Introduction

In today's fast-paced world, the landscape of manufacturing techniques is constantly evolving, presenting new opportunities and challenges for businesses. As companies strive to stay competitive in the global market, revolutionary manufacturing techniques have a profound impact on product design, offering endless possibilities for innovation and creativity. At SSOURCING INC., we understand the significance of staying ahead of these trends to drive success in product development.

The Evolving Landscape of Manufacturing Techniques

The traditional methods of manufacturing are being reshaped by technological advancements and automation, leading to a shift towards more efficient and sustainable practices. Additive manufacturing, advanced robotics, and digital twin technology are just a few examples of how the industry is embracing change and revolutionizing production processes. This evolution opens up new avenues for businesses to explore and capitalize on.

Impact of Revolutionary Manufacturing Techniques on Product Design

With the advent of these cutting-edge manufacturing techniques, product design is no longer bound by conventional limitations. The ability to create complex shapes and intricate designs with additive manufacturing allows for unprecedented levels of customization and innovation. This not only enhances the functionality of products but also improves their aesthetic appeal, giving companies a competitive edge in the market.

Unlocking New Possibilities in Product Development

As revolutionary manufacturing techniques continue to reshape the industry, they unlock new possibilities for product development that were previously unattainable. From rapid prototyping to real-time performance monitoring through digital twin technology, businesses now have the tools to streamline their development processes and bring high-quality products to market faster than ever before. Embracing these advancements is crucial for companies looking to thrive in today's dynamic business environment.

Traditional Manufacturing Methods

As we navigate through the evolving landscape of manufacturing techniques, it's crucial to understand the limitations and challenges posed by traditional methods. These include high production costs, long lead times, and limited customization options. In today's fast-paced market, these constraints can hinder a company's ability to stay competitive and meet consumer demands.

Limitations and Challenges

Traditional manufacturing methods often rely on mass production, leading to high setup costs and significant material waste. Additionally, long lead times can delay product launches and hinder a company's ability to respond quickly to market changes. Moreover, limited customization options can restrict a company's ability to offer tailored products that cater to diverse consumer preferences.

Case Study: Toyota Production System

The Toyota Production System (TPS) serves as an exemplary case study of how traditional manufacturing methods can be optimized for efficiency and quality. By implementing lean principles and just-in-time production, Toyota revolutionized the automotive industry with its streamlined processes that minimize waste and maximize value for customers.

Adapting to New Demands

In today's dynamic market, companies like SSOURCING INC. are recognizing the need to adapt traditional manufacturing methods to meet new demands for flexibility, speed, and customization. By embracing innovative technologies such as additive manufacturing and advanced robotics, businesses can overcome the limitations of traditional methods while enhancing their product development capabilities.

Additive Manufacturing

Additive manufacturing, also known as 3D printing, has revolutionized the production process by allowing for the creation of complex and customized products. This innovative technique enables SSOURCING INC. to produce prototypes and small batches of products with intricate designs that were previously impossible with traditional methods. By utilizing 3D printing, manufacturers can now offer customers personalized and tailored solutions to meet their specific needs, ultimately enhancing the overall customer experience.

3D Printing Revolution

The 3D printing revolution has significantly impacted the manufacturing industry by providing a cost-effective and efficient method for creating intricate designs and prototypes. SSOURCING INC. leverages this technology to rapidly develop new product iterations, reducing time-to-market and staying ahead of competitors in the fast-paced industry. With additive manufacturing, our company can explore new design possibilities that were previously limited by traditional manufacturing techniques, opening up a world of innovation and creativity.

Enhancing Customization and Prototyping

Additive manufacturing has transformed the way products are designed and developed by offering enhanced customization capabilities. SSOURCING INC. uses this technology to tailor products to specific customer requirements, leading to increased customer satisfaction and loyalty. Additionally, 3D printing allows for rapid prototyping, enabling our company to quickly test new concepts and iterate on designs without incurring significant costs or lead times associated with traditional prototyping methods.

Implementing Additive Manufacturing in Product Design

By implementing additive manufacturing in product design processes, SSOURCING INC. is able to optimize designs for improved functionality while reducing material waste at the same time. This sustainable approach aligns with our commitment to environmentally friendly practices while also enhancing product performance and durability. With additive manufacturing integrated into our product design workflow, we can deliver innovative solutions that meet the evolving needs of our customers while maintaining a competitive edge in the market.

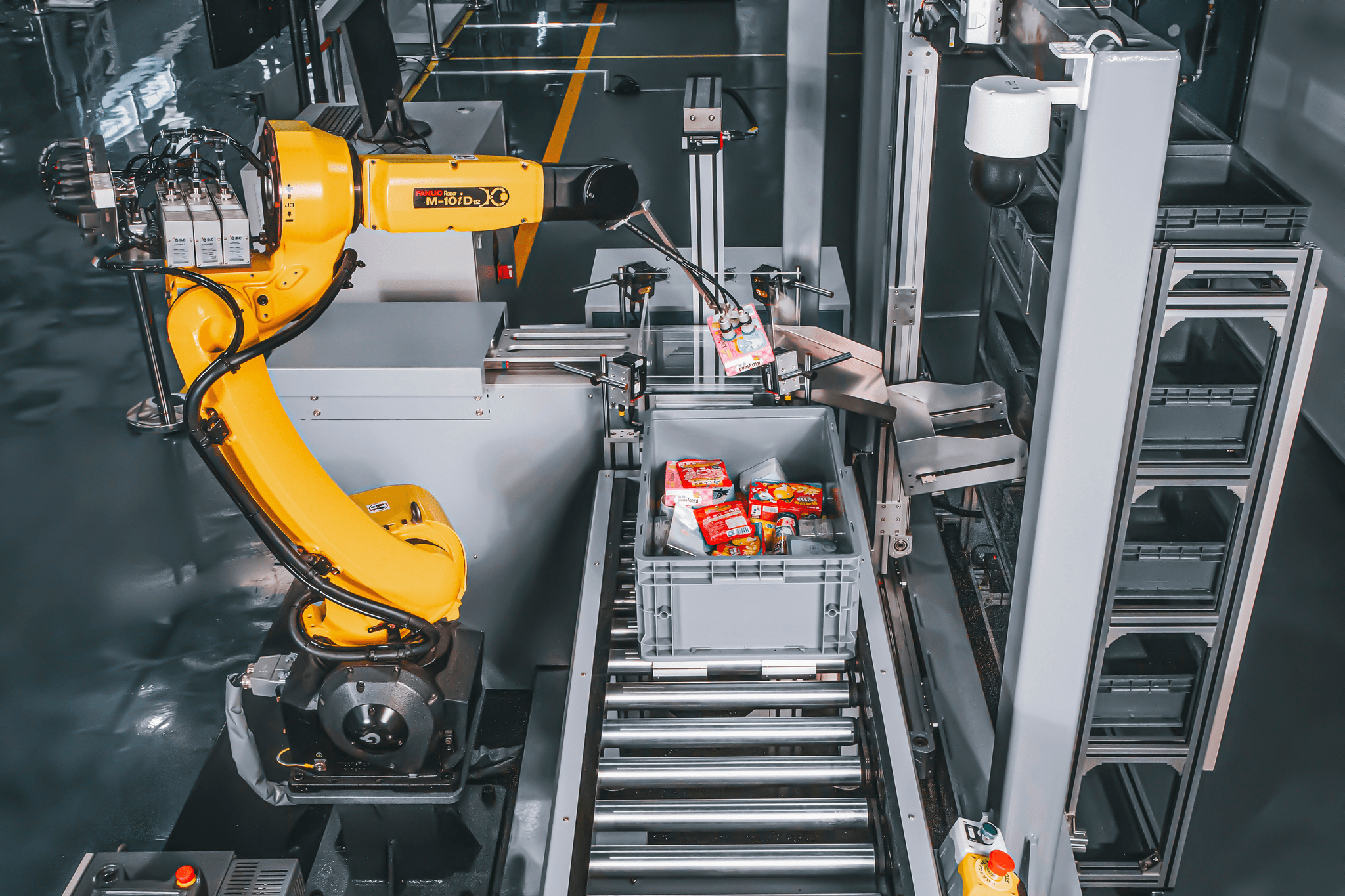

Advanced Robotics in Manufacturing

As manufacturing techniques continue to evolve, advanced robotics has emerged as a game-changer in improving efficiency and precision on the production floor. With the integration of robotics, SSOURCING INC. can streamline processes, reduce human error, and enhance overall productivity. This innovative approach allows for greater accuracy and consistency in product assembly, leading to higher quality outputs.

Improving Efficiency and Precision

Advanced robotics in manufacturing offers unparalleled efficiency by automating repetitive tasks with speed and accuracy. By utilizing robotic arms and automated systems, SSOURCING INC. can significantly reduce production time while maintaining a high level of precision in each stage of manufacturing. This ensures that products meet strict quality standards while optimizing operational efficiency.

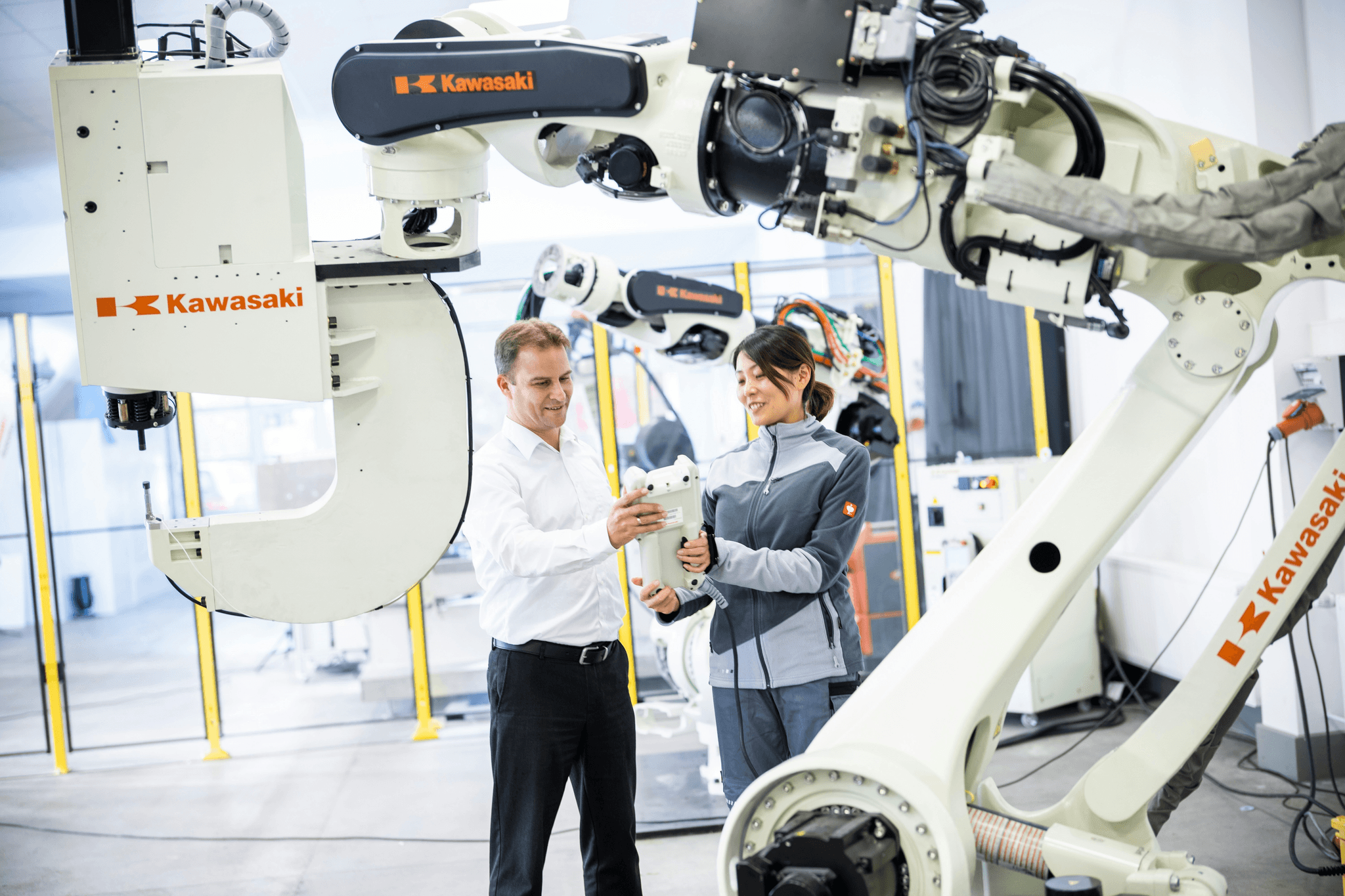

Case Study: KUKA Robotics

KUKA Robotics is a prime example of how advanced robotics have revolutionized manufacturing processes. Their robotic solutions have been instrumental in enhancing production lines across various industries, from automotive to electronics. By implementing KUKA's cutting-edge technology, SSOURCING INC. can achieve seamless automation and precision engineering, leading to improved product output.

Integrating Robotics with Product Development

Integrating robotics with product development enables SSOURCING INC. to optimize the entire manufacturing process from design to assembly. By leveraging robotic automation in the prototyping phase, precise models can be created rapidly to test product functionality and performance before mass production begins. This integration ensures that products are developed with utmost precision and efficiency from inception to completion.

By embracing advanced robotics in manufacturing, SSOURCING INC. is at the forefront of innovation by enhancing efficiency and precision throughout the production process, ultimately leading to superior quality products for their customers.

Sustainable Manufacturing Techniques

Sustainable manufacturing techniques have become increasingly vital in today's environmentally conscious world. By implementing eco-friendly processes, companies can minimize their environmental impact and contribute to a greener future. SSOURCING INC. understands the importance of sustainability in manufacturing and is committed to promoting sustainable practices across all operations.

Minimizing Environmental Impact

Incorporating sustainable manufacturing techniques involves minimizing waste, reducing energy consumption, and utilizing eco-friendly materials. By adopting these practices, companies can decrease their carbon footprint and contribute to a healthier planet. At SSOURCING INC., we prioritize sustainable manufacturing methods to ensure that our operations are environmentally responsible.

Case Study: Patagonia's Sustainable Supply Chain

Patagonia has set a remarkable example with its sustainable supply chain, emphasizing ethical sourcing, recycling initiatives, and renewable energy usage. By prioritizing sustainability throughout its production process, Patagonia has not only reduced its environmental impact but also gained a loyal customer base that values eco-conscious brands. SSOURCING INC. aims to emulate such success by integrating sustainable practices into our supply chain.

Incorporating Sustainability in Product Design

Incorporating sustainability into product design involves using recyclable materials, designing for longevity, and considering end-of-life disposal options. By creating products with a focus on sustainability, companies can appeal to environmentally conscious consumers while contributing to the circular economy. At SSOURCING INC., we are dedicated to incorporating sustainable principles into our product design process to align with the growing demand for eco-friendly solutions.

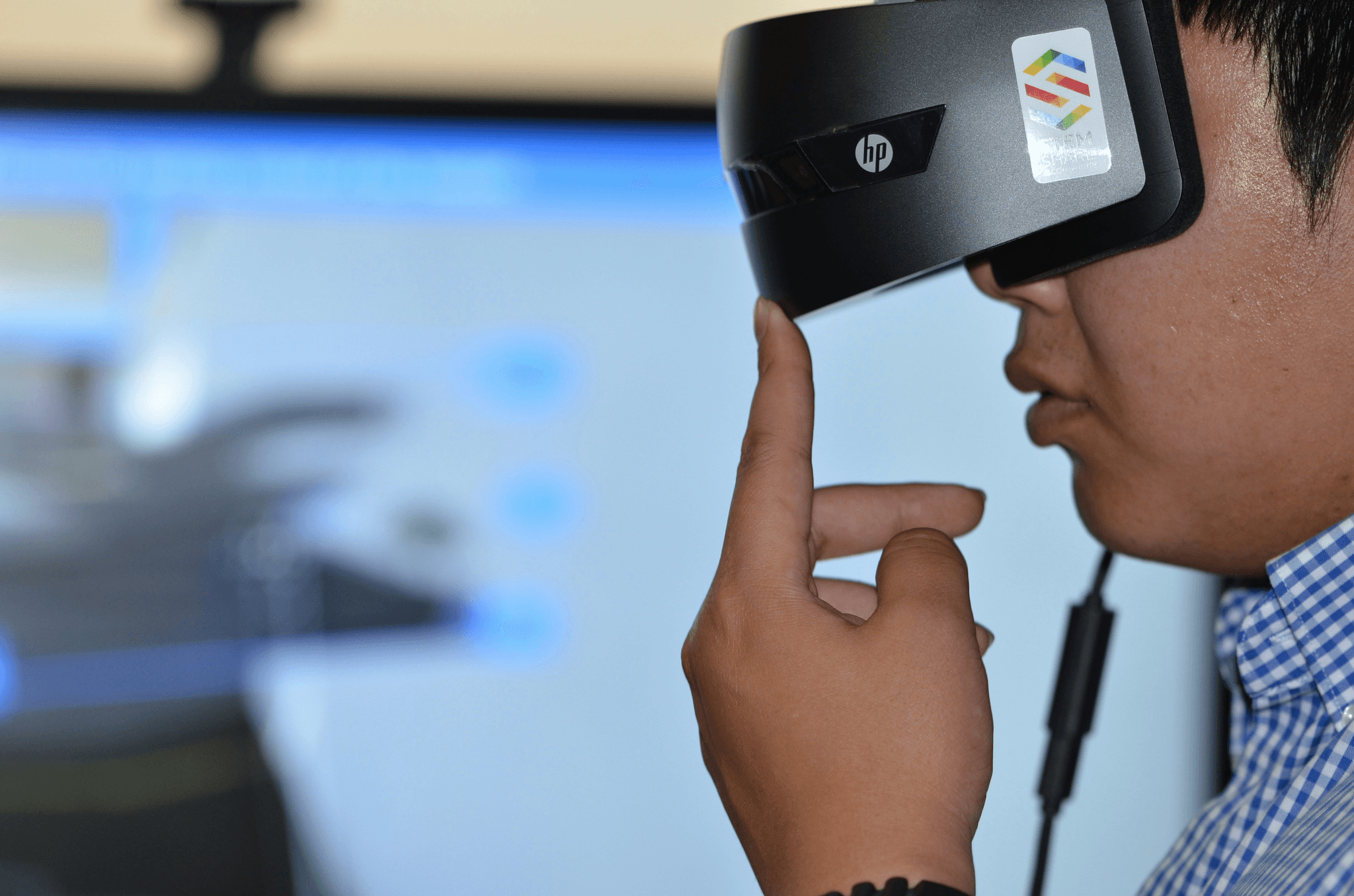

Digital Twin Technology

In today's rapidly evolving manufacturing landscape, digital twin technology has emerged as a game-changer for product development. By creating virtual replicas of physical products, manufacturers can enhance product simulation and testing to ensure optimal performance and quality. This innovative approach allows SSOURCING INC. to minimize costly errors and streamline the design process, ultimately leading to improved efficiency and customer satisfaction.

Enhancing Product Simulation and Testing

Digital twin technology enables SSOURCING INC. to simulate various operating conditions and test different design iterations in a virtual environment. This not only reduces the need for physical prototypes but also provides valuable insights into potential issues before production begins. By leveraging this advanced tool, our company can fine-tune product designs with precision, ultimately delivering superior quality products to our customers.

Real-time Performance Monitoring

With digital twin technology, SSOURCING INC. can monitor real-time performance data of physical products through their virtual counterparts. This allows us to identify any deviations from expected performance metrics and make necessary adjustments promptly. By having a comprehensive understanding of product behavior in real-world scenarios, we can ensure that our offerings meet the highest standards of reliability and functionality.

Leveraging Digital Twin in Product Design Iterations

By integrating digital twin technology into our product development process, SSOURCING INC. can iterate on designs more efficiently and effectively than ever before. Virtual simulations enable us to explore a wide range of design variations and evaluate their impact on performance without the need for extensive physical testing. This not only accelerates the design cycle but also empowers us to innovate with confidence, staying ahead in the competitive landscape of manufacturing techniques.

Conclusion

In conclusion, the future of manufacturing techniques is undoubtedly exciting, with the rapid evolution of technology and the rise of Industry 4.0. As SSOURCING INC. looks ahead, it's crucial to adapt to these changes and embrace innovative manufacturing methods to stay competitive in the market.

Future of Manufacturing Techniques

The future of manufacturing techniques is moving towards greater automation, sustainability, and customization. With advancements in additive manufacturing, robotics, and digital twin technology, SSOURCING INC. has a wealth of opportunities to explore in enhancing their production processes and product development.

Adapting to Industry 4.0

Adapting to Industry 4.0 means leveraging the power of data analytics, artificial intelligence, and interconnected systems to optimize manufacturing operations. SSOURCING INC. must be prepared to invest in smart technologies that can streamline their processes and improve overall efficiency.

Staying Ahead in Product Development with Innovative Manufacturing Techniques

Staying ahead in product development requires SSOURCING INC. to embrace innovative manufacturing techniques that can unlock new design possibilities and enhance product performance. By integrating advanced robotics, sustainable practices, and digital twin technology into their workflow, they can ensure they are at the forefront of industry trends.

With these exciting developments on the horizon for manufacturing techniques, SSOURCING INC. must remain proactive in adopting these innovations to maintain their competitive edge in the industry while continuing to deliver high-quality products that meet evolving consumer demands.