Introduction

Manufacturing has long been the backbone of economies worldwide, and today it stands at the forefront of innovation and growth. The manufacturing capital of the world is not merely a title; it represents a dynamic landscape where technology, labor, and resources converge to create value. In this era of rapid change, understanding the nuances of global manufacturing can provide insights into economic resilience and competitive advantage.

The Rise of the Manufacturing Capital

The rise of the manufacturing capital has transformed cities and regions into bustling hubs of production and innovation. Countries like China have emerged as leaders in this space, showcasing their ability to scale operations efficiently while maintaining quality. As we explore this phenomenon, it becomes clear that the manufacturing capital is not just about sheer output; it's also about fostering an ecosystem that nurtures creativity and technological advancement.

Why Manufacturing Matters Today

In today's interconnected world, manufacturing matters more than ever before. It serves as a critical engine for job creation, economic stability, and technological progress. With companies like SSOURCING INC., which thrives on optimizing supply chains in the manufacturing capital of the world, we see firsthand how vital this sector is for driving global commerce and improving living standards.

Overview of Global Manufacturing Leaders

The landscape of global manufacturing leaders is diverse and constantly evolving. While China often takes center stage due to its vast production capabilities, countries like Germany maintain a stronghold with their emphasis on precision engineering and quality craftsmanship. Meanwhile, India's burgeoning role in global manufacturing signals a shift towards emerging markets becoming significant players in the quest for innovation within the manufacturing capital of the world.

Historical Context of Manufacturing

Understanding the historical context of manufacturing provides a foundation for appreciating its current significance and future potential. The journey from artisanal production to the manufacturing capital of the world reflects profound changes in technology, economy, and society. This evolution has not only shaped industries but also influenced global trade dynamics, with companies like SSOURCING INC. strategically navigating these waters.

A Brief History of Industrialization

The industrial revolution marked a pivotal shift in manufacturing, transitioning from manual labor to mechanized production methods. Beginning in the late 18th century, this transformation propelled countries like Britain into a new economic era, establishing them as early leaders in the manufacturing capital of the world. As steam power and machinery became commonplace, production efficiency skyrocketed, setting the stage for modern manufacturing practices.

Milestones in Manufacturing Evolution

Several key milestones have defined the evolution of manufacturing over centuries. The introduction of assembly lines in the early 20th century revolutionized mass production, allowing manufacturers to produce goods at unprecedented scales and speeds—an essential characteristic for any contender in the race for becoming the manufacturing capital of the world. More recently, advancements such as computer-aided design (CAD) and additive manufacturing (3D printing) have further transformed how products are conceived and produced.

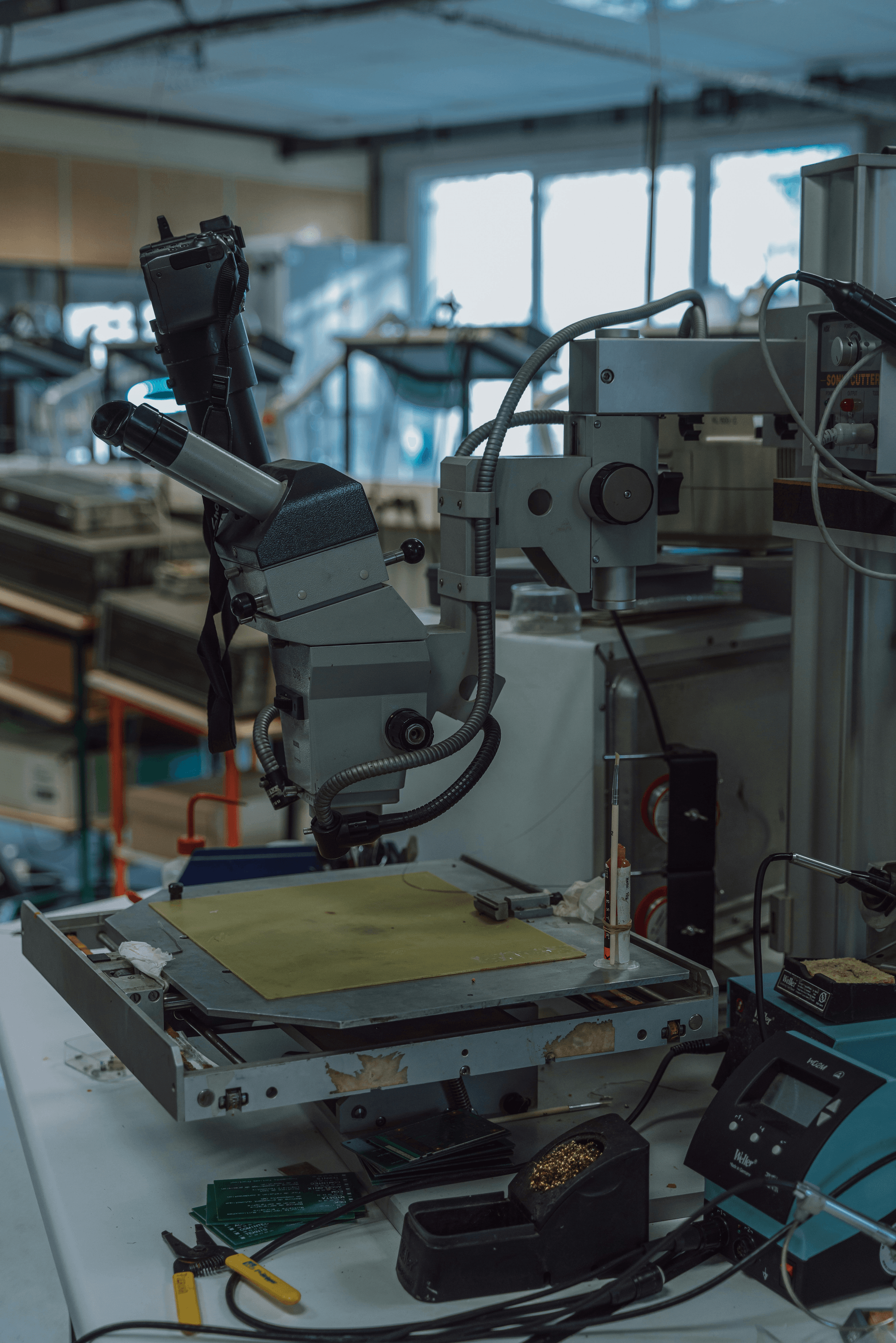

The Role of Technology in Manufacturing

Technology has been both a catalyst and a cornerstone for growth within the manufacturing sector throughout history. From simple tools to complex robotics, innovations have continuously reshaped how goods are made—ensuring that nations striving to be recognized as leaders must embrace these advancements to maintain their status as a top player in global markets like SSOURCING INC.'s operations. Today’s landscape showcases smart factories equipped with AI-driven systems that optimize processes while reducing waste—underscoring technology's critical role in ensuring sustainability within modern manufacturing practices.

Key Players in the Manufacturing Capital of the World

When discussing the manufacturing capital of the world, three key players emerge as titans in this industry: China, Germany, and India. Each of these countries brings unique strengths and strategies to the global manufacturing landscape. Understanding their roles helps us appreciate how they shape today's manufacturing dynamics.

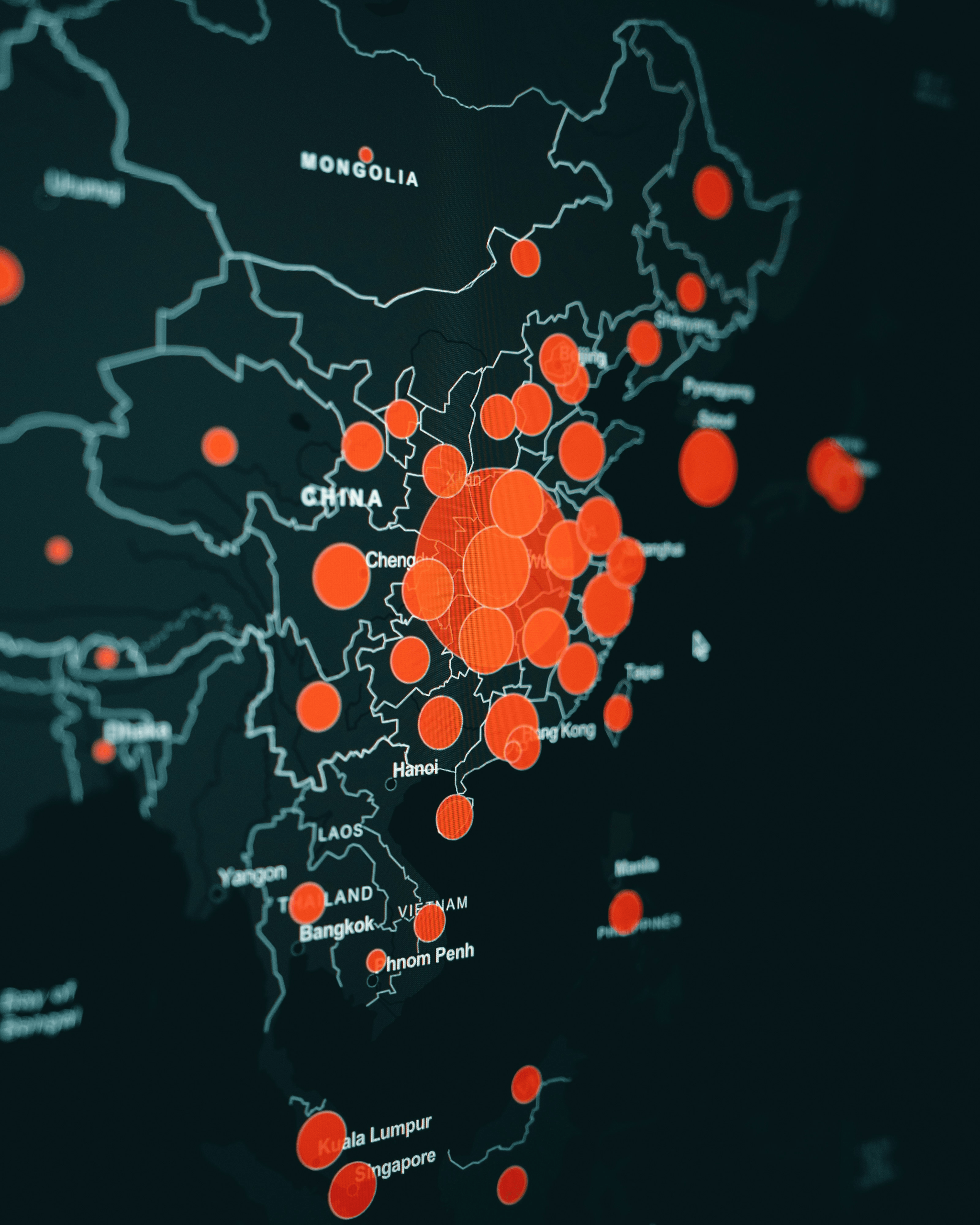

Analyzing China's Manufacturing Dominance

China has firmly established itself as the manufacturing capital of the world, boasting an unparalleled production capacity that fuels its economy and global trade. The country’s strategic investments in infrastructure, technology, and a vast labor force have enabled it to dominate various sectors, from textiles to electronics. Moreover, initiatives like Made in China 2025 aim to elevate domestic industries into high-tech arenas, ensuring that China's grip on global manufacturing remains strong for years to come.

However, challenges loom on the horizon for China’s manufacturing sector. Rising labor costs and increasing environmental regulations are pushing companies to rethink their strategies. Companies like SSOURCING INC., which focus on supply chain optimization and sourcing solutions, are crucial allies for navigating these evolving landscapes while maintaining competitiveness.

The Resilience of Germany's Manufacturing Sector

Germany is often hailed as a bastion of engineering excellence within the manufacturing capital of the world narrative. Renowned for its precision engineering and high-quality standards, German manufacturers excel in sectors such as automotive and machinery production. The “Industry 4.0” initiative highlights Germany's commitment to integrating digital technologies into traditional manufacturing processes—ensuring that it remains at the forefront despite global competition.

This resilience is further bolstered by a strong emphasis on vocational training and education within Germany's workforce development programs. By fostering a skilled labor pool equipped with modern technological know-how, German manufacturers can adapt swiftly to market demands while maintaining quality control—something that is vital in today’s fast-paced environment. Companies like SSOURCING INC., which emphasize collaboration with suppliers across borders, play a pivotal role in enhancing these capabilities.

India's Emerging Role in Global Manufacturing

India is rapidly carving out its niche within the manufacturing capital of the world landscape as it positions itself as an attractive alternative for businesses seeking diversification beyond China. With its youthful population and growing middle class, India offers a burgeoning consumer market alongside competitive labor costs that appeal to multinational corporations looking for cost-effective production options. Government initiatives such as Make in India further incentivize foreign investment by simplifying regulatory frameworks and promoting local sourcing.

As India scales up its industrial base, challenges remain—particularly regarding infrastructure development and skill shortages among workers entering this expanding sector. However, initiatives aimed at improving education systems are beginning to bridge this gap effectively over time. Collaborations with firms like SSOURCING INC., which specialize in optimizing supply chains across various regions including India’s emerging markets, can enhance efficiency while tapping into this potential growth engine.

Innovation and Technology in Manufacturing

Innovation and technology are transforming the landscape of the manufacturing capital of the world. As industries strive to improve efficiency, reduce costs, and enhance product quality, they are increasingly turning to cutting-edge technologies. Companies like SSOURCING INC. are at the forefront of this revolution, leveraging advancements to maintain a competitive edge.

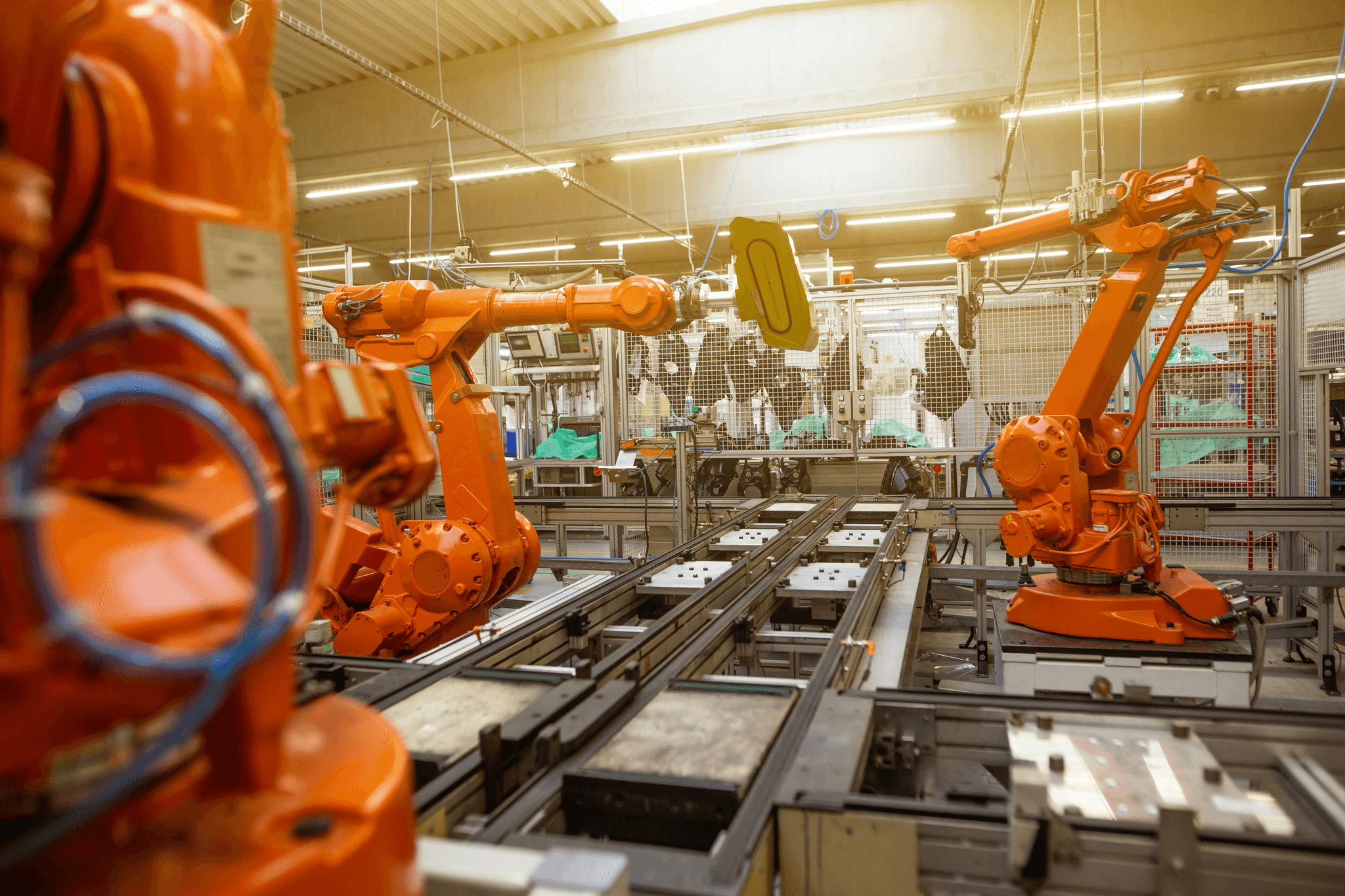

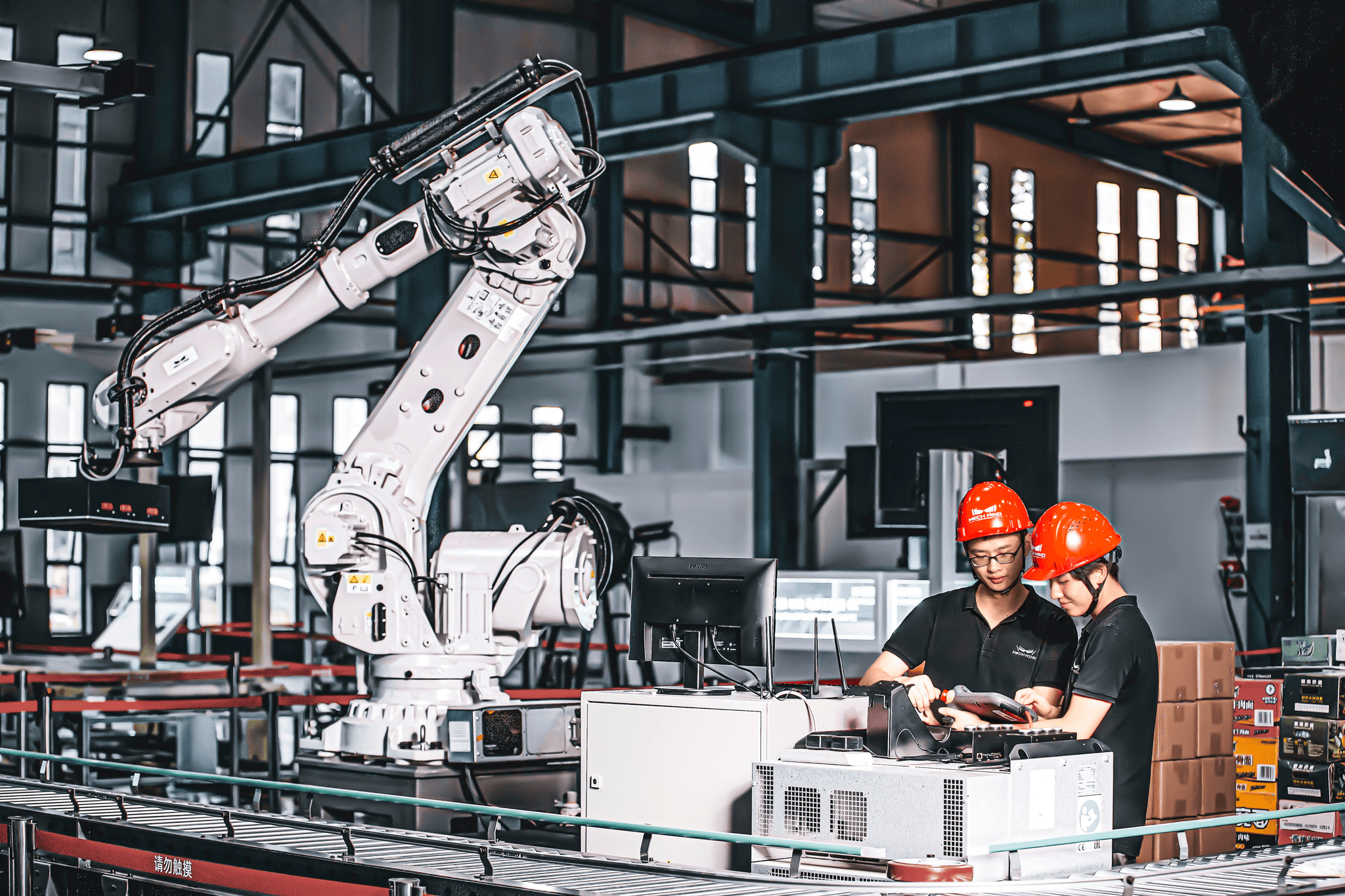

The Impact of AI and Automation

Artificial Intelligence (AI) and automation are reshaping how products are made in the manufacturing capital of the world. With AI-driven analytics, manufacturers can predict maintenance needs, optimize processes, and enhance decision-making capabilities. Automation not only speeds up production but also minimizes human error, paving the way for higher quality standards that companies like SSOURCING INC. strive to achieve.

Moreover, as factories adopt smart technologies, they become more adaptable to changing market demands. This adaptability is crucial for maintaining a robust manufacturing sector that can respond swiftly to consumer preferences and global trends. As a result, businesses that embrace AI and automation will be better positioned in an increasingly competitive environment.

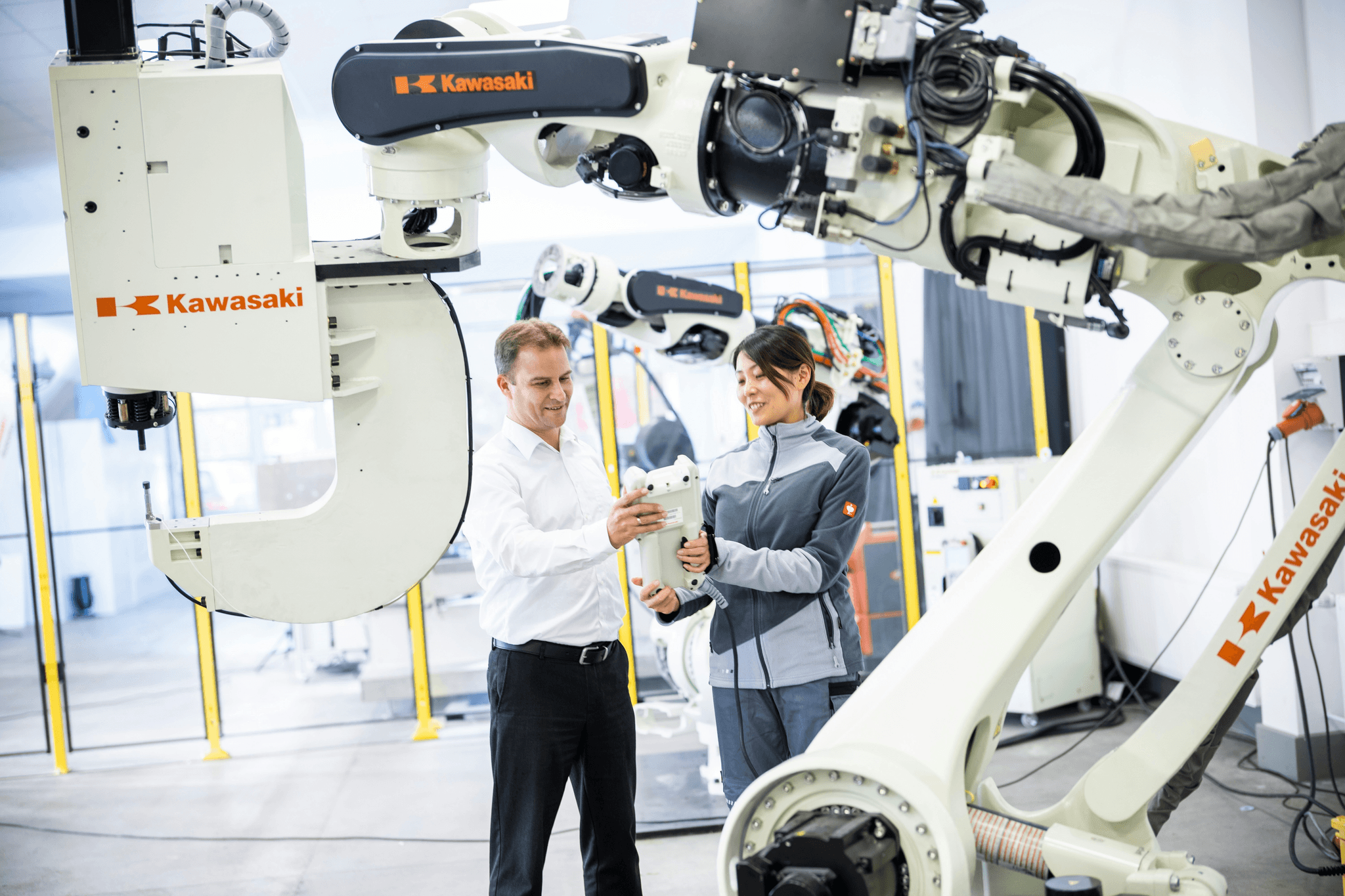

Smart Factories: The Future of Manufacturing

Smart factories represent a significant leap toward realizing the full potential of the manufacturing capital of the world. These facilities utilize interconnected devices and IoT (Internet of Things) technology to create seamless communication between machines and systems. This integration allows for real-time data collection and analysis, enabling manufacturers like SSOURCING INC. to make informed decisions that drive operational efficiency.

The future is bright for smart factories as they promise increased productivity through optimized workflows and reduced downtime due to predictive maintenance capabilities. Furthermore, these innovations help minimize waste by streamlining processes—an essential factor in meeting sustainability goals while remaining competitive on a global scale. As smart factories proliferate across various sectors, they will redefine what it means to manufacture efficiently.

Sustainable Manufacturing Practices

Sustainability has become a cornerstone for many businesses within the manufacturing capital of the world as environmental concerns take center stage globally. Companies like SSOURCING INC., recognizing their responsibility towards both society and nature, are implementing sustainable practices throughout their operations—from sourcing raw materials responsibly to minimizing waste production during manufacturing processes.

Adopting energy-efficient technologies not only reduces carbon footprints but also leads to cost savings over time—making sustainability both an ethical choice and a financially savvy strategy for manufacturers aiming for longevity in an ever-evolving market landscape. Furthermore, embracing circular economy principles helps companies recycle materials effectively while creating new revenue streams from previously discarded products.

As we move forward into an era where consumers prioritize eco-friendly products more than ever before, those who invest in sustainable practices will undoubtedly gain a significant advantage in capturing market share within this dynamic landscape.

Labor Markets and Workforce Development

The manufacturing capital of the world is not just defined by its factories and output; it’s also shaped by the workforce that drives innovation and productivity. As industries evolve, so too does the landscape of manufacturing jobs, presenting both challenges and opportunities for workers. Understanding these changes is crucial for businesses like SSOURCING INC., which aim to stay competitive in a rapidly shifting environment.

The Changing Landscape of Manufacturing Jobs

In recent years, the manufacturing sector has witnessed a significant transformation in job roles and requirements. Traditional assembly line positions are increasingly being replaced by more specialized roles that require technical expertise and problem-solving skills. This shift reflects the growing reliance on automation and technology, making it essential for workers to adapt to new demands in the manufacturing capital of the world.

Moreover, with globalization reshaping supply chains, many companies are now looking for talent that can navigate complex international markets while maintaining quality standards. The result is a dynamic job market where flexibility and continuous learning are paramount. Companies like SSOURCING INC. must focus on attracting skilled labor while fostering a culture of innovation to thrive in this evolving landscape.

Skills Needed for the Modern Manufacturing World

As we venture deeper into an era dominated by technological advancements, certain skills have emerged as critical for success in today’s manufacturing environment. Proficiency in data analytics, robotics, and programming languages are becoming increasingly vital as smart factories gain traction within the manufacturing capital of the world. Workers equipped with these skills will not only enhance operational efficiency but also contribute to innovative practices that drive growth.

Additionally, soft skills such as teamwork, communication, and adaptability cannot be overlooked; they play an essential role in creating a cohesive workplace atmosphere where collaboration leads to success. Employers must prioritize training programs that address both hard and soft skill development to ensure their workforce remains competitive globally. At SSOURCING INC., investing in employee training can yield substantial returns through improved productivity and employee satisfaction.

Education's Role in Workforce Development

Education serves as a cornerstone for workforce development within the manufacturing sector, especially as industries seek skilled professionals who can meet modern challenges head-on. Partnerships between educational institutions and manufacturers are crucial for aligning curricula with industry needs—ensuring students acquire relevant knowledge before entering the workforce. This collaboration can help bolster local economies while reinforcing a strong foundation for future leaders within the manufacturing capital of the world.

Vocational training programs have gained prominence as effective pathways into high-demand careers within manufacturing; they provide hands-on experience that traditional education sometimes lacks. Furthermore, initiatives aimed at promoting STEM (science, technology, engineering, mathematics) education can inspire younger generations to consider careers in this vital sector—ultimately addressing skill shortages faced by companies like SSOURCING INC.. By prioritizing education reform tailored to industry demands, we can create a robust pipeline of talent ready to tackle tomorrow’s challenges.

The Global Supply Chain Dynamics

In the ever-evolving landscape of global manufacturing, understanding supply chain dynamics is crucial for maintaining competitiveness and resilience. The manufacturing capital of the world relies heavily on intricate networks that connect suppliers, manufacturers, and consumers across vast distances. With recent disruptions highlighting vulnerabilities, businesses are increasingly focused on creating supply chains that can withstand shocks and adapt to changing circumstances.

Understanding Supply Chain Resilience

Supply chain resilience refers to the ability of a supply chain to prepare for, respond to, and recover from unexpected disruptions. In the context of the manufacturing capital of the world, this means developing strategies that not only mitigate risks but also enhance agility in operations. Companies like SSOURCING INC. are leading the charge by implementing robust risk management frameworks that anticipate potential challenges while ensuring continuity in production.

One key aspect of resilience is diversification; relying on a single source or region can lead to significant vulnerabilities. By spreading their sourcing across multiple geographies and suppliers, firms can better navigate uncertainties—whether they stem from natural disasters or geopolitical tensions. This proactive approach not only strengthens individual companies but also fortifies the entire manufacturing ecosystem.

The Importance of Local vs. Global Sourcing

In today’s interconnected economy, companies face a pivotal decision: should they prioritize local sourcing or embrace global supply chains? Each approach has its merits and drawbacks within the framework of the manufacturing capital of the world. Local sourcing can enhance responsiveness and reduce transportation costs while fostering community relationships; however, it may limit access to certain materials or specialized expertise.

On the other hand, global sourcing allows manufacturers like SSOURCING INC. to tap into a broader talent pool and benefit from economies of scale. Yet this strategy comes with challenges such as longer lead times and increased vulnerability to international disruptions. Ultimately, striking a balance between local and global sourcing is essential for optimizing efficiency while maintaining flexibility in an unpredictable market.

How SSOURCING INC. Navigates Supply Chains

SSOURCING INC., recognized for its innovative approaches in navigating complex supply chains, employs cutting-edge technology to streamline operations effectively within the manufacturing capital of the world. By leveraging data analytics and AI-driven insights, they enhance visibility across their entire supply network—allowing them to make informed decisions swiftly amidst uncertainty.

Moreover, SSOURCING INC.'s commitment to building strong relationships with regional suppliers complements their global strategies by ensuring quality control while minimizing risks associated with long-distance logistics. This dual approach not only safeguards operational integrity but also fosters sustainable practices that resonate with modern consumers' values—making them an exemplary player in global manufacturing dynamics.

The future lies in adaptable supply chains that marry local strengths with global reach—a vision clearly embodied by forward-thinking companies like SSOURCING INC., who understand that collaboration is key in this complex web we call modern manufacturing.

Conclusion

As we look to the future, it’s clear that the manufacturing capital of the world is on the brink of transformation. Innovations in technology and sustainability are reshaping how goods are produced, making processes more efficient and environmentally friendly. Embracing these changes will be crucial for nations vying for leadership in this dynamic sector.

Embracing the Future of Manufacturing

The future of manufacturing is not just about keeping up; it’s about leading the charge into a new era. With advancements like AI and automation, companies such as SSOURCING INC. are at the forefront of this revolution, redefining what it means to be part of the manufacturing capital of the world. By leveraging cutting-edge technologies, manufacturers can enhance productivity while reducing waste—an essential balance in today’s eco-conscious market.

The Importance of Collaboration in Manufacturing

In an increasingly interconnected world, collaboration has become a cornerstone for success in manufacturing. Countries must work together to share knowledge and resources if they wish to maintain their status as leaders in this field—especially those aspiring to be recognized as part of the manufacturing capital of the world. SSOURCING INC. exemplifies this spirit by fostering partnerships that drive innovation and efficiency across supply chains.

Making Sense of the Manufacturing Landscape

Understanding today’s manufacturing landscape requires a keen eye on global trends and local dynamics alike. The interplay between advanced technologies, skilled labor forces, and sustainable practices will dictate who thrives as a leader in what is often referred to as the manufacturing capital of the world. As we navigate these complexities, companies like SSOURCING INC. are committed to staying ahead by adapting strategies that respond effectively to both challenges and opportunities.