Introduction

In recent years, the manufacturing landscape has undergone significant transformations, with businesses weighing the merits of onshoring vs reshoring. Onshoring refers to relocating production closer to home, while reshoring involves bringing back operations that were previously moved overseas. Understanding these strategies is crucial for companies like SSOURCING INC., as they navigate a complex global economy.

Understanding Onshoring and Reshoring

Onshoring vs reshoring may sound similar, but they represent distinct approaches to manufacturing strategy. Onshoring typically focuses on relocating processes within the same country, while reshoring emphasizes returning operations from foreign locations back to the domestic market. This distinction is essential for organizations looking to optimize their supply chains and enhance operational efficiency.

Why This Comparison Matters Today

The debate over onshoring vs reshoring is particularly relevant in today's economic climate, where factors such as rising labor costs abroad and supply chain disruptions have prompted many companies to rethink their strategies. As businesses strive for resilience in an unpredictable environment, understanding these concepts can lead to better decision-making and long-term success. For SSOURCING INC., this comparison highlights opportunities for growth and innovation in manufacturing practices.

Key Factors Driving Manufacturing Changes

Several key factors are driving changes in manufacturing practices today, making the discussion of onshoring vs reshoring more pertinent than ever. Economic pressures, technological advancements, and consumer preferences are all influencing how companies approach their production strategies. By examining these elements closely, organizations can position themselves effectively in a rapidly evolving marketplace.

Defining Onshoring and Reshoring

In the ever-evolving landscape of global manufacturing, understanding the nuances of onshoring vs reshoring is crucial for companies looking to optimize their supply chains. While both strategies aim to bring production closer to the end consumer, they do so with different focuses and implications. Onshoring typically refers to relocating production back to the original country where a company is headquartered, while reshoring involves moving operations back from overseas but not necessarily to the original country.

Distinction Between Onshoring and Reshoring

The distinction between onshoring vs reshoring may seem subtle but has significant implications for businesses. Onshoring emphasizes localizing manufacturing within a company's home country, often in response to rising labor costs abroad or logistical challenges. In contrast, reshoring may involve relocating operations from one foreign country to another, seeking cost efficiencies or better market access without returning entirely home.

Understanding these definitions is essential for firms like SSOURCING INC., as they navigate their own operational strategies amidst changing economic conditions. The choice between onshoring and reshoring can impact everything from supply chain logistics and labor costs to customer satisfaction and brand loyalty. Ultimately, each strategy presents unique advantages that can align differently with a company's long-term goals.

Real-World Examples from Apple and General Motors

To illustrate the practical applications of onshoring vs reshoring, let's take a look at two industry giants: Apple and General Motors (GM). Apple has made headlines for its decision to shift some manufacturing back to the United States—specifically in Texas—demonstrating an onshoring approach aimed at reducing lead times and enhancing quality control. This move not only boosts local employment but also aligns with consumer preferences for domestically produced goods.

On the other hand, GM's strategy leans more towards reshoring as it works diligently to bring production back from various international locations while still maintaining some overseas operations for specific markets. By investing in new plants in Michigan, GM exemplifies how reshaping global manufacturing networks can enhance competitiveness while responding directly to domestic demand shifts. These examples underscore that both onshoring and reshoring are viable strategies depending on a company’s unique circumstances.

Benefits of Each Strategy

The benefits of choosing between onshoring vs reshoring are multifaceted and depend largely on individual business objectives. Onshoring can lead to improved supply chain resilience by minimizing transportation delays and ensuring quicker response times—an especially critical factor in today's fast-paced market environment. Furthermore, it fosters local job creation which can enhance corporate reputation among consumers who increasingly value socially responsible practices.

Resharing offers its own set of advantages; companies can capitalize on lower operational costs in certain regions while still gaining proximity to key markets or resources that facilitate growth strategies. For instance, by shifting production closer to emerging markets or specific customer bases abroad, businesses can tailor their offerings more effectively without compromising quality or service delivery timelines. Ultimately, whether opting for onshoring or reshaping their operational footprint through reshored initiatives like those seen at SSOURCING INC., firms must weigh these benefits against their long-term strategic goals.

The Economic Landscape Impact

The economic landscape is a complex web of factors that significantly influences the decisions surrounding onshoring vs reshoring. As businesses navigate through a globalized economy, they must weigh the benefits and drawbacks of relocating manufacturing closer to home versus bringing previously outsourced operations back. This dynamic environment requires careful consideration of costs, labor availability, and consumer demand.

How Globalization Influences Decisions

Globalization has been a double-edged sword for manufacturers deciding between onshoring vs reshoring. While it opens up new markets and opportunities for profit, it also complicates supply chains and exposes companies to geopolitical risks. Organizations must now assess how international relations, tariffs, and logistical challenges impact their operational strategies in an increasingly interconnected world.

Moreover, the COVID-19 pandemic highlighted vulnerabilities within global supply chains, prompting many firms to reconsider their approach to manufacturing. Companies are now more inclined to bring production closer to their target markets—an essential move in managing risk and ensuring quicker response times. Thus, understanding the nuances of globalization is crucial for firms like SSOURCING INC., which aim to guide clients through these pivotal decisions.

Case Studies: Boeing and Tesla's Shifts

Boeing's recent shifts illustrate the ongoing debate between onshoring vs reshoring amid changing economic conditions. The aerospace giant has faced challenges related to its reliance on global suppliers for critical components, leading them to explore options that bring more production back within U.S. borders. This strategic pivot aims not only at reducing risks but also at enhancing quality control—a vital aspect in an industry where safety is paramount.

Tesla provides another compelling case study as it expands its manufacturing footprint domestically while maintaining some international operations. By establishing Gigafactories close to key markets like Texas and Berlin, Tesla demonstrates a hybrid approach that balances onshoring with selective reshoring strategies tailored for efficiency and innovation. Such moves reflect broader trends where companies are not just reacting but proactively shaping their operational frameworks in response to evolving market dynamics.

The Role of Trade Policies

Trade policies play a crucial role in shaping decisions around onshoring vs reshoring by creating an environment that either incentivizes or discourages domestic manufacturing investments. Tariffs imposed on imported goods can make overseas production less attractive while providing a competitive edge for U.S.-based manufacturers—an essential factor influencing corporate strategies today. For instance, favorable trade agreements can encourage businesses like SSOURCING INC. to advocate for local sourcing initiatives among their clients.

Additionally, changes in political leadership often lead to shifts in trade policy that affect how companies view their supply chain strategies over time. With increasing scrutiny over foreign dependency and calls for greater self-sufficiency post-pandemic, many organizations are reassessing how they align with national interests regarding manufacturing capabilities—whether through full-scale reshoring or targeted onshoring initiatives tailored for specific products or services.

In conclusion, understanding how globalization influences decisions about onshoring vs reshoring is vital as companies navigate this complex landscape shaped by economic factors and trade policies alike.

Supply Chain Resilience

In today's fast-paced manufacturing environment, supply chain resilience has become a crucial component for businesses navigating the complexities of onshoring vs reshoring. Companies are increasingly recognizing the importance of strengthening local supply chains to mitigate risks associated with global disruptions. By focusing on local sourcing and production, organizations can enhance their responsiveness to market demands while reducing dependency on distant suppliers.

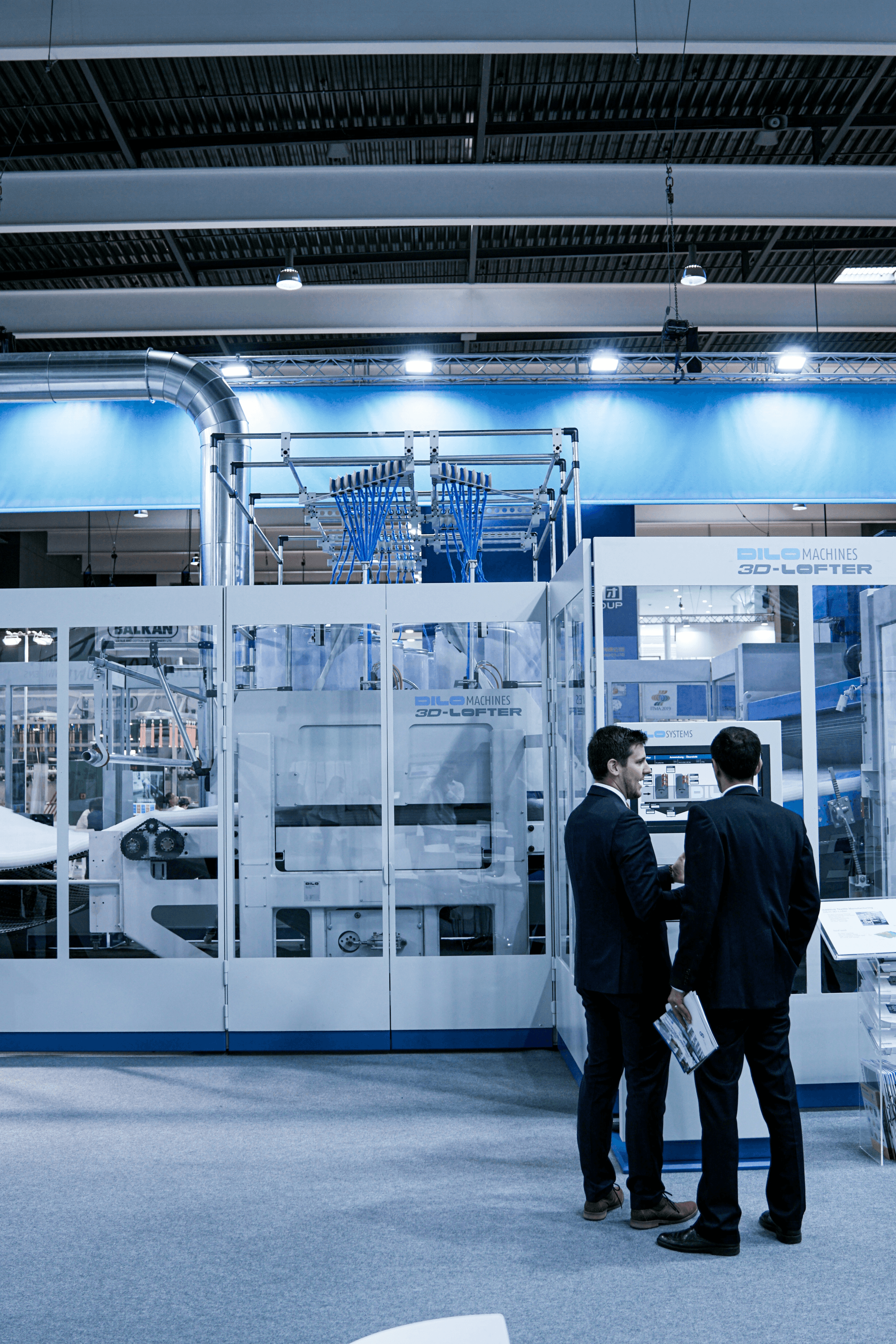

Strengthening Local Supply Chains

Strengthening local supply chains is not just a buzzword; it's a strategic necessity in the context of onshoring vs reshoring. By investing in domestic suppliers and production facilities, companies can create more robust networks that are less vulnerable to international disruptions. This shift not only boosts local economies but also fosters innovation and collaboration within communities, ultimately leading to more sustainable business practices.

Insights from Procter & Gamble

Procter & Gamble (P&G) serves as an excellent case study for understanding the dynamics of onshoring vs reshoring and its impact on supply chain resilience. With its commitment to local sourcing, P&G has successfully minimized risks by ensuring that key components are sourced closer to home. This approach has allowed the company to respond swiftly to consumer needs while maintaining high-quality standards—a critical factor in today’s competitive marketplace.

Challenges Faced by Multinational Corporations

Despite the advantages of strengthening local supply chains, multinational corporations often face significant challenges when deciding between onshoring vs reshoring strategies. Navigating varying regulations, labor costs, and market conditions can complicate these decisions further. Companies like SSOURCING INC. provide valuable insights into overcoming these hurdles, helping businesses strike a balance between cost-effectiveness and operational efficiency while enhancing their overall resilience.

Labor Considerations and Costs

When discussing onshoring vs reshoring, one of the most pressing issues is the availability of a skilled workforce. Many companies are grappling with a significant skills gap that can hinder their ability to effectively transition manufacturing operations back to domestic soil. This challenge is particularly pronounced in industries that require specialized training and expertise, making it crucial for businesses like SSOURCING INC. to invest in workforce development initiatives.

Workforce Availability and Skills Gap

The workforce availability plays a pivotal role in the onshoring vs reshoring debate, as businesses must evaluate whether they can find qualified employees locally. The skills gap has widened over recent years due to various factors, including an aging workforce and a lack of vocational training programs tailored to modern manufacturing needs. To bridge this gap, companies are increasingly collaborating with educational institutions to create programs that equip workers with the necessary skills for today’s high-tech manufacturing environment.

Analysis of Amazon's Hiring Strategies

Amazon’s approach to hiring offers valuable insights into how large corporations are addressing labor challenges amid the onshoring vs reshoring conversation. The company has invested heavily in recruitment strategies that emphasize not only filling positions but also attracting talent with advanced skill sets relevant to evolving technologies. By offering competitive wages, comprehensive benefits, and career advancement opportunities, Amazon aims to create an attractive workplace that helps mitigate labor shortages while setting a precedent for other companies considering similar shifts.

Balancing Wages with Productivity

In navigating the complexities of onshoring vs reshoring, striking a balance between wages and productivity becomes essential for maintaining profitability without sacrificing quality or employee satisfaction. Companies often face pressure to keep labor costs low while ensuring they have access to skilled workers who can enhance productivity through innovation and efficiency. Sourcing partners like SSOURCING INC. can assist businesses in finding this equilibrium by providing strategic insights into labor markets and helping them implement effective training programs tailored to their specific needs.

Sustainability Concerns

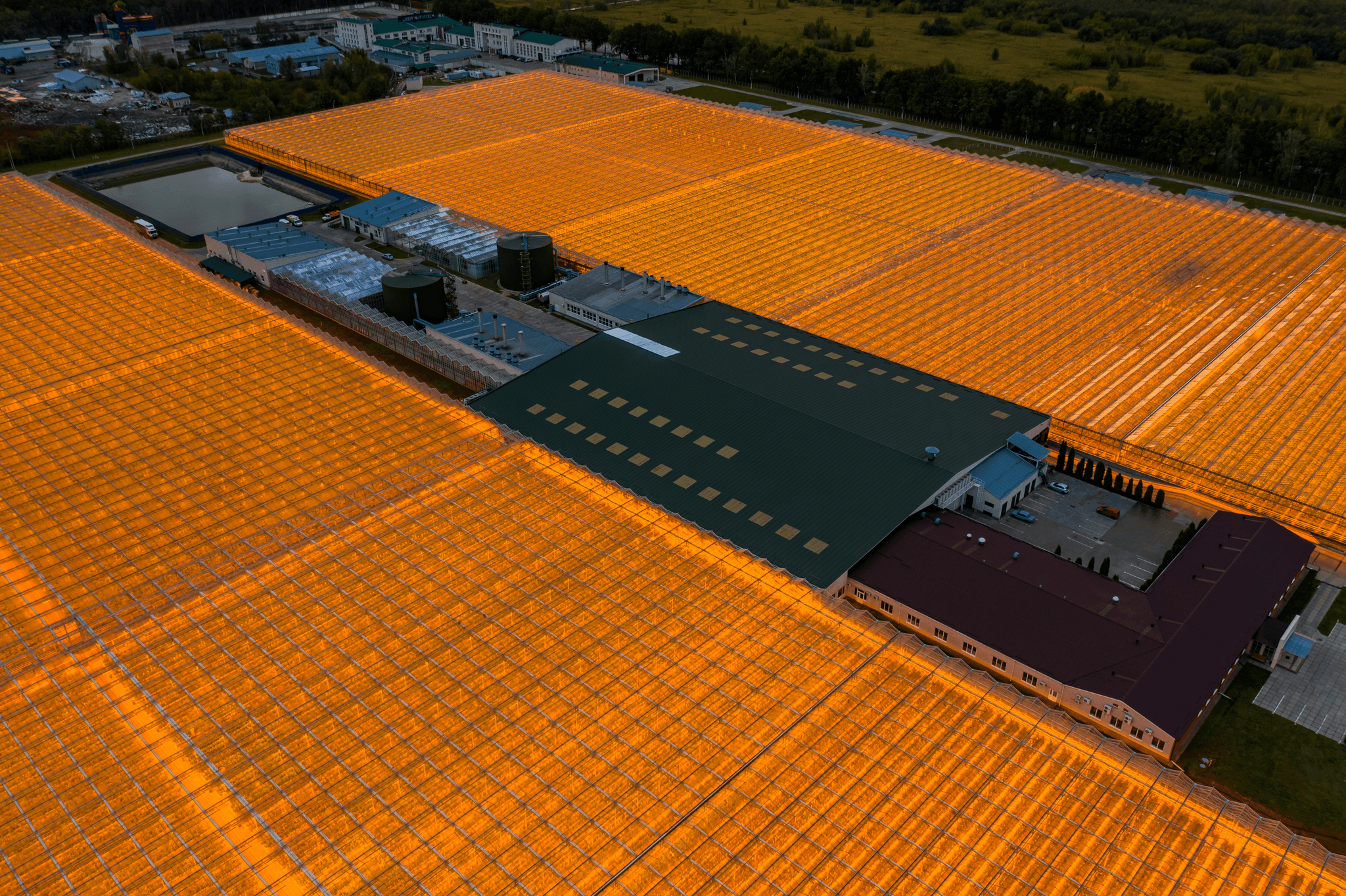

In the modern manufacturing landscape, sustainability has emerged as a crucial consideration for companies weighing onshoring vs reshoring. The environmental impact of manufacturing choices can no longer be an afterthought; it must be integral to strategic planning. Businesses are increasingly scrutinizing their supply chains and production methods to minimize their carbon footprints while meeting consumer demands.

Environmental Impact of Manufacturing Choices

The decisions surrounding onshoring vs reshoring significantly affect the environment, particularly in terms of emissions and resource consumption. Onshoring often involves relocating production closer to the end consumer, which can reduce transportation emissions but may still rely heavily on local energy sources that aren't always renewable. Conversely, reshoring can offer opportunities for companies to adopt greener technologies and practices by leveraging advanced manufacturing techniques that prioritize sustainability.

Innovations by Unilever and IKEA

Companies like Unilever and IKEA are leading the charge in sustainable innovations, showcasing how onshoring vs reshoring can align with eco-conscious practices. Unilever has committed to reducing its environmental impact through initiatives like biodegradable packaging and sustainable sourcing, demonstrating that responsible manufacturing is not just good ethics but also good business. Similarly, IKEA's focus on using renewable materials and energy-efficient processes illustrates how businesses can thrive while prioritizing sustainability in their operations.

Consumer Preferences for Eco-Friendly Products

Consumer preferences are shifting towards eco-friendly products, influencing companies' decisions about whether to pursue onshoring vs reshoring strategies. Today's consumers are more informed than ever about the environmental implications of their purchases, prompting brands to adopt greener practices or risk losing market share. As SSOURCING INC. navigates these choices alongside clients, understanding these trends becomes essential for aligning with customer values while ensuring competitive advantage.

Conclusion

In wrapping up our exploration of onshoring vs reshoring, it's clear that both strategies offer unique advantages and challenges for manufacturers seeking to optimize their operations. Onshoring focuses on relocating production closer to the market, enhancing responsiveness and reducing shipping times, while reshoring emphasizes bringing back manufacturing capabilities that were previously outsourced. Understanding these distinctions is vital for companies aiming to make informed decisions in today’s dynamic economic landscape.

Key Takeaways on Onshoring vs Reshoring

The debate between onshoring vs reshoring is not just a matter of geography; it’s about strategic alignment with business goals and market demands. Companies like Apple have demonstrated the benefits of onshoring by improving supply chain efficiency, while General Motors showcases how reshoring can revitalize domestic manufacturing capabilities. Ultimately, businesses must weigh factors such as cost, labor availability, and customer preferences when deciding which approach best suits their needs.

The Future of Manufacturing in America

As we look ahead, the future of manufacturing in America seems poised for a blend of both onshoring and reshoring strategies. With ongoing advancements in technology and a growing emphasis on sustainability, companies are likely to adopt hybrid models that leverage the strengths of each approach. This evolution will not only enhance competitiveness but also contribute to job creation and economic resilience across various sectors.

How SSOURCING INC. Can Help You Navigate Choices

Navigating the complexities of onshoring vs reshoring can be daunting—this is where SSOURCING INC. comes into play! Our expertise lies in providing tailored solutions that help businesses evaluate their options based on current market trends and operational needs. Whether you’re considering shifting production closer to home or looking to bring back previously outsourced functions, we’re here to guide you every step of the way.