Introduction

In today's competitive market, the importance of quality in manufacturing cannot be overstated. As businesses strive to deliver superior products, the emphasis on quality has become a cornerstone of success. At SSOURCING INC., we understand the pivotal role that quality plays in driving customer satisfaction and loyalty.

Importance of Quality in Manufacturing

Quality in manufacturing is not just about meeting standards; it's about exceeding them to deliver exceptional products that stand out in the market. At SSOURCING INC., we recognize that superior quality is a key differentiator and a crucial factor in building a strong brand reputation.

Impact of Efficiency on Business Success

Efficiency is another critical aspect that directly impacts business success. By streamlining processes and optimizing resources, companies can achieve higher productivity and cost-effectiveness. At SSOURCING INC., we prioritize efficiency as a means to drive sustainable growth and profitability.

SSOURCING INC.'s Commitment to Quality

At SSOURCING INC., our commitment to quality is unwavering. We have implemented stringent quality control measures across all stages of manufacturing, ensuring that every product leaving our facilities meets the highest standards of excellence.

Implementing Quality Control Measures

In the competitive landscape of manufacturing, ensuring quality is paramount. At SSOURCING INC., we have implemented robust quality assurance processes to guarantee that our products meet the highest standards. From raw material inspection to final product testing, our meticulous approach to quality control has set us apart in the industry.

Quality Assurance Processes

Our quality assurance processes are designed to identify and address any potential issues early in the production cycle. Through rigorous testing and inspection protocols, we ensure that every component and finished product meets our stringent quality criteria. This commitment to excellence has earned us a reputation for delivering reliable and high-quality products to our customers, setting us apart as an industry leader in quality manufacturing.

Continuous Improvement Strategies

In today's fast-paced market, continuous improvement is essential for staying ahead of the competition. At SSOURCING INC., we are dedicated to constantly refining our manufacturing processes to enhance efficiency and maintain exceptional quality standards. By leveraging data-driven insights and feedback from our team, we have successfully implemented continuous improvement strategies that have further elevated the quality of our products.

SSOURCING INC.'s Quality Control Success Stories

Our unwavering dedication to quality control has resulted in numerous success stories for SSOURCING INC. From achieving industry certifications to receiving accolades for product excellence, our commitment to implementing effective quality control measures has consistently yielded positive outcomes for both our company and customers alike.

Lean Manufacturing Principles

In the competitive landscape of manufacturing, the ability to streamline production processes is crucial for success. By eliminating unnecessary steps and optimizing workflows, SSOURCING INC. has been able to achieve higher productivity and reduce lead times in our manufacturing operations. Our commitment to lean principles has allowed us to deliver high-quality products to our customers in a more efficient manner.

Streamlining Production Processes

At SSOURCING INC., we have implemented a systematic approach to identify and eliminate bottlenecks in our production processes. By analyzing each step of the manufacturing workflow, we have been able to identify areas for improvement and implement solutions that streamline operations. This has not only improved our overall efficiency but also enhanced the quality of our products, ultimately leading to greater customer satisfaction.

Waste Reduction Techniques

Lean manufacturing principles also emphasize the reduction of waste in all forms, including time, materials, and resources. SSOURCING INC. has implemented strategies such as just-in-time inventory management and optimized resource allocation to minimize waste throughout our production processes. This approach not only contributes to cost savings but also aligns with our commitment to sustainable and environmentally friendly manufacturing practices.

SSOURCING INC.'s Lean Manufacturing Initiatives

Our dedication to lean manufacturing extends beyond internal operations; we also work closely with our suppliers and partners to ensure that lean principles are integrated throughout the entire supply chain. By fostering a culture of continuous improvement and waste reduction, SSOURCING INC. can deliver high-quality products efficiently while maintaining a competitive edge in the market.

Investing in Advanced Technology

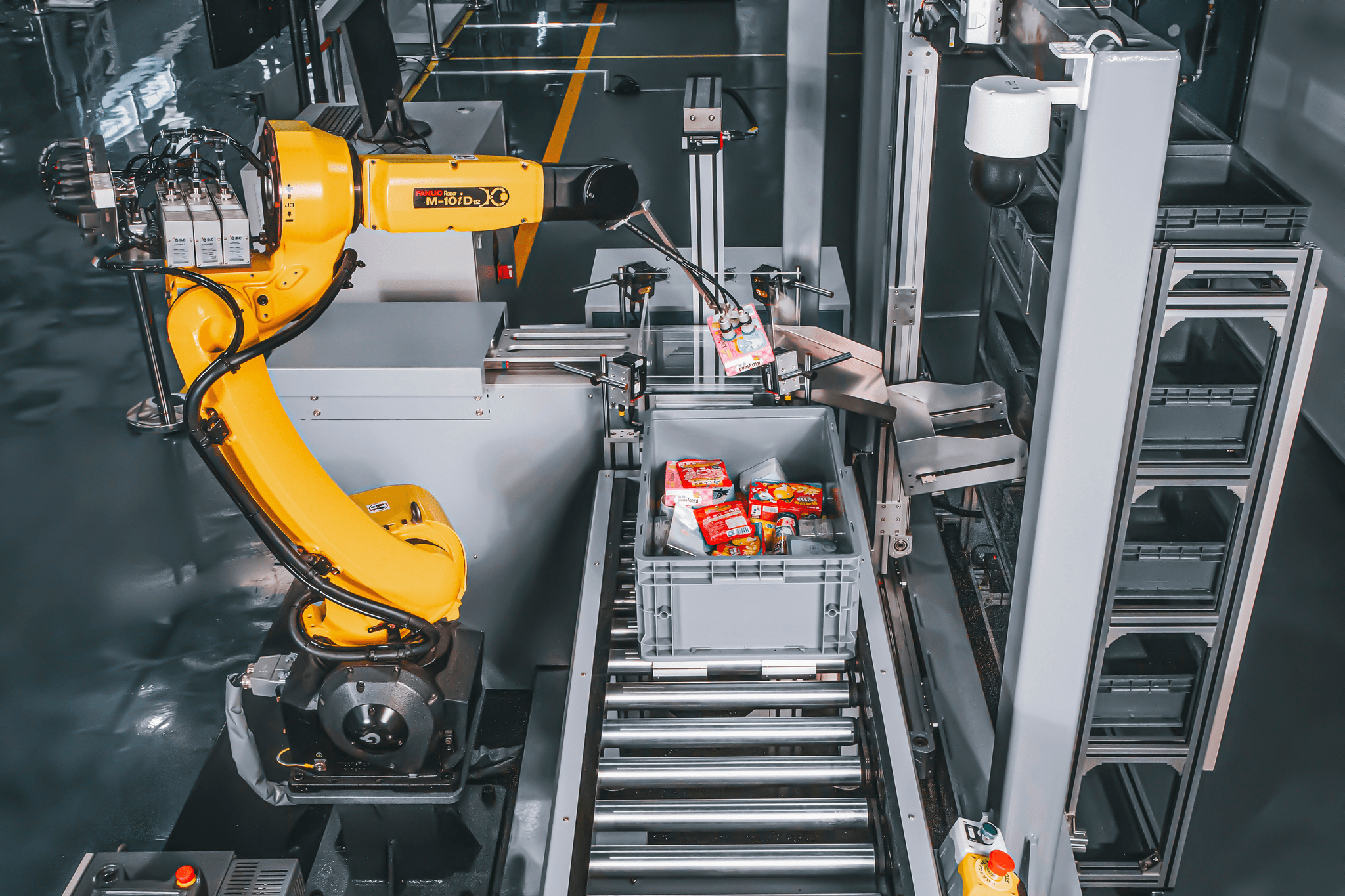

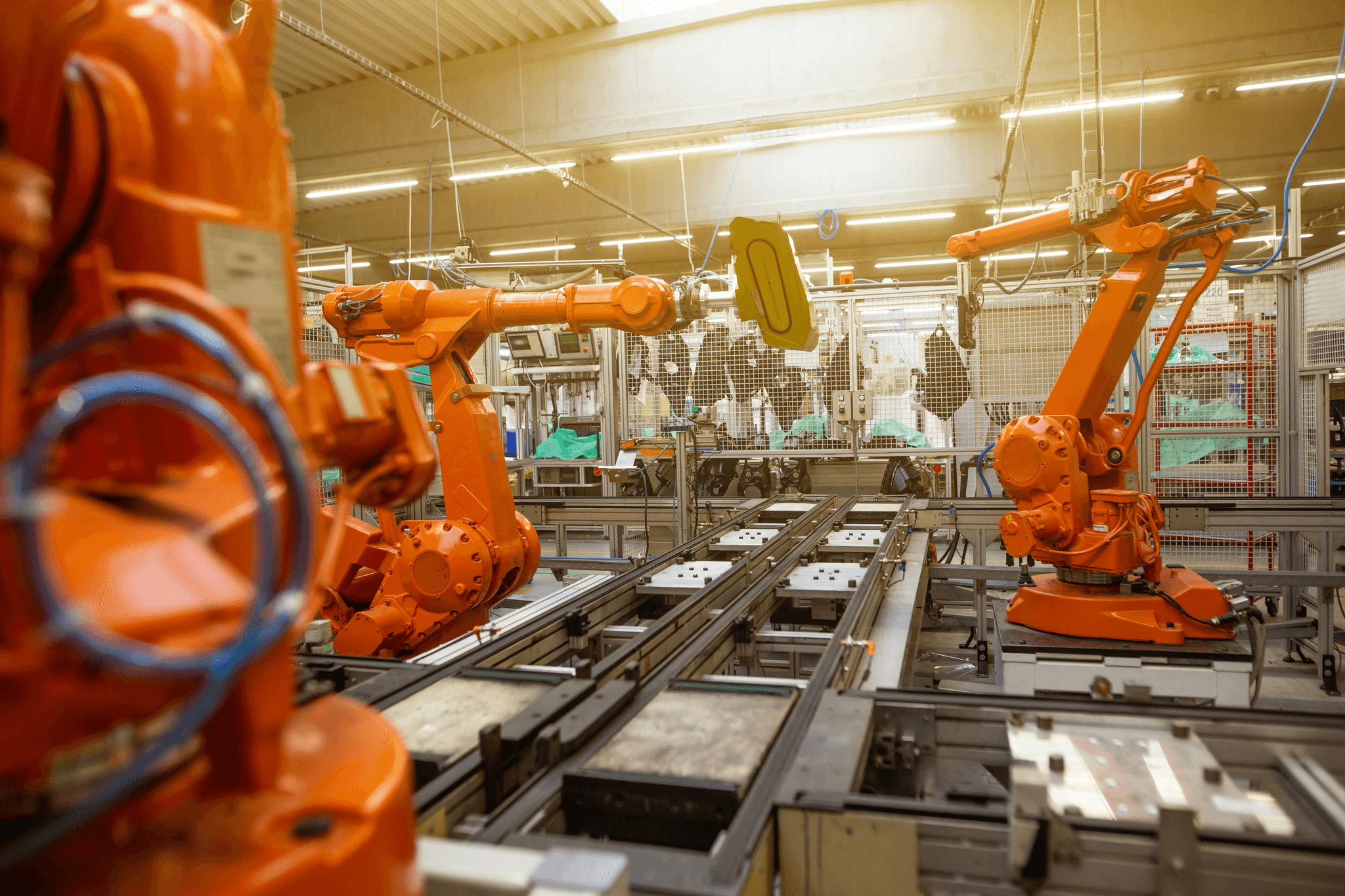

In today's competitive landscape, quality in manufacturing is closely tied to the adoption of advanced technology. At SSOURCING INC., we understand the need for automation to enhance efficiency and reduce errors in production. Our investment in state-of-the-art robotics and machinery has allowed us to streamline our manufacturing processes, ensuring top-notch quality in every product.

Automation for Enhanced Efficiency

By implementing automated systems, SSOURCING INC. has been able to significantly increase our production capacity while maintaining high levels of quality control. The use of robotics and automated assembly lines has not only improved the speed of manufacturing but also minimized human error, resulting in consistent and reliable products for our clients.

Integration of Smart Manufacturing Solutions

Integrating smart manufacturing solutions into our operations has been pivotal in optimizing our processes and driving continuous improvement. From predictive maintenance to real-time monitoring, these technologies have enabled us to identify potential issues before they escalate, thus ensuring that our products meet the highest standards of quality.

SSOURCING INC.'s Adoption of Cutting-Edge Technology

At SSOURCING INC., we are committed to staying at the forefront of technological advancements in manufacturing. Our adoption of cutting-edge technology, such as 3D printing and IoT-enabled device,s has allowed us to innovate rapidly while maintaining uncompromising quality standards across all our product lines.

With a focus on automation, smart solutions integration, and cutting-edge technology adoption, SSOURCING INC. continues to lead the way in achieving excellence through quality-driven manufacturing practices.

Empowering a Skilled Workforce

Training and Development Programs

At SSOURCING INC., we understand the pivotal role of training and development in fostering a skilled workforce that is essential for maintaining quality in manufacturing. Our comprehensive programs encompass technical skills, safety protocols, and leadership development to ensure that our employees are equipped with the necessary expertise to excel in their roles. Through continuous learning, our workforce remains adaptable and capable of meeting evolving industry demands.

Employee Engagement for Quality Improvement

Employee engagement is a cornerstone of our approach to quality improvement at SSOURCING INC. We believe that involving our team members in decision-making processes not only fosters a sense of ownership but also leads to innovative solutions for enhancing manufacturing quality. By encouraging open communication and empowering employees to contribute their ideas, we create a collaborative environment where everyone is invested in upholding the highest standards.

SSOURCING INC.'s Focus on Employee Expertise

Our commitment to quality in manufacturing extends to nurturing employee expertise at every level of our organization. We recognize the value of investing in professional development opportunities that enable our workforce to stay ahead of industry advancements and best practices. By prioritizing the growth and proficiency of our employees, SSOURCING INC. ensures that we have a highly skilled team capable of delivering superior results consistently.

Collaborating with Reliable Suppliers

In today's competitive landscape, ensuring quality in manufacturing requires a robust supply chain. SSOURCING INC. recognizes the critical role of suppliers in maintaining high standards and has implemented stringent quality assurance measures to vet and monitor its partners. By prioritizing quality at every stage of the supply chain, SSOURCING INC. guarantees that only top-notch materials and components are used in its manufacturing processes.

Quality Assurance in the Supply Chain

SSOURCING INC.'s commitment to quality extends beyond its operations to encompass its entire supply chain. Rigorous inspections, audits, and certifications are conducted to verify that suppliers meet the company's stringent quality standards. This proactive approach ensures that only reliable and reputable suppliers are selected, thereby minimizing the risk of subpar inputs compromising the final product's quality.

Strategic Partnerships for Enhanced Efficiency

Collaborating with trusted suppliers allows SSOURCING INC. to forge strategic partnerships aimed at enhancing efficiency throughout the production process. By working closely with suppliers who share its dedication to excellence, SSOURCING INC. can streamline procurement processes and optimize lead times, ultimately contributing to improved productivity and cost-effectiveness.

SSOURCING INC.'s Strong Supplier Relationships

SSOURCING INC.'s emphasis on fostering strong supplier relationships is a testament to its unwavering commitment to quality in manufacturing. By cultivating open communication channels and mutual trust with its suppliers, SSOURCING INC. ensures seamless collaboration and swift issue resolution when necessary, enabling a harmonious partnership that benefits all parties involved.

Conclusion

In today's competitive landscape, achieving a sustainable competitive edge through quality in manufacturing is crucial. SSOURCING INC. has demonstrated that prioritizing quality not only ensures customer satisfaction but also boosts operational efficiency and profitability. As the future of manufacturing excellence continues to evolve, SSOURCING INC.'s vision for quality-driven manufacturing remains unwavering.

Achieving Competitive Edge through Quality in Manufacturing

By consistently delivering high-quality products and services, SSOURCING INC. has established itself as a leader in the industry, gaining a competitive edge over its counterparts. Embracing a culture of excellence and continuous improvement, SSOURCING INC. has set new benchmarks for quality in manufacturing, setting it apart as the go-to choice for discerning customers seeking superior products.

The Future of Manufacturing Excellence

As technology advances and consumer expectations evolve, the future of manufacturing excellence will be defined by innovation, sustainability, and adaptability. SSOURCING INC.'s forward-thinking approach positions it at the forefront of this evolution, driving the industry towards greater efficiency and environmental responsibility while maintaining uncompromising quality standards.

SSOURCING INC.'s Vision for Quality-Driven Manufacturing

SSOURCING INC.'s vision for quality-driven manufacturing revolves around harnessing cutting-edge technology, empowering its workforce, nurturing strong supplier relationships, and continuously improving its processes to deliver exceptional value to customers worldwide. With an unwavering commitment to excellence, SSOURCING INC. is poised to shape the future of manufacturing through its relentless pursuit of quality.