Introduction

In the world of manufacturing, there are various methods used to create finished products. One such method involves removing material to achieve the desired shape and form. This process is known as subtractive manufacturing, and it plays a crucial role in the production of a wide range of goods.

Understanding the Core Concept

Subtractive manufacturing is the type of manufacturing that involves removing material to make a finished product. This can be achieved through processes such as cutting, drilling, milling, and grinding.

Examples of Material-Removing Manufacturing

Examples of material-removing manufacturing include CNC machining, milling, metal fabrication techniques, woodworking, carving processes, turning, grinding, laser cutting, waterjet machining, and electrical discharge machining (EDM).

Importance of Material Removal in Production

Material removal is essential in the production industry as it allows for the creation of precise and intricate designs. It enables manufacturers to transform raw materials into functional components that are vital in various industries such as automotive, aerospace, electronics, and construction.

Subtractive Manufacturing

Subtractive manufacturing involves removing material to make a finished product, and it is a widely used process in various industries. CNC machining and milling are essential techniques within this manufacturing method, allowing for precise and automated material removal to create intricate components. Metal fabrication techniques, such as cutting, drilling, and welding, also fall under subtractive manufacturing processes. Woodworking and carving processes utilize material removal to shape wood into furniture, sculptures, and other items.

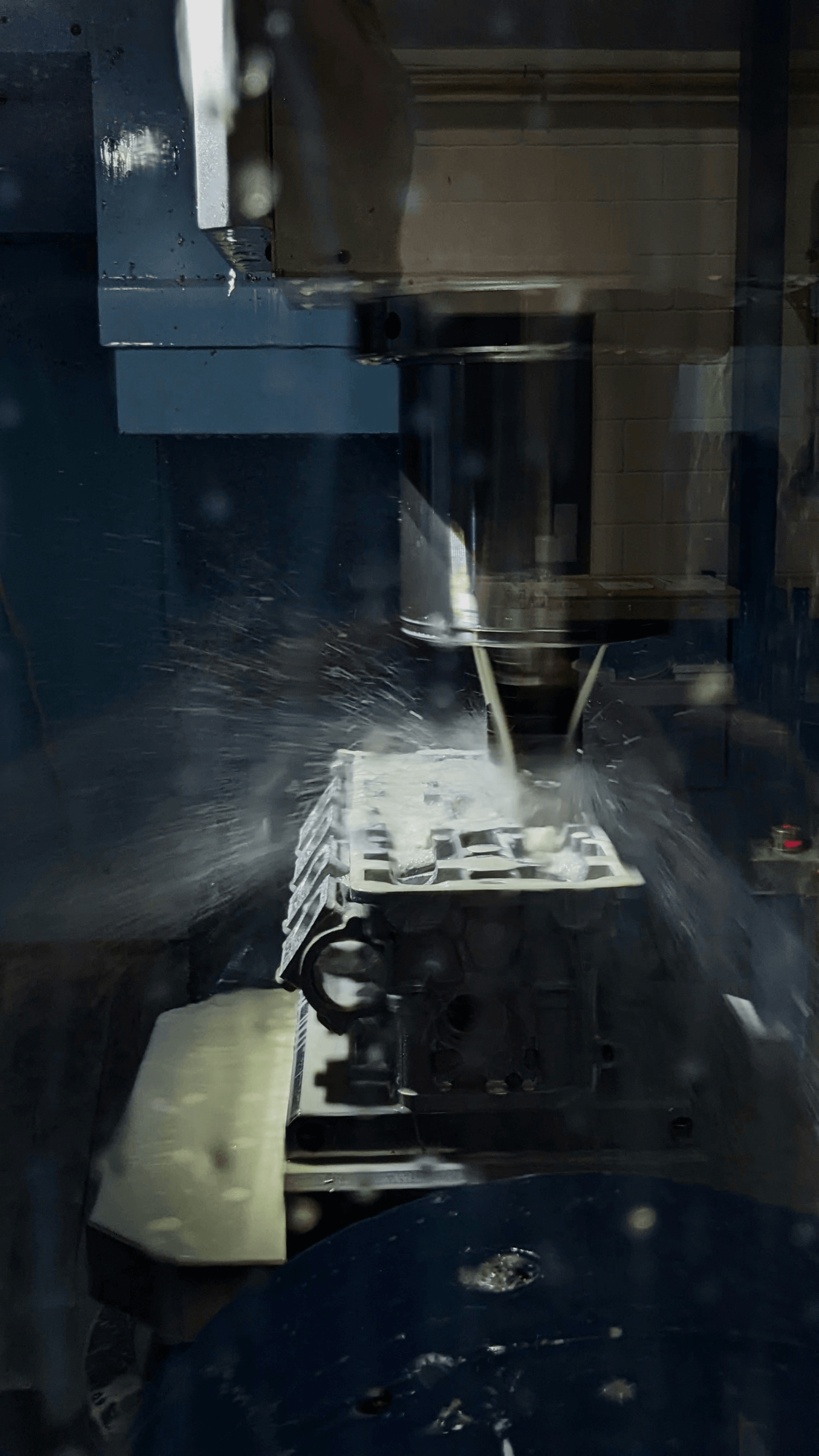

CNC Machining and Milling

CNC machining and milling are highly efficient subtractive manufacturing processes that involve computer-controlled cutting tools to remove material from a workpiece. This method offers unparalleled precision and repeatability, making it ideal for SSOURCING INC.'s production needs. The ability to work with a wide range of materials makes CNC machining versatile for creating components across various industries.

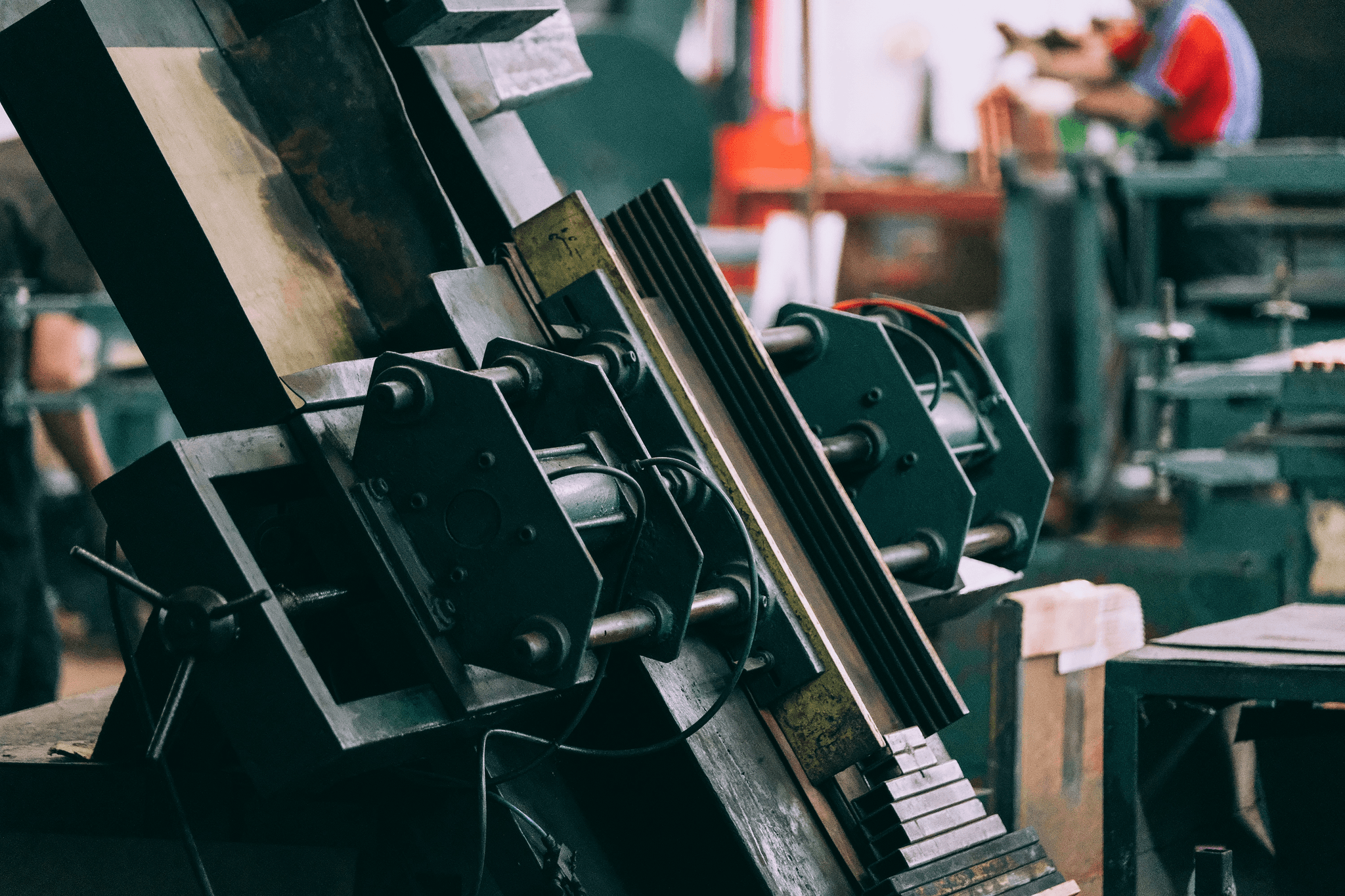

Metal Fabrication Techniques

Metal fabrication encompasses subtractive manufacturing methods like cutting, shearing, punching, bending, welding, and assembling metal structures or components. These techniques are crucial for SSOURCING INC.'s production line when working with metal-based products or parts that require specific shapes or sizes.

Woodworking and Carving Processes

Woodworking involves subtractive manufacturing through cutting, shaping, carving, or sanding wooden materials to create functional or decorative items such as furniture or art pieces. These processes are essential for SSOURCING INC.'s projects that require wooden components due to their durability and aesthetic appeal.

Remember that the key to successful subtractive manufacturing lies in choosing the right technique based on your specific production requirements!

Material Removal Techniques

When it comes to material-removing manufacturing, turning and grinding are two widely used techniques that involve the removal of excess material to create a finished product. In turning, a cutting tool is used to remove material from a rotating workpiece, while grinding involves the use of abrasive grains to remove material from a workpiece's surface. Both methods are commonly utilized in metalworking and woodworking processes, offering precision and efficiency in SSOURCING INC.'s production operations.

Turning and Grinding

Turning is a manufacturing process that involves removing material from a rotating workpiece using cutting tools such as lathes or turning machines. This technique is commonly used in the production of cylindrical components such as shafts, rods, and bushings. Grinding, on the other hand, utilizes abrasive grains to remove material from the surface of a workpiece, resulting in smooth finishes and tight tolerances for precision components. SSOURCING INC. leverages turning and grinding techniques for various applications across different industries.

Laser Cutting and Waterjet Machining

Laser cutting and waterjet machining are advanced material removal techniques that utilize high-energy beams of light (laser) or pressurized streams of water (waterjet) to cut through materials with high precision. Laser cutting is ideal for intricate designs on thin materials like sheet metal or plastic, while waterjet machining is suitable for thicker materials such as stone, glass, or metal. These methods offer versatility and accuracy in SSOURCING INC.'s production processes.

EDM (Electrical Discharge Machining)

EDM is a non-traditional machining process that uses electrical discharges to remove material from conductive workpieces with exceptional precision. This method is particularly effective for producing complex shapes and intricate details on hardened metals that are challenging to machine using conventional techniques. With its ability to achieve high levels of accuracy without inducing mechanical stress on the workpiece, EDM plays a crucial role in SSOURCING INC.'s manufacturing operations.

By leveraging these advanced material removal techniques such as turning and grinding, laser cutting and waterjet machining, as well as EDM (Electrical Discharge Machining), SSOURCING INC. continues to drive innovation and excellence in its production processes across various industries.

Advantages of Subtractive Manufacturing

Subtractive manufacturing involves removing material to make a finished product. CNC machining and milling, metal fabrication techniques, and woodworking and carving processes are all examples of subtractive manufacturing. This method is crucial in the production industry as it allows for precise and accurate creation of complex parts and components.

Precision and Accuracy

Precision and accuracy are key advantages of subtractive manufacturing. By removing material from a workpiece, manufacturers can achieve extremely tight tolerances and high-quality surface finishes. This level of precision is essential in industries such as aerospace, automotive, and medical device manufacturing where the smallest deviation can have significant implications.

Versatility in Material Selection

Subtractive manufacturing offers versatility in material selection, allowing for the creation of products from a wide range of materials including metals, plastics, ceramics, and composites. This flexibility enables SSOURCING INC. to cater to diverse client needs across various industries while maintaining high standards of quality and performance.

Cost-Effectiveness for Large-scale Production

Another advantage of subtractive manufacturing is its cost-effectiveness for large-scale production runs. Once the initial tooling and programming are set up, the process can be highly automated, leading to reduced labor costs per unit produced. This makes it an attractive option for SSOURCING INC.'s clients looking to manufacture large quantities of parts or components.

By leveraging the precision and accuracy offered by subtractive manufacturing methods such as CNC machining, SSOURCING INC. can ensure that their clients receive top-quality products that meet their exact specifications while offering versatility in material selection across various industries at a cost-effective scale.

Limitations and Challenges

Waste Management and Environmental Impact

One of the challenges in material-removing manufacturing is the proper disposal of waste materials. Whether it's metal shavings, wood chips, or other by-products, the environmental impact must be carefully managed to minimize pollution and ecological harm. SSOURCING INC. understands the importance of sustainable manufacturing practices to reduce our carbon footprint and protect the planet for future generations.

Tool Wear and Maintenance

Another limitation in subtractive manufacturing is the inevitable wear and tear on cutting tools and equipment. Regular maintenance is crucial to ensure that machines operate at peak efficiency, reducing downtime and costly repairs. SSOURCING INC. invests in high-quality tools and implements strict maintenance schedules to keep our manufacturing processes running smoothly.

Design Limitations for Complex Shapes

While subtractive manufacturing offers precision, it also presents challenges when creating intricate or complex shapes. Traditional machining methods may struggle with intricate designs that require multiple axis movements or intricate details. SSOURCING INC.'s team of skilled engineers constantly explores innovative techniques to overcome design limitations and push the boundaries of what's possible in material-removing manufacturing.

Conclusion

Applications in Various Industries

Subtractive manufacturing, which involves removing material to make a finished product, has extensive applications across various industries. From aerospace and automotive to healthcare and consumer goods, the versatility of material-removing manufacturing makes it indispensable in creating high-quality products for SSOURCING INC. and other businesses.

The Future of Material-Removing Manufacturing

The future of material-removing manufacturing is bright, with advancements in technology leading to more efficient and sustainable processes. As industries continue to demand precision and customization, subtractive manufacturing will play a crucial role in meeting these requirements. SSOURCING INC. can leverage this trend to expand its market reach and offer innovative solutions.

Choosing the Right Manufacturing Process for Your Business

Choosing the right manufacturing process for your business is essential for achieving optimal results. With the wide range of material removal techniques available, including CNC machining, laser cutting, and EDM, SSOURCING INC. can tailor its production methods to meet specific project needs while maintaining cost-effectiveness and high quality.