Introduction

In the fast-paced world of manufacturing, understanding quality issues is crucial for success. From defects in production to inefficiencies in processes, quality concerns can have a significant impact on a company's bottom line. Addressing these issues is essential to maintain customer satisfaction and uphold brand reputation. However, common challenges such as a lack of standardized processes and inadequate training can hinder effective quality control. That's where leading experts in quality management, like SSOURCING INC., come in to provide invaluable guidance and support for improvement.

Understanding Quality Issues in Manufacturing

Quality issues in manufacturing can encompass a wide range of problems, including product defects, inconsistent production processes, and supply chain disruptions. These issues can lead to increased costs, decreased productivity, and dissatisfied customers.

Importance of Addressing Quality Concerns

Addressing quality concerns is vital for maintaining customer satisfaction, upholding brand reputation, and ensuring long-term success in the competitive manufacturing industry.

Common Challenges in Manufacturing Quality Control

Common challenges in manufacturing quality control include a lack of standardized processes, inadequate training for employees, and ineffective communication between different departments.

Leading Experts in Quality Management

Leading experts in quality management play a crucial role in helping manufacturing companies identify and address their quality issues through specialized knowledge and experience.

The Role of SSOURCING INC. in Quality Improvement

SSOURCING INC.'s expertise lies in providing comprehensive solutions for improving quality control within manufacturing operations through innovative strategies and tailored approaches.

1. Identifying Quality Issues

Quality issues in manufacturing can have a significant impact on the overall production process and end product quality. Identifying these issues is crucial for maintaining high standards and meeting customer expectations. At SSOURCING INC., we understand the importance of thorough analysis to address quality concerns and ensure continuous improvement.

Root Cause Analysis

Root cause analysis is a systematic process used to identify the underlying reasons for quality issues in manufacturing. By delving deep into the factors contributing to defects or non-conformities, companies can pinpoint the exact source of problems and develop effective solutions. SSOURCING INC. emphasizes the importance of conducting comprehensive root cause analysis to eliminate recurring quality issues and enhance overall operational efficiency.

Statistical Process Control

Statistical process control (SPC) involves using statistical methods to monitor and control production processes. This approach enables manufacturers to detect variations in production output and take corrective actions before defects occur. SSOURCING INC. advocates for the implementation of SPC tools to proactively manage quality issues, minimize waste, and optimize resource utilization.

Failure Mode and Effects Analysis

Failure mode and effects analysis (FMEA) is a structured approach for identifying potential failure modes within a system, assessing their impact, and developing preventive measures. By applying FMEA methodologies, manufacturers can anticipate quality issues before they occur, thereby preventing costly disruptions in production processes. At SSOURCING INC., we recognize FMEA as an essential tool for mitigating risks and ensuring consistent product quality.

2. Implementing Quality Improvement Strategies

Quality issues in manufacturing can be effectively addressed through the implementation of various improvement strategies. These strategies aim to enhance processes, reduce defects, and ultimately improve customer satisfaction. By carefully planning and executing these strategies, SSOURCING INC. can ensure that its products meet the highest quality standards.

Total Quality Management

Total Quality Management (TQM) is a comprehensive approach that focuses on continuous improvement and customer satisfaction. By involving all employees in the quality improvement process, TQM emphasizes the importance of teamwork and collaboration. SSOURCING INC. can implement TQM by establishing clear quality objectives, conducting regular performance evaluations, and fostering a culture of accountability and excellence.

Lean Manufacturing Principles

Lean Manufacturing principles are centered around eliminating waste and optimizing production processes. By streamlining operations and minimizing non-value-added activities, SSOURCING INC. can enhance efficiency while maintaining high-quality standards. Implementing Lean Manufacturing principles involves identifying areas for improvement, implementing standardized work procedures, and empowering employees to contribute to process optimization.

Six Sigma Methodology

Six Sigma methodology aims to minimize variation and defects in manufacturing processes through data-driven decision-making and problem-solving techniques. By utilizing statistical tools and techniques, SSOURCING INC. can identify root causes of quality issues and implement targeted solutions for process improvement. The implementation of Six Sigma requires rigorous training for employees at all levels to ensure a deep understanding of statistical methods and problem-solving approaches.

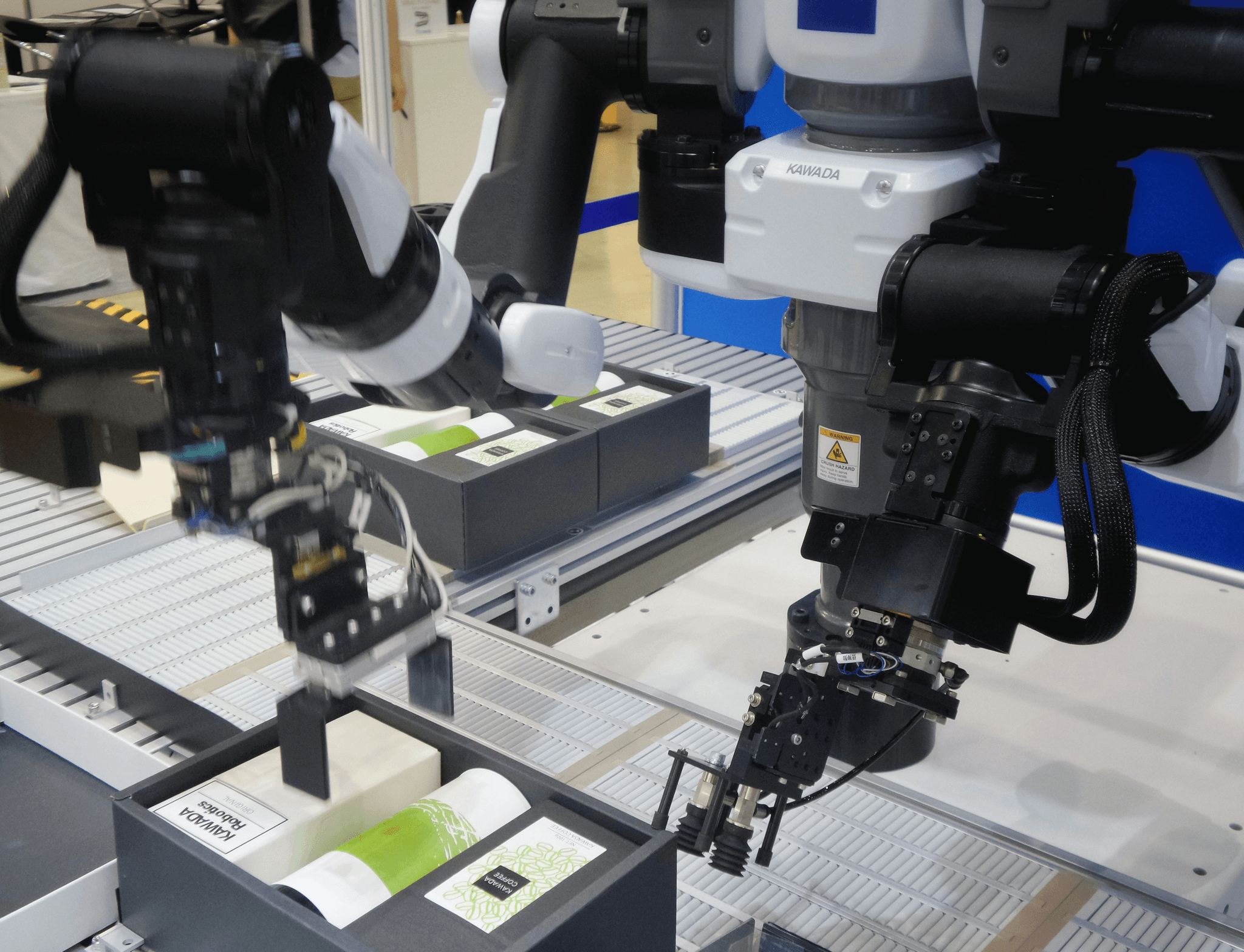

3. Utilizing Advanced Technology for Quality Assurance

In today's competitive manufacturing landscape, leveraging advanced technology is crucial in addressing quality issues. Automated inspection systems, such as vision inspection and non-contact measurement systems, can significantly improve quality control by detecting defects and inconsistencies in real-time. By integrating robotics into manufacturing processes, SSOURCING INC. can enhance precision and efficiency while minimizing human error in production lines. Furthermore, IoT and Industry 4.0 solutions enable seamless data collection and analysis, allowing for predictive maintenance and proactive quality management.

Automated Inspection Systems

Automated inspection systems play a pivotal role in ensuring product quality by offering high-speed and accurate inspections across various stages of production. These systems utilize advanced sensors and imaging technologies to detect imperfections, measure dimensions, and verify product integrity with unmatched precision. By implementing automated inspection systems at critical checkpoints, SSOURCING INC. can proactively identify potential defects and take corrective actions before they escalate into larger quality concerns.

Robotics in Manufacturing

Integrating robotics into manufacturing processes empowers SSOURCING INC. to achieve consistent product quality through enhanced precision and repeatability. Robotic arms equipped with advanced end-effectors can perform intricate tasks with unparalleled accuracy, reducing variability in the assembly process. By automating repetitive tasks that are prone to human error, robotics not only improves product quality but also frees up human resources to focus on more complex problem-solving activities.

IoT and Industry 4.0 Solutions

IoT-enabled devices and Industry 4.0 solutions provide SSOURCING INC.with real-time visibility into their manufacturing operations, enabling proactive decision-making to address quality issues promptly. By connecting machines, sensors, and other equipment through IoT platforms, manufacturers can monitor key performance indicators (KPIs) related to quality parameters such as temperature, pressure, or vibration levels in real-time. This facilitates predictive maintenance strategies that prevent equipment failures or process deviations that could compromise product quality.

4. Building a Quality-Focused Culture

Building a quality-focused culture within SSOURCING INC. begins with investing in employee training and development. By providing regular training sessions and workshops on quality control and improvement, employees can gain the knowledge and skills necessary to identify and address quality issues in manufacturing. This empowers them to take proactive measures in ensuring high-quality output.

Employee Training and Development

SSOURCING INC. recognizes the importance of continuous learning and development for its workforce. Regular training programs are conducted to educate employees on how to solve quality issues in manufacturing, emphasizing the significance of attention to detail, adherence to standard operating procedures, and the use of quality control tools such as root cause analysis and statistical process control. Through ongoing education, employees are equipped with the expertise needed to maintain high standards.

Quality Management Systems

Implementing robust quality management systems is crucial for fostering a culture of excellence at SSOURCING INC. These systems provide a framework for organizing processes, procedures, and responsibilities to ensure that products meet stringent quality requirements consistently. By integrating quality management systems into daily operations, our company can streamline workflows, minimize errors, and enhance overall efficiency.

Continuous Improvement Initiatives

SSOURCING INC.'s commitment to continuous improvement drives our efforts in addressing quality concerns head-on. By encouraging feedback from employees at all levels of the organization, we foster an environment where innovative ideas for enhancing product quality are welcomed and acted upon swiftly. This proactive approach enables us to adapt quickly to changing market demands while maintaining uncompromising standards.

Now that we have discussed building a quality-focused culture within SSOURCING INC., let's explore how advanced technology can be utilized for quality assurance in manufacturing operations.

5. Establishing Supplier Quality Management

In order to solve quality issues in manufacturing, it is essential to establish robust supplier quality management practices. SSOURCING INC. recommends conducting regular supplier audits and assessments to ensure that all partners meet the required quality standards. By implementing stringent evaluation processes, manufacturers can identify potential issues early on and take proactive measures to address them, thereby safeguarding the overall product quality.

Supplier Audits and Assessments

Supplier audits and assessments involve a comprehensive review of the supplier's manufacturing processes, quality control measures, and adherence to industry regulations. This allows SSOURCING INC. to identify any potential weaknesses or areas for improvement within the supplier's operations. Through thorough evaluations, manufacturers can mitigate risks associated with subpar suppliers and maintain consistent product quality across their supply chain.

Supplier Development Programs

To further enhance supplier quality management, SSOURCING INC. advocates for the implementation of supplier development programs. These initiatives involve collaborating closely with suppliers to address any identified shortcomings and provide necessary support for process improvements. By fostering a culture of continuous improvement among suppliers, manufacturers can drive positive change and elevate overall product quality.

Vendor Qualification and Performance Monitoring

In addition, SSOURCING INC. emphasizes the importance of rigorous vendor qualification processes and ongoing performance monitoring. This involves setting clear criteria for vendor selection based on their capabilities, reliability, and commitment to quality standards. By continuously monitoring vendor performance against predefined metrics, manufacturers can swiftly detect any deviations from expected standards and take corrective actions as needed.

By establishing robust supplier quality management practices such as audits, development programs, and performance monitoring, SSOURCING INC. enables manufacturers to proactively address potential quality issues within their supply chain while fostering a culture of continuous improvement among their partners.

Conclusion

In conclusion, addressing quality issues in manufacturing is crucial for the success and sustainability of any business. By implementing best practices for quality enhancement, companies can ensure that their products meet the highest standards and customer expectations. Empowering your manufacturing quality team with the right tools and training is essential to effectively identify and resolve quality concerns. Achieving sustainable quality excellence requires a commitment to continuous improvement and a culture that prioritizes quality at every level of the organization.

Best Practices for Quality Enhancement

To solve quality issues in manufacturing, it's essential to prioritize best practices such as root cause analysis, statistical process control, and failure mode and effects analysis. These tools can help identify the underlying causes of defects and inefficiencies, allowing for targeted solutions that improve overall product quality. Implementing these best practices at SSOURCING INC. will ensure that our manufacturing processes are optimized for excellence.

Empowering Your Manufacturing Quality Team

Empowerment of your manufacturing quality team involves providing them with the necessary training, resources, and support to effectively address quality concerns. By fostering a culture of continuous improvement and accountability, team members will be motivated to take ownership of their work and strive for excellence in every aspect of production.

Achieving Sustainable Quality Excellence

At SSOURCING INC., achieving sustainable quality excellence involves a holistic approach that encompasses advanced technology, employee development, supplier management, and a relentless commitment to improvement. By integrating these elements into our operations, we can create a culture of excellence that sets us apart in the industry.