Introduction

In today’s fast-paced business landscape, tracking supplier performance KPIs is not just a luxury; it’s a necessity. Organizations like SSOURCING INC. understand that the right metrics can make or break supplier relationships, ultimately influencing overall business success. By honing in on these key performance indicators, companies can ensure they’re not only meeting their operational goals but also fostering a culture of continuous improvement.

Key Reasons for Tracking Supplier Performance

The primary reason for tracking supplier performance KPIs is to enhance accountability and transparency within the supply chain. When businesses have a clear set of metrics to evaluate their suppliers, they can quickly identify areas for improvement and take corrective actions accordingly. Additionally, measuring these KPIs helps organizations like SSOURCING INC. mitigate risks associated with poor supplier performance, ensuring that quality standards are upheld.

The Impact of KPIs on Business Success

KPIs are the compass guiding businesses toward their strategic objectives; they help translate lofty goals into actionable insights. For instance, by focusing on supplier performance KPIs such as delivery times and quality scores, companies can optimize their operations and reduce costs significantly. Ultimately, robust KPI frameworks lead to improved customer satisfaction and loyalty—critical components of long-term business success.

What Makes KPIs Essential in Procurement

In procurement, KPIs serve as essential tools that align supplier capabilities with organizational needs and expectations. They provide valuable data that informs decision-making processes while fostering collaboration between suppliers and buyers alike. At SSOURCING INC., leveraging effective supplier performance KPIs ensures that procurement strategies are not only efficient but also adaptable to changing market demands.

Understanding Supplier Performance KPIs

In the world of procurement, understanding supplier performance KPIs is crucial for ensuring that your business runs smoothly and efficiently. These metrics serve as a compass, guiding organizations toward better decision-making and strategic planning. By measuring key aspects of supplier performance, businesses can identify areas for improvement, enhance relationships, and ultimately drive success.

The Definition and Importance of KPIs

Key Performance Indicators (KPIs) are quantifiable measures that help organizations assess their progress towards specific objectives. In the context of supplier performance, KPIs provide valuable insights into how well suppliers meet expectations regarding quality, delivery, cost efficiency, and relationship management. By focusing on these indicators, companies like SSOURCING INC. can ensure they are working with suppliers who align with their goals and contribute positively to their bottom line.

The importance of supplier performance KPIs cannot be overstated; they not only highlight successes but also reveal potential pitfalls before they escalate into significant issues. Without these metrics in place, businesses risk making uninformed decisions that could jeopardize their supply chain integrity and overall operational efficiency. Therefore, establishing a robust framework for evaluating supplier performance is essential for long-term sustainability.

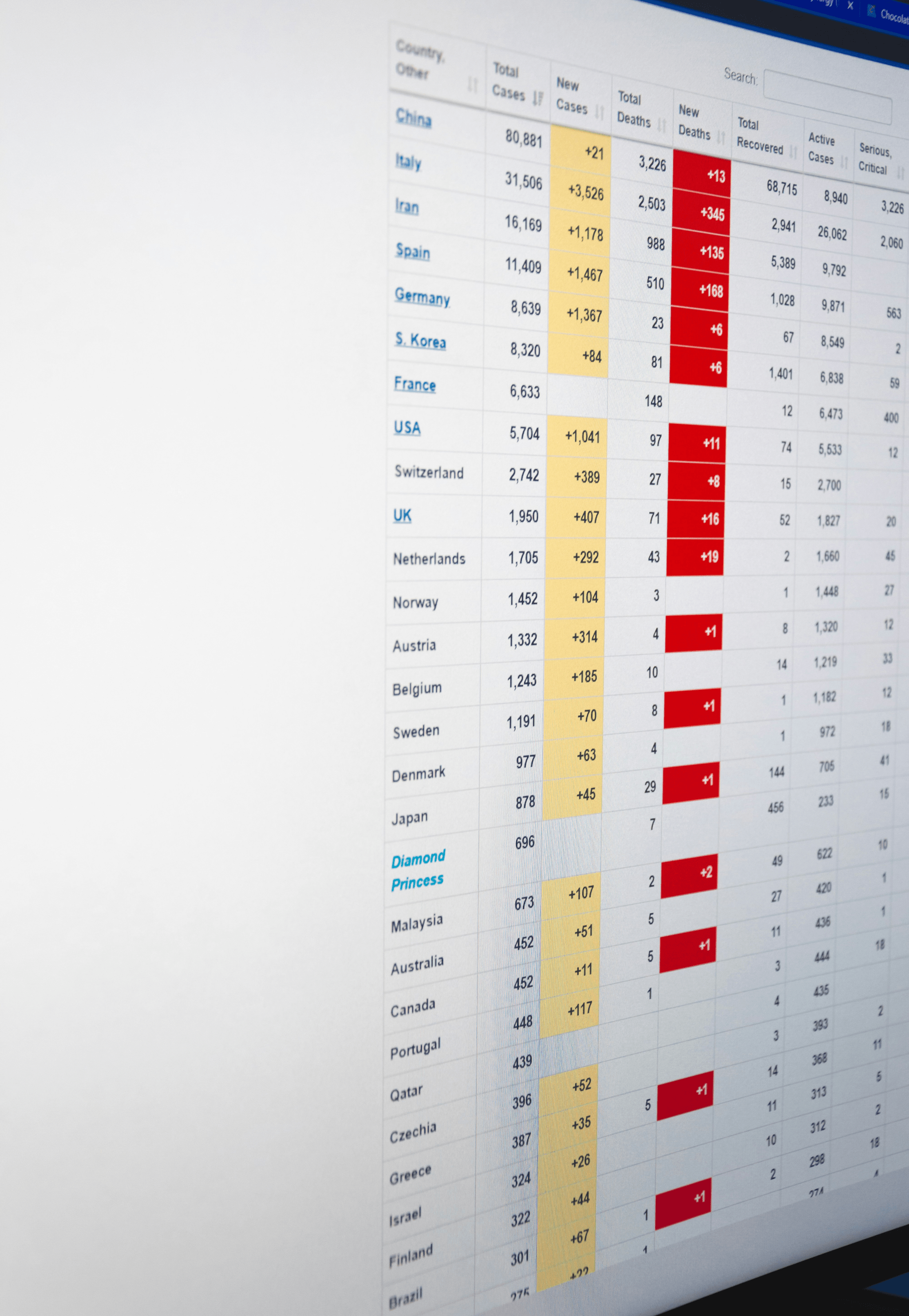

Types of Supplier Performance KPIs

Supplier performance KPIs come in various shapes and sizes to address different facets of the procurement process. Common types include quality metrics (such as defect rates), delivery performance indicators (like on-time delivery rates), financial metrics (including cost per unit), and relationship management scores (which assess communication effectiveness). Each type plays a pivotal role in painting a comprehensive picture of how well suppliers are performing.

For instance, quality-related KPIs help organizations gauge whether suppliers consistently deliver products that meet specified standards, while delivery performance indicators focus on the reliability of supply timelines. Financial KPIs delve into cost efficiency by analyzing expenses related to procurement processes or materials sourced from suppliers. By leveraging these diverse KPI types effectively, SSOURCING INC. can optimize its supply chain operations while fostering stronger partnerships with key vendors.

Aligning KPIs with Business Objectives

Aligning supplier performance KPIs with overarching business objectives is fundamental to achieving desired outcomes in procurement strategies. This alignment ensures that every metric tracked contributes directly to the company's goals—whether it's reducing costs, improving product quality or enhancing customer satisfaction levels through reliable deliveries. When KPI frameworks are designed with specific business objectives in mind, organizations can create a focused approach that drives meaningful results.

Moreover, regularly reviewing these aligned metrics allows companies like SSOURCING INC. to adapt quickly to changing market conditions or internal priorities without losing sight of what truly matters—supplier effectiveness aligned with business success! This proactive approach not only enhances accountability but also fosters an environment where continuous improvement thrives across all levels of the supply chain.

Quality Metrics That Matter

In the realm of procurement, quality metrics are not just numbers; they are the lifeblood of supplier relations. When you track supplier performance KPIs related to quality, you can identify areas for improvement and ensure that your suppliers meet your standards consistently. High-quality products lead to satisfied customers and ultimately drive business success, making it essential to prioritize these metrics.

The Role of Quality in Supplier Relations

Quality is the cornerstone of any successful supplier relationship. When suppliers deliver high-quality products or services, it fosters trust and collaboration between parties, which is crucial for long-term partnerships. Conversely, poor quality can lead to disputes, increased costs, and damaged reputations—something no business wants on its plate.

Key Quality-Related KPIs

To effectively measure quality in supplier performance KPIs, businesses should focus on several key indicators. These include defect rates, compliance with specifications, and customer complaints related to supplied products. By monitoring these KPIs regularly, SSOURCING INC. can ensure that its suppliers maintain high standards while also identifying potential risks before they escalate.

Real-World Examples of Quality Success

Consider a prominent example from the automotive industry: Toyota’s rigorous quality control processes have set benchmarks for others to follow. By employing stringent supplier performance KPIs focused on quality metrics like defect rates and production consistency, Toyota has managed to maintain its reputation for reliability and excellence over decades. Such examples demonstrate that when companies prioritize quality-related KPIs in their procurement strategies, they not only enhance their own operations but also strengthen their relationships with suppliers.

Delivery Performance Indicators

When it comes to supplier performance KPIs, timely deliveries can make or break a business relationship. Customers expect their orders to arrive on schedule, and any hiccup in the supply chain can lead to dissatisfaction, lost sales, and a tarnished reputation. This is why monitoring delivery performance is crucial for businesses aiming to maintain competitive advantage and foster strong supplier partnerships.

Importance of Timely Deliveries

Timely deliveries are the backbone of efficient supply chain management. When suppliers deliver products on time, businesses can meet customer demands effectively, ensuring smooth operations and enhancing customer satisfaction. Conversely, delivery delays often result in production stoppages or missed deadlines, which can have cascading effects throughout the organization—something SSOURCING INC. aims to avoid at all costs.

Moreover, timely deliveries contribute significantly to cost management by reducing the need for emergency shipments or last-minute sourcing solutions that can inflate expenses. By focusing on supplier performance KPIs related to delivery times, companies can identify potential issues before they escalate into significant problems. Thus, prioritizing punctuality not only strengthens relationships with suppliers but also enhances overall operational efficiency.

Critical Delivery Performance KPIs

Several key performance indicators help assess delivery effectiveness within supplier performance KPIs frameworks. On-time delivery rate (OTD) is perhaps the most critical metric; it measures the percentage of orders delivered by suppliers within the agreed timeframe. Another essential KPI is lead time variability; this tracks fluctuations in delivery times compared to established benchmarks and helps identify patterns that may signal underlying issues with specific suppliers.

Additionally, perfect order rate (POR) evaluates how many orders are delivered without any errors—no damage or inaccuracies—in quantity or quality upon arrival. This KPI reflects not just timeliness but also accuracy and reliability in service—an area where SSOURCING INC. emphasizes excellence when collaborating with its partners. By regularly monitoring these critical delivery performance KPIs, businesses can make informed decisions about their supply chain strategies.

How Amazon Excels in Delivery Metrics

Amazon has set a gold standard for delivery metrics that many aspire to achieve within their supplier performance KPIs frameworks. With its sophisticated logistics network and cutting-edge technology like predictive analytics and real-time tracking systems, Amazon consistently delivers packages on time while minimizing errors—a feat that has redefined consumer expectations globally. Their commitment to continuous improvement ensures they remain ahead of competitors by refining their processes based on data-driven insights.

One notable strategy employed by Amazon is its use of localized fulfillment centers, which drastically reduces shipping distances and timeframes—ensuring customers receive their orders quickly and efficiently every single time! Additionally, they leverage advanced machine learning algorithms that predict demand trends, allowing them to optimize inventory levels accordingly—a brilliant move that keeps them agile in an ever-changing market landscape.

By studying how industry leaders like Amazon excel in managing their delivery metrics through effective supplier performance KPIs, companies like SSOURCING INC. can glean valuable lessons for enhancing their own procurement practices while fostering stronger relationships with suppliers along the way.

Cost Efficiency and Financial KPIs

In the realm of supplier performance KPIs, cost efficiency stands as a cornerstone for evaluating supplier contributions to a business’s bottom line. Analyzing cost-related supplier performance involves scrutinizing various financial metrics to ensure that suppliers not only meet quality and delivery expectations but also provide value for money. By focusing on these financial indicators, companies like SSOURCING INC. can make informed decisions that enhance profitability while maintaining strong supplier relationships.

Analyzing Cost-Related Supplier Performance

When analyzing cost-related supplier performance, businesses need to look beyond just the price tag of goods or services. It’s essential to consider the total cost of ownership (TCO), which includes factors such as shipping costs, potential penalties for late deliveries, and the impact of quality issues on overall expenses. By employing effective supplier performance KPIs in this analysis, organizations can pinpoint areas where suppliers may be underperforming or where opportunities for savings exist.

Moreover, tracking these financial metrics helps businesses identify patterns over time that could indicate a shift in a supplier's reliability or efficiency. For instance, if a particular supplier consistently incurs higher costs due to delays or quality issues, it might be time to reassess their role in your supply chain strategy. Ultimately, effective analysis leads to smarter procurement decisions that align with SSOURCING INC.'s long-term financial goals.

Key Financial Performance Indicators

Key financial performance indicators (KPIs) are vital tools for assessing how well suppliers contribute to an organization's success from an economic standpoint. Some essential KPIs include cost per unit, purchase price variance (PPV), and return on investment (ROI). These metrics provide insights into how effectively suppliers manage their costs and how those costs impact your overall procurement budget.

Another critical KPI is the payment terms compliance rate; this metric evaluates whether suppliers adhere to agreed-upon payment schedules, which can significantly affect cash flow management for companies like SSOURCING INC. Additionally, tracking invoice accuracy rates ensures that billing discrepancies are minimized—an often overlooked aspect of financial performance that can lead to substantial savings over time. By focusing on these key financial KPIs, organizations can maintain a tighter grip on their budgets while fostering healthy supplier relationships.

Case Study: Walmart's Cost Management

Walmart serves as an exemplary case study in mastering cost management through robust supplier performance KPIs. The retail giant employs meticulous tracking of its supply chain expenses by leveraging data analytics and advanced forecasting techniques—ensuring they always get the best bang for their buck from suppliers. Their approach includes regular evaluations based on key financial indicators such as TCO and PPV.

Walmart’s commitment to understanding its supply chain costs has allowed it not just to negotiate better deals but also to foster long-term partnerships with suppliers who demonstrate consistent value delivery at competitive prices. This strategy has helped Walmart maintain its position as a market leader while ensuring customer satisfaction through low prices—a win-win scenario! Companies like SSOURCING INC., looking up to this model, can adopt similar tactics by integrating comprehensive cost-related KPIs into their procurement processes.

Supplier Relationship Management KPIs

In the ever-evolving landscape of procurement, managing supplier relationships is paramount for achieving business success. Supplier performance KPIs play a crucial role in fostering these relationships, allowing organizations like SSOURCING INC. to measure and enhance collaboration with suppliers effectively. By focusing on these key performance indicators, businesses can ensure that their partnerships are mutually beneficial and aligned with strategic objectives.

Building Strong Supplier Relationships

Building strong supplier relationships is akin to nurturing a garden; it requires attention, care, and the right tools to flourish. Engaging suppliers through open communication and regular feedback helps create an atmosphere of trust and transparency, which is essential for long-term success. By utilizing supplier performance KPIs, organizations can identify areas for improvement and celebrate achievements together, reinforcing the bond between partners.

Moreover, strong supplier relationships lead to better negotiation outcomes and improved service levels, ultimately benefiting both parties involved. SSOURCING INC. understands that a collaborative approach not only fosters loyalty but also encourages innovation among suppliers. This synergy can lead to enhanced product offerings and more efficient processes that drive overall business growth.

KPIs for Relationship Assessment

To effectively assess supplier relationships, it’s essential to establish relevant KPIs that provide insight into performance dynamics. Key relationship-focused KPIs might include communication effectiveness scores, responsiveness rates, and collaboration metrics that gauge how well teams work together across organizational boundaries. By tracking these supplier performance KPIs regularly, businesses can pinpoint strengths and weaknesses in their partnerships.

Additionally, evaluating the frequency of joint initiatives or projects can provide valuable context around relationship health; after all, collaboration often leads to breakthroughs in efficiency or quality improvements. SSOURCING INC.'s commitment to leveraging data-driven insights ensures they maintain robust partnerships while continuously adapting strategies based on KPI findings. This proactive approach cultivates an environment where both parties feel valued and motivated to succeed.

Lessons from Apple's Supplier Partnerships

Apple's approach to managing its suppliers offers valuable lessons in cultivating strong relationships through effective use of supplier performance KPIs. The tech giant emphasizes transparency by sharing critical metrics with its suppliers while also setting clear expectations regarding quality standards and delivery timelines—fostering accountability across the board. This collaborative framework not only enhances trust but also drives continuous improvement in every aspect of their supply chain.

By investing time in understanding each supplier's unique challenges and capabilities, Apple has been able to tailor its engagement strategies accordingly—ensuring alignment with broader business goals while maximizing value creation for all stakeholders involved. SSOURCING INC., inspired by such practices, recognizes the importance of adaptability when working with diverse suppliers across various industries; this flexibility allows them to forge deeper connections rooted in mutual respect.

Ultimately, learning from industry leaders like Apple enables organizations to refine their own approaches toward establishing successful partnerships through effective assessment of supplier performance KPIs—creating pathways for shared success well into the future.

Conclusion

In the fast-paced world of procurement, investing in supplier performance KPIs is not just a good idea; it’s essential for sustained success. These metrics provide invaluable insights that can drive strategic decisions and foster continuous improvement. By focusing on supplier performance KPIs, businesses can enhance their operational efficiency, reduce costs, and ultimately improve customer satisfaction.

Why Investing in KPIs is Crucial

The importance of supplier performance KPIs cannot be overstated; they are the backbone of effective supply chain management. By measuring key metrics such as quality, delivery, and cost efficiency, organizations can identify areas for improvement and make data-driven decisions. This proactive approach not only mitigates risks but also enhances collaboration with suppliers, leading to stronger partnerships that benefit all parties involved.

How SSOURCING INC. Can Enhance Performance

At SSOURCING INC., we understand that effective supplier performance KPIs are vital for unlocking your business’s full potential. Our innovative solutions streamline the tracking and analysis of these metrics, ensuring you have real-time visibility into your supply chain health. With our expertise, you can leverage supplier performance KPIs to optimize relationships and drive value throughout your procurement processes.

Future Trends in Supplier Performance Measurement

Looking ahead, the landscape of supplier performance measurement is evolving rapidly due to advancements in technology and data analytics. We will likely see a greater emphasis on predictive analytics to anticipate issues before they arise while integrating AI-driven tools for real-time KPI tracking. As businesses increasingly adopt these innovations, the role of supplier performance KPIs will become even more critical in shaping successful procurement strategies.