Introduction

In the world of manufacturing and production, understanding different types of production is crucial for success. Whether it's lean manufacturing, mass production, or job shop production, each method has its own set of advantages and challenges. At SSOURCING INC., we recognize the importance of effective production planning in maximizing efficiency and minimizing waste. Exploring the best strategies for production efficiency is essential for staying competitive in today's market.

Understanding Different Types of Production

When it comes to types of production, there are various approaches that companies can take to meet their manufacturing needs. From high-volume mass production to custom job shop production, each method requires a unique set of tools and techniques to achieve optimal results. At SSOURCING INC., we understand the nuances of each type of production and can help businesses navigate the complexities of choosing the right approach for their specific needs.

Importance of Effective Production Planning

Effective production planning is the backbone of any successful manufacturing operation. It involves carefully coordinating resources, materials, and processes to ensure smooth operations and timely delivery of products. At SSOURCING INC., we emphasize the significance of robust planning to avoid bottlenecks, reduce lead times, and optimize resource utilization.

Exploring the Best Strategies for Production Efficiency

In today's fast-paced business environment, finding ways to improve production efficiency is key to staying ahead of the competition. Whether it's through implementing advanced technologies or adopting lean principles, there are numerous strategies that can help streamline operations and drive productivity gains. At SSOURCING INC., we specialize in identifying tailored solutions that align with our clients' unique goals and challenges.

The Basics of Types of Production

When it comes to different types of production, understanding lean manufacturing is essential for optimizing efficiency and minimizing waste in the production process. Lean manufacturing focuses on continuous improvement and eliminating non-value adding activities, making it a key strategy for SSOURCING INC. to enhance productivity and reduce costs.

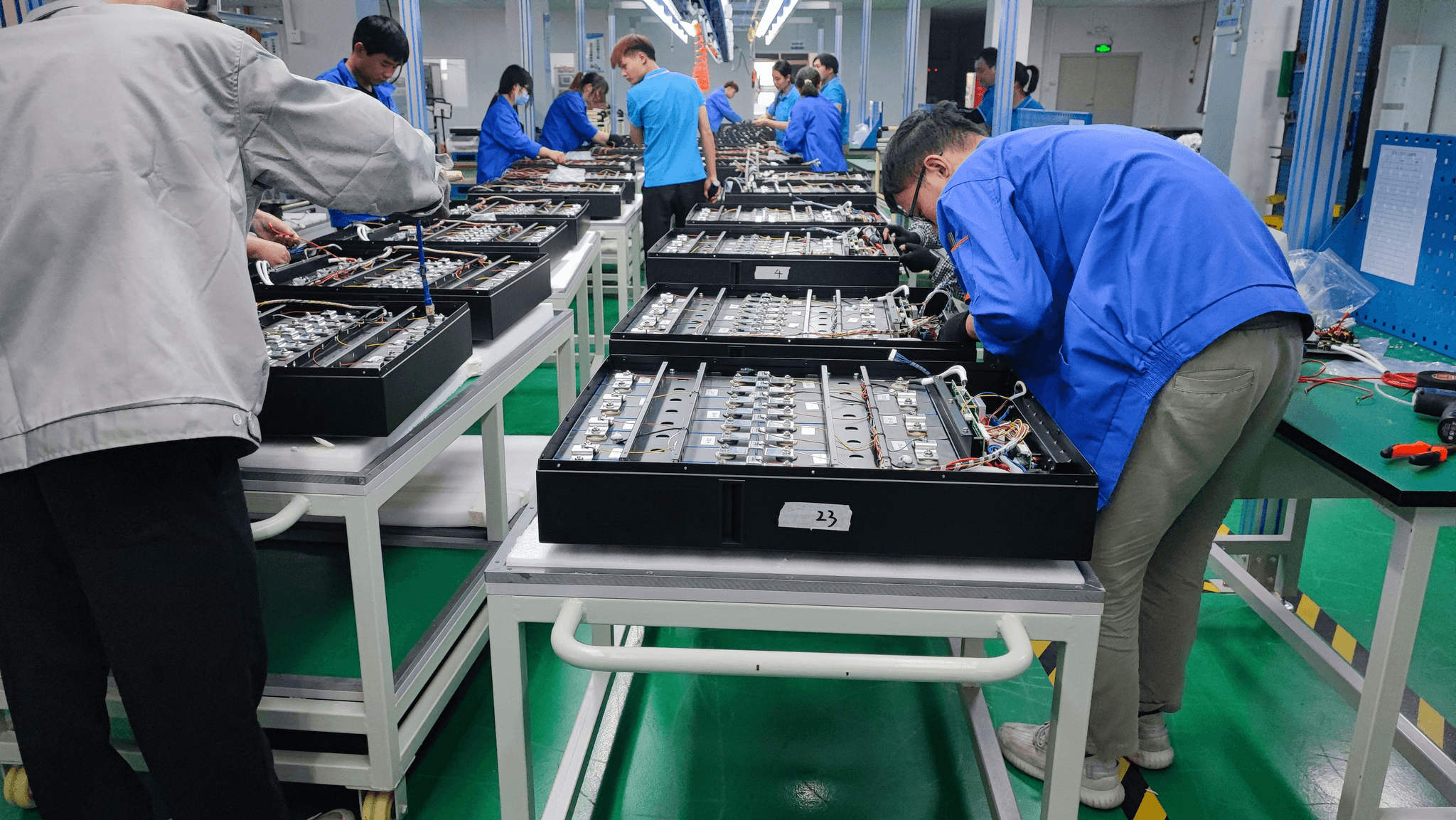

Embracing mass production techniques is another crucial aspect of different types of production. By standardizing processes and utilizing assembly lines, SSOURCING INC. can efficiently produce large quantities of goods at lower costs, meeting the demands of mass markets while maintaining quality standards.

Implementing job shop production allows SSOURCING INC. to cater to custom orders and diverse product variations by setting up flexible manufacturing systems. This approach enables the company to be versatile in meeting customer needs while maintaining operational efficiency across various product lines.

Now that we have explored the basics of different types of production, let's delve into finding the best production planning tools to further enhance efficiency at SSOURCING INC.

Finding the Best Production Planning Tools

In today's fast-paced manufacturing landscape, finding the right production planning tools is crucial for optimizing different types of production. Utilizing ERP systems for production management is essential for integrating various business processes and ensuring efficient resource utilization. With SSOURCING INC., implementing ERP systems can streamline operations, improve data accuracy, and enhance decision-making processes across all levels of the organization.

Leveraging advanced planning and scheduling (APS) software is another key aspect of effective production planning. APS software enables detailed scheduling, capacity planning, and real-time monitoring to ensure smooth production workflows. At SSOURCING INC., integrating APS software can help in optimizing resource allocation, minimizing lead times, and maximizing on-time deliveries across diverse types of production.

Incorporating just-in-time (JIT) inventory management is also a critical tool for efficient production planning. By synchronizing inventory levels with customer demand, JIT helps in reducing waste, minimizing carrying costs, and enhancing overall operational efficiency. At SSOURCING INC., adopting JIT principles can lead to improved flexibility, reduced lead times, and enhanced responsiveness to changing market demands.

With the right production planning tools in place, SSOURCING INC. can effectively optimize different types of production while staying ahead in today's competitive manufacturing landscape.

Optimizing Production Workflow

In the quest for efficiency, SSOURCING INC. understands the importance of optimizing production workflow. One effective method is streamlining operations with Value Stream Mapping, a visual tool that helps identify waste and streamline processes to improve overall production efficiency. By implementing this strategy, our company can identify bottlenecks and inefficiencies in our production process, leading to improved productivity and cost savings.

Streamlining Operations with Value Stream Mapping

Value Stream Mapping allows SSOURCING INC. to visualize the flow of materials and information required to bring a product or service to customers. By analyzing each step in the production process, we can identify areas for improvement and implement changes that lead to reduced lead times, improved quality, and increased productivity. This approach aligns with our commitment to continuous improvement and ensures that we deliver high-quality products in a timely manner.

Implementing Total Productive Maintenance (TPM)

Another key strategy for optimizing production workflow is implementing Total Productive Maintenance (TPM). By focusing on proactive and preventive maintenance practices, SSOURCING INC. can minimize equipment downtime, reduce defects, and improve overall equipment effectiveness. This approach not only enhances our operational efficiency but also prolongs the lifespan of our machinery, resulting in long-term cost savings.

Utilizing Six Sigma Methodologies for Process Improvement

SSOURCING INC. recognizes the value of Six Sigma methodologies in achieving process improvement within our production workflow. By utilizing data-driven approaches such as DMAIC (Define, Measure, Analyze, Improve, Control), we can systematically identify and eliminate defects or variations in our processes. This results in higher product quality, reduced waste, and increased customer satisfaction – all essential components of successful production optimization.

By implementing these strategies for optimizing production workflow at SSOURCING INC., we are committed to achieving operational excellence while delivering exceptional products to our valued customers.

Strategies for Sustainable Production

In today's fast-paced world, sustainable production has become a key focus for businesses across all industries. At SSOURCING INC., we understand the importance of implementing green manufacturing practices to minimize environmental impact and reduce waste. By incorporating eco-friendly materials and processes into our production, we strive to create a more sustainable future for generations to come.

Implementing Green Manufacturing Practices

Green manufacturing practices involve using environmentally friendly materials and processes to minimize the negative impact on the environment. At SSOURCING INC., we prioritize the use of recycled materials and sustainable sourcing methods in our production. By reducing waste and energy consumption, we aim to contribute to a healthier planet while meeting the demands of our customers.

Adopting Circular Economy Principles

Adopting circular economy principles is essential for creating a more sustainable production model. At SSOURCING INC., we are committed to designing products that can be reused, recycled, or repurposed at the end of their lifecycle. By embracing a circular economy approach, we aim to minimize resource depletion and reduce the environmental footprint of our operations.

Utilizing Renewable Energy Sources in Production

Utilizing renewable energy sources such as solar or wind power is crucial for reducing greenhouse gas emissions and promoting sustainability in production. At SSOURCING INC., we have invested in renewable energy technologies to power our manufacturing facilities. By harnessing clean energy sources, we not only reduce our carbon footprint but also contribute to a more sustainable future for our planet.

The Role of Automation in Modern Production

In today's fast-paced manufacturing landscape, automation plays a pivotal role in enhancing efficiency and productivity across different types of production. Implementing robotics in manufacturing processes allows SSOURCING INC. to streamline operations, reduce human error, and increase output capacity. By leveraging artificial intelligence for production optimization, our company can analyze vast amounts of data to make real-time decisions and improve overall performance.

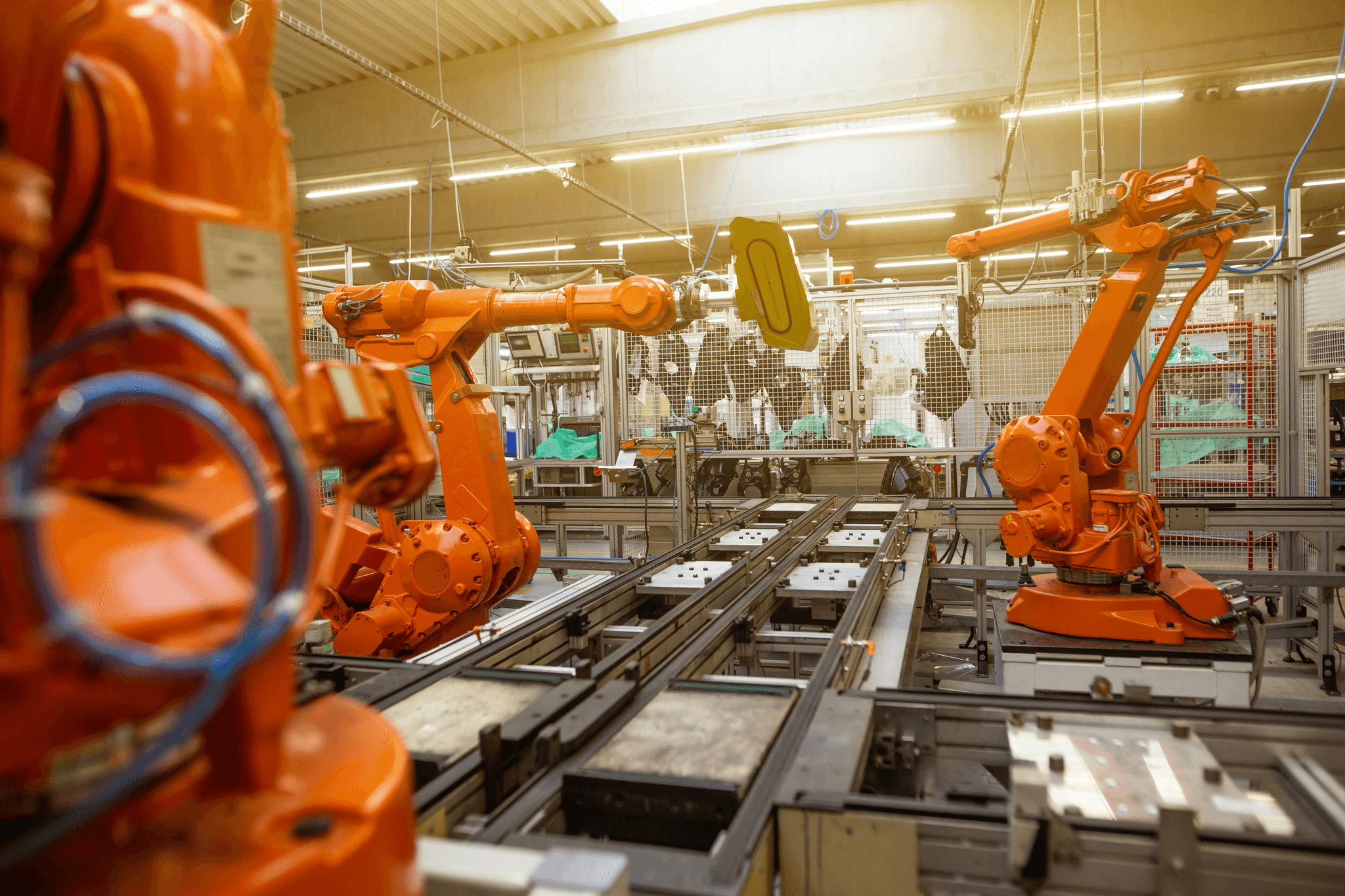

Implementing Robotics in Manufacturing

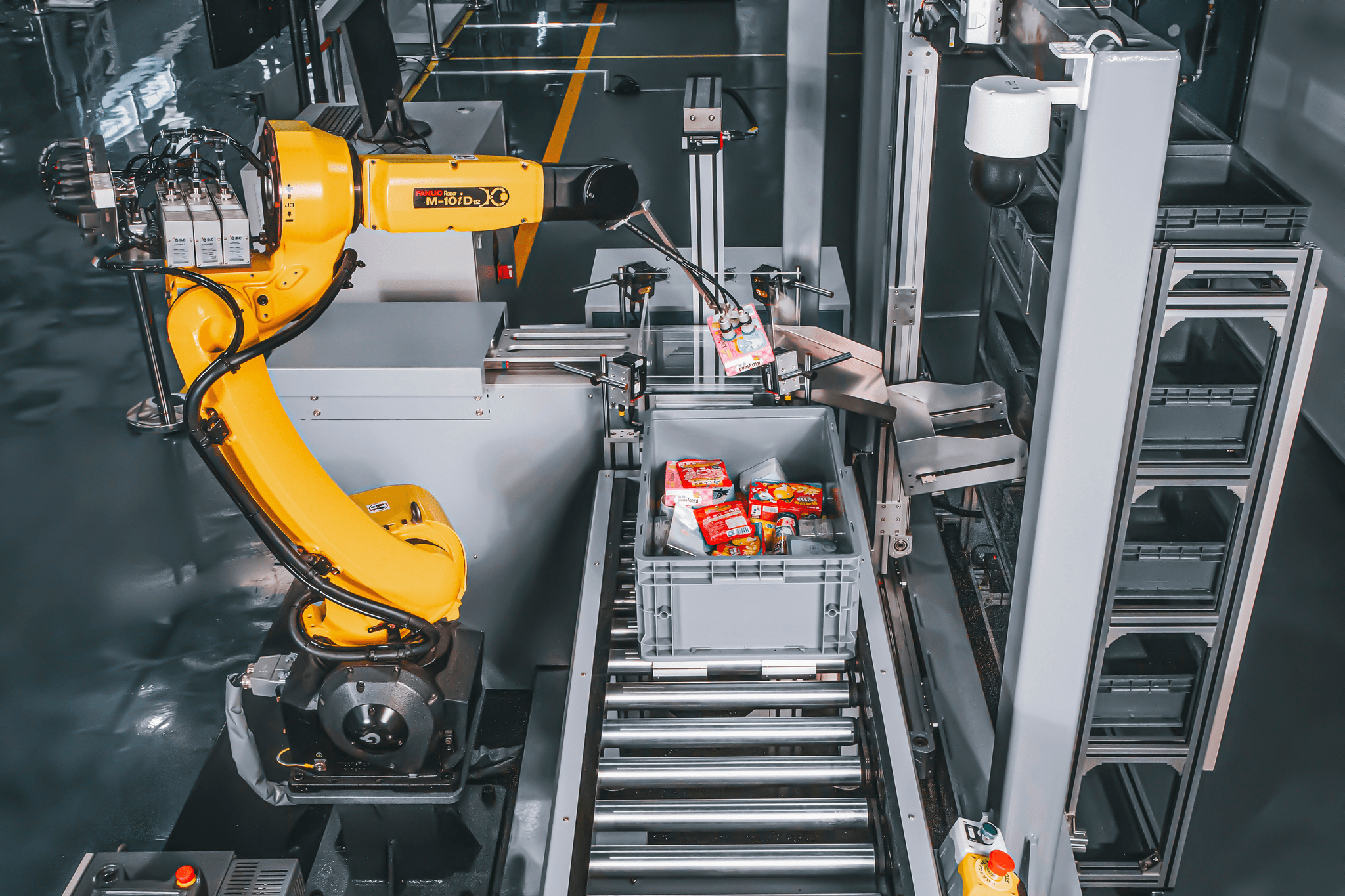

By integrating robotics into our production processes, SSOURCING INC. can automate repetitive tasks, such as assembly and packaging, leading to increased accuracy and speed. This not only reduces the risk of errors but also allows our workforce to focus on more complex and value-added activities, ultimately improving overall productivity.

Leveraging Artificial Intelligence for Production Optimization

Artificial intelligence enables SSOURCING INC. to optimize production by predicting maintenance needs, identifying potential bottlenecks, and even adjusting workflows based on changing demand patterns. With AI-driven insights, our company can make informed decisions that drive efficiency and minimize downtime.

Enhancing Efficiency with Internet of Things (IoT) Technology

The use of IoT technology allows SSOURCING INC. to connect various devices within the production environment to gather valuable data in real time. This data can then be used to monitor equipment performance, track inventory levels, and even adjust environmental conditions for optimal production output.

With the implementation of these advanced automation technologies in modern production processes at SSOURCING INC., we are able to achieve higher levels of precision, productivity, and adaptability while meeting the demands of different types of production efficiently.

Conclusion

In conclusion, efficient production planning is crucial for the success of any organization. By understanding the different types of production and embracing innovative strategies, companies can optimize their operations and stay ahead in the competitive market. SSOURCING INC. is committed to helping businesses achieve production efficiency through cutting-edge solutions and best practices.

Advantages of Implementing Efficient Production Planning

Implementing efficient production planning offers numerous benefits, including cost savings, improved productivity, and better resource utilization. By carefully strategizing and scheduling production activities, companies can minimize waste, reduce lead times, and meet customer demands more effectively. At SSOURCING INC., we understand the advantages of efficient production planning and offer tailored solutions to help businesses achieve their goals.

Best Practices for Optimizing Different Types of Production

Optimizing different types of production requires a deep understanding of lean manufacturing, mass production techniques, job shop production, and more. SSOURCING INC. specializes in providing comprehensive guidance on the best practices for each type of production, ensuring that our clients can maximize their operational efficiency and achieve sustainable growth.

Embracing Innovation in Production Strategies

Embracing innovation in production strategies is essential for staying competitive in today's dynamic market. Companies need to adopt green manufacturing practices, leverage automation technologies, and implement advanced planning tools to drive continuous improvement in their operations. SSOURCING INC. is at the forefront of innovation, offering cutting-edge solutions that enable businesses to thrive in an ever-evolving industry.