having access to a wide range of suppliers allows companies to tap into various resources and innovations; on the other hand, it complicates coordination efforts across different cultures and operational practices. SSOURCING INC. recognizes that building strong relationships with diverse suppliers is essential for ensuring consistency in product quality.

To effectively manage these networks, companies should implement standardized processes that facilitate communication and collaboration among suppliers. This includes sharing best practices related to quality control measures as well as conducting regular audits to assess supplier performance. By fostering transparency within these relationships, organizations can enhance their overall supply chain quality while reducing potential disruptions.

Risks of Political Instability

Political instability poses significant risks that can jeopardize supply chain quality on a global scale. Changes in government policies or civil unrest can lead to sudden disruptions in production or transportation routes—impacting everything from delivery times to product availability. SSOURCING INC.'s approach involves proactive risk management strategies designed to identify potential political threats before they affect operations.

One effective strategy is diversifying sourcing locations so that companies are not overly reliant on any single market prone to instability. Additionally, establishing contingency plans allows businesses to respond swiftly when crises arise—ensuring minimal impact on supply chain quality during turbulent times. Ultimately, understanding the geopolitical landscape is key for organizations aiming to maintain resilience amidst uncertainty.

Technology's Role in Quality Control

In today's fast-paced business environment, technology plays a crucial role in enhancing supply chain quality. Companies are increasingly leveraging advanced tools to streamline processes, improve accuracy, and ensure that every component of the supply chain meets rigorous quality standards. With innovations like AI, blockchain, and real-time data analytics, organizations such as SSOURCING INC. can elevate their quality control measures significantly.

Implementing AI and Machine Learning

Artificial Intelligence (AI) and machine learning are revolutionizing the landscape of supply chain quality management. By analyzing vast amounts of data from various sources, these technologies can identify patterns and predict potential issues before they escalate into costly problems. For instance, at SSOURCING INC., implementing AI-driven solutions allows for proactive decision-making that enhances overall supply chain quality while minimizing waste and inefficiencies.

Moreover, machine learning algorithms can continuously improve over time by learning from historical data and outcomes. This adaptability ensures that companies remain agile in a constantly changing market environment while maintaining high standards for supply chain quality. As businesses embrace these technologies, they not only enhance operational efficiency but also foster greater customer satisfaction through consistent product excellence.

Blockchain for Traceability

Blockchain technology is making waves in the realm of supply chain quality by providing unparalleled traceability and transparency. With its decentralized ledger system, blockchain enables businesses to track products at every stage of their journey—from raw material sourcing to final delivery—ensuring that each step adheres to established quality protocols. For SSOURCING INC., this means being able to verify the integrity of suppliers and materials more effectively than ever before.

The ability to trace products back through the entire supply chain also helps mitigate risks associated with recalls or compliance failures. If an issue arises with a product's quality, businesses can quickly identify where things went wrong and take corrective action without delay. This level of accountability not only boosts consumer trust but also reinforces the commitment to maintaining high standards in supply chain quality.

Real-time Data Analytics

Real-time data analytics has emerged as a game-changer for enhancing supply chain quality across industries. By harnessing live data streams from various points within the supply chain, companies can monitor performance metrics instantaneously and make informed decisions on the fly. At SSOURCING INC., utilizing real-time analytics allows teams to spot trends or anomalies early on—empowering them to address potential issues before they impact overall product quality.

Furthermore, this immediate access to information fosters collaboration among different departments involved in the supply chain process. When everyone is equipped with up-to-date insights on inventory levels or supplier performance, it creates a more cohesive approach toward achieving optimal supply chain quality together as a team rather than working in silos. Ultimately, real-time data analytics not only improves operational efficiency but also strengthens customer relationships through enhanced service delivery.

Sustainability and Ethical Practices

In today's world, sustainability and ethical practices are no longer just buzzwords; they are essential components of supply chain quality. Companies like SSOURCING INC. recognize that a commitment to environmental stewardship not only enhances brand reputation but also leads to long-term operational efficiency. As consumers become more environmentally conscious, the pressure for businesses to adopt sustainable practices is mounting.

Environmental Impact on Supply Chain Quality

The environmental impact of supply chains can significantly influence overall supply chain quality. From sourcing raw materials to the final delivery of products, every step can contribute to ecological degradation if not managed responsibly. SSOURCING INC. prioritizes eco-friendly practices by selecting suppliers who demonstrate a commitment to reducing their carbon footprint and minimizing waste, ultimately enhancing the integrity of the entire supply chain.

Moreover, implementing sustainable logistics solutions can lead to cost savings and improved efficiency, which directly correlates with higher supply chain quality. For instance, optimizing transportation routes reduces fuel consumption while ensuring timely deliveries—two factors that resonate well with both profitability and environmental responsibility. By focusing on these aspects, companies can achieve a harmonious balance between operational excellence and ecological sustainability.

Corporate Social Responsibility Initiatives

Corporate social responsibility (CSR) initiatives play a crucial role in fostering trust and loyalty among consumers while enhancing supply chain quality. SSOURCING INC.'s commitment to ethical sourcing practices ensures that all suppliers adhere to fair labor standards and environmentally responsible methods. This not only improves relationships within the supply chain but also boosts overall product quality by aligning with consumer values.

Investing in CSR initiatives often leads to enhanced brand recognition as customers increasingly favor companies that prioritize social responsibility over profit alone. Furthermore, transparent communication about these efforts strengthens consumer trust, which is paramount in today’s competitive market landscape focused on quality assurance in every aspect of production and distribution processes. Ultimately, when businesses like SSOURCING INC. champion CSR initiatives, they pave the way for a more responsible approach toward achieving superior supply chain quality.

The Role of Consumer Demands

Consumer demands have shifted dramatically over recent years; customers now expect brands to take an active stance on sustainability and ethical practices as part of their commitment to high supply chain quality. This shift has prompted companies like SSOURCING INC. to adapt their strategies accordingly by integrating sustainable practices into their core operations while ensuring transparency throughout the supply chain process.

As more consumers seek out environmentally friendly products, brands must respond by demonstrating how their sourcing choices positively impact both society and the planet without compromising on product excellence or availability—an essential aspect of maintaining high supply chain quality standards. The convergence of consumer expectations with corporate accountability drives innovation across industries as brands strive for continuous improvement in sustainability efforts while meeting growing market demands.

In summary, adopting sustainable practices is no longer optional; it’s imperative for businesses aiming for top-notch supply chain quality in today’s conscientious marketplace.

The Impact of COVID-19

The COVID-19 pandemic has been a seismic event that shook the foundations of global supply chains, exposing vulnerabilities and highlighting the critical importance of supply chain quality. With lockdowns, travel restrictions, and sudden shifts in consumer demand, many businesses found their operations disrupted in unprecedented ways. However, these challenges also sparked creativity and resilience among companies like SSOURCING INC., leading to innovative strategies that aimed to maintain or even improve supply chain quality amid chaos.

Disruptions and Resilience Strategies

The initial wave of disruptions caused by COVID-19 forced organizations to reevaluate their supply chain quality management practices. Companies faced delays in shipments, shortages of raw materials, and increased costs due to the need for alternative sourcing strategies. In response, resilient firms adopted multi-sourcing approaches and built buffer inventories while leveraging technology to enhance visibility across their networks—ensuring they could respond swiftly to changing circumstances.

For SSOURCING INC., this meant not only addressing immediate challenges but also investing in infrastructure that would enable agility moving forward. By prioritizing flexibility in supplier agreements and diversifying supplier bases, businesses could better navigate future disruptions while maintaining high standards for supply chain quality. This strategic pivot underscored the importance of being proactive rather than reactive when it comes to operational resilience.

Supply Chain Adaptation and Innovation

COVID-19 catalyzed a wave of adaptation and innovation within supply chains as companies sought new ways to uphold supply chain quality amidst uncertainty. The crisis prompted many organizations to accelerate digital transformation efforts; adopting technologies such as AI-driven forecasting tools became essential for predicting demand fluctuations accurately. Additionally, automation emerged as a key player in streamlining operations while ensuring consistency in product quality.

SSOURCING INC., recognizing the need for innovation during these times, embraced collaborative platforms that allowed real-time communication with suppliers and customers alike. This helped them stay ahead of potential disruptions while enhancing overall transparency throughout the supply chain process—ultimately improving overall supply chain quality. As businesses continue adapting post-pandemic, those who remain committed to innovation will likely emerge stronger than before.

Lessons Learned for Future Quality

As we reflect on the impact of COVID-19 on supply chains, several lessons emerge regarding maintaining high standards of supply chain quality going forward. First and foremost is the recognition that flexibility is paramount; companies must be prepared not only for expected challenges but also for unforeseen events that can disrupt operations at any time. Building robust contingency plans will become an integral part of any effective strategy moving forward.

Moreover, cultivating strong relationships with suppliers has never been more crucial; collaboration fosters trust, which can lead to better problem-solving during crises like pandemics or natural disasters. For SSOURCING INC., investing time into nurturing these partnerships proved invaluable during tumultuous times—demonstrating how effective communication can enhance overall supply chain quality despite external pressures.

In conclusion, COVID-19 served as both a wake-up call and an opportunity for improvement within global supply chains; embracing change will be essential for future success.

Collaboration and Communication

In the realm of supply chain quality, collaboration and communication are paramount. The intricate web of suppliers, manufacturers, and distributors demands a cohesive approach to ensure that every link in the chain maintains high standards. By fostering open lines of communication and collaboration, organizations can significantly enhance their supply chain quality.

Building Strong Supplier Relationships

Strong supplier relationships are the backbone of any successful supply chain quality strategy. When companies invest time in nurturing these connections, they create a foundation of trust that facilitates better communication and problem-solving. This collaborative spirit allows for quicker responses to issues and ensures that suppliers align with the company’s quality standards.

Moreover, engaging suppliers in discussions about quality expectations can lead to innovative solutions that benefit both parties. Regular meetings or check-ins can help identify potential risks early on, allowing for proactive measures to be taken before they escalate into larger problems. Ultimately, strong supplier relationships not only improve supply chain quality but also foster a more resilient network capable of adapting to market changes.

Cross-functional Teams for Quality Improvement

Cross-functional teams play a vital role in enhancing supply chain quality by bringing together diverse expertise from various departments within an organization. When representatives from procurement, logistics, production, and quality assurance collaborate on projects, they can address challenges from multiple perspectives. This holistic approach ensures that all aspects of the supply chain are considered when implementing improvements.

Additionally, cross-functional teams encourage knowledge sharing and innovation as team members learn from each other’s experiences and insights. By breaking down silos within an organization, these teams can streamline processes and drive continuous improvement in supply chain quality. The synergy created through such collaboration not only enhances operational efficiency but also leads to higher levels of customer satisfaction.

The Role of SSOURCING INC. in Enhancing Quality

At SSOURCING INC., we understand the critical importance of collaboration and communication in achieving exceptional supply chain quality. Our commitment to building strong partnerships with suppliers is evident in our rigorous selection process and ongoing engagement strategies aimed at ensuring alignment with our high-quality standards. By leveraging technology tools for real-time communication and feedback loops, we enhance transparency across our entire network.

Moreover, our cross-functional teams at SSOURCING INC., composed of experts from various disciplines like logistics management and product development, work tirelessly to identify opportunities for improvement within our operations. This collaborative effort enables us to respond swiftly to challenges while continuously refining our processes for optimal performance in supply chain quality management. Ultimately, it is this dedication to teamwork that empowers us to set new benchmarks for excellence across all facets of our business.

Conclusion

As we navigate the intricate world of supply chain quality, it's clear that embracing change is not just a necessity but a strategic advantage. Organizations like SSOURCING INC. are leading the charge in adapting to new technologies, regulations, and consumer expectations that shape today's supply chains. By fostering a culture of continuous improvement and innovation, businesses can ensure their supply chain quality remains resilient and competitive.

Embracing Change for Supply Chain Quality

To truly enhance supply chain quality, companies must be open to embracing change at every level of operation. This means investing in technology, training employees, and re-evaluating supplier relationships to align with evolving market demands. At SSOURCING INC., we understand that the agility to adapt not only boosts efficiency but also enhances overall product integrity and customer satisfaction.

Future Trends to Watch

Looking ahead, several trends are poised to redefine supply chain quality in profound ways. The integration of advanced technologies such as AI and blockchain will offer unprecedented levels of transparency and traceability, making it easier for companies to maintain high standards throughout their networks. Additionally, as sustainability continues to rise in importance among consumers, organizations must prioritize eco-friendly practices that align with their commitment to exceptional supply chain quality.

Final Thoughts on Quality Improvement

In conclusion, the journey toward improved supply chain quality is ongoing and multifaceted; it requires dedication from all stakeholders involved—from suppliers to end consumers. Companies like SSOURCING INC. stand at the forefront of this evolution by championing innovative solutions while maintaining ethical practices that resonate with modern values. By remaining vigilant about emerging trends and committed to continuous improvement, businesses can ensure they not only meet but exceed expectations in an ever-changing landscape.