Introduction

In today's fast-paced world, the importance of sustainable manufacturing cannot be overstated. With revolutionary advances in manufacturing methods, companies like SSOURCING INC. are leading the charge towards eco-friendly and efficient production processes. Our commitment to sustainable production is not just a trend, but a core value that drives our innovative approach to manufacturing.

Importance of Sustainable Manufacturing

Sustainable manufacturing is crucial for reducing environmental impact, conserving resources, and minimizing waste. It also promotes long-term viability and resilience in the face of global challenges. At SSOURCING INC., we understand that prioritizing sustainability is not just responsible business practice - it's essential for shaping a better future for generations to come.

Revolutionary Advances in Manufacturing Methods

The landscape of manufacturing has been transformed by cutting-edge technologies and processes. From additive manufacturing to automation and robotics, these revolutionary advances have paved the way for more sustainable and efficient production methods. At SSOURCING INC., we embrace these innovations as opportunities to elevate our commitment to sustainable production.

SSOURCING INC.'s Commitment to Sustainable Production

At SSOURCING INC., sustainability is at the heart of everything we do. We are dedicated to integrating eco-friendly practices into our manufacturing processes, from sourcing materials to end-of-life product management. Our goal is not only to minimize our environmental footprint but also to inspire positive change within the industry.

Cutting-Edge Additive Manufacturing

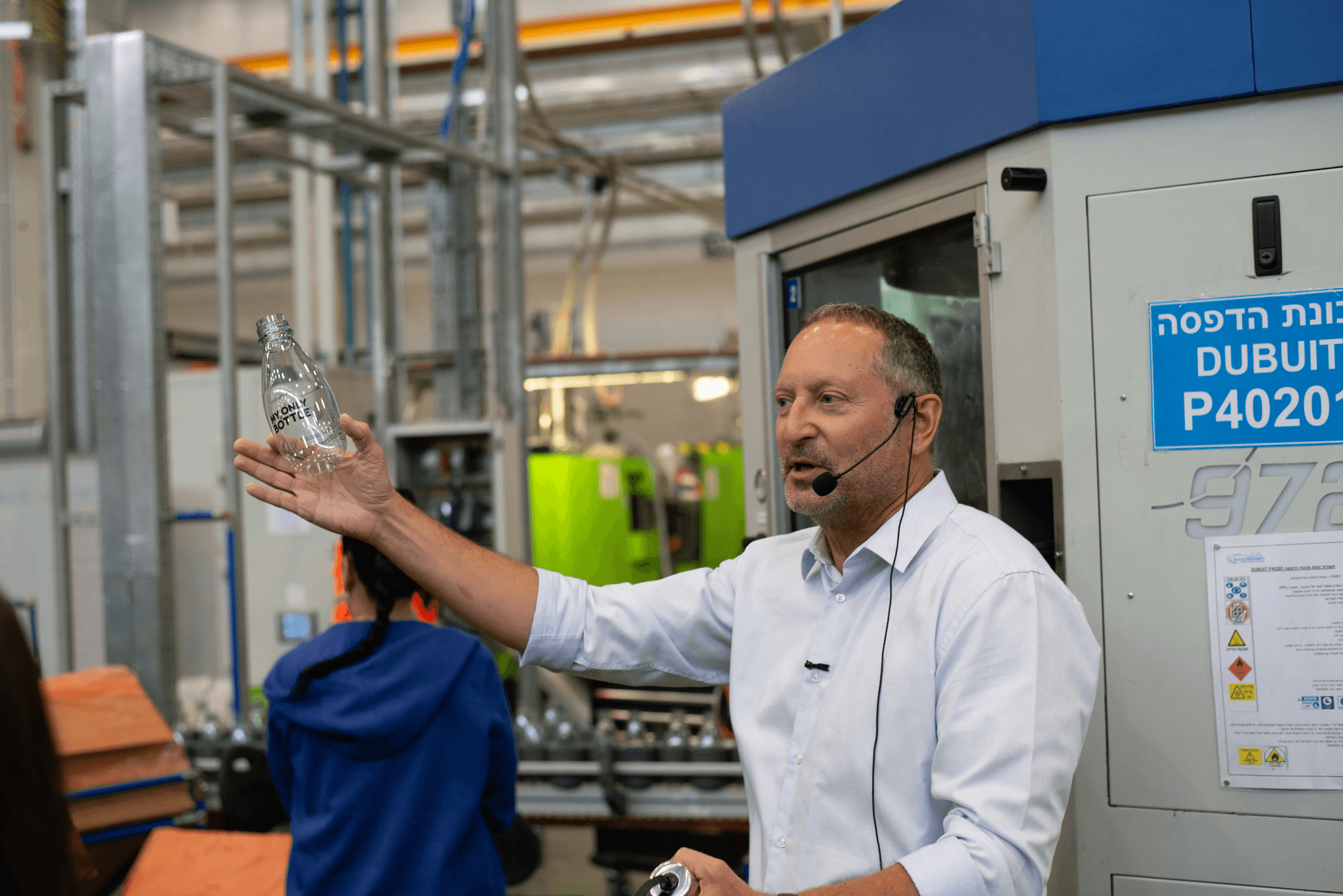

In today's fast-paced world, innovative manufacturing methods are crucial for staying ahead of the competition. SSOURCING INC. recognizes the significance of cutting-edge additive manufacturing in achieving sustainable production. By leveraging 3D printing and direct metal laser sintering, we are able to reduce waste and energy consumption while maintaining high-quality output.

3D Printing

3D printing has revolutionized the manufacturing industry by allowing for rapid prototyping and customization. At SSOURCING INC., we utilize 3D printing to create complex geometries and intricate designs with sustainable materials, reducing material waste and energy consumption in the process. This method not only enhances efficiency but also minimizes environmental impact, aligning with our commitment to sustainable production.

Direct Metal Laser Sintering

Direct Metal Laser Sintering (DMLS) is another game-changing additive manufacturing method that SSOURCING INC. has embraced. By using this technology, we can produce high-strength metal parts with intricate features, all while minimizing material waste and energy usage. DMLS enables us to achieve sustainable production without compromising on quality or performance.

Sustainable Materials for Additive Manufacturing

In line with our dedication to sustainability, SSOURCING INC. prioritizes the use of eco-friendly materials for additive manufacturing processes. From biodegradable polymers to recycled metals, we carefully select materials that minimize environmental impact without sacrificing durability or functionality. Our commitment to sustainable materials underscores our vision for responsible and forward-thinking manufacturing practices.

Lean Manufacturing Principles

Lean manufacturing methods are essential for optimizing production processes and minimizing waste in the manufacturing industry. SSOURCING INC. has embraced lean principles to improve efficiency and reduce environmental impact throughout its operations. By implementing lean practices, our company has been able to streamline workflows, enhance productivity, and minimize resource consumption.

Waste Reduction

SSOURCING INC. has prioritized waste reduction as a fundamental aspect of our sustainable manufacturing approach. Through the implementation of lean principles, we have been able to identify and eliminate various forms of waste, including overproduction, excess inventory, and unnecessary motion in our production processes. By minimizing waste generation, we have significantly reduced our environmental footprint while simultaneously improving cost-effectiveness.

Efficient Production Processes

Efficiency is at the core of SSOURCING INC.'s manufacturing methods. By optimizing production processes through lean principles, we have been able to enhance throughput and reduce lead times while maintaining high-quality standards. Our commitment to efficient production not only benefits our bottom line but also contributes to resource conservation and sustainability in the manufacturing industry.

Sustainable Practices in Lean Manufacturing

In addition to waste reduction and efficient production processes, SSOURCING INC. integrates sustainable practices into every aspect of lean manufacturing. This includes the utilization of eco-friendly materials, energy-efficient technologies, and responsible disposal methods for any remaining waste generated during production. Our dedication to sustainable practices within lean manufacturing reflects our ongoing commitment to environmentally conscious operations.

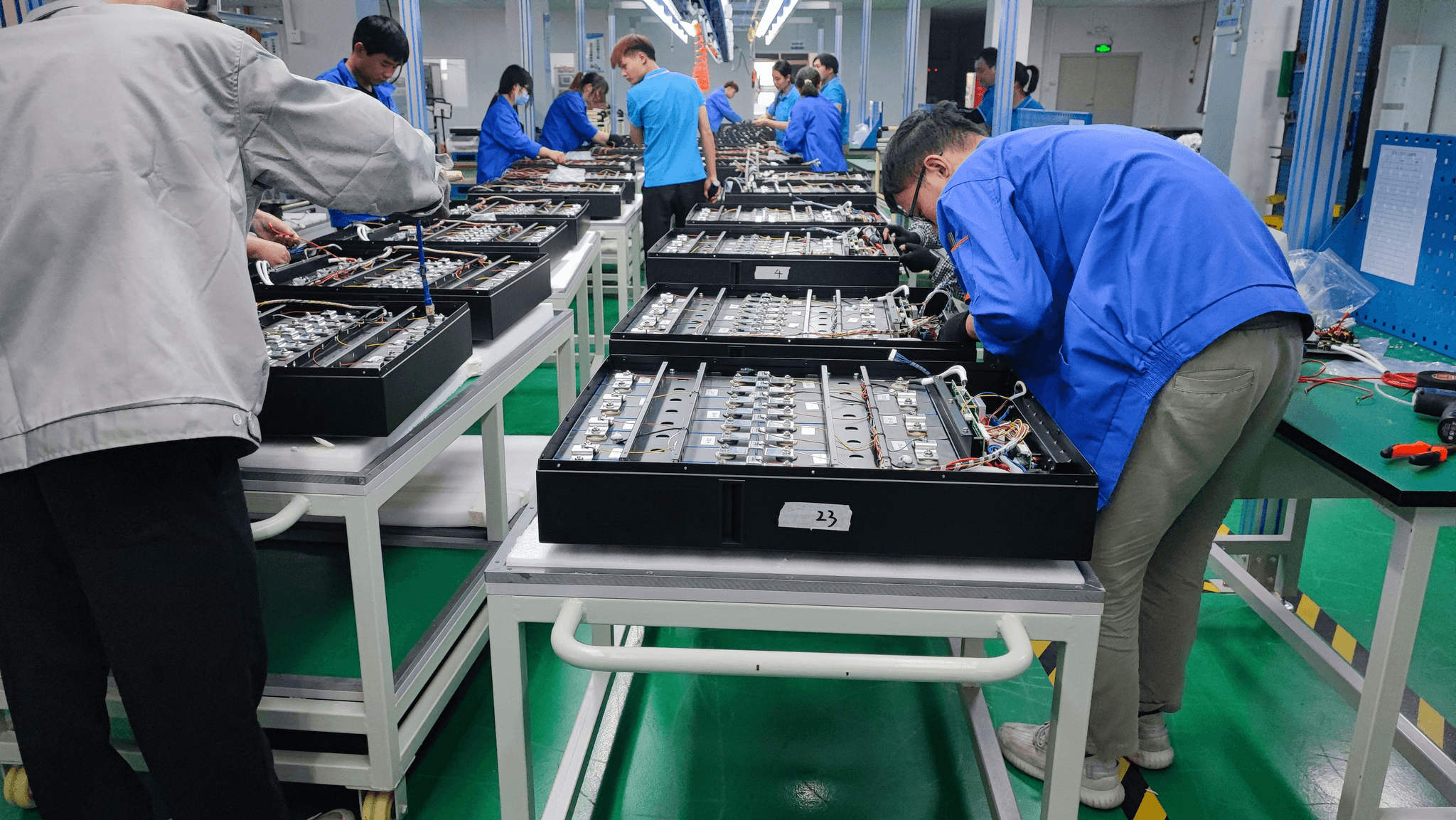

Automation and Robotics in Manufacturing

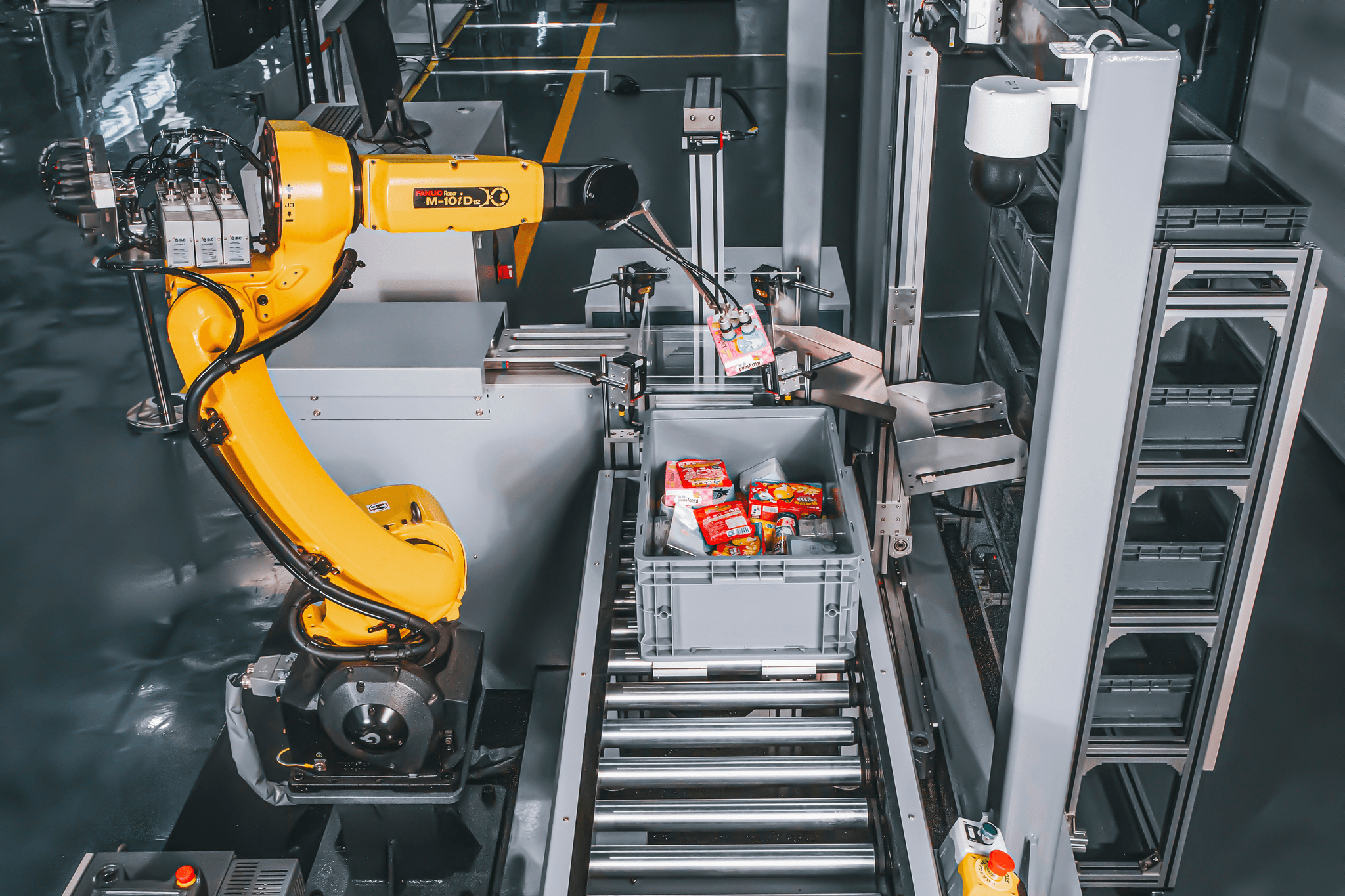

In today's fast-paced manufacturing landscape, the integration of robotics has become increasingly prevalent. With the help of advanced automation technologies, SSOURCING INC. has been able to streamline production processes, improve efficiency, and reduce operational costs. By incorporating state-of-the-art robotics, our company has significantly enhanced its manufacturing capabilities, ensuring precision and consistency in every product.

Integration of Robotics

The seamless integration of robotics into our manufacturing facilities has revolutionized the way we operate. From assembly lines to material handling, robots have taken over repetitive tasks, allowing our skilled workforce to focus on more complex and value-added activities. This has not only increased productivity but also improved workplace safety by minimizing human intervention in hazardous environments.

Advantages of Automation

The advantages of automation in manufacturing are manifold. By leveraging robotic systems, SSOURCING INC. has experienced reduced cycle times, increased throughput, and enhanced product quality. Furthermore, automation has enabled us to adapt quickly to market demands and scale production without compromising on precision or consistency.

Sustainable Automation Solutions

SSOURCING INC.'s commitment to sustainable production extends to our automation solutions as well. Our robotics are designed to optimize energy consumption and minimize waste generation during operation. By implementing sustainable automation practices, we strive to reduce our environmental footprint while maintaining high levels of productivity.

With innovative manufacturing methods like the integration of robotics at the forefront of sustainable production practices, SSOURCING INC. continues to lead the way in environmentally conscious manufacturing.

Green Supply Chain Management

In today's rapidly evolving manufacturing landscape, sustainable sourcing has become a top priority for companies like SSOURCING INC. Our commitment to sustainable production extends to every aspect of our supply chain, from the materials we use to the partners we choose. By prioritizing sustainable sourcing, we ensure that our manufacturing methods align with our environmental values and contribute to a greener future.

Sustainable Sourcing

At SSOURCING INC., we understand the importance of responsible sourcing in our manufacturing methods. We prioritize suppliers who share our commitment to sustainability, seeking out partners who adhere to ethical labor practices and environmental regulations. By choosing sustainable sources for raw materials and components, we not only minimize our environmental impact but also support businesses that share our values.

Eco-Friendly Packaging

In line with our dedication to sustainable manufacturing methods, SSOURCING INC. is dedicated to utilizing eco-friendly packaging solutions throughout our supply chain. From biodegradable materials to minimalistic designs that reduce waste, we strive to ensure that every product leaving our facilities is packaged in an environmentally responsible manner.

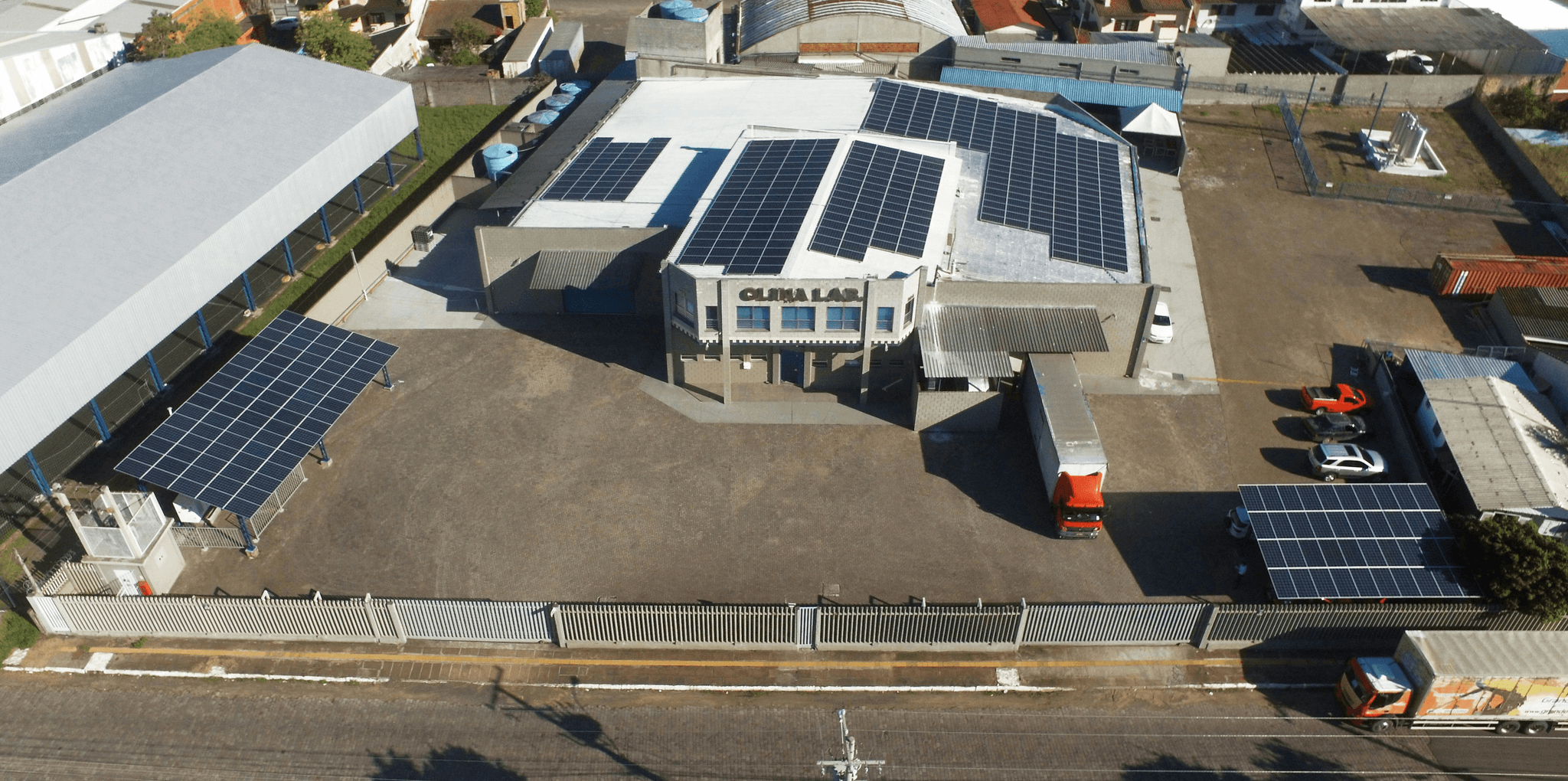

Renewable Energy Integration in Supply Chain

As part of our ongoing efforts to reduce carbon emissions and embrace sustainable manufacturing methods, SSOURCING INC. has integrated renewable energy sources into our supply chain operations. By leveraging solar, wind, and other renewable energy technologies, we not only minimize the environmental impact of our operations but also contribute positively towards a cleaner energy future.

Circular Economy in Manufacturing

In the realm of sustainable manufacturing methods, the concept of a circular economy has gained significant traction. At SSOURCING INC., we understand the importance of closed-loop systems, which emphasize recycling and reusing materials within the production cycle. By implementing closed-loop systems, we minimize waste and reduce our environmental impact while maintaining a cost-effective approach to manufacturing.

Closed-Loop Systems

Closed-loop systems in manufacturing involve the continual use of resources, such as materials and energy, without generating waste or pollution. At SSOURCING INC., we have integrated closed-loop systems into our production processes, ensuring that materials are recycled and reused whenever possible. This not only reduces our reliance on raw materials but also decreases the amount of waste sent to landfills, contributing to a more sustainable manufacturing approach.

Product Life Extension

Extending the life cycle of products is another crucial aspect of sustainable manufacturing methods. SSOURCING INC. focuses on designing products with durability and longevity in mind, allowing for a longer usage period before disposal or recycling is necessary. By promoting product life extension, we aim to reduce overall resource consumption and minimize environmental impact throughout a product's lifecycle.

Sustainable End-of-Life Processes

In line with sustainable manufacturing methods, SSOURCING INC. prioritizes responsible end-of-life processes for our products. This includes implementing efficient recycling programs and ensuring proper disposal methods for components that cannot be reused or repurposed. By embracing sustainable end-of-life processes, we contribute to the reduction of waste while also adhering to environmentally conscious practices.

Conclusion

Sustainable manufacturing methods are the future of the industry, and SSOURCING INC. is at the forefront of this movement. As the demand for eco-friendly products grows, innovative manufacturing methods will play a crucial role in meeting these needs. SSOURCING INC.'s commitment to sustainable production sets the standard for the industry.

Future of Sustainable Manufacturing

The future of sustainable manufacturing looks promising, with advancements in technology and a growing emphasis on environmental responsibility. As consumer awareness increases, there will be a greater demand for products manufactured using sustainable methods. SSOURCING INC. is dedicated to leading this charge and setting new standards for sustainable manufacturing.

Role of Innovative Manufacturing Methods

Innovative manufacturing methods will play a pivotal role in shaping the future of sustainable production. From cutting-edge additive manufacturing to lean principles and automation, these methods are essential for reducing waste and energy consumption while increasing efficiency. SSOURCING INC.'s adoption of these innovative methods demonstrates its commitment to sustainability.

SSOURCING INC.'s Vision for Sustainable Production

SSOURCING INC.'s vision for sustainable production is one that prioritizes environmental stewardship without compromising on quality or efficiency. By integrating state-of-the-art manufacturing techniques with green supply chain management and circular economy principles, SSOURCING INC. is leading by example in creating a more sustainable future for manufacturing.