Introduction

There's something undeniably enchanting about stepping into a factory, where the hum of machinery and the rhythm of production come together to create a symphony of innovation. A factory visit offers a rare glimpse into the heart of manufacturing, revealing not just how products are made, but also the passion and precision that fuel these processes. At SSOURCING INC., we believe that experiencing manufacturing firsthand is an adventure that can spark curiosity and inspire future generations.

Discover the Magic of Factory Visits

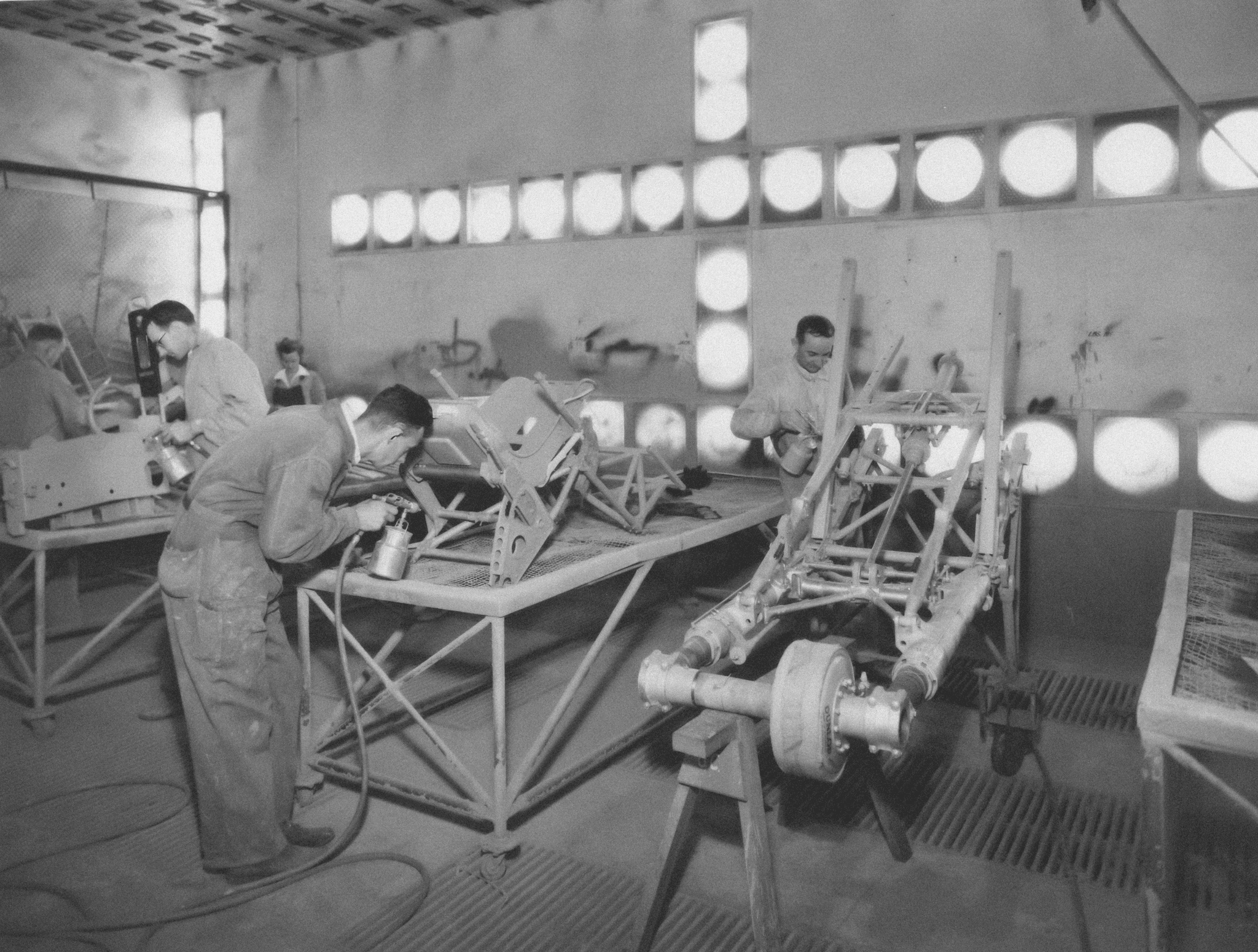

When you embark on a factory visit, you enter a world where creativity meets engineering, and ideas transform into tangible products. The sights and sounds provide an immersive experience that can ignite your imagination, making you appreciate the craftsmanship behind everyday items. Whether it's witnessing an assembly line in action or seeing artisans hone their skills, each moment in the factory is filled with magic waiting to be discovered.

Why You Should Experience Manufacturing Firsthand

Experiencing manufacturing firsthand allows you to break down preconceived notions about factories being cold and sterile environments; instead, you'll find them alive with energy and collaboration. A factory visit provides invaluable insights into not only how goods are produced but also how teams work together to overcome challenges and innovate solutions. By engaging directly with skilled workers at places like SSOURCING INC., you'll gain a deeper understanding of industry practices that shape our world.

Uncover Unique Insights in the Factory

Every factory has its own story to tell—stories woven through raw materials transformed into finished products by dedicated hands. On a factory visit, you’ll uncover unique insights about production methodologies, quality control measures, and even sustainability efforts that may surprise you. These experiences offer more than just knowledge; they foster appreciation for the intricate dance between technology and human ingenuity in creating what we often take for granted.

The People Behind the Production

When you embark on a factory visit, one of the most enriching experiences is meeting the talented individuals who bring products to life. These skilled craftsmen and women are the backbone of manufacturing, combining artistry with precision to create exceptional goods. At SSOURCING INC., we believe that understanding their stories adds a personal touch to your factory exploration.

Meet the Skilled Craftsmen at Toyota

At Toyota, every factory visit reveals a world where craftsmanship meets innovation. The skilled craftsmen here are not just assembly line workers; they are artisans dedicated to perfecting each vehicle that rolls off the line. With years of training and a commitment to quality, they embody Toyota's philosophy of continuous improvement, or Kaizen, ensuring that every car reflects their expertise and passion.

During your time at Toyota, you'll witness firsthand how these craftsmen work in harmony with cutting-edge technology. Their ability to adapt and innovate is crucial in maintaining Toyota's reputation for reliability and excellence in manufacturing. This blend of tradition and modernity makes a factory visit to Toyota an unforgettable experience that highlights human ingenuity.

Understanding Teamwork at Boeing

A factory visit to Boeing showcases an extraordinary level of teamwork that is essential for building some of the world's most advanced aircraft. Here, collaboration takes center stage as engineers, technicians, and assembly workers unite their skills toward a common goal: creating safe and efficient airplanes for travelers worldwide. The synergy among teams is palpable; it’s as if each person plays an instrument in a grand symphony of aviation.

Boeing’s commitment to teamwork also extends beyond its production lines into its training programs, where employees learn from one another while honing their skills in state-of-the-art facilities. By immersing yourself in this environment during your factory visit, you’ll gain insights into how effective communication can lead to groundbreaking innovations in aerospace manufacturing. Experience how Boeing transforms individual talents into collective achievements—a true testament to what can be accomplished when people work together.

The Artisans of the Harley-Davidson Experience

No factory visit would be complete without diving into the world of Harley-Davidson—where raw power meets artistic expression! The artisans here don’t just assemble motorcycles; they craft legends that resonate with riders around the globe. Each bike tells a story through its design elements—everything from polished chrome accents to meticulously painted tanks reflects an artisan's dedication.

In this vibrant environment, creativity flows freely as artisans collaborate on custom builds while adhering to Harley-Davidson’s high standards for quality and performance. During your tour at SSOURCING INC., you’ll have the chance to engage with these passionate individuals who pour their hearts into every machine they create—ensuring each ride is not just about transportation but about freedom on two wheels!

Innovative Technologies in Action

In today’s fast-paced world, innovative technologies are reshaping the landscape of manufacturing, making factory visits more exciting than ever. Witnessing these advancements firsthand provides a unique perspective on how industries are evolving to meet modern challenges. From robotics to sustainable practices, each factory visit offers a treasure trove of insights that can inspire and educate.

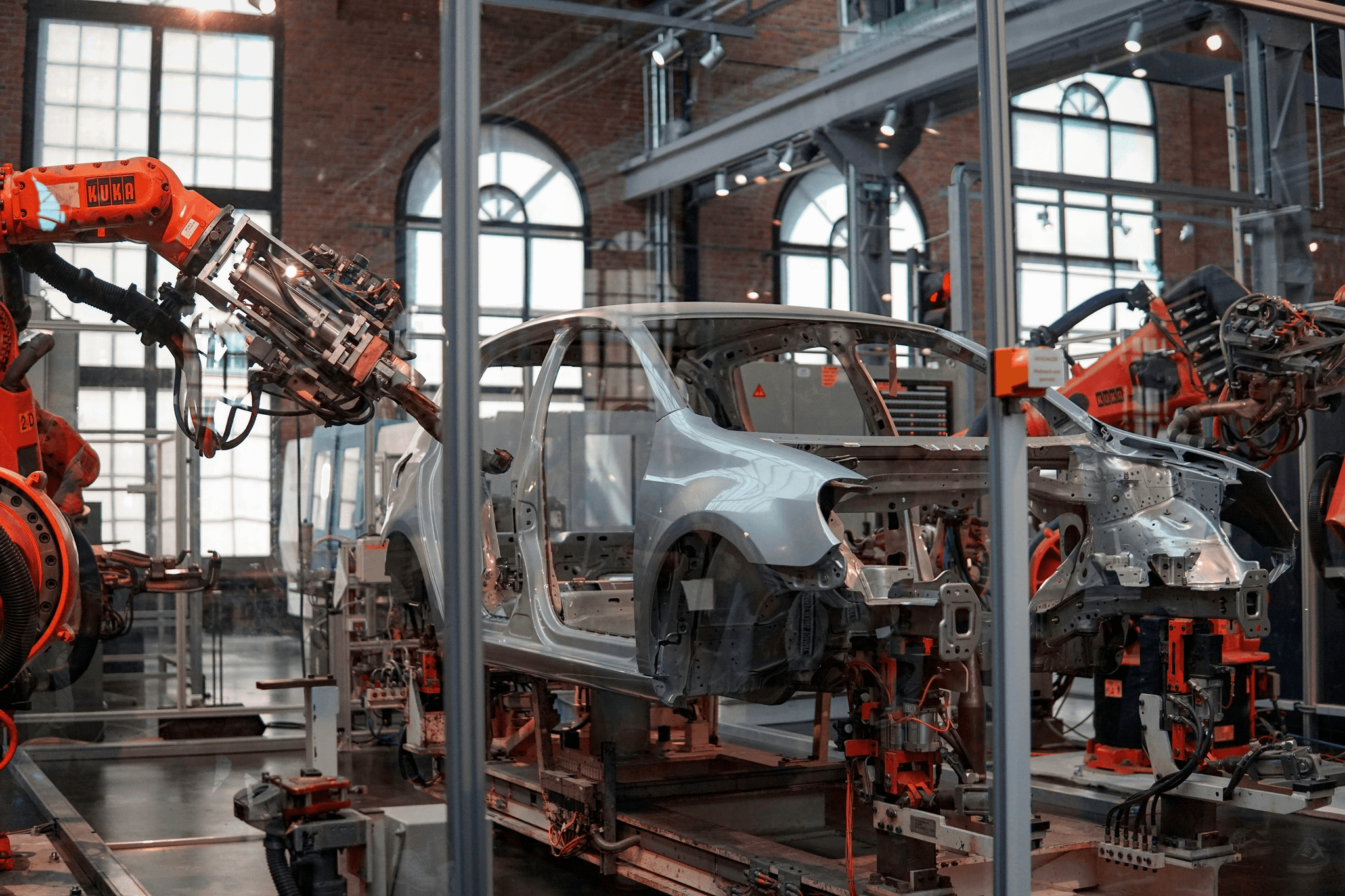

Robotics Revolutionizing Manufacturing at Tesla

At Tesla's Gigafactory, robots are not just metal machines; they’re the backbone of production efficiency. During your factory visit, you’ll observe how these robotic systems work alongside skilled technicians to streamline assembly lines and enhance precision. The synergy between human ingenuity and robotic automation is a sight to behold, showcasing Tesla's commitment to innovation while setting new standards for the automotive industry.

3D Printing Wonders at GE Aviation

A factory visit to GE Aviation reveals the magic of 3D printing technology transforming traditional manufacturing processes. Here, complex components that once took weeks to produce can now be created in a fraction of the time using additive manufacturing techniques. This cutting-edge approach not only reduces waste but also opens up endless possibilities for design innovation—something that SSOURCING INC. is keen on exploring further.

Sustainable Practices in Action at Unilever

Unilever stands at the forefront of sustainability in manufacturing, making it a must-see during any factory visit focused on eco-friendly practices. Their commitment to reducing environmental impact is evident through their innovative use of renewable energy and waste reduction strategies implemented across their production facilities. By observing these initiatives firsthand, you’ll gain valuable insights into how companies like Unilever are paving the way toward a more sustainable future—an essential lesson for any business-minded individual.

The Journey of Raw Materials

When you embark on a factory visit, one of the most fascinating aspects is witnessing how raw materials undergo dramatic transformations into finished products. This journey not only showcases the intricate processes involved but also highlights the craftsmanship and technology that drive modern manufacturing. Let’s dive into three remarkable examples that illustrate this journey: gold refining at Barrick Gold Corporation, cotton processing at Levi Strauss & Co., and steel transformation at ArcelorMittal.

How Gold is Refined at the Barrick Gold Corporation

At Barrick Gold Corporation, a factory visit reveals the meticulous process of gold refining that starts with raw ore extraction from mines around the world. Visitors can observe how gold is separated from impurities through advanced techniques like cyanidation and smelting, transforming unrefined rock into gleaming bars of precious metal. This process not only emphasizes precision but also underscores Barrick's commitment to sustainability in mining practices, making it an enlightening experience for anyone interested in resource management.

From Cotton to Clothing at Levi Strauss & Co.

Levi Strauss & Co. offers a captivating factory visit where guests can trace the journey of cotton as it evolves into iconic denim jeans. Starting from raw cotton bales, visitors witness each stage—spinning, dyeing, weaving—until they see fabric ready for cutting and sewing into stylish apparel. This immersive experience highlights both tradition and innovation in textile manufacturing while showcasing Levi’s dedication to sustainable practices within their supply chain.

The Transformation of Steel at ArcelorMittal

At ArcelorMittal, a factory visit takes you through the fascinating world of steel production—a material integral to countless industries worldwide. From iron ore extraction to molten steel pouring, each step exemplifies cutting-edge technology combined with skilled labor that transforms raw materials into vital infrastructure components. Observing this transformation provides deep insights not only into manufacturing techniques but also into ArcelorMittal's efforts towards reducing environmental impact throughout their operations.

Quality Control Like You’ve Never Seen

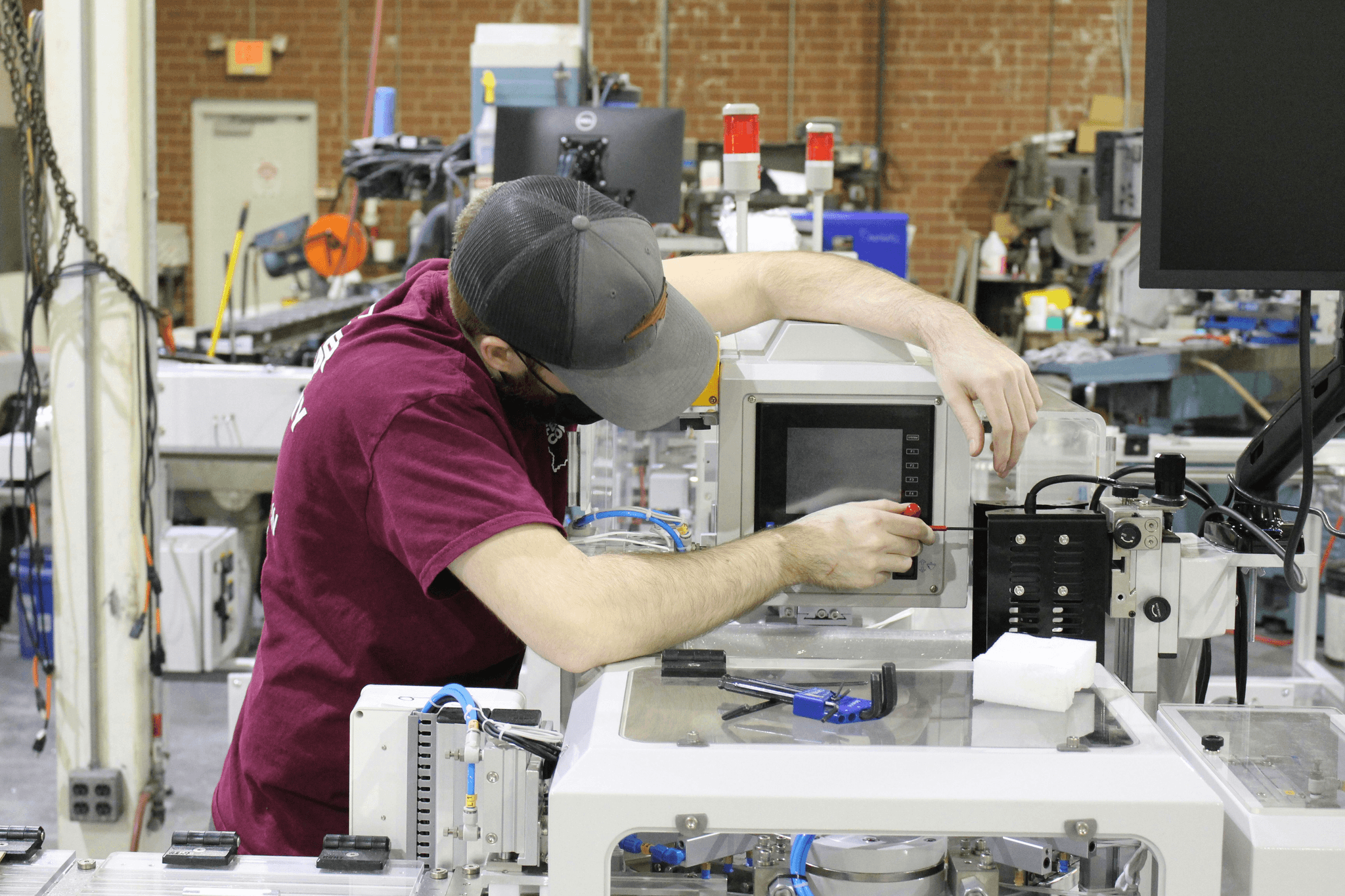

When it comes to manufacturing, quality control is the unsung hero that ensures products meet rigorous standards before they hit the market. A factory visit can give you a front-row seat to the meticulous processes that guarantee excellence in production. From innovative inspection techniques to stringent testing standards, witnessing quality control in action will leave you impressed and informed.

Inspection Techniques at Samsung Electronics

Samsung Electronics takes quality control to a whole new level with their advanced inspection techniques. During a factory visit, you'll see how they utilize cutting-edge technology, including AI and machine learning, to detect defects at lightning speed. Their commitment to precision ensures that every device meets the high expectations of consumers worldwide.

Imagine standing on the factory floor as skilled technicians monitor real-time data from automated systems designed for fault detection. You’ll witness how each product undergoes rigorous visual inspections and automated testing procedures before leaving the assembly line. This level of scrutiny not only enhances product reliability but also reinforces Samsung’s reputation for excellence in electronics.

Testing Standards at Coca-Cola

Coca-Cola is synonymous with refreshment, but behind every bottle lies an unwavering commitment to quality through stringent testing standards. A factory visit here reveals how they meticulously test ingredients and finished products alike to ensure consistency and safety across their extensive beverage lineup. From taste tests to chemical analyses, each step is crucial in delivering that iconic flavor we all know and love.

During your tour, you'll see lab technicians conducting various tests on samples taken directly from production lines—checking everything from carbonation levels to pH balance. It's fascinating to observe how Coca-Cola maintains its high standards while innovating new flavors and products without compromising quality. The dedication they show during this process highlights why Coca-Cola remains a leader in the beverage industry.

Meeting Compliance at Pfizer

In the pharmaceutical world, compliance isn't just a box to check; it's a matter of life and death—and Pfizer knows it well! On your factory visit, you'll be guided through their rigorous compliance protocols designed not only for regulatory adherence but also for ensuring patient safety worldwide. Every step of their manufacturing process is meticulously documented and monitored for complete transparency.

As you explore Pfizer's facilities, you'll learn about their comprehensive approach to quality assurance that includes extensive employee training programs and regular audits by external agencies. Witnessing this dedication firsthand emphasizes why Pfizer has earned its place as a trusted name in healthcare globally. It's an eye-opening experience that showcases just how seriously they take their responsibility towards public health.

Environmental Efforts on Display

In today’s world, where sustainability is more than just a buzzword, factory visits offer a unique lens into how companies are embracing eco-friendly practices. Witnessing environmental efforts firsthand not only educates visitors about responsible manufacturing but also inspires a sense of accountability in consumers and businesses alike. At SSOURCING INC., we believe that understanding these initiatives can spark meaningful discussions about our own environmental impact.

Sustainability Initiatives by Procter & Gamble

Procter & Gamble (P&G) is leading the charge with its ambitious sustainability initiatives, which are evident during any factory visit to their facilities. P&G has committed to using 100% recyclable or reusable packaging by 2030, showcasing their dedication to reducing plastic waste. Visitors can see how innovative materials and processes are implemented to achieve this goal, transforming the way products are packaged and delivered.

Additionally, P&G's focus on water conservation is noteworthy; they’ve developed technologies that minimize water usage during production without compromising quality. During your factory visit, you’ll learn how these practices not only benefit the environment but also enhance operational efficiency. It’s clear that P&G understands that sustainable manufacturing is essential for both business success and planetary health.

Zero Waste Goals at Interface

When it comes to zero waste goals, Interface sets the bar high—literally! This flooring company has made significant strides in its mission to eliminate waste from its manufacturing processes entirely. A factory visit here reveals their commitment to recycling and repurposing materials, ensuring that nothing goes to landfill.

Interface's innovative approach includes turning old carpets into new products through a closed-loop system that reduces reliance on virgin materials. Visitors will be amazed at how creativity meets sustainability in every corner of the facility, demonstrating that eco-conscious practices can lead to impressive business outcomes. Learning about Interface’s journey towards becoming a carbon-negative company inspires everyone involved in manufacturing—proof that going green is not just possible but profitable too.

Energy Efficiency Strategies at Nestlé

At Nestlé, energy efficiency isn’t just an initiative; it’s woven into the very fabric of their operations—something you’ll witness during your next factory visit! The company has set ambitious targets for reducing greenhouse gas emissions across its global operations while continuously innovating energy-efficient technologies in production processes. Visitors will discover how Nestlé integrates renewable energy sources like solar and wind power into their factories.

Moreover, Nestlé's commitment extends beyond energy use; they focus on optimizing logistics and supply chains for reduced carbon footprints as well. By implementing smart technologies and data-driven strategies, they ensure each step of production aligns with sustainable practices while maintaining product quality and safety standards. A factory visit here will undoubtedly leave you inspired by how major corporations like Nestlé are taking tangible steps toward creating a more sustainable future.

Conclusion

Factory visits offer a unique opportunity to dive deep into the world of manufacturing, revealing insights that are often hidden from view. Witnessing the intricate processes and passionate people behind the scenes can ignite a newfound appreciation for the products we often take for granted. At SSOURCING INC., we believe that these experiences are not just enlightening—they're transformative.

Why a Factory Visit is Enlightening

A factory visit is like peeling back the layers of an onion; each layer reveals something more fascinating than the last. You get to see firsthand how raw materials morph into finished products, all while meeting the skilled individuals who make it happen. This immersive experience allows you to connect with manufacturing in a way that textbooks simply cannot replicate.

Learn About Modern Manufacturing Practices

During your factory visit, you'll be introduced to cutting-edge technologies and practices that define modern manufacturing today. From robotics at Tesla to sustainable initiatives at Unilever, these visits showcase how innovation drives efficiency and quality in production. By observing these practices up close, you gain valuable insights that can inspire your own business strategies or career choices.

Capture Memorable Experiences at SSOURCING INC.

At SSOURCING INC., we know that every factory visit has the potential to create unforgettable memories and learning opportunities. Whether you're marveling at 3D printing wonders or engaging with artisans at Harley-Davidson, each moment spent on-site is an adventure waiting to happen. So why wait? Plan your next factory visit with us and unlock a treasure trove of knowledge!