Introduction

In the world of manufacturing, understanding different types of manufacturing processes is crucial for businesses to thrive. From casting to additive manufacturing, each process plays a unique role in shaping the final product. At SSOURCING INC., we recognize the significance of knowing various manufacturing processes and their impact on production efficiency and product quality.

Understanding Different Types of Manufacturing Processes

Manufacturing processes encompass a wide range of methods used to transform raw materials into finished products. These include casting, machining, forming, joining, and additive manufacturing. Each process offers distinct advantages and limitations that affect the overall production process.

Importance of Knowing Various Manufacturing Processes

Knowing various manufacturing processes is essential for making informed decisions about production methods and equipment investments. By understanding the strengths and weaknesses of each type of manufacturing process, businesses can optimize their operations and achieve cost-effective production while maintaining high-quality standards.

Exploring the World of Manufacturing Processes

Exploring the world of manufacturing processes opens up opportunities for innovation and growth. By staying updated with emerging technologies and advancements in different types of manufacturing processes, companies can stay ahead in the competitive market landscape. At SSOURCING INC., we are committed to exploring new frontiers in manufacturing to provide cutting-edge solutions for our clients.

1. Casting

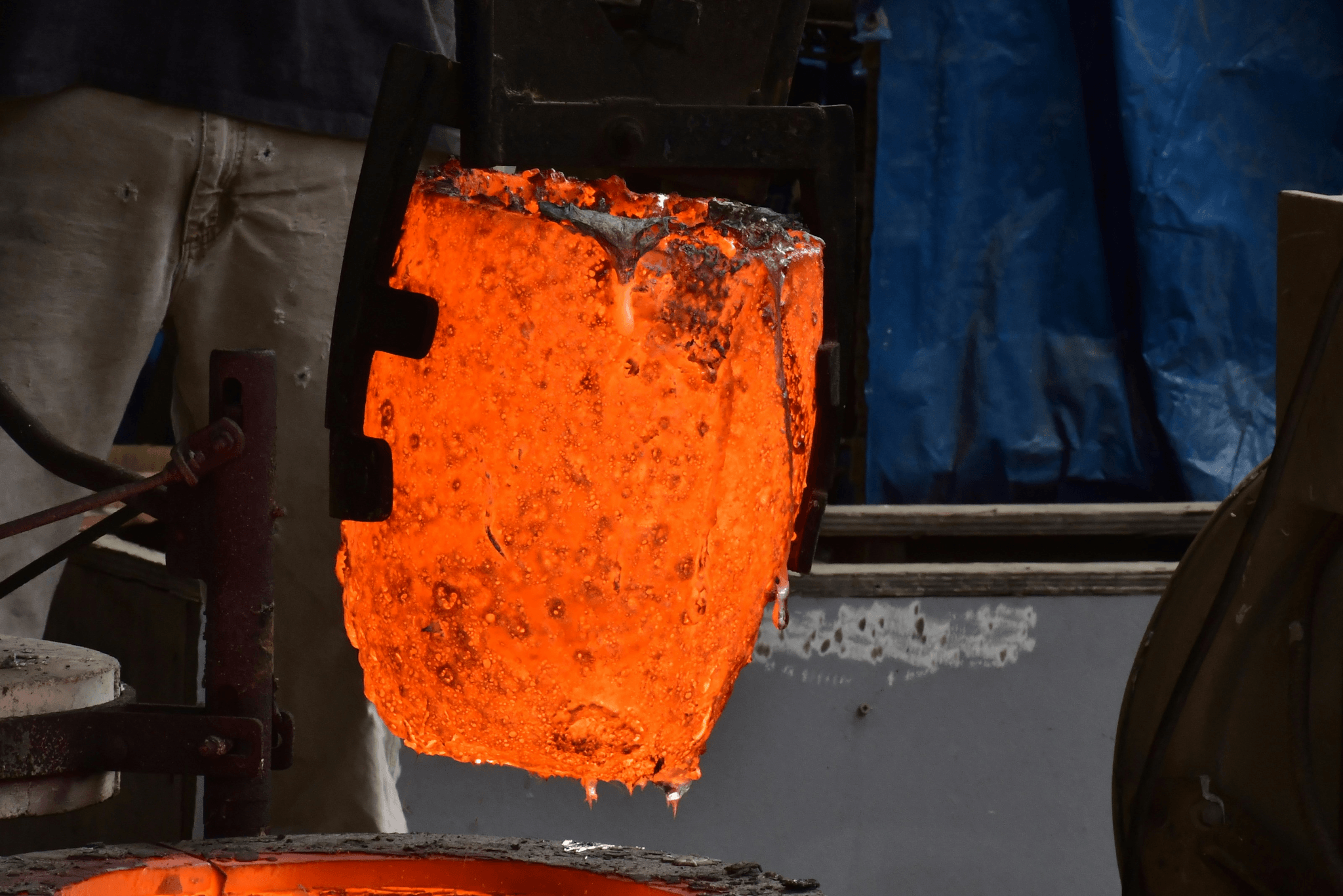

Casting is a crucial type of manufacturing process that involves pouring molten material into a mold to create the desired shape. This process is widely used in the production of complex metal parts for various industries. Understanding the basics of casting is essential for manufacturers looking to optimize their production processes and enhance product quality.

Overview of Casting in Manufacturing

Casting plays a vital role in SSOURCING INC.'s manufacturing operations, allowing us to produce intricate components with high precision and consistency. By melting metals such as aluminum, iron, or steel and pouring them into molds, we can create complex shapes that may be difficult to achieve through other methods. This process enables us to meet the diverse needs of our clients across different industries.

Different Types of Casting Processes

There are several types of casting processes, including sand casting, investment casting, die casting, and centrifugal casting. Each method has its unique advantages and limitations, making it suitable for specific applications. At SSOURCING INC., we carefully select the most appropriate casting technique based on factors such as material properties, design complexity, and production volume to ensure optimal results.

Advantages and Disadvantages of Casting

One advantage of casting is its ability to produce complex shapes with minimal machining or finishing required, resulting in cost savings and reduced waste. However, drawbacks such as longer production lead times and limited dimensional accuracy should also be considered when choosing this manufacturing method. By weighing these pros and cons, manufacturers can make informed decisions about incorporating casting into their production processes.

2. Machining

Machining is a crucial type of manufacturing process that involves the use of various cutting tools to remove excess material from a workpiece, shaping it into the desired form. Machining plays a vital role in the production of intricate parts and components for a wide range of industries, including automotive, aerospace, and electronics.

Exploring Machining in Manufacturing

Machining is an essential process in SSOURCING INC.'s manufacturing operations, as it allows us to create precise and complex components for our clients' products. By utilizing advanced machining techniques, we are able to meet the highest standards of quality and precision, ensuring that our clients receive top-notch products that exceed their expectations.

Common Machining Techniques

Some common machining techniques include turning, milling, drilling, and grinding. Each technique has its own unique advantages and applications, allowing manufacturers to produce a diverse range of parts with varying shapes, sizes, and surface finishes. At SSOURCING INC., we employ these techniques to meet the specific requirements of our clients' projects with utmost accuracy.

Role of Machining in Modern Manufacturing

In the modern manufacturing landscape, machining continues to be a cornerstone process for producing high-precision components across various industries. With advancements in technology and automation, machining has become more efficient and cost-effective than ever before. At SSOURCING INC., we leverage state-of-the-art machining equipment to deliver exceptional results while maintaining competitive pricing for our clients.

3. Forming

When it comes to different types of manufacturing processes, forming plays a crucial role in shaping raw materials into finished products. Key aspects of forming processes include the application of pressure, heat, or a combination of both to achieve the desired shape and size. Understanding the various forming methods is essential for manufacturers to choose the most suitable technique for their specific production needs.

Key Aspects of Forming Processes

Forming processes involve the transformation of materials through bending, stretching, and compressing to create intricate shapes and structures. The use of specialized tools and machinery allows for precise control over the formation process, ensuring high-quality end products. At SSOURCING INC., we recognize the significance of mastering different forming techniques to meet the diverse requirements of our clients across various industries.

Various Forming Methods

From traditional methods like forging and stamping to modern techniques such as hydroforming and roll forming, there are numerous ways to achieve effective material shaping in manufacturing. Each method offers unique advantages in terms of cost-effectiveness, production speed, and complexity of shapes that can be achieved. Our team at SSOURCING INC. stays updated on the latest advancements in forming technology to provide innovative solutions for our clients.

Application of Forming in Different Industries

The versatility of forming processes makes them indispensable across a wide range of industries, including automotive, aerospace, construction, and consumer goods. Whether it's creating intricate components for aircraft engines or producing durable metal structures for architectural projects, forming techniques play a vital role in bringing designs from concept to reality. At SSOURCING INC., we leverage our expertise in forming processes to deliver tailored solutions that meet the specific needs of each industry we serve.

4. Joining

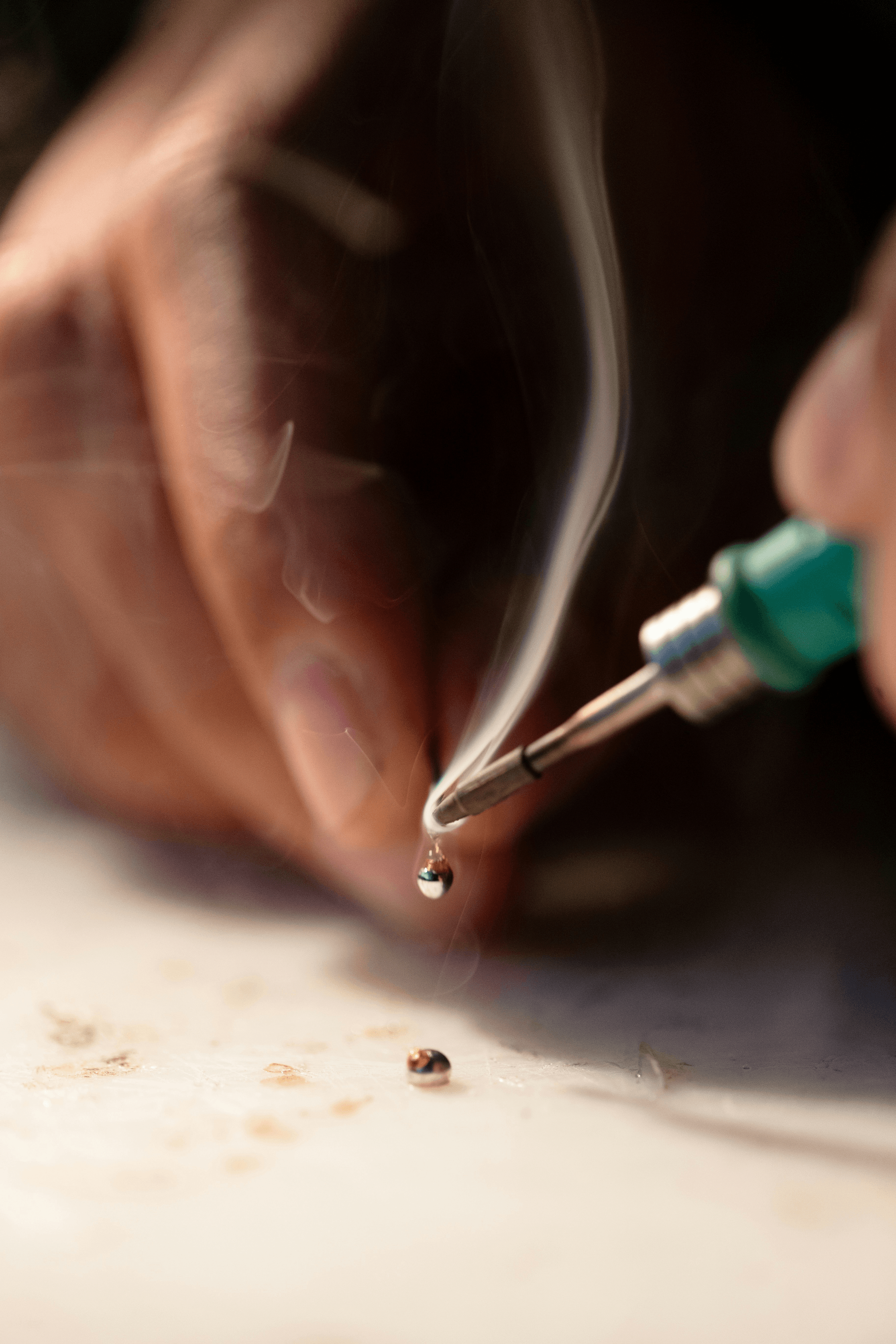

Joining is a crucial aspect of manufacturing processes, as it involves combining different parts to create a final product. The importance of joining in manufacturing cannot be overstated, as it allows for the creation of complex structures and enables the assembly of various components. At SSOURCING INC., we understand that selecting the right joining technique is essential for ensuring the structural integrity and functionality of the end product.

Different techniques of joining, such as welding, brazing, and soldering, offer unique advantages and are suitable for specific applications. Welding, for example, provides a strong and permanent bond between materials, making it ideal for heavy-duty industrial applications. Brazing, on the other hand, is well-suited for joining dissimilar metals with lower melting points. At SSOURCING INC., we have expertise in evaluating the most suitable joining technique based on our clients' specific requirements.

The impact of joining processes on product quality cannot be overlooked. A well-executed joining process ensures that the final product meets performance standards and durability requirements. Poorly executed joints can compromise the structural integrity of a product and lead to premature failure. Our team at SSOURCING INC. pays meticulous attention to detail when selecting and implementing joining techniques to ensure that our clients receive high-quality products that meet their exact specifications.

By understanding the importance of various types of manufacturing processes such as casting, machining, forming, additive manufacturing, and joining in creating high-quality products at SSOURCING INC., we are able to provide comprehensive solutions that enhance production efficiency and contribute to business growth.

5. Additive Manufacturing

Additive manufacturing, also known as 3D printing, is a type of manufacturing process that builds objects layer by layer using digital 3D models. This innovative technology has revolutionized the production process by allowing for complex and customized designs to be created with ease. Additive manufacturing is gaining traction in various industries due to its ability to reduce material waste and speed up production times.

Understanding Additive Manufacturing

Additive manufacturing is a cutting-edge process that involves the deposition of material layer by layer to create a three-dimensional object. This technique allows for the production of intricate and customized parts that may be difficult or impossible to achieve using traditional manufacturing methods. As SSOURCING INC. looks to stay ahead in the competitive market, understanding additive manufacturing can open up new possibilities for product development and design.

Types of Additive Manufacturing Technologies

There are several types of additive manufacturing technologies, including Fused Deposition Modeling (FDM), Stereolithography (SLA), Selective Laser Sintering (SLS), and Direct Metal Laser Sintering (DMLS). Each technology has its own unique advantages and limitations, making it crucial for SSOURCING INC. to carefully evaluate which method best suits their specific production needs.

Future of Additive Manufacturing in Industry

The future of additive manufacturing is bright, with ongoing advancements in materials and technology driving its growth across various industries. As companies like SSOURCING INC. continue to embrace additive manufacturing, we can expect to see increased efficiency, reduced costs, and greater design flexibility in the production process. Embracing this future-forward approach will position SSOURCING INC. as an industry leader in adopting cutting-edge technologies.

Conclusion

In conclusion, understanding the different types of manufacturing processes is crucial for SSOURCING INC. to make informed decisions about production. By choosing the right manufacturing process for your product, you can ensure high-quality output and cost-effectiveness. Enhancing production efficiency through manufacturing process selection allows for streamlined operations and reduced lead times, ultimately benefiting your bottom line. Leveraging different manufacturing processes for business growth opens up opportunities to diversify your product offerings and expand into new markets.

Choosing the Right Manufacturing Process for Your Product

Choosing the right manufacturing process for your product is a strategic decision that can impact the overall success of your business. At SSOURCING INC., understanding the specific requirements of each type of manufacturing process is essential in order to match them with the characteristics of your product. By carefully analyzing factors such as material properties, production volume, and design complexity, you can make an informed choice that aligns with your business goals.

Enhancing Production Efficiency through Manufacturing Process Selection

Enhancing production efficiency through manufacturing process selection is key to optimizing operations at SSOURCING INC. By identifying bottlenecks and inefficiencies in the current processes, you can implement improvements that result in smoother workflows and increased output. Additionally, adopting advanced technologies and automation where applicable can further enhance efficiency and reduce production costs.

Leveraging Different Manufacturing Processes for Business Growth

Leveraging different manufacturing processes for business growth provides SSOURCING INC. with opportunities to diversify its product portfolio and enter new markets. By staying abreast of emerging technologies and industry trends, you can capitalize on innovative manufacturing processes to develop unique products that cater to evolving consumer demands. This proactive approach positions your business for sustained growth and long-term success.