Introduction

In the ever-evolving landscape of manufacturing, traditional methods have given way to innovative processes that are revolutionizing the industry. As technology continues to advance, the types of manufacturing processes have expanded to include additive manufacturing, smart manufacturing, advanced materials processing, and sustainable manufacturing. SSOURCING INC. recognizes the need for businesses to adapt and thrive in this new era of production.

Evolution of Manufacturing

From the early days of manual labor and hand tools to the industrial revolution and mass production, the evolution of manufacturing has been marked by significant advancements in efficiency and output. With the advent of digital technologies, automation, and robotics, manufacturers have been able to streamline their operations and increase productivity.

Impact of Innovative Processes

The introduction of innovative processes such as 3D printing, Internet of Things (IoT), nanotechnology, and green technology has had a profound impact on the manufacturing sector. These technologies have not only improved production capabilities but also opened up new possibilities for customization, sustainability, and cost-effectiveness.

Future of Manufacturing

As we look ahead, it is clear that the future of manufacturing will be shaped by continued advancements in digital twin technology, bioprocessing, circular economy practices, and predictive maintenance. SSOURCING INC. understands that embracing these cutting-edge developments will be crucial for companies aiming to stay competitive in a rapidly changing market.

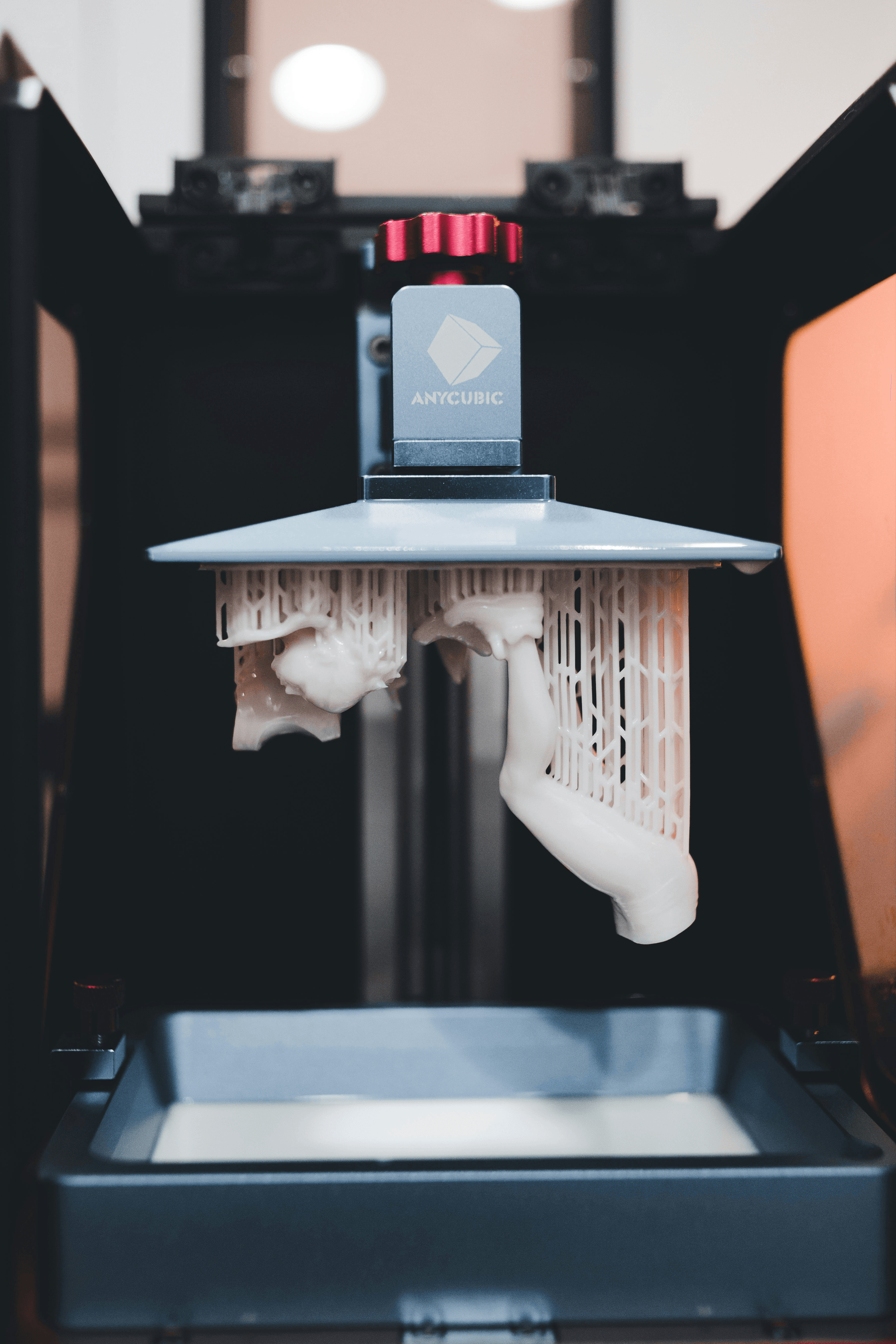

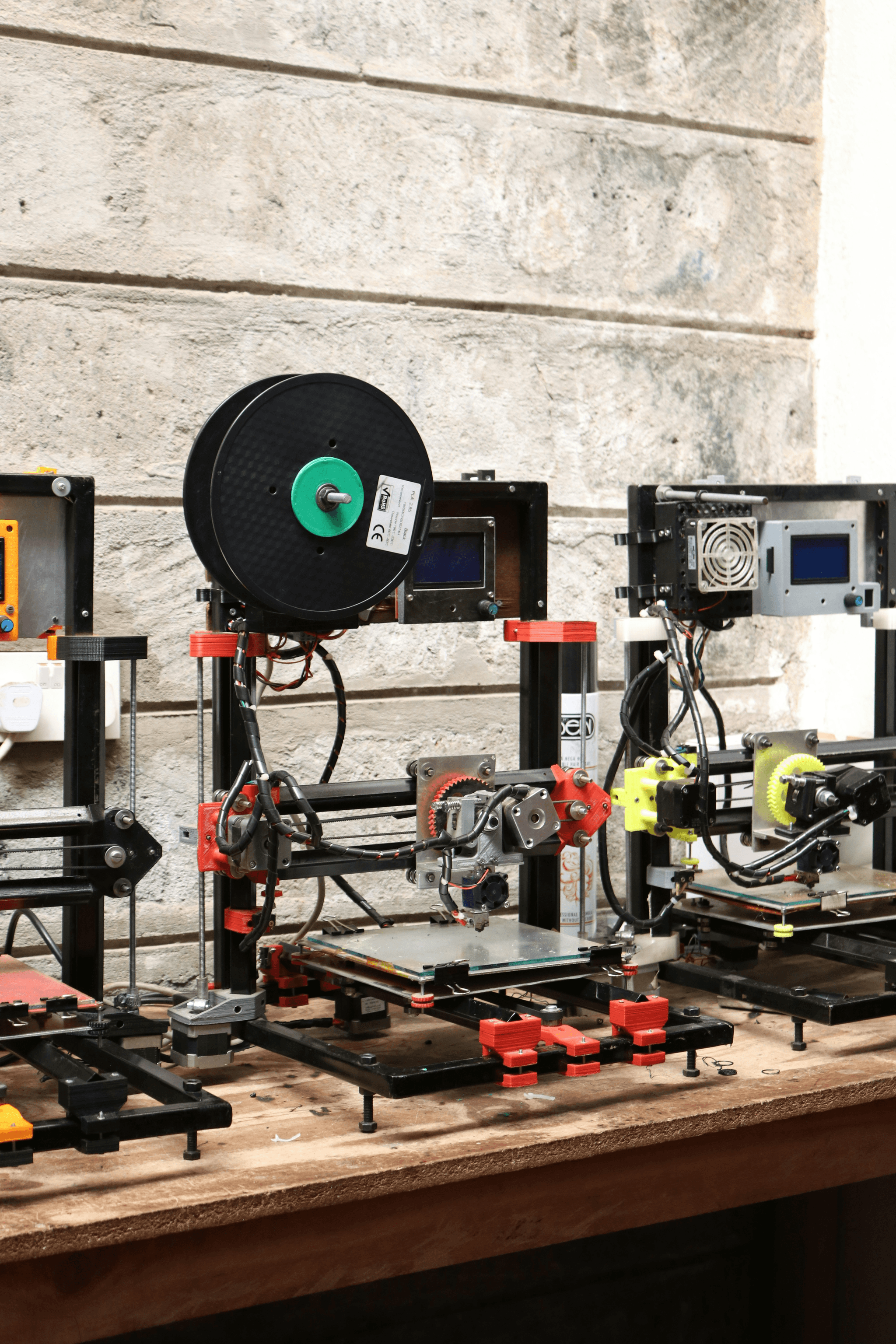

Additive Manufacturing

Additive manufacturing, also known as 3D printing, has revolutionized the manufacturing industry by enabling the production of complex and customized parts with reduced material waste. This innovative process involves layering materials to create three-dimensional objects based on digital models. 3D printing is gaining popularity in various industries due to its ability to quickly prototype designs and manufacture intricate components.

3D Printing

3D printing, a type of additive manufacturing, utilizes materials such as plastics, metals, and ceramics to build objects layer by layer from digital designs. This technology allows for rapid prototyping and customization of products, leading to cost-effective production processes for SSOURCING INC. The flexibility of 3D printing enables the creation of intricate geometries that are challenging to achieve through traditional manufacturing methods.

Selective Laser Melting

Selective Laser Melting (SLM) is a type of additive manufacturing that uses a high-powered laser to melt and fuse metallic powders together, layer by layer, to create solid parts. This process is particularly suitable for producing complex metal components with superior mechanical properties for SSOURCING INC.'s advanced applications. SLM offers the advantage of producing fully dense parts with excellent material properties.

Electron Beam Melting

Electron Beam Melting (EBM) is another additive manufacturing process that utilizes an electron beam to melt and fuse metal powders into solid components with intricate geometries. EBM is well-suited for producing high-strength and lightweight parts for aerospace and medical industries at SSOURCING INC.. This technology enables the fabrication of complex structures with minimal material waste.

By incorporating additive manufacturing technologies such as 3D printing, Selective Laser Melting, and Electron Beam Melting into its operations, SSOURCING INC. can enhance its production capabilities while reducing lead times and material costs. These innovative processes offer flexibility in design and production that traditional methods cannot match, positioning the company at the forefront of advanced manufacturing techniques.

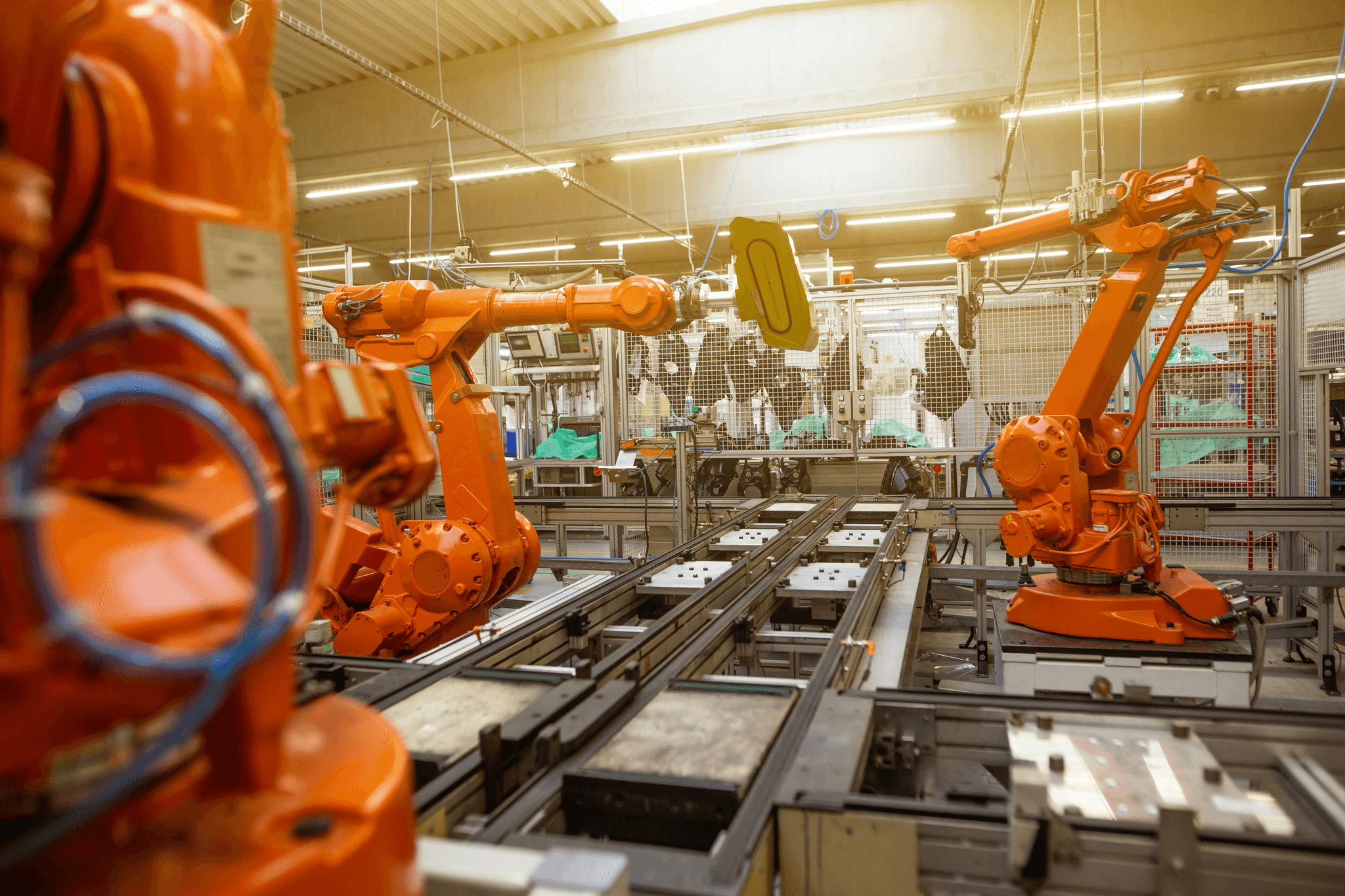

Smart Manufacturing

Smart manufacturing is revolutionizing the industry by integrating advanced technologies into the production process. At SSOURCING INC., we recognize the importance of leveraging Internet of Things (IoT) to connect and monitor equipment, ensuring seamless communication and data exchange across different types of manufacturing processes. This connectivity enables real-time insights, predictive maintenance, and improved operational efficiency.

Internet of Things (IoT)

The Internet of Things (IoT) has transformed traditional manufacturing methods by enabling machines to communicate with each other and with centralized systems. At SSOURCING INC., we implement IoT solutions to optimize production, enhance quality control, and minimize downtime by collecting and analyzing data from various sensors and devices. By harnessing the power of IoT, we empower manufacturers to make informed decisions based on accurate, real-time information.

Robotics and Automation

Robotics and automation play a vital role in smart manufacturing by streamlining repetitive tasks, increasing productivity, and ensuring precision in production processes. SSOURCING INC. integrates cutting-edge robotics technology to automate assembly lines, material handling, and packaging operations for our clients. By embracing robotics and automation, manufacturers can achieve higher output rates while maintaining consistent product quality.

Cyber-Physical Systems

Cyber-physical systems combine computing elements with physical components to create intelligent manufacturing systems that adapt to changing conditions in real time. At SSOURCING INC., we leverage cyber-physical systems to synchronize production processes seamlessly, optimize resource utilization, and enable adaptive decision-making. By implementing these systems, manufacturers can achieve greater flexibility in responding to market demands while maintaining operational resilience.

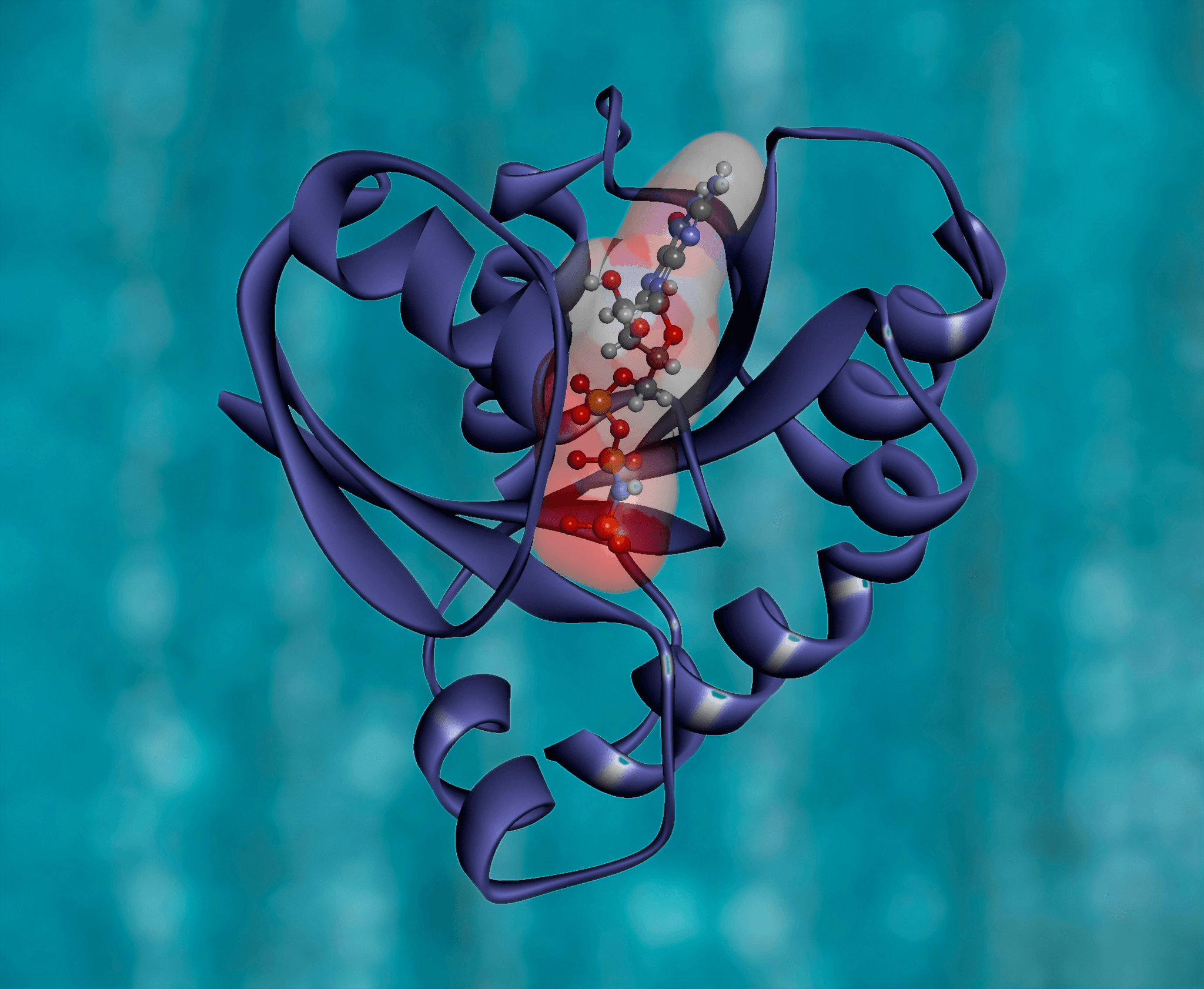

Advanced Materials Processing

In the realm of advanced materials processing, SSOURCING INC. is at the forefront of leveraging cutting-edge technologies to drive innovation. Nanotechnology, one of the most exciting types of manufacturing processes, involves manipulating materials at the atomic and molecular level to create new functionalities and properties. From enhancing material strength to improving electrical conductivity, nanotechnology holds immense potential for revolutionizing various industries.

Nanotechnology

Nanotechnology enables SSOURCING INC. to develop high-performance materials with exceptional strength-to-weight ratios, making them ideal for aerospace and automotive applications. By incorporating nanoparticles into traditional materials, we can enhance their mechanical properties and durability while reducing overall weight. This not only improves fuel efficiency but also contributes to sustainability by minimizing resource consumption.

Bioprocessing

Bioprocessing is another key area where SSOURCING INC. excels in harnessing biological systems to produce valuable materials and chemicals. Through bioprocessing techniques such as fermentation and enzymatic reactions, we can create bio-based polymers and renewable fuels that offer a greener alternative to traditional petroleum-derived products. This aligns with our commitment to sustainable manufacturing practices while reducing our environmental footprint.

Composite Manufacturing

Composite manufacturing involves combining different materials to create a single, high-performance product that exhibits the best properties of each component. SSOURCING INC.'s expertise in composite manufacturing allows us to engineer lightweight yet durable components for various industries including sports equipment, construction, and renewable energy systems. By utilizing advanced composite materials, we can optimize performance while minimizing material usage and waste.

With our focus on advanced materials processing, SSOURCING INC.'s commitment to innovation remains unwavering as we continue to push boundaries in creating sustainable solutions through nanotechnology, bioprocessing, and composite manufacturing processes.

Sustainable Manufacturing

Sustainable manufacturing is a crucial aspect of SSOURCING INC.'s operations, as we strive to minimize our environmental impact while maximizing efficiency. Green technology plays a key role in this, with the use of renewable energy sources and eco-friendly materials in our manufacturing processes. By incorporating green technology into our operations, we can significantly reduce our carbon footprint and contribute to a healthier planet for future generations.

Green Technology

One example of green technology that SSOURCING INC. employs is the use of solar panels to power our manufacturing facilities. By harnessing the power of the sun, we are able to reduce our reliance on traditional energy sources and lower our overall carbon emissions. Additionally, we have implemented energy-efficient lighting and heating systems to further minimize our environmental impact. These initiatives not only benefit the planet but also contribute to cost savings for the company.

Circular Economy

SSOURCING INC. is committed to embracing the principles of a circular economy, where products and materials are reused, repaired, or recycled rather than being disposed of after single use. Through remanufacturing and refurbishing processes, we extend the lifespan of our products and reduce waste generation. This approach not only conserves valuable resources but also creates new business opportunities for us within the growing circular economy market.

Waste Reduction Strategies

In line with our dedication to sustainable manufacturing, SSOURCING INC. has implemented comprehensive waste reduction strategies across all stages of production. This includes minimizing packaging materials, optimizing material usage through lean manufacturing practices, and implementing recycling programs for both industrial and office waste streams. By prioritizing waste reduction at every level of operation, we are able to mitigate environmental harm while enhancing operational efficiency.

Digital Twin Technology

Digital twin technology is revolutionizing the manufacturing industry by creating virtual replicas of physical systems to optimize performance and efficiency. At SSOURCING INC., we understand the importance of virtual simulation in predicting behavior and simulating various types of manufacturing processes. By utilizing digital twins, manufacturers can accurately replicate production environments, test different scenarios, and identify potential areas for improvement.

Virtual Simulation

Virtual simulation allows manufacturers to visualize and analyze the entire production process before any physical changes are made. At SSOURCING INC., we recognize the value of virtual simulations in optimizing manufacturing operations and reducing downtime. By creating digital twins of equipment and processes, manufacturers can identify potential issues, make informed decisions, and streamline their operations for maximum productivity.

Real-time Monitoring

Real-time monitoring through digital twin technology enables manufacturers to track the performance of their equipment and processes in real time. SSOURCING INC. understands the significance of real-time monitoring in ensuring smooth operations and identifying any deviations from expected outcomes. By continuously monitoring digital twins, manufacturers can proactively address issues, prevent downtime, and maintain optimal production levels.

Predictive Maintenance

Predictive maintenance is a key application of digital twin technology that allows manufacturers to anticipate equipment failures before they occur. At SSOURCING INC., we emphasize the importance of predictive maintenance in minimizing disruptions and maximizing uptime. By analyzing data from digital twins, manufacturers can predict when maintenance is needed, schedule repairs proactively, and avoid costly downtime.

Conclusion

In conclusion, the evolution of manufacturing has led to the emergence of various innovative processes that offer several advantages. These types of manufacturing processes have significantly improved efficiency, reduced costs, and enhanced product quality for companies like SSOURCING INC. Additive manufacturing, smart manufacturing, advanced materials processing, sustainable manufacturing, and digital twin technology are revolutionizing the industry.

Advantages of Innovative Processes

The implementation of these advanced types of manufacturing processes has allowed companies like SSOURCING INC. to create more complex designs with greater precision and speed through 3D printing, nanotechnology, and virtual simulation. Furthermore, the integration of IoT and robotics has enabled real-time monitoring and predictive maintenance to optimize production processes.

Adoption Challenges and Solutions

Despite the numerous advantages offered by innovative processes, many companies face challenges in adopting these technologies due to high initial costs and workforce retraining requirements. However, SSOURCING INC. has successfully overcome these challenges by investing in employee training programs and partnering with technology providers for cost-effective solutions.

SSOURCING INC. at the Forefront

SSOURCING INC. is at the forefront of embracing innovative manufacturing processes to stay competitive in the market while minimizing environmental impact through green technology and waste reduction strategies. By leveraging these advanced technologies, SSOURCING INC. continues to lead in delivering high-quality products while maintaining sustainability practices.