Introduction

In today's global marketplace, quality control in China has become increasingly vital for businesses like SSOURCING INC. to ensure product excellence and customer satisfaction. With the rise of manufacturing in China, the need for stringent quality control measures has never been more critical. As a leading player in the industry, SSOURCING INC. understands the significance of maintaining high-quality standards in every aspect of production and supply chain management.

Importance of Quality Control in China

The importance of quality control in China cannot be overstated, especially as it directly impacts consumer trust and brand reputation. For SSOURCING INC., ensuring that products meet international standards is essential for maintaining a competitive edge and building long-term relationships with customers. By prioritizing quality control, businesses can mitigate risks associated with subpar products and avoid costly recalls or reputational damage.

New Trends and Developments

Amidst rapid technological advancements, new trends and developments are shaping the landscape of quality control in China. From AI-powered inspection systems to blockchain-enabled traceability solutions, SSOURCING INC. recognizes the need to stay abreast of these innovations to enhance product quality and operational efficiency.

Key Challenges and Solutions

As companies navigate the complexities of manufacturing in China, they encounter key challenges such as counterfeit products, supply chain disruptions, and regulatory compliance issues. However, proactive measures such as implementing robust supplier vetting processes, leveraging advanced testing methods, and fostering transparent partnerships with manufacturers can help mitigate these challenges effectively.

The Evolution of Quality Control in China

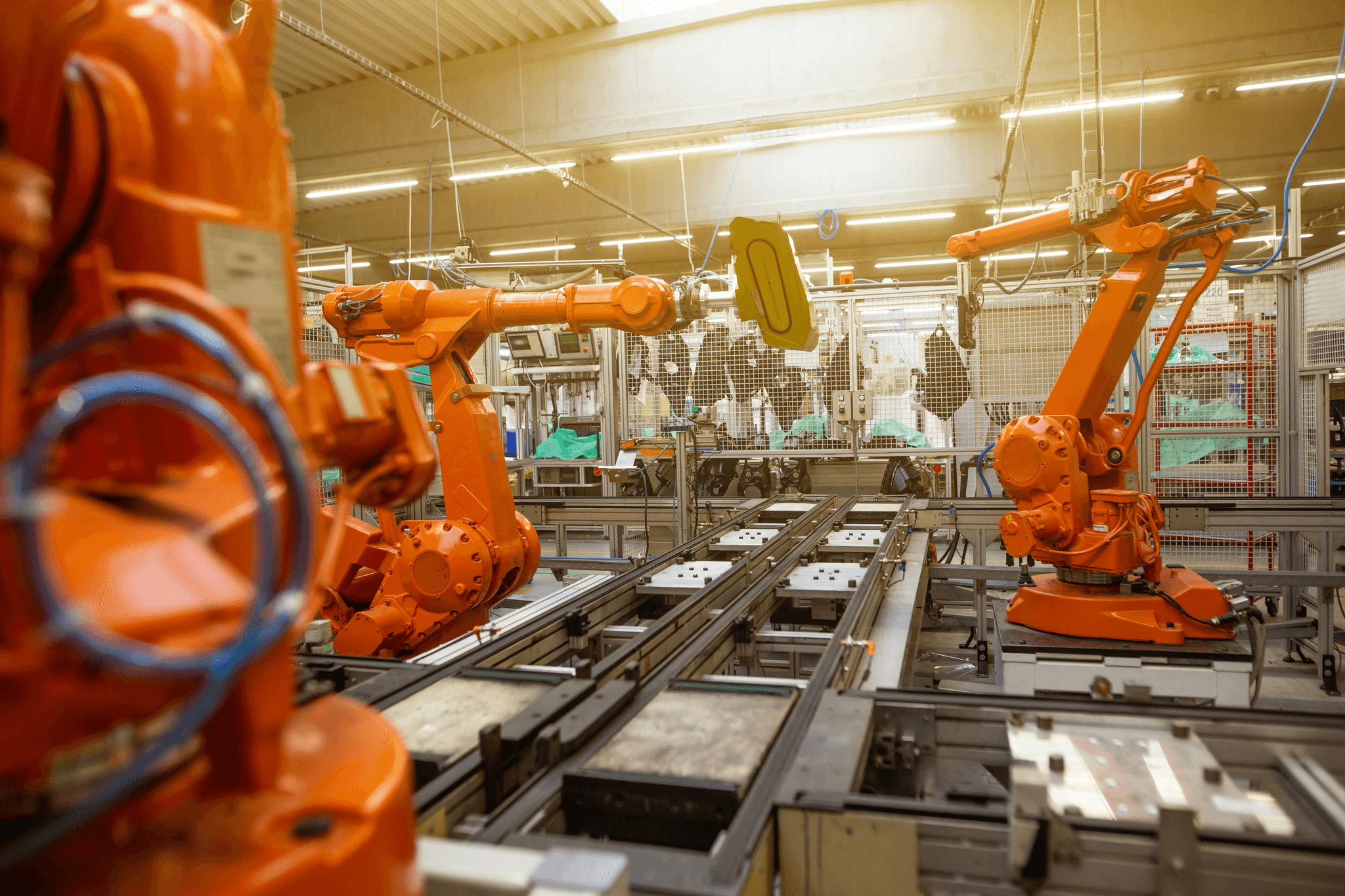

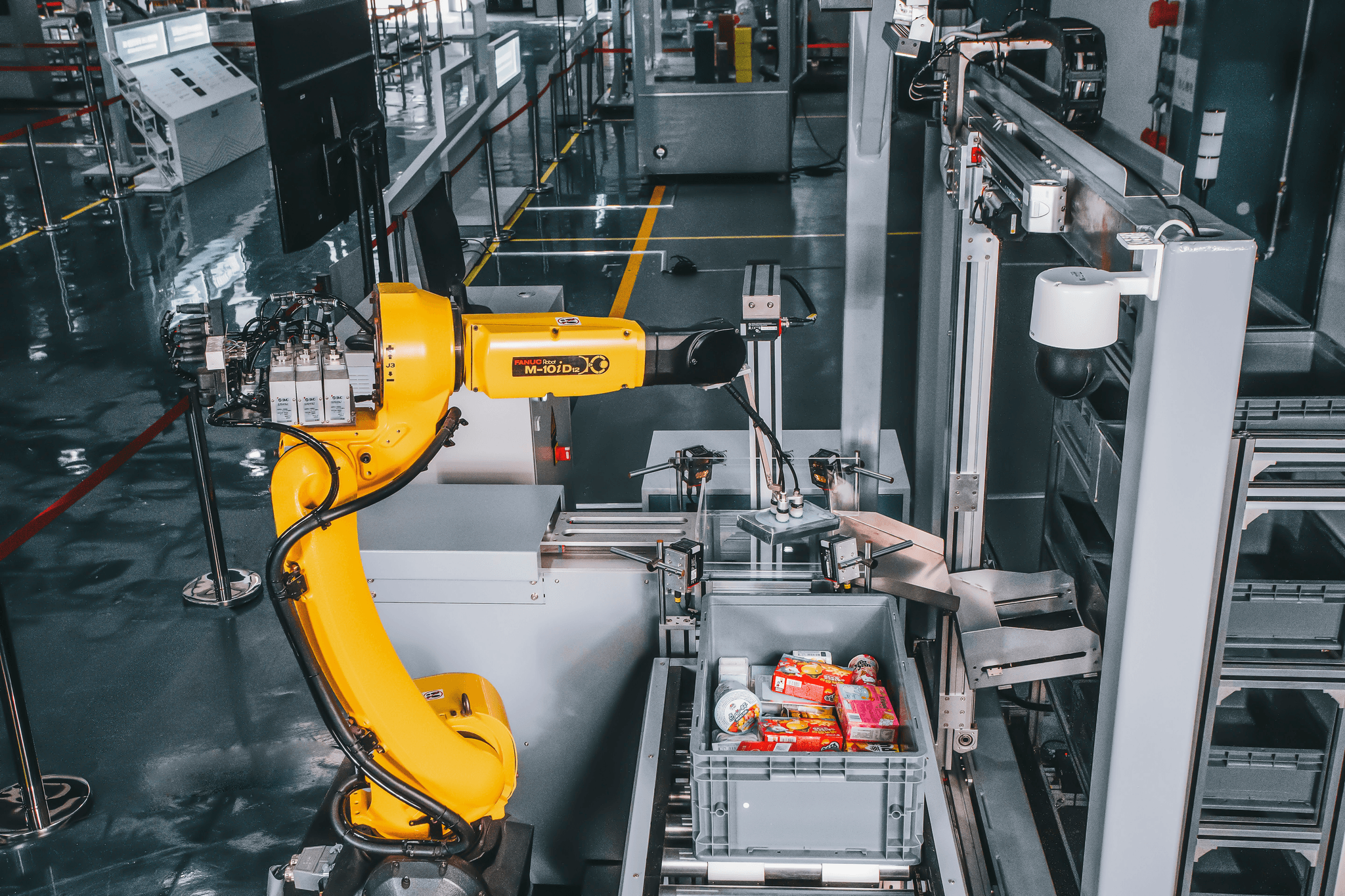

As China continues to solidify its position as a global manufacturing powerhouse, the role of AI and automation in quality control has become increasingly prominent. With the integration of advanced technologies, SSOURCING INC. has witnessed a significant improvement in production efficiency and product consistency. Through the implementation of AI-powered inspection systems and automated assembly lines, our company has been able to ensure that stringent quality standards are met at every stage of production.

Rising Role of AI and Automation

The rising role of AI and automation in quality control has revolutionized the manufacturing landscape in China. SSOURCING INC. has embraced this trend by leveraging cutting-edge machine learning algorithms to detect defects and anomalies with unparalleled accuracy. By automating repetitive tasks, we have been able to minimize human error and optimize our quality control processes, ultimately resulting in higher customer satisfaction and reduced operational costs.

Impact of Sustainable Practices

In response to growing environmental concerns, sustainable practices have become integral to quality control in China. SSOURCING INC. has adopted eco-friendly manufacturing processes and materials, aligning with the country's push for green initiatives. By prioritizing sustainability, our company not only ensures compliance with regulations but also appeals to environmentally conscious consumers who are increasingly demanding ethically sourced products.

Adoption of Industry 4.0 Technologies

The adoption of Industry 4.0 technologies such as IoT (Internet of Things) and big data analytics has transformed the way quality control is managed in China's manufacturing sector. SSOURCING INC.'s implementation of IoT-enabled sensors and real-time data analysis has enabled proactive maintenance, predictive quality assurance, and seamless communication across our production facilities. This technological leap has empowered us to identify potential issues before they escalate, leading to enhanced product reliability.

By embracing these advancements in quality control practices within China's dynamic industrial landscape, SSOURCING INC. is well-positioned to maintain its competitive edge while shaping the future of manufacturing excellence in the region.

Key Players in Quality Control in China

When it comes to quality control in China, key players like Apple Inc., Nike Inc., and Samsung Electronics Co., Ltd. have set the bar high for ensuring top-notch product quality. These global giants have implemented stringent quality control measures to maintain their reputation for excellence in manufacturing and production. Let's take a closer look at how these industry leaders are shaping the landscape of quality control in China.

Case Study: Apple Inc.

Apple Inc. has been at the forefront of quality control in China, leveraging cutting-edge technology and meticulous inspection processes to deliver flawless products to consumers worldwide. By partnering with trusted suppliers and conducting rigorous assessments, Apple ensures that every component meets its exacting standards before assembly. This commitment to uncompromising quality has solidified Apple's position as a leader in the tech industry, setting a benchmark for other companies, including SSOURCING INC., to follow.

Case Study: Nike Inc.

Nike Inc.'s dedication to quality control is evident through its comprehensive supplier management system and strict adherence to ethical manufacturing practices in China. The company conducts regular factory audits and performance evaluations to uphold product integrity and ethical labor standards. By prioritizing transparency and accountability throughout its supply chain, Nike has established itself as a trailblazer in sustainable and responsible manufacturing practices, inspiring SSOURCING INC. to adopt similar principles.

Case Study: Samsung Electronics Co., Ltd.

Samsung Electronics Co., Ltd. has implemented robust quality control measures across its operations in China, focusing on continuous improvement and innovation to meet consumer demands for high-quality electronic devices. The company emphasizes stringent testing protocols and process optimization to ensure that every product meets rigorous performance standards before reaching the market. By prioritizing innovation and reliability, Samsung has solidified its reputation as a leading provider of cutting-edge technology, serving as an inspiration for SSOURCING INC.'s pursuit of excellence.

These case studies highlight the pivotal role that industry leaders play in driving advancements within the realm of quality control in China while inspiring other companies like SSOURCING INC. to prioritize excellence across their operations.

Effective Strategies for Quality Control in China

Implementing Advanced Testing Methods

In order to ensure top-notch quality control in China, SSOURCING INC. must prioritize the implementation of advanced testing methods. This involves leveraging cutting-edge technology and equipment to conduct rigorous quality assessments at every stage of production. By investing in state-of-the-art testing facilities, our company can uphold the highest standards and deliver superior products to our customers, thereby solidifying our reputation as a trusted brand in the market.

Enhancing Supply Chain Transparency

Another pivotal strategy for quality control in China is enhancing supply chain transparency. SSOURCING INC. should establish clear communication channels with all suppliers and partners involved in the production process, ensuring full visibility into every aspect of the supply chain. This transparency not only enables us to monitor quality standards but also fosters accountability among all stakeholders, ultimately leading to improved product integrity and customer satisfaction.

Building Strong Partnerships with Manufacturers

Building strong partnerships with manufacturers is essential for effective quality control in China. By forging collaborative relationships based on mutual trust and respect, SSOURCING INC. can align with manufacturers who share our commitment to excellence and ethical practices. These partnerships enable us to work closely with suppliers to implement stringent quality control measures, driving continuous improvement and innovation throughout the manufacturing process.

Now that we have discussed effective strategies for quality control in China, let's explore the regulatory framework and compliance measures that are crucial for businesses operating in this dynamic market.

Regulatory Framework and Compliance

In the ever-changing landscape of quality control in China, staying updated with the latest regulations is crucial. SSOURCING INC. understands the importance of adhering to Chinese regulations, which are constantly evolving to meet international standards. By closely monitoring and adapting to these changes, we ensure that our products maintain top-notch quality and compliance.

Changes in Chinese Regulations

As China continues to position itself as a global manufacturing hub, the government has been implementing stricter regulations to uphold product quality and safety. SSOURCING INC. closely monitors these changes to ensure that our operations align with the latest standards set by Chinese regulatory bodies. By staying ahead of these developments, we demonstrate our commitment to delivering high-quality products that meet or exceed industry requirements.

Ensuring Ethical and Legal Compliance

Ethical and legal compliance is a cornerstone of SSOURCING INC.'s approach to quality control in China. We prioritize ethical sourcing practices and adhere to all legal requirements related to manufacturing, labor, and environmental sustainability. By upholding stringent ethical standards, we not only safeguard our brand reputation but also contribute positively to the social and environmental landscape in China.

Navigating Trade Tariffs and Policies

Amidst ongoing trade tensions, navigating trade tariffs and policies is a critical aspect of quality control in China for SSOURCING INC.. Our team continuously evaluates the impact of trade policies on our supply chain operations, ensuring minimal disruption while optimizing cost-efficiency. By strategically managing trade tariffs and policies, we mitigate potential risks while maximizing opportunities for growth within the dynamic Chinese market.

Future Outlook and Opportunities

Leveraging Data Analytics for Quality Improvement

In the rapidly evolving landscape of quality control in China, leveraging data analytics is crucial for SSOURCING INC. to enhance its manufacturing processes. By analyzing large volumes of production data, we can identify trends, detect defects, and make informed decisions to improve product quality and efficiency.

Embracing Digital Transformation

As technology continues to reshape the manufacturing industry, SSOURCING INC. must embrace digital transformation to stay ahead in quality control in China. This involves integrating smart technologies such as IoT devices and cloud-based platforms into our operations, enabling real-time monitoring and proactive maintenance to ensure consistent product quality.

Collaborating with Industry Leaders for Best Practices

To further strengthen our position in quality control in China, SSOURCING INC. should actively seek collaborations with industry leaders to exchange best practices and insights. By engaging with key players in the market, we can gain valuable knowledge and expertise that will help us optimize our quality control processes and drive continuous improvement.

Conclusion

In conclusion, embracing innovation for quality excellence is crucial in the ever-evolving landscape of quality control in China. SSOURCING INC. must stay ahead of the curve by investing in cutting-edge technologies and staying abreast of industry trends to maintain a competitive edge.

Embracing Innovation for Quality Excellence

As the market continues to demand higher quality standards, SSOURCING INC. must embrace innovation to ensure that its products meet and exceed customer expectations. By leveraging advanced testing methods and adopting Industry 4.0 technologies, the company can stay at the forefront of quality control in China.

Enhancing SSOURCING INC.'s Competitive Edge

To enhance SSOURCING INC.'s competitive edge, it is imperative to build strong partnerships with manufacturers and suppliers who prioritize quality control. By fostering transparent and collaborative relationships, the company can ensure that its products meet stringent quality standards while maintaining cost-efficiency.

Shaping the Future of Manufacturing in China

As a key player in the manufacturing industry, SSOURCING INC. has an opportunity to shape the future of manufacturing in China by setting a benchmark for quality control practices. By adhering to ethical and legal compliance, navigating trade tariffs and policies, and embracing digital transformation, the company can lead by example and influence positive change in the industry.