Introduction

In the ever-evolving landscape of supply chains, understanding Supplier Performance Management KPIs has become essential for businesses striving for excellence. These key performance indicators serve as a compass, guiding organizations like SSOURCING INC. in assessing and enhancing their supplier relationships. By establishing clear metrics, companies can better navigate the complexities of supplier performance and ultimately drive their success.

Understanding Supplier Performance Management KPIs

Supplier Performance Management KPIs are specific metrics used to evaluate how well suppliers meet predefined standards and expectations. These indicators encompass various aspects of supplier performance, such as quality, delivery time, cost efficiency, and compliance with regulations. For SSOURCING INC., grasping the nuances of these KPIs is crucial to ensure that suppliers align with business objectives and contribute positively to overall operational efficiency.

Why KPIs Are Essential for Suppliers

KPIs are not just numbers; they are vital tools that help suppliers understand where they stand in relation to their clients' expectations. By implementing effective supplier performance management KPIs, companies can foster transparency and accountability throughout the supply chain. For SSOURCING INC., this means building stronger partnerships with suppliers that lead to improved service delivery and enhanced competitiveness in the marketplace.

Key Trends in Supplier Performance for 2025

As we look ahead to 2025, several key trends are poised to shape supplier performance management strategies across industries. Increasing emphasis on sustainability will drive organizations to incorporate environmental metrics into their supplier performance management KPIs. Additionally, advancements in technology will enable real-time monitoring solutions that provide deeper insights into supplier activities—transforming how businesses like SSOURCING INC. approach vendor relationships moving forward.

Defining Key Supplier Performance Metrics

In the realm of supplier performance management KPI, defining effective metrics is crucial to ensure that suppliers contribute positively to your business goals. These metrics serve as benchmarks for evaluating supplier efficiency, reliability, and overall contribution to your supply chain. By establishing clear performance indicators, businesses like SSOURCING INC. can enhance collaboration with suppliers and drive continuous improvement.

What Makes a KPI Effective

An effective KPI in supplier performance management must be specific, measurable, attainable, relevant, and time-bound (SMART). This means that each KPI should provide clarity on what is being measured and why it matters for your organization’s objectives. Additionally, the best KPIs are actionable; they should empower teams at SSOURCING INC. to make informed decisions based on real-time data rather than guesswork.

Furthermore, an effective KPI aligns with both operational efficiency and strategic goals. For example, if one of your business goals is to reduce lead times by 20%, a corresponding KPI could track the average delivery time from suppliers. Ultimately, the right KPIs will not only reflect past performance but also guide future actions within supplier performance management.

Aligning KPIs with Business Goals

Aligning KPIs with overarching business goals is essential for maximizing impact in supplier performance management KPI initiatives. Each metric should directly relate to specific objectives such as cost reduction, quality improvement, or enhanced customer satisfaction at SSOURCING INC. When KPIs are aligned with these objectives, it becomes easier to motivate suppliers toward shared success.

Moreover, this alignment fosters accountability among stakeholders involved in the supply chain process. If a supplier knows that their performance will be evaluated against clearly defined metrics tied to business objectives, they are more likely to prioritize those areas effectively. In turn, this creates a culture of collaboration where both parties work together towards common goals.

Lastly, reviewing and adjusting these aligned KPIs periodically ensures that they remain relevant amid changing market conditions or organizational priorities. As new challenges arise or strategies evolve at SSOURCING INC., so too should the metrics used to evaluate suppliers’ contributions.

Real-World Examples of Effective KPIs

To illustrate how effective KPIs can transform supplier relationships within the framework of supplier performance management KPI practices at SSOURCING INC., consider these real-world examples:

1. On-Time Delivery Rate: This metric tracks what percentage of orders are delivered by suppliers on or before the agreed-upon date—a vital indicator of reliability.

2. Quality Defect Rate: Measuring the number of defective products received from suppliers allows businesses to assess quality control processes effectively.

3. Cost Variance: Comparing actual costs against projected costs for goods supplied over a specific period can help identify pricing inconsistencies or opportunities for negotiation.

These examples showcase how targeted metrics can lead not just to improved operational efficiencies but also stronger partnerships between companies like SSOURCING INC. and their suppliers—ultimately driving better outcomes for everyone involved.

Best Practices for KPI Implementation

Implementing effective supplier performance management KPIs is crucial for ensuring that your supply chain runs smoothly and efficiently. With the right approach, you can transform raw data into actionable insights that drive supplier accountability and enhance overall performance. Here, we’ll explore the essential steps, tools, and lessons learned from industry leaders to help you optimize your supplier relationships.

Steps for Effective KPI Integration

Integrating supplier performance management KPIs requires a systematic approach that begins with clear communication of expectations. First, identify what specific metrics align with your business goals; this ensures everyone involved understands the objectives and their role in achieving them. Next, develop a framework for collecting data consistently; regular reviews will foster transparency and help maintain focus on continuous improvement.

Once you've established a baseline, engage suppliers in the process by sharing goals and encouraging feedback on the KPIs selected. This collaborative effort not only strengthens relationships but also allows suppliers to take ownership of their performance metrics. Finally, regularly revisit your KPIs to adapt them as necessary; market conditions change rapidly, and so should your approach to managing supplier performance.

Tools for Monitoring Supplier Performance

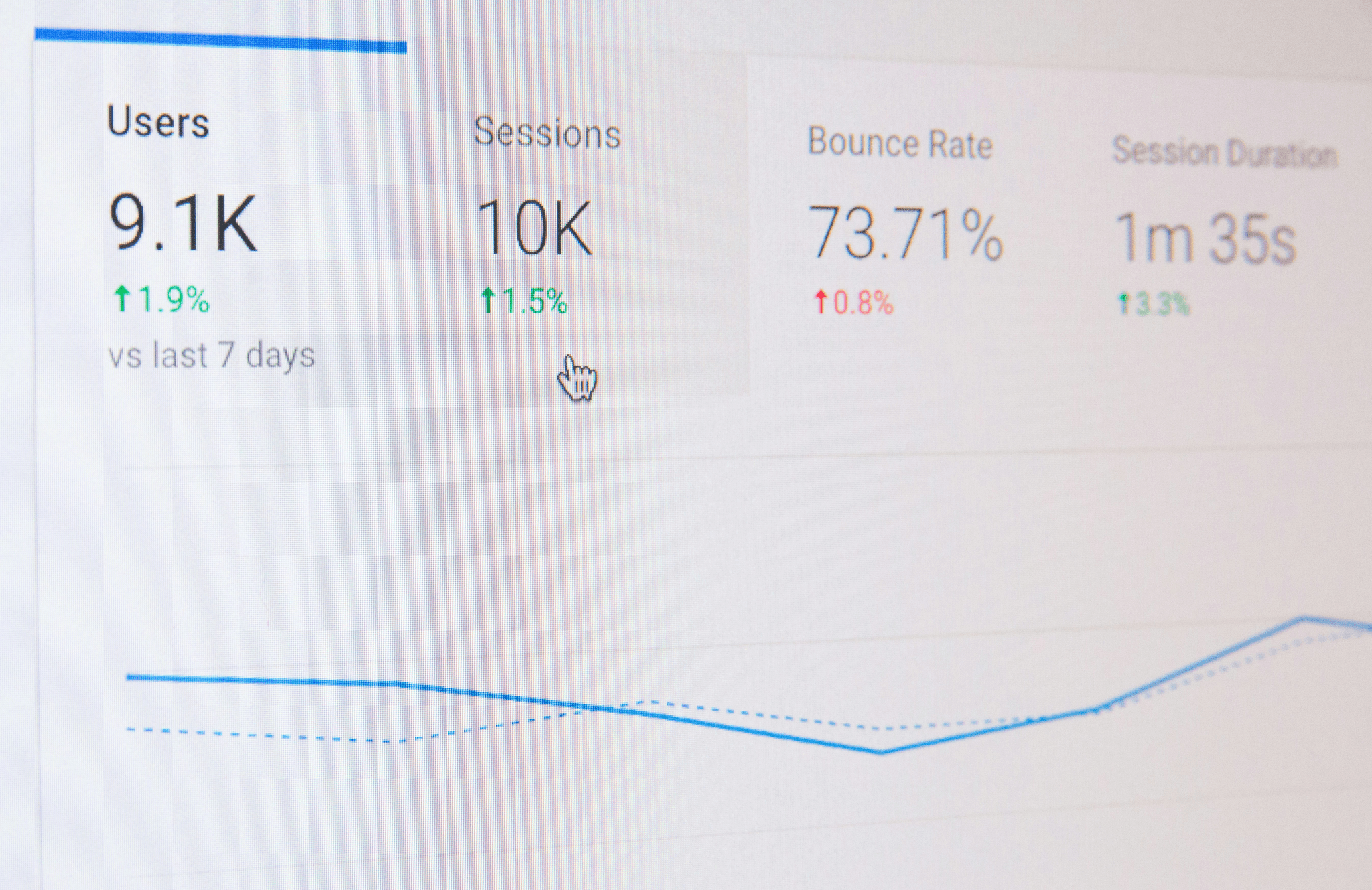

In today’s fast-paced business environment, leveraging technology is key to effective supplier performance management KPI oversight. Various software solutions can streamline data collection and analysis processes while providing real-time insights into supplier activities. Platforms such as SSOURCING INC.'s proprietary tools offer dashboards that visualize key metrics at a glance—allowing you to spot trends or issues before they escalate.

Additionally, integrating automated alerts can notify stakeholders of significant deviations from expected performance levels—ensuring timely interventions when necessary. Collaboration tools also play an essential role by facilitating communication between teams and suppliers alike; this promotes alignment around shared objectives related to those all-important KPIs. Remember: the right tools not only save time but also enhance accuracy in tracking supplier performance.

Lessons from Industry Leaders

Learning from industry leaders can provide invaluable insights into effective supplier performance management KPI strategies. Companies like Amazon have mastered the art of leveraging data analytics to fine-tune their supply chains continually; they emphasize agility by adapting their KPIs based on evolving market conditions or consumer demands. One key takeaway is that flexibility in KPI design enables organizations to pivot quickly when faced with unexpected challenges.

Another lesson is the importance of fostering strong partnerships with suppliers through transparent communication regarding expectations related to KPIs—this builds trust and encourages collaboration towards common goals. Lastly, successful companies often invest in training programs aimed at both internal teams and external partners; equipping everyone with knowledge about what constitutes good supplier performance helps ensure everyone is on the same page regarding those critical metrics.

The Role of Technology in KPI Management

In the rapidly evolving landscape of supplier performance management, technology plays a pivotal role in shaping how businesses define and track their KPIs. By harnessing advanced tools and systems, organizations can gain deeper insights into supplier performance, ensuring that they remain competitive and agile. SSOURCING INC. recognizes that leveraging technology not only streamlines processes but also enhances decision-making capabilities.

Leveraging Data Analytics for Insights

Data analytics has transformed the way companies approach supplier performance management KPIs. By analyzing historical data, organizations can identify trends and patterns that inform future strategies, allowing them to make data-driven decisions rather than relying on gut feelings or outdated metrics. With tools like predictive analytics, businesses can forecast potential issues with suppliers before they arise, ensuring smoother operations and stronger partnerships.

Moreover, advanced analytics can provide insights into supplier reliability, quality control issues, and compliance levels—all critical components of effective KPI management. SSOURCING INC. employs these techniques to ensure that their suppliers meet established benchmarks consistently while identifying areas for improvement proactively. Ultimately, using data analytics not only enhances transparency but also fosters a culture of continuous improvement among suppliers.

Real-Time Monitoring Solutions

In today's fast-paced environment, real-time monitoring solutions are essential for effective supplier performance management KPIs. These systems allow organizations to track key metrics instantly rather than waiting for periodic reviews or reports—essentially putting them in the driver's seat when it comes to managing supplier relationships. With real-time insights at their fingertips, companies can quickly address any deviations from expected performance levels.

For instance, dashboards equipped with live data feed enable procurement teams to visualize KPIs such as delivery times and product quality on-the-fly. This immediate access allows teams at SSOURCING INC. to respond swiftly to any emerging issues or opportunities with their suppliers—transforming potential problems into actionable insights before they escalate into significant concerns. The ability to monitor performance continuously reinforces accountability among suppliers while enhancing collaboration between partners.

Case Study: How Amazon Optimizes Supplier KPIs

Amazon is often hailed as a pioneer in utilizing technology for effective supplier performance management KPIs—and for good reason! By implementing sophisticated algorithms and machine learning models within its supply chain operations, Amazon has revolutionized how it assesses supplier efficiency and responsiveness over time. This case study illustrates the power of technology in driving successful KPI strategies.

One notable example is Amazon's use of automated systems that analyze vast amounts of transactional data from suppliers daily; this enables them to identify underperforming vendors quickly or flag discrepancies in inventory levels immediately. As a result, Amazon maintains high standards across its supply chain while minimizing disruptions—ultimately enhancing customer satisfaction through timely deliveries and product availability.

SSOURCING INC., inspired by such industry leaders, aims to adopt similar technologies tailored specifically toward optimizing their own supplier relationships through effective KPI management practices.

Common Pitfalls in Supplier Performance Management

Navigating the landscape of supplier performance management KPIs can be tricky, and missteps can lead to significant setbacks. Companies like SSOURCING INC. must be vigilant in identifying and avoiding these common pitfalls to ensure that their supplier relationships flourish rather than flounder. Understanding these pitfalls is crucial for maintaining a competitive edge in today's fast-paced market.

Avoiding KPI Misalignment

KPI misalignment can wreak havoc on your supplier performance management strategy. When KPIs don't align with your overarching business objectives, it creates confusion and can lead to wasted resources—after all, what’s the point of tracking metrics that don’t drive value? At SSOURCING INC., it's vital to ensure that every KPI directly supports your business goals, fostering a cohesive strategy that benefits both suppliers and the organization.

To avoid this pitfall, start by clearly defining your business objectives and translating them into specific, measurable KPIs tailored for each supplier relationship. Regularly review these metrics to ensure they remain relevant as market conditions change or as your company grows. Remember, an effective KPI should not only measure performance but also inspire action toward shared goals.

Understanding the Human Element

While data drives decisions in supplier performance management KPIs, it's essential not to overlook the human element involved in these relationships. Suppliers are not just numbers on a dashboard; they are partners whose engagement and morale significantly impact performance outcomes. At SSOURCING INC., recognizing the importance of communication and collaboration with suppliers is key to fostering strong partnerships.

To effectively manage this human aspect, invest time in building relationships with suppliers through regular check-ins and feedback sessions. Encourage open dialogue about challenges faced by suppliers so you can collaboratively find solutions rather than merely imposing metrics from above. After all, a happy supplier is often a high-performing one!

Examples of Mistakes to Learn From

Learning from others’ mistakes is one of the best ways to refine your approach to supplier performance management KPIs at SSOURCING INC. One common mistake companies make is focusing too heavily on quantitative metrics while ignoring qualitative factors such as supplier satisfaction or innovation capabilities—these elements can greatly influence overall performance but are often overlooked.

Another pitfall occurs when organizations set unrealistic expectations for their suppliers based on poorly defined KPIs or historical data without considering current market dynamics or individual supplier capabilities. This can lead to frustration on both sides when targets become unattainable or irrelevant over time. By studying these examples closely, you can adjust your own strategies accordingly and create more effective partnerships moving forward.

Future-Proofing Your Supplier KPIs

In the ever-evolving landscape of supply chain management, future-proofing your supplier performance management KPIs is essential for sustained success. As market dynamics shift, businesses must adapt their strategies to remain competitive and resilient. SSOURCING INC. emphasizes the importance of being proactive rather than reactive in managing supplier relationships.

Preparing for Market Changes

To effectively prepare for market changes, organizations need to stay ahead of industry trends and anticipate shifts in consumer behavior. This involves regularly reviewing and updating supplier performance management KPIs to ensure they remain relevant and aligned with business objectives. By adopting a flexible approach, companies can quickly pivot their strategies based on real-time data and insights.

Engaging suppliers in discussions about market trends can also provide valuable perspectives that enhance your KPI framework. Collaborating with partners allows for a more comprehensive understanding of potential disruptions or opportunities within the supply chain ecosystem. Ultimately, agile supplier performance management KPIs will empower businesses to navigate uncertainties with confidence.

Embracing Sustainability in Supplier Metrics

Sustainability has emerged as a critical factor influencing supplier performance management KPIs in recent years. Companies are increasingly recognizing the need to integrate environmental, social, and governance (ESG) criteria into their evaluation processes. SSOURCING INC. advocates for developing KPIs that not only measure traditional performance metrics but also assess suppliers' sustainability practices.

By incorporating sustainability into your KPI framework, you can drive positive change throughout your supply chain while meeting consumer demand for ethical sourcing practices. This approach not only enhances brand reputation but also mitigates risks associated with non-compliance and environmental impact. As stakeholders prioritize sustainable practices, aligning your supplier performance management KPIs with these values will become essential for long-term viability.

Insights from Supply Chain Innovators

Learning from supply chain innovators can provide invaluable insights into optimizing your supplier performance management KPIs effectively. Industry leaders often share best practices that emphasize transparency, collaboration, and technology-driven solutions as key components of successful KPI frameworks. SSOURCING INC.’s research highlights how forward-thinking companies leverage data analytics to refine their metrics continually.

Innovators understand that a one-size-fits-all approach doesn’t work; tailoring your KPIs based on specific business goals is crucial for achieving desired outcomes in supplier relationships. Furthermore, fostering an environment of continuous improvement encourages suppliers to innovate alongside you—ultimately leading to greater efficiency and competitiveness within the market landscape.

As we move forward into an uncertain future filled with opportunities and challenges alike, embracing innovative approaches will be vital in ensuring that our supplier performance management KPIs remain effective.

Conclusion

In the ever-evolving landscape of supply chain management, understanding and implementing supplier performance management KPIs is crucial for success. These metrics not only help businesses gauge supplier efficiency but also align with broader organizational goals. As we wrap up this discussion, let’s revisit the essential insights and explore the long-term benefits of effective KPI management.

Recap of Essential KPI Insights

Throughout our exploration, we've highlighted that effective supplier performance management KPIs are tailored to meet specific business objectives while being measurable and relevant. Aligning these KPIs with your company’s strategic goals ensures that you can monitor progress effectively and make informed decisions. Remember, real-world examples from industry leaders demonstrate that successful implementation hinges on clarity and alignment.

The Long-Term Benefits of Effective KPI Management

Investing in robust supplier performance management KPIs yields significant long-term benefits for organizations like SSOURCING INC. Not only do these metrics enhance operational efficiency and reduce costs, but they also foster stronger relationships with suppliers by promoting transparency and accountability. Over time, companies that prioritize KPI management can expect improved quality, faster delivery times, and a more resilient supply chain.

Next Steps for Optimizing Supplier Relationships

To truly optimize your supplier relationships, start by reviewing your current supplier performance management KPIs to ensure they align with evolving business needs. Engage with suppliers to co-create metrics that reflect mutual goals; this collaboration will enhance trust and commitment on both sides. Finally, leverage technology and data analytics tools to continuously monitor these KPIs for actionable insights—because staying ahead in today’s market means being proactive rather than reactive.