Introduction

In today’s fast-paced business environment, direct material sourcing has emerged as a critical component for companies striving to maintain a competitive edge. This approach not only optimizes costs but also enhances the overall efficiency of supply chains, allowing businesses to respond swiftly to market demands. At SSOURCING INC., we recognize that embracing direct material sourcing is more than just a trend; it’s a necessary evolution in how companies manage their resources.

Why Direct Material Sourcing Matters

Direct material sourcing matters because it directly impacts the bottom line and operational effectiveness of an organization. By focusing on procuring materials directly from suppliers, businesses can reduce costs, improve quality, and enhance supply chain visibility. The importance of this strategy cannot be overstated; effective direct material sourcing can lead to significant savings and improved relationships with suppliers.

Challenges in Traditional Supply Chains

Traditional supply chains often face numerous challenges that hinder efficiency and cost-effectiveness. These include long lead times, lack of transparency, and dependency on intermediaries that complicate communication and increase expenses. As businesses strive to innovate their operations, recognizing these challenges is essential for transitioning towards a more streamlined approach like direct material sourcing.

Benefits of Transforming Your Supply Chain

Transforming your supply chain through direct material sourcing brings a plethora of benefits that can propel your business forward. Enhanced agility allows companies to adapt quickly to changes in demand while reducing waste through better inventory management practices. Additionally, organizations like SSOURCING INC. can leverage these transformations not just for cost savings but also for fostering deeper collaborations with suppliers that drive innovation and sustainability.

Understanding Direct Material Sourcing

In the world of supply chain management, direct material sourcing stands as a crucial pillar that supports operational efficiency and cost-effectiveness. It involves procuring raw materials that are directly used in the production of goods, making it essential for manufacturers to get it right. By mastering direct material sourcing, companies can enhance their competitive edge while ensuring product quality.

Defining Direct Material Sourcing

Direct material sourcing refers to the process of acquiring materials that are integral to the manufacturing process. These materials include everything from metals and plastics to textiles and chemicals, depending on the industry. Understanding this concept is vital because effective direct material sourcing can significantly impact a company's bottom line and overall operational success.

Key Elements of the Process

Several key elements define successful direct material sourcing strategies. First, identifying reliable suppliers is paramount; these partnerships ensure consistent quality and delivery timelines. Next, evaluating pricing structures and negotiating favorable terms can lead to substantial cost savings—an area where SSOURCING INC. excels by leveraging its extensive network of suppliers.

Another critical element is maintaining flexibility within your supply chain; being able to pivot quickly in response to market changes or supplier issues is essential for longevity in any business model focused on direct material sourcing.

The Role of Technology in Sourcing

Technology plays an increasingly vital role in transforming how businesses approach direct material sourcing today. Advanced software solutions enable companies to track inventory levels, forecast demand accurately, and analyze supplier performance in real-time—features that enhance decision-making processes significantly. SSOURCING INC., for example, utilizes cutting-edge technology tools that allow for seamless integration with suppliers and improve overall efficiency in direct material sourcing efforts.

Moreover, automation can streamline repetitive tasks such as order processing, freeing up valuable human resources for strategic planning initiatives instead of mundane paperwork.

Streamlining Your Supply Chain Strategy

In today’s fast-paced market, streamlining your supply chain strategy is essential for staying competitive and efficient. A well-structured approach to direct material sourcing can significantly enhance your operational effectiveness, reduce costs, and improve product quality. By taking a closer look at your current practices and adopting innovative strategies, you can transform your supply chain into a powerhouse of productivity.

Assessing Current Supply Chain Practices

Before diving into direct material sourcing, it's crucial to assess your existing supply chain practices thoroughly. This involves evaluating every aspect of the process—from procurement to delivery—to identify inefficiencies or bottlenecks that may be hindering performance. By conducting this assessment, companies like SSOURCING INC. can pinpoint areas where direct material sourcing could yield significant improvements and cost savings.

Understanding how materials flow through your supply chain will provide valuable insights into where direct material sourcing can be integrated effectively. Look for patterns in supplier performance, lead times, and quality issues that may indicate the need for change. This foundational analysis sets the stage for a more streamlined approach to sourcing that aligns with both operational goals and market demands.

Integrating Direct Material Sourcing

Once you've assessed current practices, it's time to integrate direct material sourcing into your overall strategy. This step requires careful planning and collaboration across departments to ensure everyone is on board with the new processes being introduced. Incorporating direct material sourcing not only optimizes procurement but also fosters stronger relationships with suppliers who are integral to your success.

To make this integration seamless, consider leveraging technology that supports real-time data sharing and communication between teams involved in the supply chain process. Tools such as inventory management systems can help track materials from suppliers directly to production lines, minimizing delays caused by miscommunication or stock shortages. With SSOURCING INC.'s expertise in this area, you can create a cohesive framework that enhances efficiency while maintaining high standards of quality through effective direct material sourcing.

Case Study: Unilever’s Sourcing Success

Unilever serves as an exemplary case study showcasing the transformative power of effective direct material sourcing within their supply chain strategy. Facing challenges related to sustainability and cost control, Unilever implemented innovative practices focused on responsible sourcing of raw materials while optimizing their supplier network. The company’s commitment to integrating direct material sourcing allowed them not only to reduce costs but also enhance their brand reputation among environmentally-conscious consumers.

By collaborating closely with suppliers and leveraging data analytics for better decision-making, Unilever successfully streamlined its operations while ensuring high-quality standards were met consistently across all products. Their strategic focus on sustainability has resulted in long-term partnerships with suppliers who share similar values—an essential component of successful direct material sourcing strategies today! Companies looking up to Unilever's success story can find inspiration in their methodical approach towards building a resilient supply chain.

Cost Savings Through Direct Material Sourcing

In today’s competitive landscape, understanding the cost savings associated with direct material sourcing is crucial for any business aiming to thrive. By focusing on direct material sourcing, companies can unearth significant opportunities to reduce expenses while enhancing product quality and supplier relationships. This section will explore how identifying cost reduction opportunities, comparing direct versus indirect sourcing costs, and examining real-world examples like Intel's savings can help organizations maximize their financial efficiency.

Identifying Cost Reduction Opportunities

The first step in harnessing the power of direct material sourcing is identifying where potential cost reductions lie within your supply chain. Companies often overlook inefficiencies in procurement processes, such as excess inventory or suboptimal supplier contracts. By conducting a thorough assessment of current practices, businesses can pinpoint specific areas where direct material sourcing can streamline operations and cut costs significantly.

Moreover, evaluating supplier performance can reveal opportunities for negotiation or consolidation that may lead to better pricing or terms. SSOURCING INC. emphasizes the importance of leveraging data analytics to track spending patterns and identify which materials are driving costs up unnecessarily. Ultimately, recognizing these opportunities allows companies to make informed decisions that enhance their bottom line through effective direct material sourcing strategies.

Comparing Direct vs. Indirect Sourcing Costs

When considering cost savings through direct material sourcing, it's essential to compare it against indirect sourcing costs effectively. Direct materials are those that become part of the finished product, while indirect materials support production but do not directly contribute to it—think office supplies or maintenance tools. While indirect costs might seem lower at a glance, they often accumulate over time and can overshadow the benefits gained from efficient direct material sourcing.

By analyzing both categories side-by-side, businesses can uncover hidden expenses associated with indirect materials that may be siphoning off funds better spent elsewhere—like investing in high-quality suppliers for direct materials instead! SSOURCING INC.'s approach focuses on ensuring that every dollar spent contributes directly to value creation through enhanced quality and reliability in supply chains via strategic direct material sourcing practices.

Real-World Example: Intel’s Savings

Intel serves as a prime example of how effective direct material sourcing translates into substantial cost savings for large-scale operations. By refining their procurement strategy and focusing on building strong relationships with key suppliers, Intel was able to negotiate favorable contracts that reduced raw material costs significantly—saving millions annually! Their commitment to optimizing their supply chain through strategic partnerships exemplifies how embracing a robust approach to direct material sourcing pays dividends.

Additionally, Intel leveraged technology and data analytics tools to gain insights into market trends and pricing fluctuations—allowing them to make proactive adjustments rather than reactive ones when it came time for contract renewals or new purchases. This forward-thinking mindset not only bolstered their financial performance but also positioned them as a leader in innovation within the tech industry—a testament to what smart investments in direct material sourcing can achieve!

Building Strong Supplier Relationships

In the realm of direct material sourcing, strong supplier relationships are not just beneficial; they are essential for success. Collaborating effectively with suppliers can lead to improved quality, reduced costs, and enhanced innovation. When companies like SSOURCING INC. cultivate these relationships, they create a foundation that supports long-term growth and adaptability in a rapidly changing market.

Importance of Supplier Collaboration

Supplier collaboration is crucial in direct material sourcing because it fosters trust and transparency between parties. When suppliers feel valued and integrated into the decision-making process, they're more likely to provide better service and innovative solutions that align with your business goals. Moreover, effective collaboration can lead to shared risks and rewards, ultimately resulting in a more resilient supply chain.

Strategies for Effective Communication

To enhance supplier relationships within direct material sourcing, effective communication strategies must be employed. Regular meetings—whether virtual or face-to-face—can facilitate open dialogue about expectations, challenges, and opportunities for improvement. Additionally, utilizing collaborative tools such as shared platforms or project management software can streamline communication processes and ensure everyone is on the same page.

Insights from Walmart’s Supplier Network

Walmart’s approach to building strong supplier relationships offers valuable insights for companies engaged in direct material sourcing. The retail giant emphasizes transparency by sharing data with suppliers to foster trust and collaboration. By implementing initiatives like joint business planning and consistent feedback loops, Walmart has been able to optimize its supply chain while ensuring that suppliers remain invested in mutual success—a strategy that SSOURCING INC. could emulate for its own growth.

Leveraging Data Analytics for Better Sourcing

In the modern world of direct material sourcing, data analytics has become a game-changer. Companies that harness the power of data can make informed decisions that not only streamline their supply chains but also enhance their competitive edge. SSOURCING INC. recognizes that leveraging data effectively can transform sourcing strategies and lead to significant improvements in efficiency and cost savings.

Using Data to Inform Sourcing Decisions

Data-driven decision-making is at the heart of successful direct material sourcing strategies. By analyzing historical purchase patterns, market trends, and supplier performance metrics, organizations can identify the best materials at the most favorable prices. This approach allows businesses to respond swiftly to changing market dynamics while ensuring they maintain quality standards in their sourcing processes.

Moreover, insights gained from data analysis can help companies predict future needs and align their purchasing strategies accordingly. SSOURCING INC. encourages businesses to embrace this analytical mindset as it fosters agility and resilience in supply chain management. Ultimately, utilizing data not only enhances operational efficiency but also strengthens supplier relationships through better-informed negotiations.

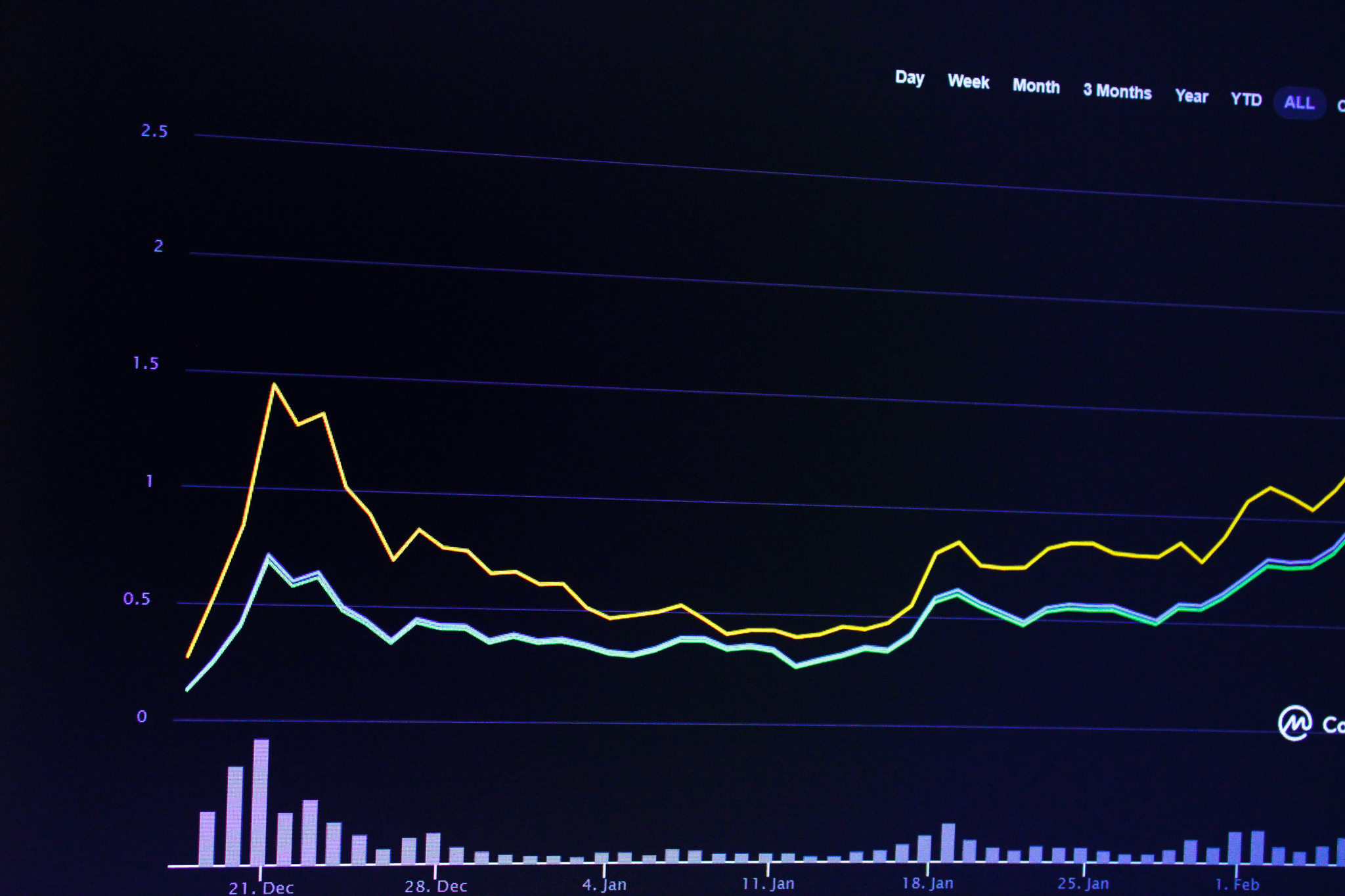

Predictive Analytics in Supply Chains

Predictive analytics is revolutionizing how companies approach direct material sourcing by forecasting demand with remarkable accuracy. This powerful tool analyzes vast amounts of historical data to predict future trends, allowing businesses to anticipate changes in demand for specific materials before they occur. With this foresight, organizations can optimize inventory levels and reduce excess stock costs while ensuring that they have enough materials on hand when needed.

For instance, if a company knows through predictive analytics that demand for a particular product will surge during a specific season, it can adjust its sourcing strategy accordingly by securing necessary materials ahead of time. This proactive approach minimizes disruptions and maximizes cost efficiency throughout the supply chain process. At SSOURCING INC., we believe integrating predictive analytics into direct material sourcing practices leads to smarter decisions that drive profitability.

How Amazon Innovates with Data

Amazon stands as a prime example of how effective data utilization can enhance direct material sourcing strategies on a massive scale. The e-commerce giant employs sophisticated algorithms that analyze customer behavior, inventory levels, and supplier performance metrics in real-time to refine its procurement processes continually. By leveraging this wealth of information, Amazon ensures it meets customer demands promptly while minimizing costs associated with overstocking or stockouts.

Additionally, Amazon's use of machine learning enables it to identify patterns within its supply chain operations that may not be immediately apparent to human analysts. This level of innovation not only streamlines its own logistics but also sets industry standards for what is possible through smart data utilization in direct material sourcing efforts across various sectors. Companies like SSOURCING INC., inspired by Amazon’s success story, are keen on adopting similar innovative practices to elevate their own supply chain effectiveness.

Conclusion

In the fast-paced world of supply chain management, direct material sourcing stands out as a game-changer. By embracing this approach, businesses can streamline operations, reduce costs, and enhance supplier relationships. As we've explored throughout this discussion, the benefits of direct material sourcing are not just theoretical; they are backed by real-world success stories.

Takeaways on Direct Material Sourcing

The key takeaways from our exploration of direct material sourcing emphasize its critical role in modern supply chains. First and foremost, it allows companies to gain greater control over their materials, leading to improved quality and consistency. Additionally, leveraging technology and data analytics can transform how organizations approach sourcing, making informed decisions that drive efficiency and cost savings.

Moreover, fostering strong supplier relationships is essential in maximizing the advantages of direct material sourcing. Collaboration with suppliers not only enhances communication but also creates opportunities for innovation and shared growth. Ultimately, businesses that prioritize direct material sourcing will find themselves better positioned to adapt to market changes while maintaining a competitive edge.

Next Steps for Your Supply Chain

To effectively implement direct material sourcing within your supply chain strategy, start by assessing your current practices and identifying areas for improvement. This evaluation should include a thorough analysis of existing supplier relationships and an exploration of potential new partnerships that align with your goals. Once you have this foundation in place, consider integrating technology solutions that facilitate data-driven decision-making.

It's also vital to engage stakeholders across your organization in discussions about the benefits of direct material sourcing. By fostering a culture that embraces change and innovation, you’ll be able to navigate the complexities of modern supply chains with confidence. Remember: every step taken toward enhancing your supply chain will yield substantial long-term rewards.

Embracing Change with SSOURCING INC.

At SSOURCING INC., we recognize that change is not just inevitable; it's essential for growth and success in today’s marketplace. Embracing direct material sourcing can propel your organization forward by unlocking new efficiencies while reducing costs significantly. Our team is dedicated to helping you navigate this transition smoothly by providing tailored solutions designed specifically for your needs.

As you embark on this journey toward optimizing your supply chain through direct material sourcing, remember that collaboration is key—both internally within your organization and externally with suppliers. By working together towards common goals, we can ensure sustainable success for all parties involved. So let’s embrace these changes together; after all, the future belongs to those who dare to innovate!