Introduction

In the world of manufacturing, wood plays a crucial role due to its versatility and durability. From furniture to construction materials, wood manufacturing is an integral part of various industries. SSOURCING INC. recognizes the significance of this sector and aims to provide innovative solutions to meet the demands of the market.

The Importance of Wood Manufacturing

Wood manufacturing is essential in creating a wide range of products that are used in everyday life. It provides raw materials for furniture, flooring, cabinetry, and much more. SSOURCING INC. understands the importance of sustainable practices in wood manufacturing to ensure a steady supply for future generations.

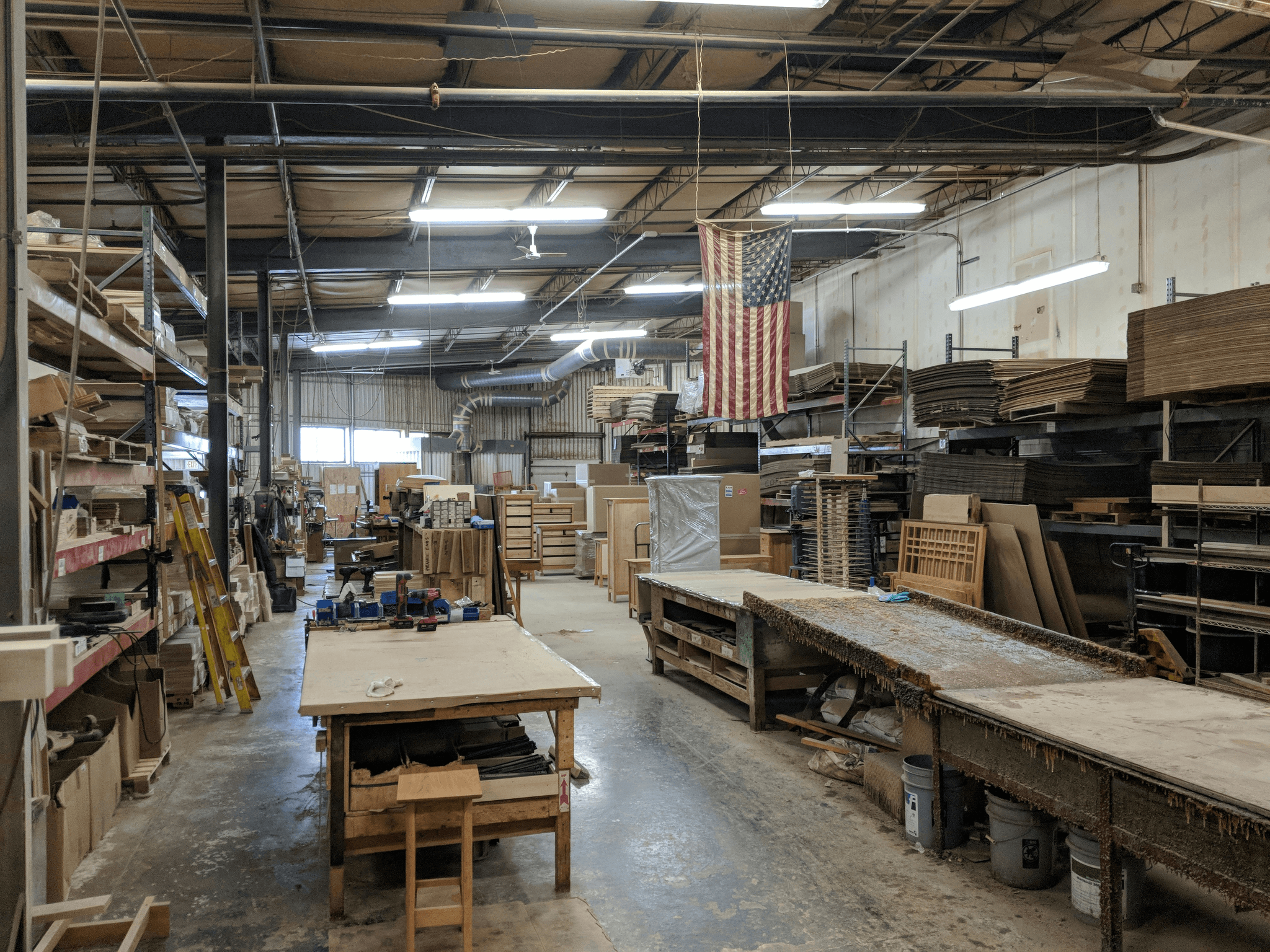

Key Players in the Wood Manufacturing Industry

The wood manufacturing industry is comprised of key players such as lumber mills, sawmills, and woodworking facilities that process raw timber into usable products. These players contribute significantly to the global economy by providing essential materials for various sectors. SSOURCING INC.'s network includes reputable suppliers and manufacturers within this industry.

Trends in Wood Manufacturing

With technological advancements and growing environmental awareness, trends in wood manufacturing are constantly evolving. Sustainable forestry practices and eco-friendly production methods are becoming more prevalent in response to consumer demand for environmentally responsible products. SSOURCING INC.'s commitment to sustainability aligns with these industry trends.

Understanding Wood Manufacturing

Wood manufacturing is a complex and fascinating process that involves transforming raw wood into various products. From logging to milling, drying, and finishing, wood goes through several stages before it becomes the furniture, flooring, or other items we use every day. SSOURCING INC. understands the intricacies of this process and is committed to delivering high-quality wood products to its clients.

The Process of Wood Manufacturing

The process of wood manufacturing begins with logging, where trees are harvested and transported to sawmills for processing. At the sawmill, the logs are cut into lumber and then dried to remove excess moisture. Once dried, the lumber is planed, sanded, and finished according to specific product requirements. SSOURCING INC. ensures that each step in the manufacturing process is carefully executed to produce top-notch wood products for its customers.

Types of Wood Used in Manufacturing

There are various types of wood used in manufacturing, each with unique characteristics and applications. Hardwoods such as oak, maple, and cherry are popular choices for furniture and cabinetry due to their durability and attractive grain patterns. Softwoods like pine and cedar are commonly used for construction materials such as framing lumber and decking due to their strength and affordability. SSOURCING INC. sources a wide range of wood species to meet the diverse needs of its clients.

Sustainable Practices in Wood Manufacturing

Sustainable practices in wood manufacturing aim to minimize environmental impact by promoting responsible forestry management, reducing waste, and utilizing renewable energy sources. SSOURCING INC.'s commitment to sustainability is evident in its use of certified sustainable wood sources and implementation of eco-friendly production processes that prioritize resource conservation.

Quality Control in Wood Manufacturing

Quality control is a crucial aspect of wood manufacturing to ensure that the final products meet the highest standards. At SSOURCING INC., we prioritize product quality by implementing stringent quality control measures throughout the manufacturing process. This includes thorough inspections of raw materials, precise production techniques, and rigorous testing of finished products to guarantee excellence.

Ensuring Product Quality in Wood Manufacturing

SSOURCING INC. employs a comprehensive approach to ensure product quality in wood manufacturing. We carefully select high-quality raw materials and utilize advanced production techniques to maintain consistency and precision in our products. Our dedicated quality control team conducts regular inspections and tests to identify any defects or inconsistencies, ensuring that only top-notch products reach our customers.

Compliance and Regulations in Wood Manufacturing

Compliance with industry regulations and standards is non-negotiable at SSOURCING INC. We strictly adhere to all relevant regulations, including those related to environmental sustainability, worker safety, and product quality. By staying updated on regulatory developments and continuously improving our processes, we guarantee that our wood manufacturing operations comply with the highest industry standards.

Innovations in Quality Control for Wood Manufacturing

Innovation plays a key role in enhancing quality control processes in wood manufacturing. At SSOURCING INC., we embrace technological advancements such as automated inspection systems and digital monitoring tools to improve the accuracy and efficiency of our quality control procedures. These innovations enable us to detect even the smallest imperfections and address them proactively, resulting in superior end products for our clients.

By prioritizing product quality, complying with regulations, and embracing innovative quality control practices, SSOURCING INC. continues to make a significant impact on the wood manufacturing industry while ensuring customer satisfaction at every step of the process.

Machinery and Technology in Wood Manufacturing

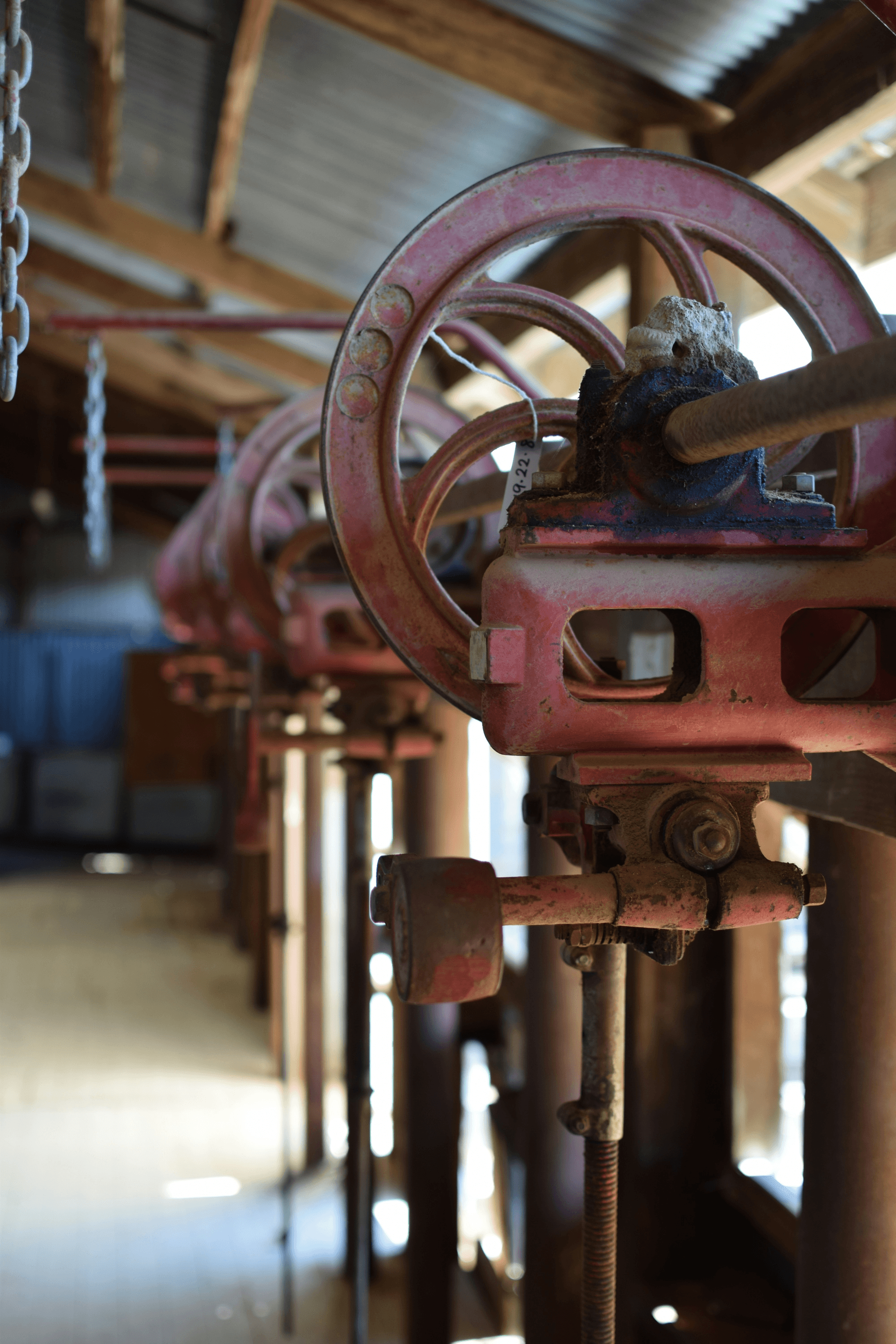

When it comes to wood manufacturing, having the right machinery is crucial for efficiency and quality. Saws, planers, and sanders are essential for cutting and shaping wood, while CNC machines have revolutionized precision cutting and carving. SSOURCING INC. provides state-of-the-art machinery for wood manufacturing, ensuring our clients have access to the best tools for their production needs.

Essential Machinery for Wood Manufacturing

Saws are a fundamental tool in wood manufacturing, used for cutting raw materials into various sizes and shapes. Planers are essential for creating smooth and uniform surfaces on wooden boards, while sanders are necessary for achieving a polished finish. At SSOURCING INC., we offer a wide range of essential machinery to meet the diverse needs of our clients in the wood manufacturing industry.

Advancements in Technology for Wood Manufacturing

Advancements in technology have significantly impacted wood manufacturing, leading to increased precision and efficiency. Computer Numerical Control (CNC) machines have revolutionized the industry by allowing for automated cutting, drilling, and carving processes with unparalleled accuracy. At SSOURCING INC., we stay at the forefront of technological advancements to provide our clients with innovative solutions that enhance their wood manufacturing operations.

Automation in Wood Manufacturing

Automation has become increasingly prevalent in wood manufacturing, streamlining production processes and reducing labor costs. From automated sawing and shaping to robotic assembly lines, automation has transformed the way wooden products are manufactured. SSOURCING INC.'s commitment to embracing automation ensures that our clients can optimize their production processes while maintaining high-quality standards.

Market Analysis of Wood Manufacturing

As the demand for sustainable and eco-friendly products continues to rise, the global wood manufacturing market has seen an upward trend. With a growing focus on environmentally responsible practices, consumers are increasingly turning to wood-based products. This has led to an increase in market opportunities for companies like SSOURCING INC., who prioritize sustainability in their wood manufacturing processes.

Global Wood Manufacturing Market Trends

The global wood manufacturing market is experiencing a shift towards sustainable and renewable resources, with an emphasis on using certified and responsibly sourced wood. This trend is driven by consumer demand for environmentally friendly products, as well as regulations promoting sustainable practices. SSOURCING INC.'s commitment to sustainability positions them well to capitalize on this growing trend.

Key Factors Affecting Wood Manufacturing Demand

Consumer preferences play a significant role in shaping the demand for wood manufacturing products. As more consumers prioritize eco-friendly and natural materials, the demand for wood-based products continues to grow. Additionally, technological advancements in wood manufacturing have made it possible to create innovative and high-quality products, further driving demand in the industry.

Opportunities in the Wood Manufacturing Industry

The wood manufacturing industry presents numerous opportunities for growth and innovation. With the increasing popularity of wooden furniture, flooring, and construction materials, companies like SSOURCING INC. have the chance to expand their product offerings and reach new markets. By embracing sustainable practices and investing in technology, there is potential for significant growth within the industry.

With a focus on sustainability and innovation, SSOURCING INC.'s impact on the wood manufacturing industry is poised to be substantial as they continue to lead the way in providing high-quality wood-based products while prioritizing environmental responsibility.

Conclusion

The future of wood manufacturing looks promising as technology continues to advance, making the process more efficient and sustainable. With the increasing demand for eco-friendly products, sustainability in wood manufacturing is becoming a key focus for industry players. SSOURCING INC.'s impact on wood manufacturing has been significant, with its commitment to implementing sustainable practices and innovative technologies.

The Future of Wood Manufacturing

As technology evolves, the future of wood manufacturing is expected to see further automation and digitalization, leading to increased productivity and reduced waste. With the growing emphasis on sustainable practices, there will also be a shift towards using more environmentally friendly materials and processes. SSOURCING INC.'s forward-thinking approach positions it well to lead the way in this evolving landscape.

Sustainability in Wood Manufacturing

Sustainability is no longer just a trend but a necessity in wood manufacturing. As consumers become more conscious of their environmental impact, there is a growing demand for sustainably sourced and produced wood products. SSOURCING INC.'s commitment to sustainability not only aligns with market demands but also sets an example for others in the industry to follow.

SSOURCING INC.'s Impact on Wood Manufacturing

SSOURCING INC.'s influence on wood manufacturing has been substantial, particularly in driving innovation and promoting sustainable practices within the industry. By leveraging cutting-edge technologies and prioritizing eco-friendly initiatives, SSOURCING INC. has set a new standard for wood manufacturing companies globally.