Introduction

In today's fast-paced manufacturing landscape, the concept of smart factory sourcing has emerged as a game-changer for businesses aiming to optimize their supply chains. Smart factory sourcing not only enhances efficiency but also fosters innovation, ensuring that companies remain competitive in a global market. As industries evolve, understanding and implementing effective factory sourcing strategies becomes increasingly crucial for success.

The Importance of Smart Factory Sourcing

Smart factory sourcing is essential for organizations looking to streamline operations and reduce costs while maintaining high-quality standards. By leveraging advanced technologies and data analytics, businesses can make informed decisions that enhance their sourcing processes. This strategic approach allows companies to respond quickly to market changes and consumer demands, ultimately driving growth and profitability.

Key Trends in Factory Sourcing Techniques

Several key trends are shaping the future of factory sourcing, including automation, artificial intelligence (AI), and the Internet of Things (IoT). These innovations enable manufacturers to gather real-time data, optimize inventory management, and improve supplier collaboration. Staying ahead of these trends is vital for companies seeking to enhance their competitive edge through smarter sourcing practices.

How SSOURCING INC. Can Help

SSOURCING INC. specializes in providing tailored solutions that empower businesses to navigate the complexities of smart factory sourcing effectively. With our expertise in integrating cutting-edge technology into supply chain management, we help clients achieve operational excellence while minimizing risks associated with traditional sourcing methods. Partnering with SSOURCING INC., organizations can confidently embrace the future of factory sourcing and unlock new opportunities for growth.

Understanding Smart Factory Concepts

In today's rapidly evolving industrial landscape, understanding the concept of a smart factory is crucial for effective factory sourcing. A smart factory leverages advanced technologies to create a highly automated and interconnected production environment. This not only enhances operational efficiency but also enables real-time data analysis, making it easier for companies like SSOURCING INC. to streamline their sourcing processes.

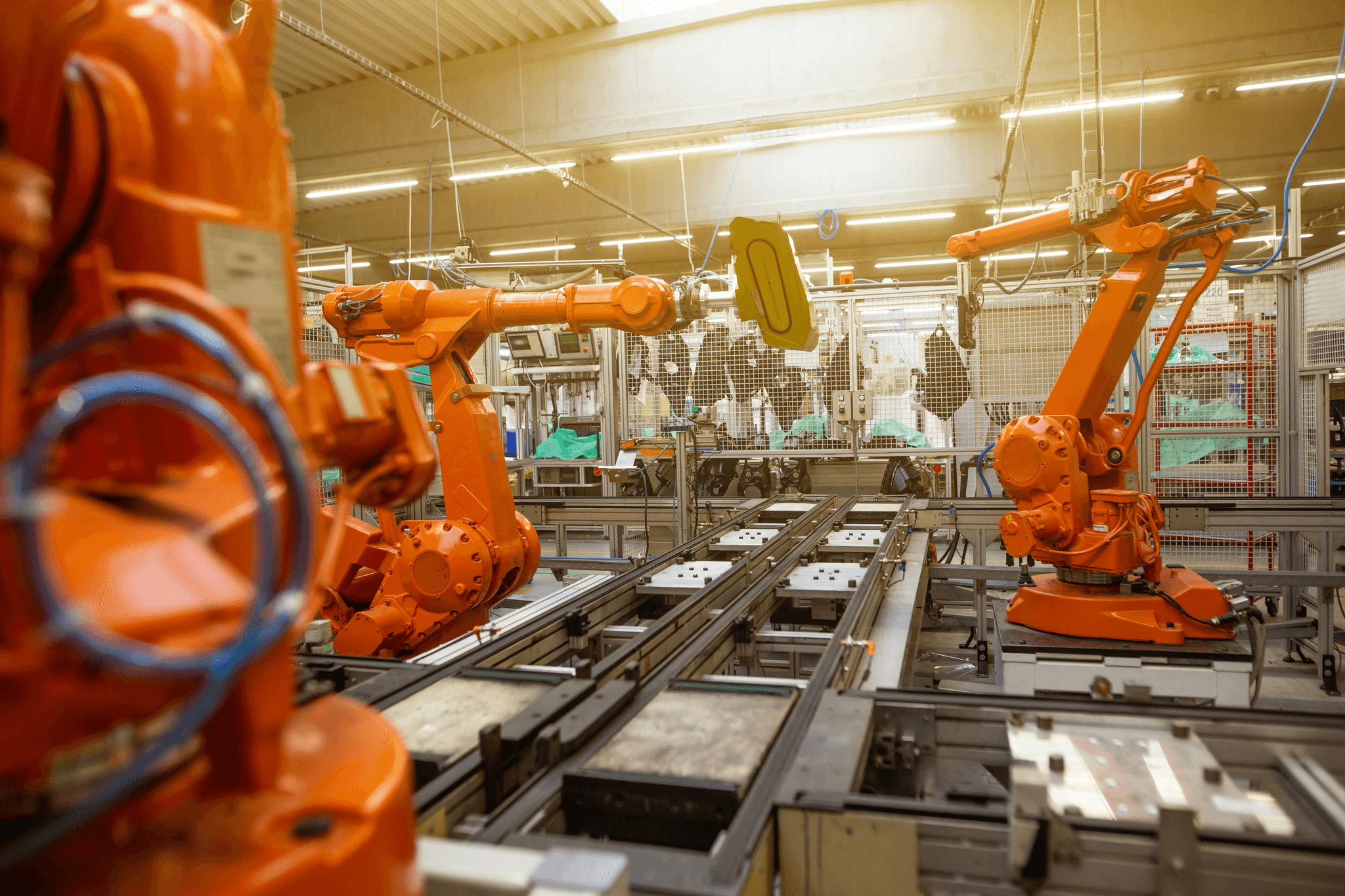

What is a Smart Factory?

A smart factory is essentially the epitome of modern manufacturing, where machines, systems, and humans communicate seamlessly through the Internet of Things (IoT). This integration allows for enhanced decision-making capabilities and greater flexibility in production lines. By utilizing technologies such as AI and machine learning, smart factories can adapt to changes in demand or supply chain disruptions more effectively than traditional manufacturing setups.

Benefits of Smart Factory Sourcing

The benefits of smart factory sourcing are manifold and significant for businesses looking to stay competitive. First off, it drastically reduces lead times by automating processes and optimizing supply chain management. Additionally, companies can achieve greater transparency in their operations, allowing them to make informed decisions about supplier relationships and resource allocation—something that SSOURCING INC. advocates strongly.

Moreover, smart factories enable businesses to implement sustainable practices more easily by analyzing energy consumption and waste production in real-time. This not only helps in reducing costs but also aligns with consumer demands for eco-friendly products—a win-win situation that enhances brand reputation while improving bottom lines.

Real-World Examples: Siemens and GE

Siemens has been at the forefront of implementing smart factory concepts into its manufacturing processes by utilizing digital twins—virtual replicas of physical assets that allow for predictive maintenance and streamlined operations. Their approach exemplifies how integrating technology into factory sourcing can lead to improved efficiency and reduced downtime.

Similarly, General Electric (GE) has embraced the concept through its Brilliant Factory initiative which focuses on leveraging big data analytics to optimize production workflows. By adopting these advanced techniques in factory sourcing, both Siemens and GE have demonstrated how traditional manufacturing can evolve into a smarter paradigm that benefits all stakeholders involved.

Integrating Technology in Factory Sourcing

In the era of smart factories, integrating technology into factory sourcing is not just a luxury; it’s a necessity. The right technologies streamline operations, enhance efficiency, and foster better supplier relationships, ultimately leading to improved bottom lines. With SSOURCING INC., businesses can leverage these technologies to transform their factory sourcing processes.

Automation in Supply Chain Management

Automation has revolutionized supply chain management by reducing manual errors and speeding up operations. By automating repetitive tasks, companies can focus on strategic decision-making and innovation in their factory sourcing strategies. SSOURCING INC. emphasizes the importance of automation to optimize workflows and ensure that sourcing activities are both efficient and effective.

Automated systems provide real-time data analytics that help businesses make informed decisions about suppliers and materials. This level of insight is crucial for adapting to market changes swiftly, which is vital in today’s fast-paced environment. As companies embrace automation, they find themselves better equipped to handle the complexities of modern factory sourcing.

The Role of AI and IoT

Artificial Intelligence (AI) and the Internet of Things (IoT) are game-changers for factory sourcing practices. AI algorithms can analyze vast amounts of data from various sources, predicting demand trends and identifying optimal suppliers based on performance metrics. Meanwhile, IoT devices enable real-time monitoring of supply chains, ensuring transparency throughout the entire process.

By integrating AI into their factory sourcing strategies, companies can enhance decision-making capabilities while minimizing risks associated with supplier relationships. Additionally, IoT enhances connectivity among machines and systems within a smart factory environment—leading to improved operational efficiencies that directly impact production quality and timelines. SSOURCING INC.’s expertise ensures that businesses harness these technologies effectively for superior outcomes.

Case Study: Bosch and Its Smart Factory

Bosch stands as a prime example of how technology integration can elevate factory sourcing practices significantly. Their smart factories utilize advanced automation along with AI-driven analytics to optimize production processes while maintaining high-quality standards across all products. By implementing IoT solutions, Bosch has enhanced visibility throughout its supply chain—allowing for more agile responses to disruptions or market demands.

Through these initiatives, Bosch has not only reduced costs but also improved collaboration with suppliers—ensuring timely deliveries without compromising quality or sustainability goals in their factory sourcing strategy. This case illustrates how forward-thinking companies can leverage technology for smarter supplier relationships that drive growth while remaining competitive in an ever-evolving marketplace. SSOURCING INC.’s approach mirrors this success by equipping clients with tools necessary for effective technology integration into their own factory sourcing efforts.

Assessing Supplier Capabilities

In the world of factory sourcing, evaluating supplier capabilities is crucial for ensuring a smooth and efficient operation. Suppliers are not just vendors; they are partners in your supply chain journey. Therefore, understanding how to assess their strengths can significantly impact the success of your smart factory initiatives.

Criteria for Evaluating Suppliers

When it comes to factory sourcing, several criteria should be at the forefront of your evaluation process. First and foremost is reliability; a dependable supplier can make or break your production timeline. Next, consider quality control measures—suppliers must adhere to strict standards to ensure that the materials meet your specifications consistently.

Additionally, financial stability is essential; you want a partner who won’t go belly up when you need them most. Finally, innovation capabilities should also be assessed; suppliers that embrace new technologies can enhance efficiency and drive down costs in your factory sourcing strategies. By focusing on these criteria, SSOURCING INC. helps businesses streamline their sourcing processes effectively.

The Importance of Transparency

Transparency in supplier relationships is like a breath of fresh air in the often murky waters of factory sourcing. When suppliers are open about their processes, pricing structures, and challenges, it fosters trust and collaboration between parties involved. This transparency allows companies like SSOURCING INC. to address issues proactively rather than reactively.

Moreover, transparent communication helps mitigate risks associated with supply chain disruptions—if everyone knows what’s going on behind the scenes, it’s easier to pivot when problems arise. In today’s interconnected world of smart factories, transparency can serve as a competitive advantage that sets you apart from others still operating under less open practices.

Success Story: Toyota's Supplier Relationships

Toyota has long been lauded for its exceptional approach to supplier relationships within its factory sourcing framework. The automaker employs rigorous evaluation criteria while maintaining transparent communication with its suppliers—this synergy has led to remarkable efficiencies and innovations over time. For instance, Toyota's famous just-in-time manufacturing system relies heavily on strong partnerships with reliable suppliers who understand their role in the overall process.

By fostering collaborative relationships built on trust and mutual benefit, Toyota has been able to minimize waste while maximizing productivity—a classic example of how effective supplier assessment can lead to monumental success in factory sourcing strategies. This approach not only enhances performance but also creates a resilient supply chain that withstands market fluctuations.

Sustainable Practices in Sourcing

In today's fast-paced manufacturing landscape, sustainable practices in factory sourcing are no longer optional; they’re essential. Companies are increasingly recognizing that adopting eco-friendly approaches not only benefits the environment but also enhances brand reputation and customer loyalty. By integrating sustainability into their sourcing strategies, businesses can create a positive impact while ensuring long-term viability.

Eco-Friendly Approaches to Factory Sourcing

Eco-friendly approaches to factory sourcing encompass a variety of practices aimed at minimizing environmental harm. This includes selecting suppliers who prioritize renewable materials, energy-efficient processes, and waste reduction initiatives. SSOURCING INC. advocates for a holistic view of sustainability, encouraging clients to partner with suppliers that demonstrate a commitment to environmentally responsible practices.

Moreover, implementing circular economy principles is gaining traction in factory sourcing strategies. This involves rethinking product life cycles and focusing on recycling or repurposing materials rather than relying solely on new resources. By doing so, companies can significantly reduce their carbon footprint while fostering innovation within their supply chains.

The Business Case for Sustainability

The business case for sustainability in factory sourcing is compelling and multifaceted. First off, consumers today are more informed and concerned about environmental issues than ever before; they often prefer brands that align with their values regarding sustainability. By embracing eco-friendly practices in factory sourcing, companies not only attract these conscientious consumers but also differentiate themselves from competitors.

Additionally, sustainable sourcing can lead to cost savings over time through improved efficiency and reduced waste management expenses. Furthermore, regulatory pressures are mounting globally; companies that proactively adopt sustainable practices will be better positioned to comply with future regulations and avoid potential fines or sanctions related to environmental violations. In this context, SSOURCING INC.'s expertise becomes invaluable as it helps businesses navigate the complexities of sustainable factory sourcing.

Example: Unilever’s Sustainable Supply Chain

Unilever serves as an exemplary model of how effective sustainable practices can be integrated into factory sourcing strategies. The company has committed itself to reducing its environmental impact by ensuring that all its products are sourced sustainably by 2025—a bold yet achievable goal that reflects its dedication to corporate responsibility. Unilever’s Sustainable Living Plan emphasizes transparency throughout its supply chain while engaging suppliers in efforts to enhance eco-friendliness.

By leveraging innovative technologies and collaborating closely with suppliers, Unilever has successfully minimized waste and optimized resource use across its operations—demonstrating the tangible benefits of responsible factory sourcing practices. Their commitment not only fosters goodwill among consumers but also contributes positively to the planet's health—showing us all how we can blend profit with purpose effectively.

Risk Management in Factory Sourcing

In the dynamic landscape of factory sourcing, risk management is paramount. With global supply chains becoming increasingly complex, identifying potential risks is essential for maintaining operational efficiency and safeguarding your company's bottom line. SSOURCING INC. emphasizes a proactive approach to risk management, ensuring that businesses can navigate uncertainties with confidence.

Identifying Potential Risks

The first step in effective risk management for factory sourcing is recognizing the various types of risks that can impact operations. These may include supply chain disruptions due to geopolitical tensions, natural disasters, or even shifts in market demand. Additionally, quality control issues and compliance violations can arise when working with suppliers who do not meet industry standards or ethical practices.

Understanding these risks allows businesses to develop a more resilient sourcing strategy. This means creating a comprehensive list of potential threats and assessing their likelihood and impact on operations. By doing so, companies can prioritize which risks require immediate attention and allocate resources accordingly.

Mitigation Strategies for Smart Factories

Once potential risks have been identified, it's crucial to implement effective mitigation strategies tailored to smart factories. One approach is diversifying the supplier base; relying on multiple suppliers reduces dependency on any single source and minimizes the impact of disruptions in one area. SSOURCING INC. recommends regularly evaluating supplier performance to ensure they align with your company's standards and expectations.

Another key strategy is leveraging technology for real-time monitoring of supply chain activities. By integrating advanced analytics and IoT devices into factory sourcing processes, businesses can gain insights into potential vulnerabilities before they escalate into significant issues. This proactive approach enables swift decision-making and helps maintain continuity in production.

Insight: How Apple Manages Supply Risks

Apple exemplifies excellence in managing supply risks through meticulous planning and strategic partnerships within its factory sourcing framework. The tech giant employs a dual-supplier strategy for critical components, ensuring that it isn't overly reliant on a single source for essential materials like chips or displays—this creates a safety net against unforeseen disruptions.

Moreover, Apple invests heavily in developing strong relationships with its suppliers by providing them with resources and training to enhance their capabilities continually. This collaboration fosters transparency within the supply chain while also ensuring adherence to Apple's stringent quality standards—a win-win for both parties involved! With SSOURCING INC.'s guidance, other companies can adopt similar strategies tailored to their unique needs.

Conclusion

In wrapping up our exploration of smart factory sourcing, it’s clear that the future is bright and brimming with potential. Embracing innovative techniques in factory sourcing not only enhances operational efficiency but also positions businesses to thrive in a competitive landscape. As we move forward, it’s essential to recognize the transformative power of technology and sustainable practices in shaping the next generation of factory sourcing.

Embracing the Future of Factory Sourcing

The evolution of factory sourcing is not just a trend; it's a necessity for companies aiming to stay relevant. By integrating advanced technologies like AI and IoT into their operations, businesses can streamline processes and enhance productivity while minimizing costs. The future will demand agility and adaptability, making smart factory sourcing an integral part of any successful strategy.

SSOURCING INC.'s Impact on Your Business

At SSOURCING INC., we understand that effective factory sourcing is at the heart of operational excellence. Our tailored solutions help businesses navigate the complexities of modern supply chains while ensuring they remain competitive and sustainable. With our expertise, your company can harness the benefits of smart factories, transforming challenges into opportunities for growth.

Steps to Get Started with Smart Sourcing

Starting your journey toward smarter factory sourcing doesn’t have to be daunting; it begins with a clear plan! First, assess your current supply chain practices and identify areas for improvement through technology integration or sustainability initiatives. Next, partner with experts like SSOURCING INC., who can guide you through implementing these strategies effectively to maximize your operational potential.