Introduction

Welcome to a comprehensive guide on manufacturing processes brought to you by SSOURCING INC. In today's competitive market, understanding different manufacturing processes is crucial for businesses looking to stay ahead of the curve. Choosing the right manufacturing process can make or break a product's success in the market, and optimizing these processes is key to achieving efficiency and cost-effectiveness.

Understanding Different Manufacturing Processes

Understanding the various manufacturing processes, such as casting, molding, machining, joining, forming, and additive manufacturing, is essential for making informed decisions about production methods. Each process has its own advantages and limitations, and knowing how they work can help businesses determine which one best suits their specific needs.

Importance of Choosing the Right Manufacturing Process

Choosing the right manufacturing process is vital for achieving high-quality products at competitive prices. It impacts production time, costs, and overall product performance. By selecting the most suitable process for their products, businesses can ensure that they meet customer demands while maintaining profitability.

Key Considerations for Optimizing Manufacturing Processes

Optimizing manufacturing processes involves considering factors such as material selection, equipment capabilities, workforce skills, and production volume. By carefully analyzing these aspects and making necessary adjustments, companies can improve productivity and reduce waste in their operations.

Overview of Manufacturing Processes

When it comes to manufacturing processes, it's crucial to understand the various methods available. Casting and molding are traditional techniques that involve pouring molten material into a mold to create a specific shape, while machining and joining rely on cutting, drilling, and welding to produce intricate components. On the other hand, forming and additive manufacturing utilize innovative technologies like 3D printing to build products layer by layer, offering new possibilities for design and customization.

Casting and Molding

Casting and molding are versatile manufacturing processes that can be used for producing a wide range of products, from simple shapes to complex parts. These methods are commonly employed in industries such as automotive, aerospace, and consumer goods. By utilizing molds or dies, SSOURCING INC. can efficiently mass-produce items with consistent quality and precision. This cost-effective approach is ideal for creating components with intricate details or unique geometries.

Machining and Joining

Machining involves shaping materials through cutting, drilling, or grinding processes using specialized tools such as lathes or mills. Joining techniques like welding or soldering are then used to assemble individual parts into a final product. With expertise in precision engineering, SSOURCING INC. excels in machining and joining operations to deliver high-performance components for diverse applications across industries.

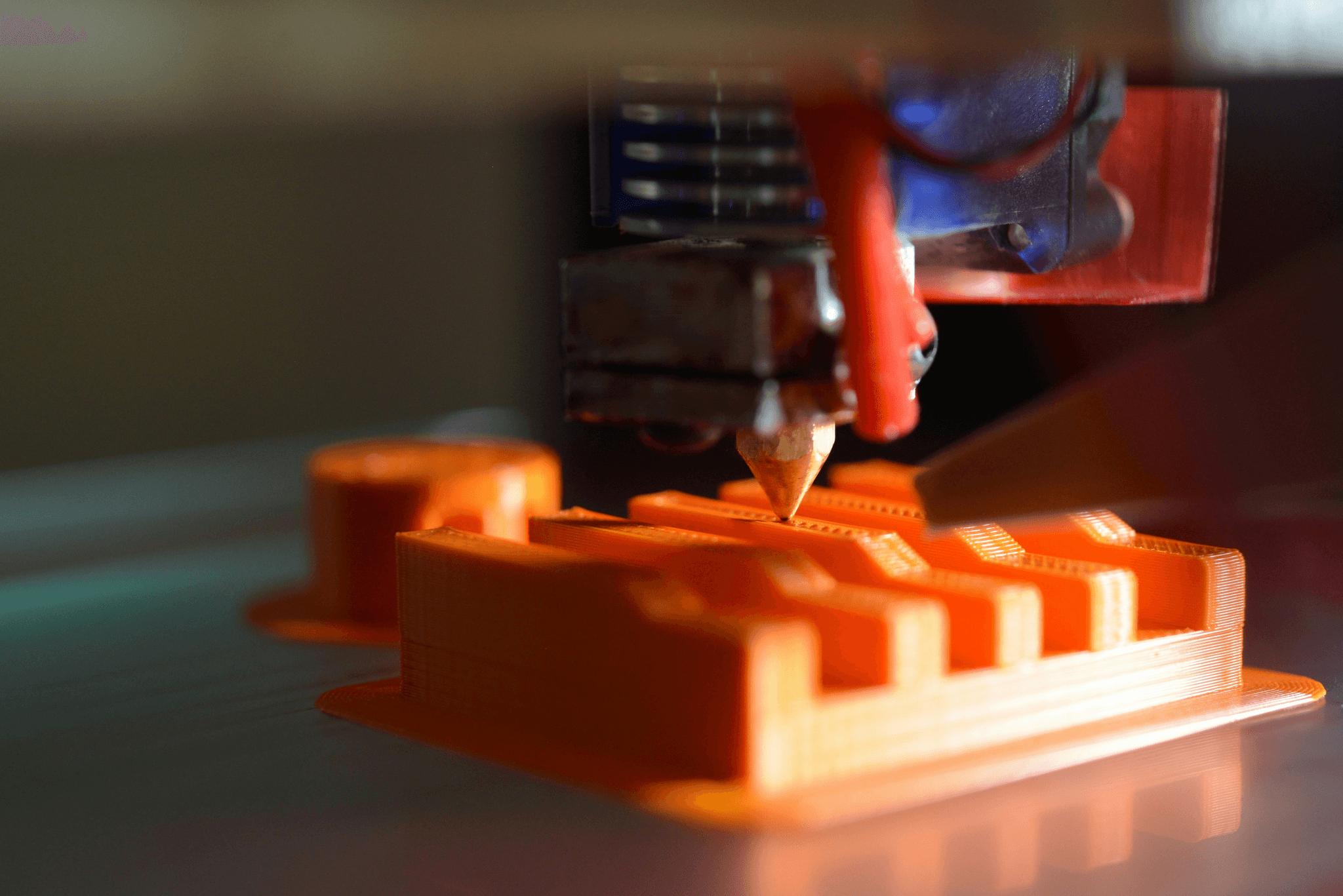

Forming and Additive Manufacturing

Forming encompasses various methods like bending, stamping, or forging metal sheets into desired shapes while additive manufacturing involves building objects layer by layer using 3D printing technology. SSOURCING INC.'s commitment to innovation enables us to leverage these advanced techniques for rapid prototyping, customized production runs, and complex geometries that traditional methods cannot achieve.

Efficiency in Manufacturing Processes

In today's competitive market, optimizing manufacturing processes is crucial for business success. Lean manufacturing principles play a key role in eliminating waste and improving efficiency throughout the production cycle. By implementing lean methodologies, SSOURCING INC. can streamline operations, reduce lead times, and enhance overall productivity.

Lean Manufacturing Principles

Lean manufacturing focuses on continuous improvement and waste reduction to achieve operational excellence. By embracing concepts such as 5S, value stream mapping, and Kaizen events, companies can identify and eliminate non-value-added activities in their manufacturing processes. This results in improved resource utilization, higher quality products, and increased customer satisfaction.

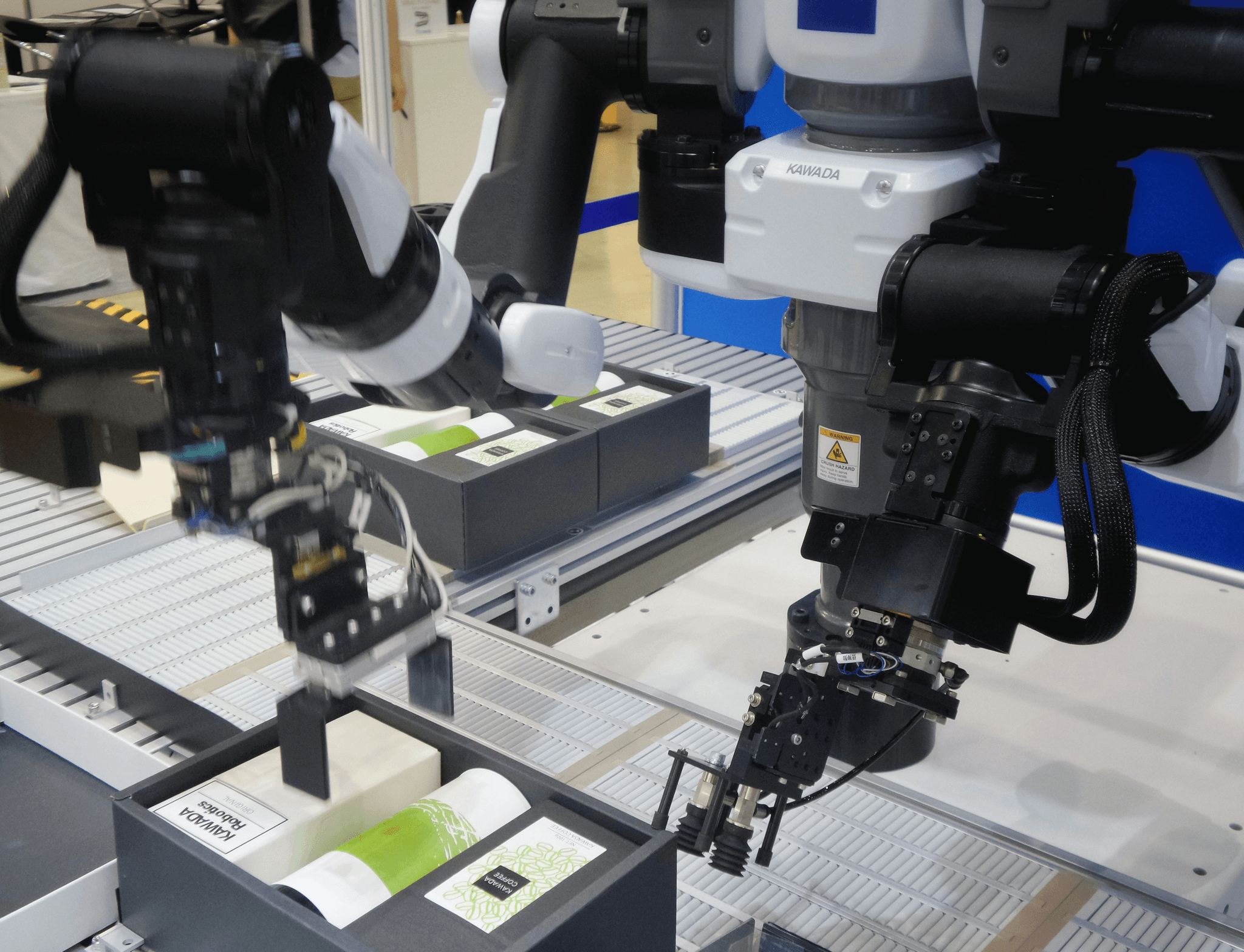

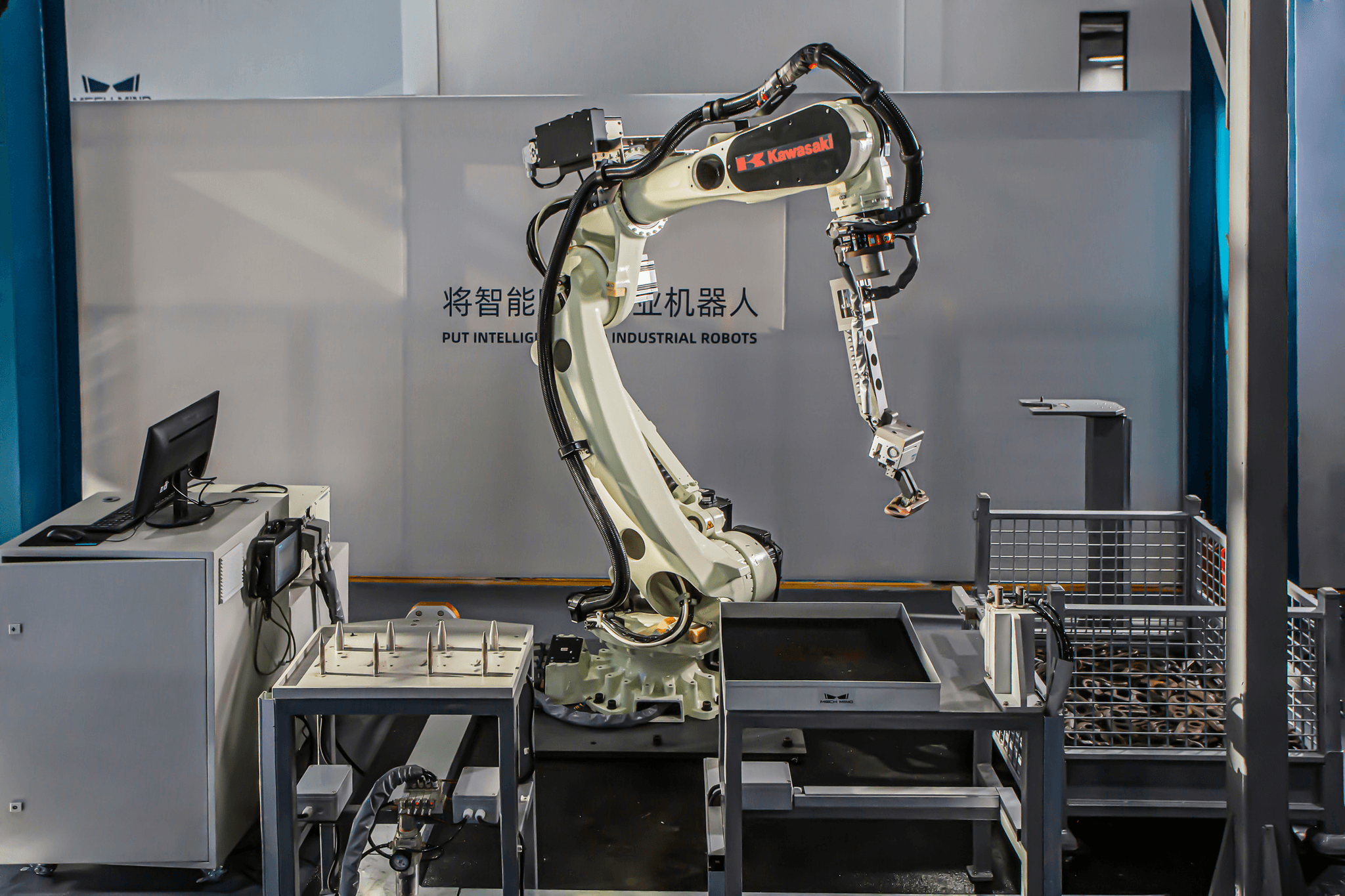

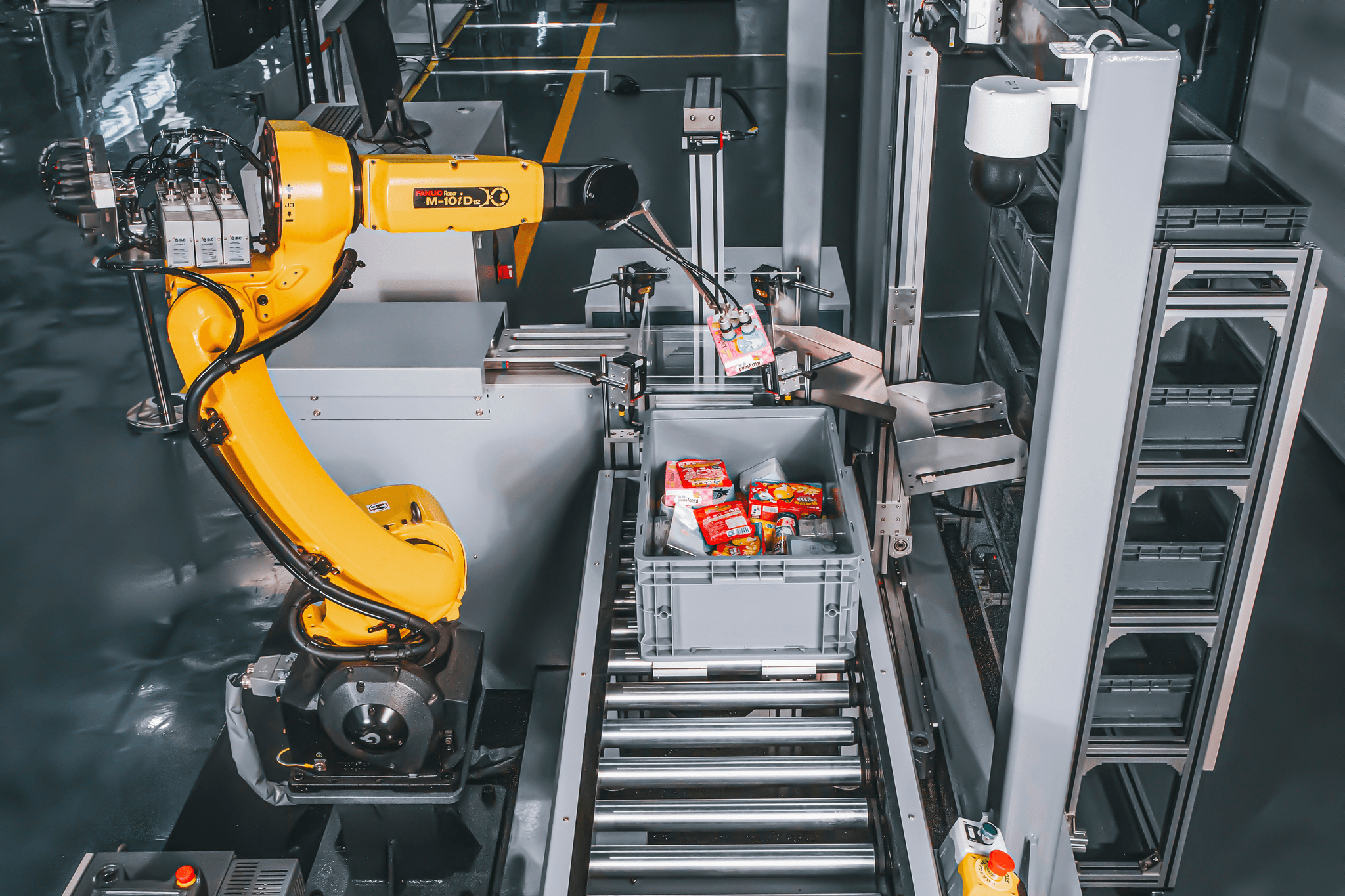

Automation and Robotics

Automation and robotics have revolutionized modern manufacturing by enhancing speed, precision, and consistency in production processes. By leveraging advanced technologies such as robotic arms and automated assembly lines, SSOURCING INC. can significantly increase output while minimizing human error. This not only boosts efficiency but also creates a safer work environment for employees.

Quality Control and Continuous Improvement

Quality control is essential for maintaining high standards in manufacturing processes. Through rigorous inspection protocols and adherence to ISO standards, SSOURCING INC. can ensure that products meet or exceed customer expectations. Additionally, fostering a culture of continuous improvement allows the company to adapt to changing market demands and stay ahead of the competition.

By integrating lean principles, automation technologies, and a commitment to quality control into its operations, SSOURCING INC. can achieve unparalleled efficiency in its manufacturing processes while staying at the forefront of industry innovation.

Sustainable Manufacturing Processes

As we look towards a more sustainable future, it's crucial for companies like SSOURCING INC. to prioritize recycling and waste reduction in their manufacturing processes. Implementing efficient waste management systems and promoting recycling initiatives can significantly reduce the environmental impact of production activities. By incorporating these practices, we can contribute to a cleaner and healthier planet for future generations.

Recycling and Waste Reduction

SSOURCING INC. is committed to minimizing waste by implementing comprehensive recycling programs across all manufacturing facilities. By segregating and recycling materials such as metal, plastic, and paper, we aim to divert significant amounts of waste from landfills while also reducing our overall carbon footprint. Our goal is to create a circular economy where resources are utilized efficiently, promoting a more sustainable approach to manufacturing processes.

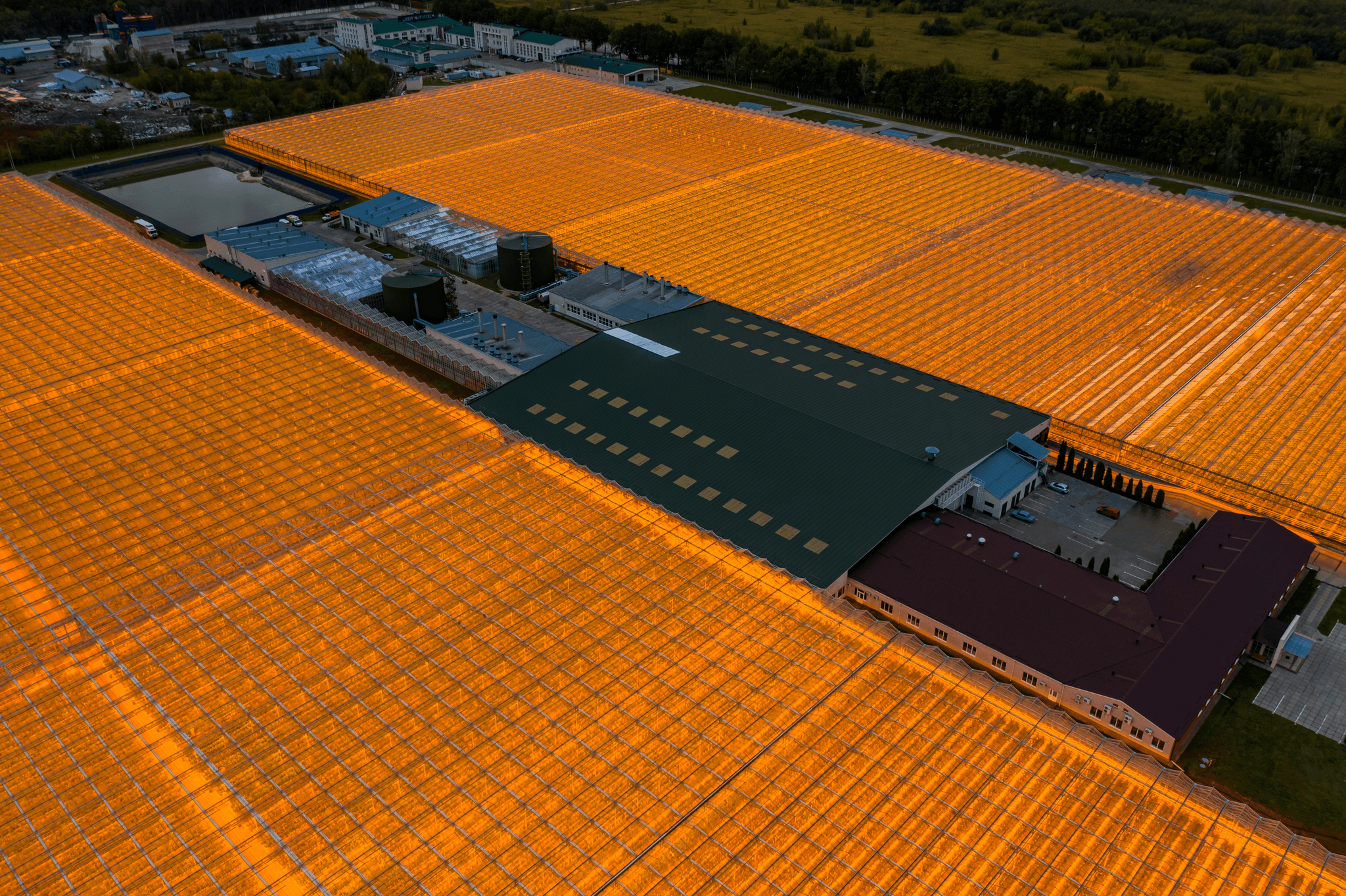

Renewable Energy Integration

At SSOURCING INC., we understand the importance of transitioning towards renewable energy sources in our manufacturing operations. By harnessing solar, wind, and hydroelectric power, we can significantly reduce our reliance on fossil fuels and decrease greenhouse gas emissions associated with traditional energy consumption. Embracing renewable energy integration not only aligns with our commitment to sustainability but also helps in creating a cleaner environment for future generations.

Environmentally Friendly Materials

In line with our dedication to sustainable manufacturing processes, SSOURCING INC. is actively exploring the use of environmentally friendly materials in our production activities. This includes leveraging bio-based plastics, recycled metals, and sustainable alternatives to conventional raw materials that have a lower environmental impact throughout their lifecycle. By prioritizing the use of eco-friendly materials, we aim to minimize resource depletion while promoting a more sustainable approach to manufacturing.

Advanced Technologies in Manufacturing Processes

3D Printing and Smart Manufacturing

3D printing has revolutionized manufacturing processes by enabling rapid prototyping and customization of products. With the ability to create complex geometries and reduce material waste, 3D printing offers SSOURCING INC. a competitive edge in product development. Smart manufacturing, on the other hand, integrates data analytics and automation to optimize production efficiency, allowing for real-time monitoring and predictive maintenance.

Internet of Things (IoT) in Manufacturing

The Internet of Things (IoT) has transformed traditional manufacturing processes by connecting machines and devices to gather real-time data for analysis. By leveraging IoT, SSOURCING INC. can enhance operational visibility, improve supply chain management, and enable predictive maintenance for equipment. This interconnected ecosystem enables seamless communication between different components of the manufacturing process.

Artificial Intelligence and Predictive Maintenance

Artificial intelligence (AI) plays a crucial role in optimizing manufacturing processes by analyzing large datasets to identify patterns and predict potential equipment failures before they occur. By implementing AI-driven predictive maintenance strategies, SSOURCING INC. can minimize downtime, reduce maintenance costs, and extend the lifespan of machinery. This proactive approach ensures smooth operations while maximizing productivity.

Future Trends in Manufacturing Processes

Industry 4.0 and Digital Transformation

The future of manufacturing processes is heavily influenced by Industry 4.0, which encompasses the integration of digital technologies such as IoT, AI, and big data analytics into the manufacturing environment. This digital transformation enables SSOURCING INC. to enhance efficiency, productivity, and decision-making through real-time data monitoring and analysis.

Customization and On-demand Manufacturing

Customization and on-demand manufacturing are becoming increasingly important trends as consumer preferences continue to evolve. SSOURCING INC. is leveraging advanced technologies to meet the growing demand for personalized products, allowing for greater flexibility in production processes and enabling quick response to market changes.

Global Supply Chain Integration

Global supply chain integration is essential for SSOURCING INC.'s success in an interconnected world economy. By embracing advanced technologies such as blockchain and advanced logistics systems, the company can ensure seamless coordination with suppliers and distributors worldwide, resulting in improved efficiency and reduced lead times.

By embracing these future trends in manufacturing processes, SSOURCING INC. is poised to stay ahead of the competition while meeting the evolving needs of its customers worldwide.

Conclusion

In conclusion, the optimization of manufacturing processes is crucial for SSOURCING INC. to stay competitive in the industry. By implementing efficient manufacturing processes, our company can reduce production costs and lead times while maintaining high-quality standards. Leveraging innovation in streamlined manufacturing will allow us to adapt to changing market demands and technological advancements, ensuring our continued success in the future.

Enhancing Competitiveness Through Efficient Manufacturing Processes

Efficient manufacturing processes are essential for SSOURCING INC. to enhance its competitiveness in the market. By continuously improving and optimizing our production methods, we can achieve cost savings, faster delivery times, and superior product quality. This will enable us to meet customer demands more effectively and outperform competitors in the industry.

Leveraging Innovation for Streamlined Manufacturing

As a forward-thinking company, SSOURCING INC. understands the importance of leveraging innovation for streamlined manufacturing processes. Embracing advanced technologies such as 3D printing, IoT, and artificial intelligence allows us to automate tasks, improve accuracy, and increase productivity. By staying at the forefront of technological advancements, we can ensure efficiency and agility in our operations.

The Future of Manufacturing Processes: Adapting to Change

The future of manufacturing processes is synonymous with change, and SSOURCING INC. is prepared to adapt accordingly. With Industry 4.0 driving digital transformation and customization becoming more prevalent, we are committed to evolving our production methods to meet evolving consumer needs and market trends. Embracing global supply chain integration will further solidify our position as a leader in adapting to change within the industry.

With a focus on enhancing competitiveness through efficient manufacturing processes, leveraging innovation for streamlined operations, and adapting to future changes within the industry landscape; SSOURCING INC is poised for sustained success in an ever-evolving market environment.