Introduction

In today's rapidly evolving business landscape, sustainable innovations have become paramount for companies looking to reduce their environmental impact and improve their bottom line. As consumer demand for eco-friendly products continues to rise, businesses are increasingly recognizing the importance of integrating sustainable practices into their operations. Key players in sustainable manufacturing, such as Adidas, Ford, and Toyota, have set the stage for industry-wide adoption of green initiatives, showcasing the benefits of embracing sustainability in traditional manufacturing processes.

Importance of Sustainable Innovations

Sustainable innovations are no longer just a trend; they are a necessity for businesses aiming to stay competitive in a rapidly changing marketplace. By prioritizing sustainability, companies can enhance their brand reputation, attract environmentally conscious consumers, and drive cost savings through efficient resource utilization.

Benefits of Adopting Sustainable Practices

The benefits of adopting sustainable practices extend beyond environmental stewardship. Businesses that integrate eco-friendly initiatives into their operations often experience improved operational efficiencies, reduced waste generation, and enhanced employee morale. Additionally, sustainability efforts can lead to long-term cost savings and increased profitability.

Key Players in Sustainable Manufacturing

Leading companies like Adidas, Ford, and Toyota have emerged as trailblazers in sustainable manufacturing by implementing innovative strategies to minimize their environmental footprint while maintaining production efficiency. These key players serve as role models for other organizations seeking to transition towards more sustainable business practices.

Case Study: Adidas’ Eco-Friendly Initiatives

Adidas has been at the forefront of sustainable manufacturing, with a focus on using recycled materials in their products. The company has incorporated recycled polyester from plastic waste into their footwear and apparel, reducing their environmental impact. This commitment to eco-friendly materials aligns with SSOURCING INC.'s dedication to sustainable practices.

Use of Recycled Materials

Adidas' innovative use of recycled materials goes beyond just reducing waste - it also showcases the potential for eco-friendly materials to be high-performing and stylish. By incorporating recycled plastics into their products, Adidas sets an example for other companies to follow suit in embracing sustainability in traditional manufacturing processes. SSOURCING INC. recognizes the importance of adopting such practices to create a greener future.

Sustainable Supply Chain Practices

In addition to using recycled materials, Adidas has implemented sustainable supply chain practices to further minimize their environmental footprint. The company partners with suppliers who adhere to strict environmental and labor standards, ensuring that their entire production process is eco-conscious. This approach aligns with SSOURCING INC.'s commitment to ethical and sustainable sourcing throughout the supply chain.

Ford’s Green Manufacturing Techniques

Ford has been at the forefront of integrating renewable energy sources into its manufacturing processes. By harnessing solar and wind power, they have significantly reduced their reliance on traditional energy sources, leading to a considerable decrease in their carbon footprint. This innovative approach not only aligns with Ford's commitment to sustainability but also sets a positive example for other companies looking to adopt similar practices.

Integration of Renewable Energy

In line with its dedication to sustainable manufacturing, Ford has invested in solar panel installations across its facilities, allowing them to generate clean energy on-site. This initiative has not only reduced their environmental impact but has also resulted in substantial cost savings, demonstrating the business case for embracing renewable energy sources in traditional manufacturing processes. By incorporating solar and wind power into their operations, Ford is leading the way towards a greener future.

Waste Reduction Strategies

Ford has implemented various waste reduction strategies as part of its green manufacturing techniques. Through efficient recycling programs and innovative waste management practices, they have minimized the amount of waste generated during production processes. This commitment to reducing waste not only benefits the environment but also contributes to cost savings and operational efficiency. By prioritizing waste reduction, Ford is demonstrating how traditional manufacturing processes can be optimized for sustainability.

Toyota’s Innovations in Traditional Processes

Toyota has long been a pioneer in the automotive industry, and their commitment to sustainable manufacturing is no exception. By implementing lean manufacturing principles, Toyota has significantly reduced waste and improved efficiency in their production processes. This has not only resulted in cost savings but also minimized their environmental impact, making them a leader in sustainable manufacturing.

Implementing Lean Manufacturing Principles

Toyota's adoption of lean manufacturing principles has revolutionized traditional manufacturing processes by focusing on eliminating waste and optimizing production flow. By streamlining operations and reducing unnecessary steps, Toyota has been able to minimize resource consumption and improve overall productivity. This approach aligns with SSOURCING INC.'s dedication to promoting eco-friendly practices within the industry.

Sustainable Packaging Solutions

In addition to their advancements in production, Toyota has also prioritized sustainable packaging solutions as part of their commitment to environmental responsibility. By utilizing eco-friendly materials and reducing excess packaging, they have minimized the environmental impact of their products while also appealing to environmentally conscious consumers. This emphasis on sustainability aligns with SSOURCING INC.'s mission to promote green initiatives across all facets of manufacturing.

By embracing lean manufacturing principles and sustainable packaging solutions, Toyota continues to set the standard for environmentally responsible practices within traditional manufacturing processes.

The Role of Technology in Sustainable Manufacturing

In today's rapidly evolving manufacturing landscape, technology plays a pivotal role in driving sustainable practices. Traditional manufacturing processes are being revolutionized through the integration of cutting-edge automation and digitalization techniques. These advancements not only enhance efficiency but also reduce environmental impact, aligning with the ethos of sustainability. At SSOURCING INC., we recognize the significance of leveraging technology to foster eco-friendly manufacturing solutions that benefit both businesses and the planet.

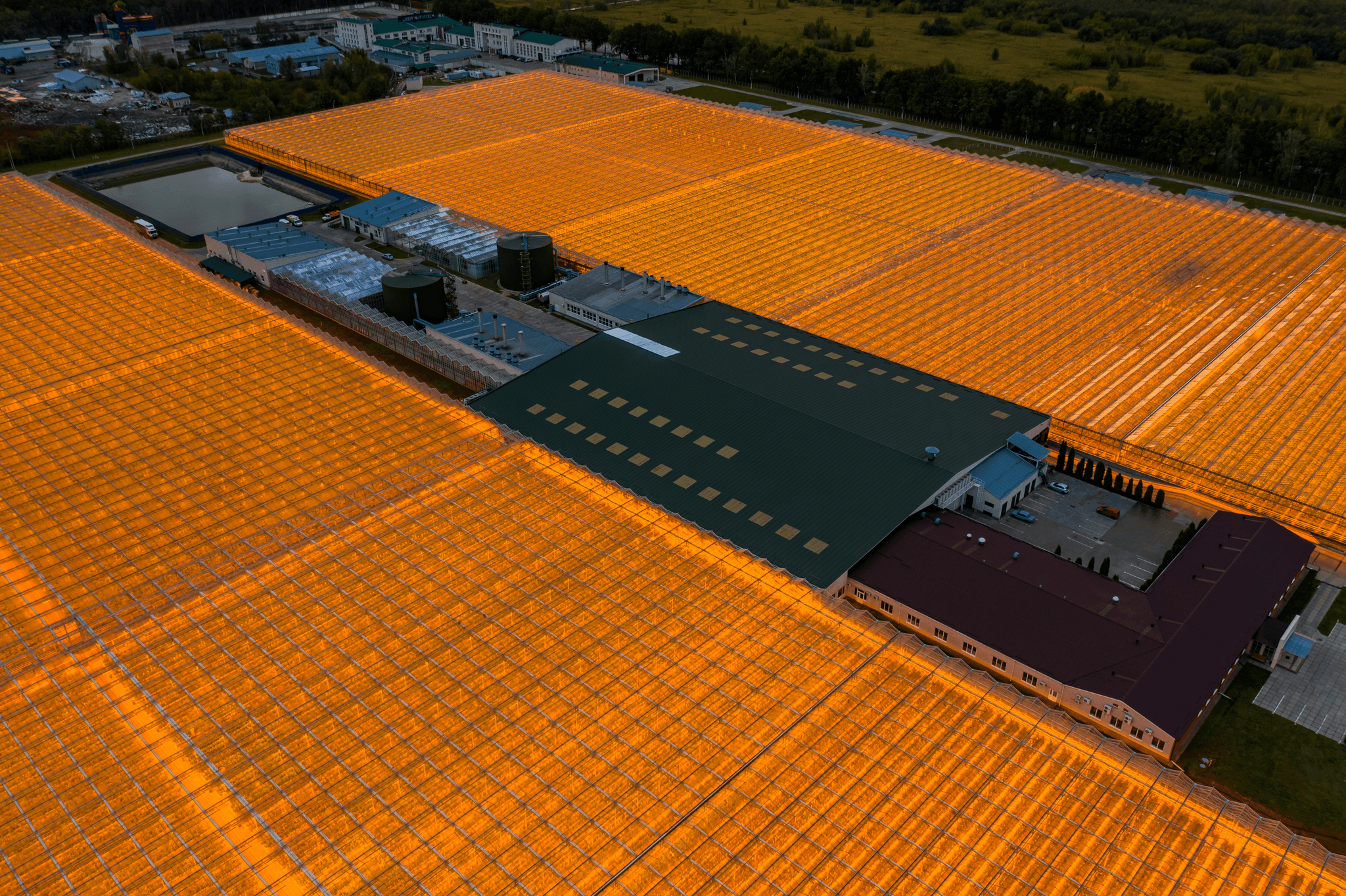

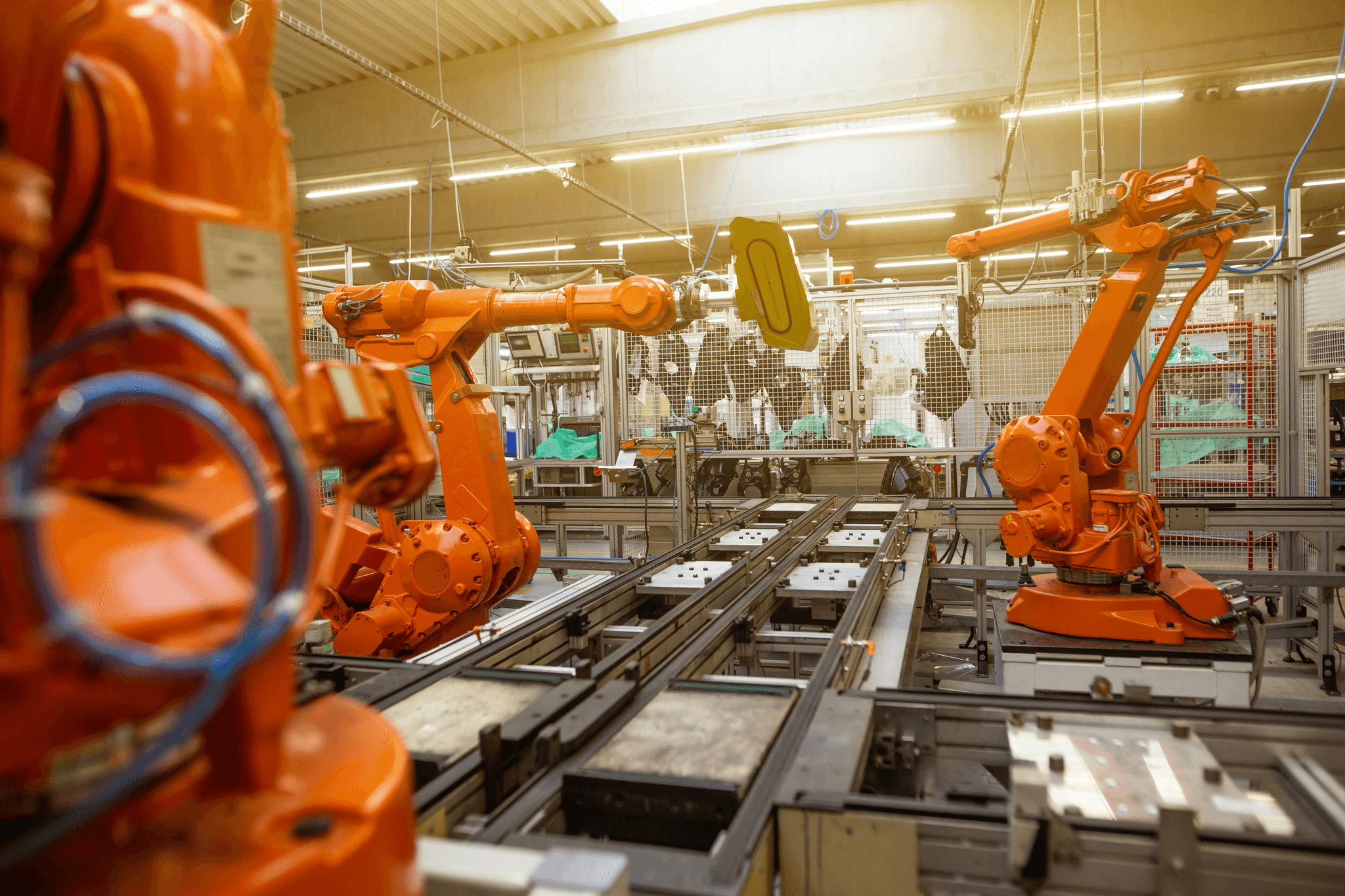

Automation in Green Manufacturing

Automation has emerged as a game-changer in green manufacturing, streamlining production processes while minimizing resource consumption. By incorporating automated systems into manufacturing operations, companies can optimize energy usage, reduce waste, and enhance overall productivity. This shift towards automation enables manufacturers to align with sustainable goals by efficiently utilizing resources and reducing their carbon footprint. At SSOURCING INC., we advocate for the adoption of automated solutions to drive sustainable practices across various industries.

Digitalization of Traditional Processes

The digitalization of traditional manufacturing processes has opened up new avenues for sustainable innovation. Through advanced data analytics and IoT integration, manufacturers can gain valuable insights into their operations, enabling them to make informed decisions that prioritize sustainability. Digital technologies also facilitate real-time monitoring of energy usage and emissions, empowering companies to proactively identify areas for improvement in their environmental impact. At SSOURCING INC., we champion the digital transformation of traditional processes as a means to promote sustainability within the global supply chain.

By embracing technological advancements such as automation and digitalization, companies can revolutionize traditional manufacturing processes while advancing their sustainability efforts. These innovations not only drive operational efficiency but also contribute to a greener future for generations to come.

Conclusion

Sustainable manufacturing is not just a trend, but a necessity for a greener future. Embracing eco-friendly practices is crucial in reducing our environmental footprint and ensuring the longevity of our planet. By adopting sustainable manufacturing processes, companies can not only contribute to a healthier environment but also benefit from cost savings and improved brand reputation.

Embracing Sustainability for a Greener Future

As we look towards the future, it's essential for businesses to prioritize sustainability in their operations. Traditional manufacturing processes have been known to have detrimental effects on the environment, but by embracing sustainable practices, we can work towards minimizing these impacts. SSOURCING INC. recognizes the importance of sustainability and is committed to integrating eco-friendly initiatives into our manufacturing processes.

The Business Case for Sustainable Manufacturing

The business case for sustainable manufacturing is strong and compelling. Companies that invest in green initiatives often see long-term cost savings through reduced energy consumption, waste reduction, and improved operational efficiency. Additionally, consumers are increasingly demanding environmentally responsible products, making sustainability a key driver of brand loyalty and market competitiveness.

SSOURCING INC.'s Commitment to Sustainable Practices

At SSOURCING INC., we understand the significance of sustainable manufacturing in today's global landscape. Our commitment to integrating eco-friendly initiatives into our operations is unwavering as we strive to minimize our environmental impact while delivering high-quality products to our customers.